Heat-Fab Saf-T Liner User manual

Heat-Fab Inc. Saf-T Vent®

Stainless Steel Chimney Liner

Sizes: 4", 5", 6", 7", 8" Diameters

9", 10", 12", 14" Available

Installation and Maintenance Instructions

Saf-T Liner®

130 Industrial Boulevard

Turners Falls, MA 01376

Call (800) 772-0739

Fax (413) 863-4803

www.heat-fab.com

Stainless Steel Chimney Liner

The Heat-Fab Saf-T Liner system is intended for use in conjunction with any residential building,

heating appliance burning gas, liquid or solid fuels, such as a woodstove, fireplace insert, or an oil or

gas fired central heating furnace, vented through masonry chimneys only. These heating appliances

may not exceed the maximum continuous flue-gas outlet temperatures of 1000OF or cause

condensation of corrosive acids on the liner, or create positive pressures in the chimney system.

Saf-T Liner is a high quality U.L. tested and Listed stainless steel lining system designed for relining existing

masonry chimneys. It satisfies code requirements as a substitute for 5/8" fireclay liners and has undergone

extensivetestingtomakeittheleaderinthestainlesssteelchimneyliningindustry. Heat-Fabrecommendsthat

the installation of Saf-T Liner be performed by an experienced professional who works with chimney and

woodstove related products on a regular basis. Saf-T Wrap is a safe, high quality, easy to install ceramic

insulation jacket for stainless steel lined masonry chimneys. Saf-T Wrap when used in conjunction with Saf-

TLinerwillupgradeachimneytoanHTtypechimneysystem. Thefollowinginstructionsareintendedasaguide

to assist a qualified professional installer. Check your local building codes and contact local building or fire

officials to obtain any required permits. Warning: Incorporation of parts or materials not manufactured or

supplied by Heat-Fab may not provide a Listed system. Order Heat-Fab’s installation videotape for further

information, available in VHS format.

