Page

5

(

)

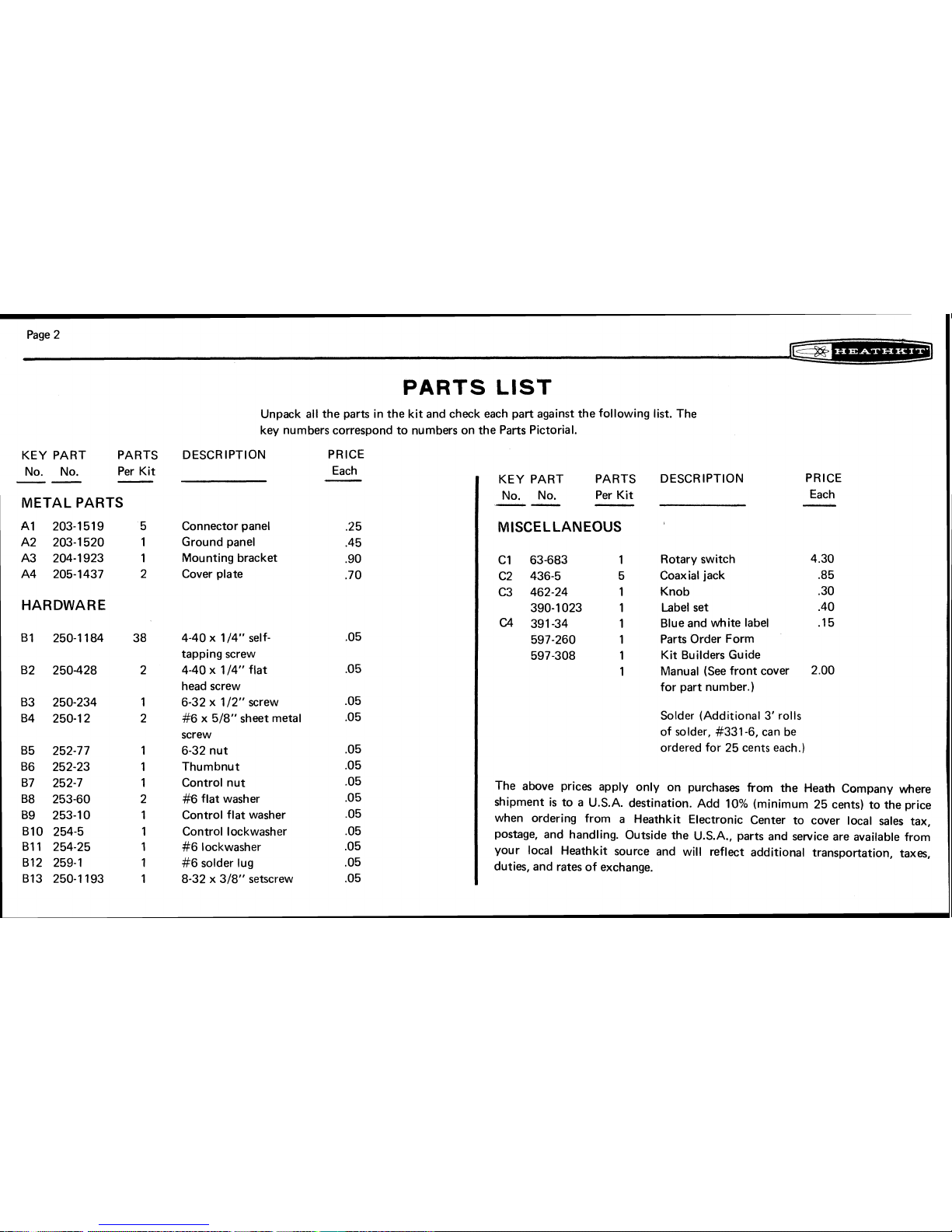

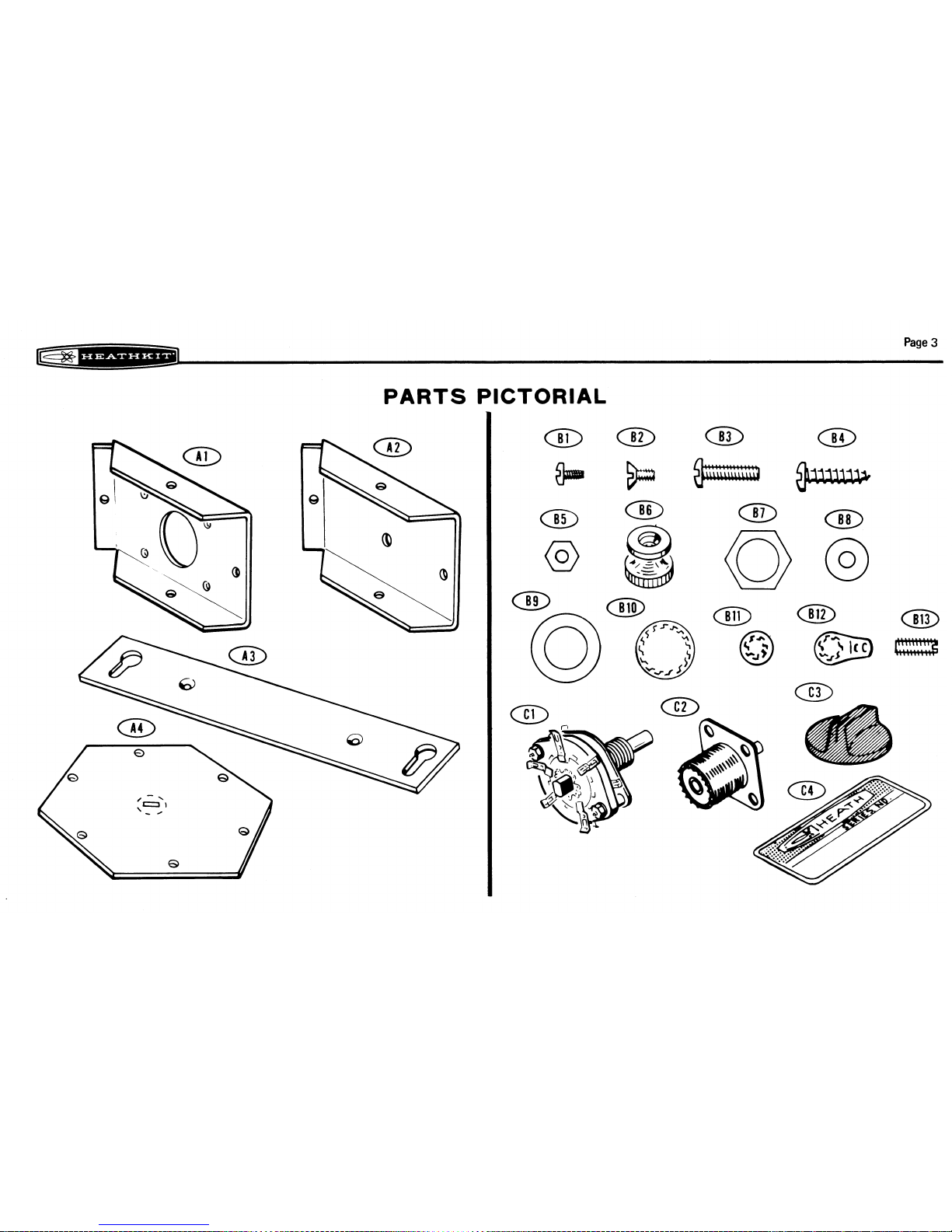

In the same manner, mount the four remaining coaxial jacks onto four