SAFETY FIRST

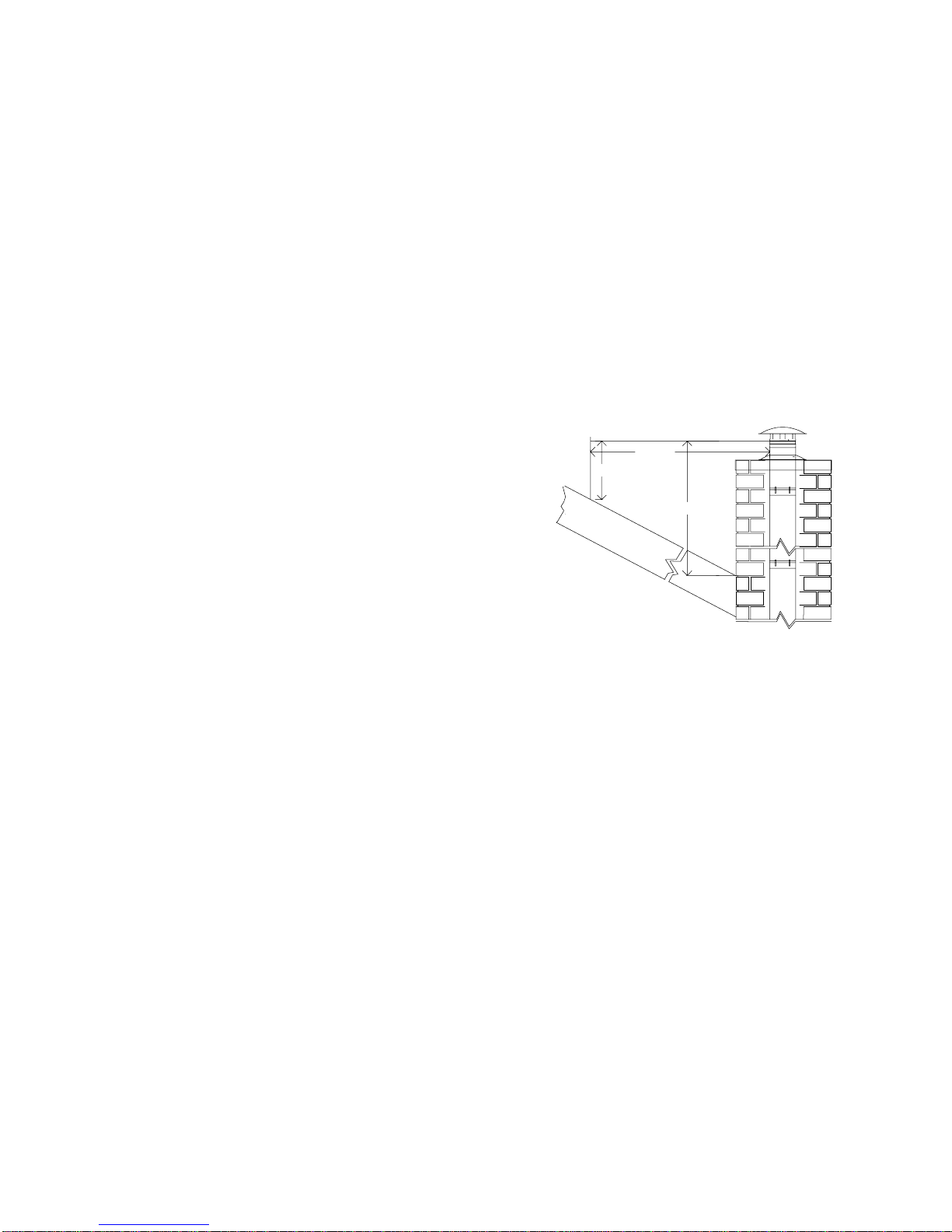

The National Fire Protection Association Standards Nos. 54 and

211requirethechimneytoextendatleast3feetabovethehighest

pointwhereitpassesthroughtheroof,andatleast2feethigherthan

any portion of the building within 10 feet (Fig.1).

The Saf-T Liner should not extend more than 6 inches above the

masonry chimney. Any additional flue liner height above the

masonrychimney willcreate condensationresulting inthe buildup

of excessive creosote.

Do not connect more than one solid fuel burning appliance to a single chimney flue and do not connect gas or

liquid fired appliances to chimney flues serving a solid fuel burning appliance.

Wear eye protection and heavy gloves throughout installation. Wear eye protection and dust respirator

whenever in contact with creosote, soot, mortar or insulation. Caution must be used when working on a roof.

Properandsafescaffoldingshouldbeusedforasafeinstallation. Allladdersshouldbesecuredtothebuilding.

Check overhead for antennas, power lines, or other obstacles before erecting the ladder and installing liner.

CHIMNEY PREPARATION

Layoutground clothstoprotect theinsideof thehomebefore sweepingthechimney. Clean andremoveall tar

glazedcreosote and sootdeposited on theinternal chimney walls,and smoke chamberof the fireplace,failure

to throughly clean the chimney before installing a new liner system may lead to fire and or smoke damage to

the home. Always use a dust respirator when in contact with soot and creosote.

Inspect the chimney for the following structural weaknesses before it is lined:

• Loose or eroded mortar

• Cracks in the masonry

• Missing bricks

• Internal obstructions that could inhibit installation

Repair all structural weaknesses before proceeding with installation of Saf-T Liner.

10 Feet

2 Feet

3 Feet

Fig. 1

CLEARANCE FROM COMBUSTIBLES

Air space clearances between the masonry chimney exterior and

combustible materials should be checked to verify that the chimney is in

accordance with the following clearance specifications (Fig. 2). The

minimum air space clearance between masonry chimneys and combustible

materials shall be at least 1" for a UL Listed Installation.

DETERMINING THE LINER DIAMETER

The Saf-T Liner must be properly sized for your heating appliance. The

diameter of the Saf-T Liner for a single appliance shall not be less than the

diameter of the appliance flue collar or that specified in the appliance

manufacturer’sinstructions. Measurethedimensionofthechimneyopening

atitssmallestpoint(Fig.3). Takethesmallerofthetwomeasurements(A&B)

and deduct 2" to arrive at the maximum diameter of Saf-T Liner that may be

installed. Saf-TLinermaybeinstalledinanychimneywithaninsidediameter

greaterthan7"x7"andconstructed of4"thick nominalsolidor cored,brickor

masonry. When using Saf-T Liner to vent a fireplace, the cross section

openingoftheflueshallnotbelessthan1/10thofthefaceareaofthefireplace

opening, to insure proper draft (Fig. 4). Custom rectangle or square Saf-T

Liner is available for flues which will not fit the required size round liner.

DETERMINING THE TOTAL LENGTH OF SAF-T LINER

Saf-T Liner is recommended for use in chimneys measuring in height from

8' to 80'.

Non-Fireplace Chimney

Measurethelengthofthechimneyfluetodeterminethelengthoflinerneeded

by utilizing a tape measure. From this length subtract 14" for each tee

required. Itis recommended thatSaf-T Linerbe installed withan accessible

clean-outteethatwillfacilitateeasycleaningandmaintenanceofthechimney

system. Oneteewillberequiredfortheappliance,aswellasateeatthebase

oftheSaf-TLinerasaclean-out. Determinethedistancebetweenthesetwo

teesandthenthedistanceabovetheapplianceteetothetopofthechimney.

The liner assembly will be supported by the tee take-offs and the clean-out tee resting on non-combustible

material.

Hearth/Fireplace Insert Stove

If installing a hearth or fireplace insert stove using an existing fireplace chimney, the length of rigid Saf-T Liner

required will be the distance from the chimney top to the top of the smoke chamber. Listed stainless steel

ChimneyLinercomponents,anengineeredDirectConnectAssemblyoranyothermethodapprovedbythelocal

buildingauthoritywillberequiredtopassthroughthesmokechamber/damperareatotheappliancefluecollar.

Theliner assembly willbesupported fromthetop of thechimney. The installer mustverify that thereis at least

1 inch clearance to combustibles outside a 3" nominal layer of masonry as well as 1 inch clearance from the

masonryto theconnectorinside thesmoke chamberareafor theentire lengthwithinthe smokechamber area.

Fireplace

When lining an open fireplace, the total liner length will be the distance from the top of the smoke chamber to

the top of the chimney. This liner assembly will be supported from the top of the chimney. The liner may also

be extended to the damper area if the smoke chamber area is in poor condition. The installer must verify that

thereisatleast1inchclearancetocombustiblesoutsidea3"nominallayerofmasonrytoinsuresafeoperation

of the fireplace.

2"

Minimum

1" minimum

Insulation

Combustible

framing

member or

wall

Fig. 3

AB

Fig. 2

Area B

AreaA

1/10 Area B

Fig. 4

DETERMINE THE NUMBER OF LINER SECTIONS

Saf-T Liner is available in 12", 18", 24", 36" and 48" fixed lengths and telescoping sections. NOTE: Two is the

maximumnumberoftelescopinglengthswhichmaybeinstalledabovetheappliancetee.A telescopingsection

betweentheapplianceandcleanoutteewillallowforbothradialandverticaladjustmentsduringtheinstallation.

To determine the length and number of liner sections required complete the following:Calculate the number of

fixedand/ortelescopinglengthsrequiredtolinethechimneyandextendnotmorethan6"abovethetermination

of the masonry (Remember each fixed length’s measurement must be reduced by 2" to account for overlap of

each section)

-Determine the number of fixed or telescoping lengths between the appliance tee and the clean out tee (if

required).

DETERMINING THE AMOUNT OF SAF-T WRAP INSULATION

Saf-TWrapisavailableinteesectionsand24"lengths,thereforetwolengthswillberequiredforeach4'section

of Saf-T Liner. Saf-T Wrap must cover the Saf-T Liner from the appliance tee or the top of the smoke chamber

area to within 8" but not closer than 3" of the top of the masonry chimney.

ASSEMBLY MATERIALS REQUIRED

The following tools and supplies are needed to complete the installation of the Saf-T Liner System:

•Hammer •1/8" or #30 high speed drill bit •Rope •Bag of mortar mix •Mortar pan •Screwdriver

•Eye protection •Cold chisel •Masonry drill bit •Electric or hand drill •Ladder and staging

•Tin Snips •Trowel •Duct tape •Pliers •Silcone caulking •Drop Cloth •Pop rivet gun

•Dust respirator (3M 9900, 3M8710 or equiv.)

PRE-ASSEMBLY OF SAF-T LINER PARTS

In order to reduce unnecessary trips up and down the ladder, the liner may be pre-assembled into sections 8-

10' in length. These can be safely carried up a ladder to the chimney. However, always check overhead for

antennaes,powerlines,orotherobstaclesbeforeerectingyourladderandinstallingliner. PreassembletheSaf-

TLineronthegroundandchecktheoveralllength. REMEMBER-thesmall,crimpedendisalwaysfacingdown

andthearrows markedoneach linersectionare topointup. Using thehighspeeddrillbit,drillthrough thepilot

holesof onesectioninto thecrimped endofthe nextsection. Pop rivettheliner intomanageable lengthsusing

the four rivets supplied.

Non-Fireplace Chimney

Inthecaseofastraightchimneylinerjob,thecleanoutteeshouldberivetedtothefirstlinersectionandthetee

cover attached to the tee. Place either a telescoping section or slip connector and a liner section between the

cleanout tee and the appliance tee to allow for expansion and contraction of the system.

Hearth/Fireplace Insert Stove

The appliance connector should be riveted to the first liner section with four opposing pop rivets.

ATTACHING LOWERING ROPE

Theloweringrope should beattached to the firstsection of Saf-TLinerby any oneof many methods including,

S hooks, duct tape or by riveting loops into place on the liner. Use any method that will provide a secure hold

on the liner and allow easy removal of the rope after installation.

When using telescoping sections, it will be necessary to attach an additional length of rope that will drop to the

base of the chimney flue. This rope will extend the telescoping sections as they are lowered into the chimney.

OPENING THE CHIMNEY

NOTE: Wear eye protection and dust respirator.

An opening for the liner system will have to made for any existing chimney without an opening. If there is an

opening,itmayneedtobeexpandedinordertoinserttheteetakeoffintotheremovableteeoraccomodatethe

support system chosen.

To make the initial opening into the chimney, select a brick that is at the level you want the stove pipe to enter

thewall(atleast18"fromunprotectedcombustiblesunlessalistedwallpenetrationassemblyorotherapproved

methodisused). Thewallpenetrationassemblymustbeabovetheappliance. Drillaseriesofholesinthemortar

around the perimeter of the brick with a masonry drill bit.

Knock the remaining mortar surrounding the brick free with a hammer and cold chisel and remove the brick.

Additional bricks are usually easier to remove than the first one.

Non-Fireplace Chimney

Repeatforcleanouttee,beingsuretomaintainthedistancebetweenthetwoteesasoriginallyplanned. Position

the two take offs, with the retractable bands fully extended, into the opening in the chimney making sure there

is room to tighten the screw on the take off’s retractable band.

INSTALLING YOUR SAF-T LINER AND SAF-T WRAP INSULATION

CAUTIONmust be used whenworking onaroof. Proper and safe scaffoldingshould beusedfor a safe

installation of the Saf-T Liner. Always use a respirator and eye protection when using Saf-T Wrap.

Non-Fireplace Chimney

Carefully lower the first section of liner, consisting of cleanout tee body, tee

cover and first liner section for between the tees, until the top is about 6"-12"

abovethechimneytop. Securetheloweringropetothechimneytoptoprevent

the Saf-T Liner from falling further into the chimney. Insulate the first section

of Saf-T Liner with a 24" section Saf-T Wrap by closing the snap-lock seam

and crimping and slide it down to form a continuous enclosure of insulation.

Attachthenextlinersectiontotheoneinthechimneyandrivetthetwosections

together with four opposing rivets. Repeat these procedures until the liner

section is ready to be guided through the retractable bands of the appliance

and clean-out tee take offs. Carefully lower the liner system through the

appliance take off, then through the clean out take off band until the cut out

sections line up. Secure the take off to the clean out tee by tightening the

retractableband. Returntotheapplianceopeningandtightentheretractable

bandin thesame fashion. Trimthe lastsection ofSaf-T Wrap asrequired so

thatitisatleast4"fromthecoverplateatthetopofthechimney. Thiswillallow

for expansion of the liner during normal use.

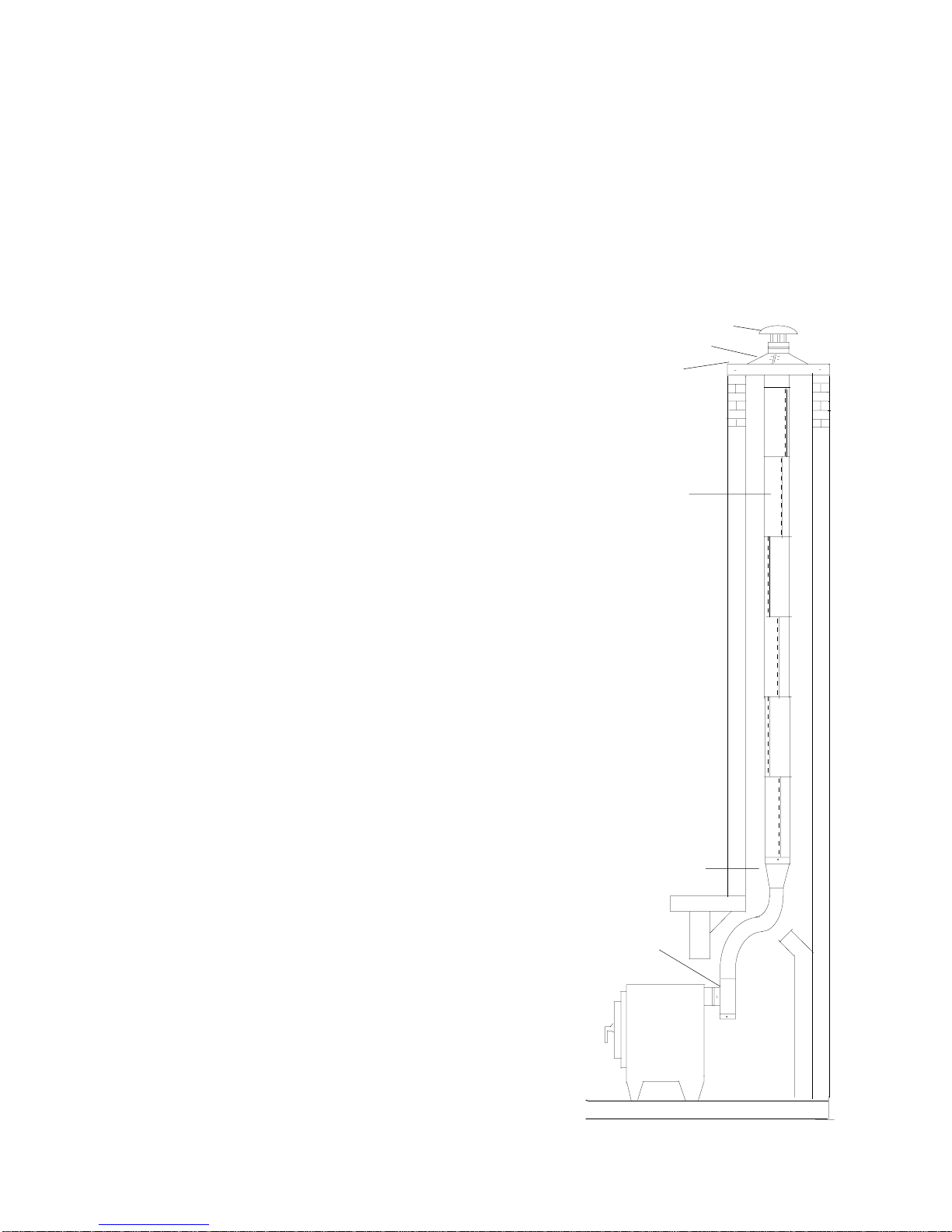

Hearth Stove and Fireplace Insert Stove

Insulate the first section of Saf-T Liner with a 24" section of Saf-T Wrap by

closing the snap-lock seam and crimping. Slide the Saf-T Wrap down until it

abuts the top of the appliance connector. Attach the next sections of Saf-T

Liner and insulate with Saf-T Wrap using the above procedures until the

desired height is acheived. Trim the last section of Saf-T Wrap as required

so that it is at least 4" from the cover plate at the top of the chimney. This will

allow for expansion of the liner during normal use.

Saf-TLiner

Section

Appliance

Tee

Saf-TWrap

Tee

Fig. 5

Saf-TWrap

Section

CLOSING THE CHIMNEY OPENING

Non-Fireplace Chimney

Beforeclosing theopening inthechimney,makecertain thatthe Saf-T Wrapis positionedsecurelyaroundthe

applaincetee.

Severalbrick halvesandmortar willbe neededtoclose inaround thetakeoff. Rebuild thechimney usingbrick

assquare as possible. Fillmortar intightly around thetake off. Makesure that thestarter sectionfits smoothly

into the takeoff before the mortar cures.

If desired a cover plate may be installed over the opening in lieu of filling with masonry. Attach the cover plate

with four tapcon screws or other masonry anchors.

INSTALLING THE COVER PLATE, RAINCAP AND STORM COLLAR

Place the coverplate on the top of the masonry chimney to create a dead

airspacearound the Saf-TLiner system. Trim the coverplate to 4"larger

thantheoutsideofthechimney. Usingtinsnips,notcheachcorner2"and

foldeach cornerunder 90degress. Set thecoverplateoverthe lineronto

a bead of silicone caulk on the chimney top. Do not attempt to secure

the liner with mortar or fasteners directly to the masonry chimney

top. There must be room for vertical expansion of the Saf-T Liner

due to the heating and cooling process during normal use.

Install the storm collar directly below the expanded portion of the liner by

tightening the clamp screw. The storm collar will then rest on the cover

plate,supportingtheuppersectionsofthelinersystem. Slidetheraincap

into the expanded portion of the liner and secure with the four self-drilling

screws provided. (see Fig. 6)

INSTALLING THE APPLIANCE

Non-Fireplace Chimney

Thefirstsectionofstovepipewillconnecttotheteetakeoff,eitherthrough

aSaf-TThimbleorotherlistedand/orapprovedwallpenetrationassembly.

Any stove pipe connector used which is not open to plain view from the

room must be made of stainless steel. The wall penetration assembly

must be located above the appliance and may not be located directly

behind the heating appliance. Note: When a listed or approved wall

penetration assembly is not used, the single wall connector pipe must be

at least 18" from combustible construction materials.

Clearances from the solid fuel burning appliances to combustible materi-

als must be strictly adhered to. Follow all local codes and appliance

manufacturer’s directions (Fig.7 next page).

Hearth Stove and Fireplace Insert Stove

Installthe bottomtermination ofthe linersystem andappliance connector

to the appliance flue collar. (see Fig.6)

Complete the hearth stove or fireplace insert installation per the

manufacturer’s instructions and guidelines.

Aftercompletingtheinstallationoftheapplianceitisrequiredthattheinitial

firing precautions of the appliance manufacturer’s instructions be strictly followed.

Saf-T Liner w/

Saf-T Wrap

Storm Collar

Tee Cover

Appliance

Tee

Fig. 6

Cover Plate

Rain Cap

Appliance

Connector

CHIMNEY MAINTENANCE

The chimney connector and Saf-T Liner should be inspected frequently

duringthe heatingseasonand cleanedannually(moreoftenif necessary)

by a professional, certified chimney sweep. Formation of creosote and

soot and the need for removal occurs when wood is burned slowly,

producing tar and other organic vapors, which combine with expelled

moisturetoformcreosote. Thecreosotevaporscondenseintherelatively

cool flue of a slow burning fire. As a result, creosote residue accumulates

on the flue lining. If ignited, this can make an extremely hot chimney fire.

The chimney should be inspected at least every 6 to 8 weeks during the

woodburning season to determine if a creosote or soot buildup has

occured. Toinspectand/orcleanthechimney,loosenthefourTekscrews

with a nutdriver and remove the rain cap. If creosote or soot have

accumulated, have the chimney professionally cleaned to reduce the risk

of a chimney fire.

A round-wire steel or Poly chimney cleaning brush is recommended to

cleantheSaf-TLiner. Heat-Fabdoesnotrecommendtheuseofchemical

chimney cleaners which may be harmful to the Saf-T Liner. After thor-

oughly cleaning the chimney re-install the rain cap by using the four Tek

screws.

WARNING! Do not use any loose fill, cementious, or

blanket insulation thicker than 1/4 inch equivalent

refractory ceramic fiber. These products void the

Saf-T Liner and may create unsafe conditions

resulting in damage to the masonry chimney and/or

the liner system.

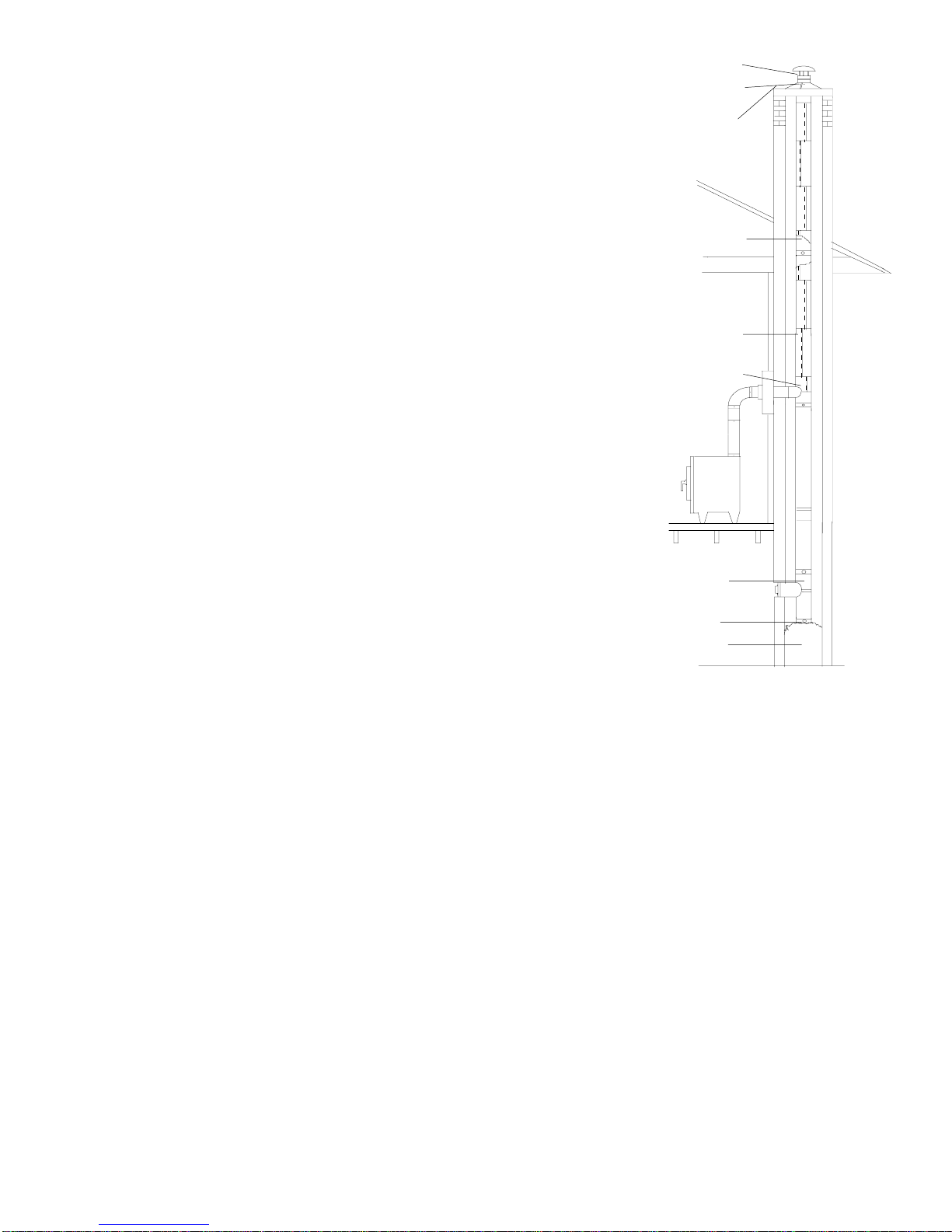

Rain Cap

Storm Collar

Cover Plate

Saf-T Liner

Saf-T Wrap

Appliance Tee

Clean Out Tee

Tee Cover

Fig. 7

Fill

Saf-T Liner Stainless Steel Chimney Liner

LimitedWarranty

Heat-Fab,Inc.warrantstotheoriginalconsumerpurchaserthattheType304Saf-T Linerwillbefreefromdefectsinmaterial

or manufacturer’s workmanship when properly installed with Saf-T Wrap insulation pursuant to these manufacturer’s

installationinstructionsandaccordingtothelocalbuildingcodes,whenusedundernormalconditionsasconnectorpipeor

chimneyreliningmaterialforWoodBurningresidentialappliancesTestedandListedbyarecognizedlaboratory,orsitebuild

masonryfireplacesandwheninspectedandcleanedbyacertifiedprofessionalattheconsumer’sexpenseatintervalsofno

morethantwelve(12)months,commencingfromthedateofpurchase,asverifiedbelow.Type316Saf-TLinerwillbefreefrom

thesesame defects when connected to coalburning appliancesfor aperiod of10 years.

Inordertoobtainwarrantyservice,theconsumermustgivepromptwrittennoticeofanydefecttoHeat-Fab,Inc.atit'scurrent

addressorviae-mailto [email protected]. The sole responsibility of Heat-Fab, Inc. shall be to replace those lengths of

linerfoundto be defective upon return F.O.B. to the Heat-Fab factory. Heat-Fab, Inc. shall not be responsible for the cost

ofremovingorinstallingthelengthswhicharesubjecthereto,norshallitbeliableforanyspecial,incidentalorconsequential

damagesor expenses incurred by the consumer.

Thiswarrantygivestheconsumerspecificlegalrights,inadditiontoanyotherrightswhichmaypertain,whichvaryfromstate

to state.

Year1Maintenance Year2Maintenance Year3Maintenance Year4Mainentance

Done by__________ Done by____________ Done by__________ Done by_________

Date_______ Date_______ Date_______ Date_______

Year 5 Maintenance Year 6 Maintenance Year 7 Maintenance Year 8 Maintenance

Done by___________ Done by _____ Done by __________ Done by_________

Date_______ Date_______ Date_______ Date_______

Year 9 Maintenance Year 10 Maintenance.

Done by__________ Done by __________

Date_______ Date _______

HOMEOWNER

KEEP FOR YOUR RECORDS

Name

Address

City, State, Zip

Installing Company

Address

Phone ( )

Date of Installation

Installed by

FOLLOW THESE CHIMNEY MAINTENANCE INSTRUCTIONS:

ThechimneyconnectorandSaf-TLinershouldbeinspectedfrequentlyduringtheheatingseasonandcleaned

annually (more often if necessary) by a professional, certified chimney sweep.

The chimney should be inspected at least every 6 to 8 weeks during the heating season and once prior to the

season to determine if (1) a creosote or soot buildup has occured or (2) if some other mechanism has caused

a failure of the liner system. To inspect and/or clean the chimney, loosen the four Tek screws with a nutdriver

and remove the rain cap. If creosote or soot has accumulated, have the chimney professionally cleaned to

reduce the risk of a chimney fire.

Properlyinstalledandwellmaintainedstovepipesandchimneyscanusuallywithstandanoccasionalmoderate

chimney fire, but the intentional setting of a chimney fire to "burnout" the creosote should be avoided. This is

a dangerous method to clean a chimney and can cause severe damage to chimneys, liners and possible

damage to the structure of the house.

Afteranychimneyfirealwayshavethechimneysysteminspectedbyaknowlegeableandcertifiedprofessional

beforeanyfurtheruse. Theexcessiveheatduringachimneyfirecancrackchimneywalls,andcausecracking,

buckling, distortion and/or burnout in chimney liners. A chimney liner damaged in such a way as to permit

leakage of flue gases should be repaired or replaced, since there is a greater likelihood that a subsequent

chimney fire could spread beyond the confines of the damaged flue to the house itself. If no such damage is

visible the chimney system, installed per these instructions, is suited for further use subject to the inspection

schedule outlined above.

ATTENTIONHOMEOWNER

PI-LINER R0301

Table of contents

Other Heat-Fab Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Faber

Faber INCA PRO PLUS Installation instructions; use and care information

M7

M7 SM-0502 manual

KitchenAid

KitchenAid KXI4336YSS Installation Instructions and Use & Care Guide

DeDietrich

DeDietrich DHD7000X Guide to installation

Whirlpool

Whirlpool UXI0600DYS installation instructions

Zanussi

Zanussi IH6048B Instructions for use and care

Xo

Xo XOIL4819KSE manual

CookMax

CookMax 315020 INSTRUCTIONS FOR INSTALLATION, ADJUSTMENT, USE AND MAINTENANCE

Broan

Broan ELITE E661 installation instructions

Glem

Glem CK90TBLED Instruction manual and installation guide

Blanco

Blanco BRS60X Instructions for the use and care and installation

DeDietrich

DeDietrich DHG397 Instructions for installation and use