connector panelswith 4-40 x 114'' self-tapping screws.

(

)

Add a small amount of solder to pre-tineach connector solder post.

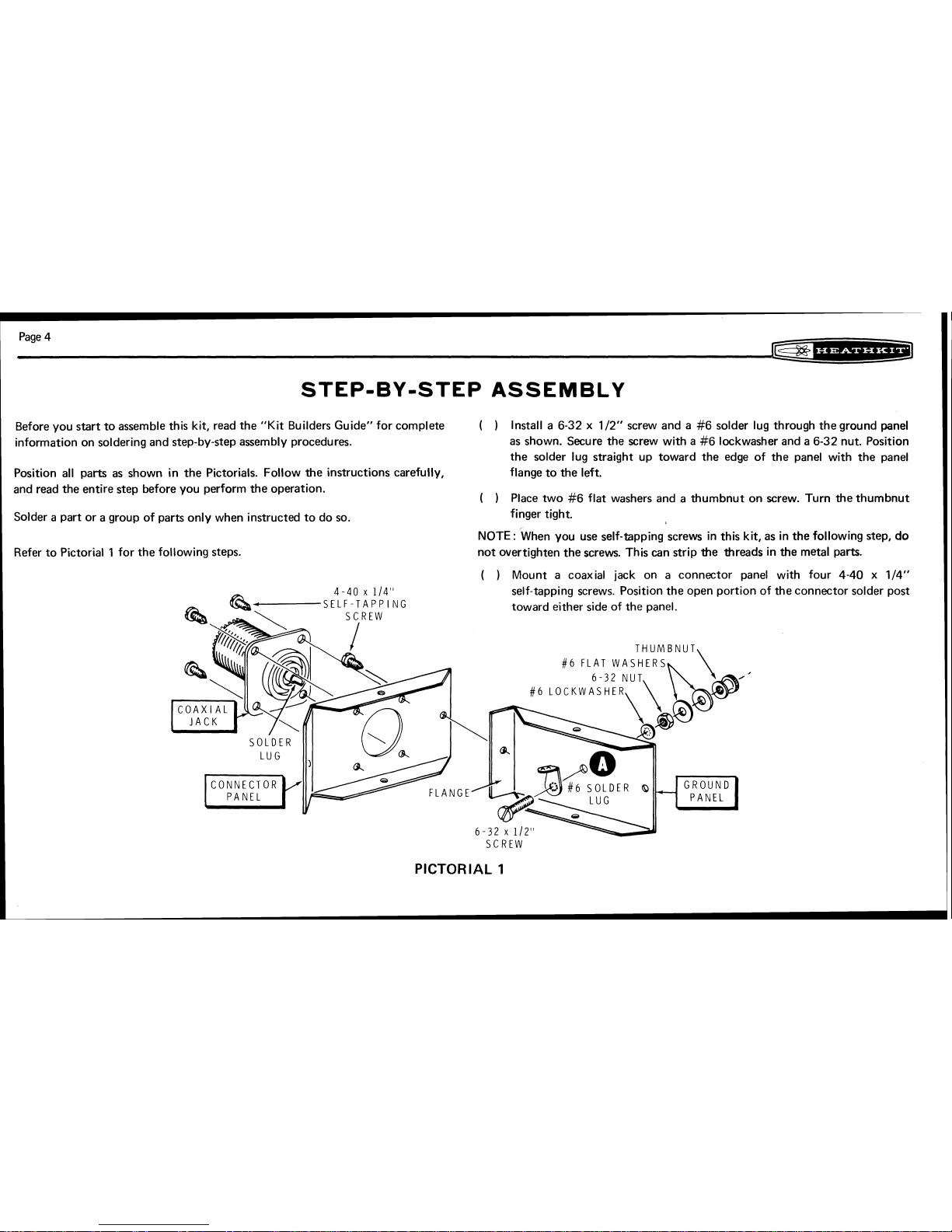

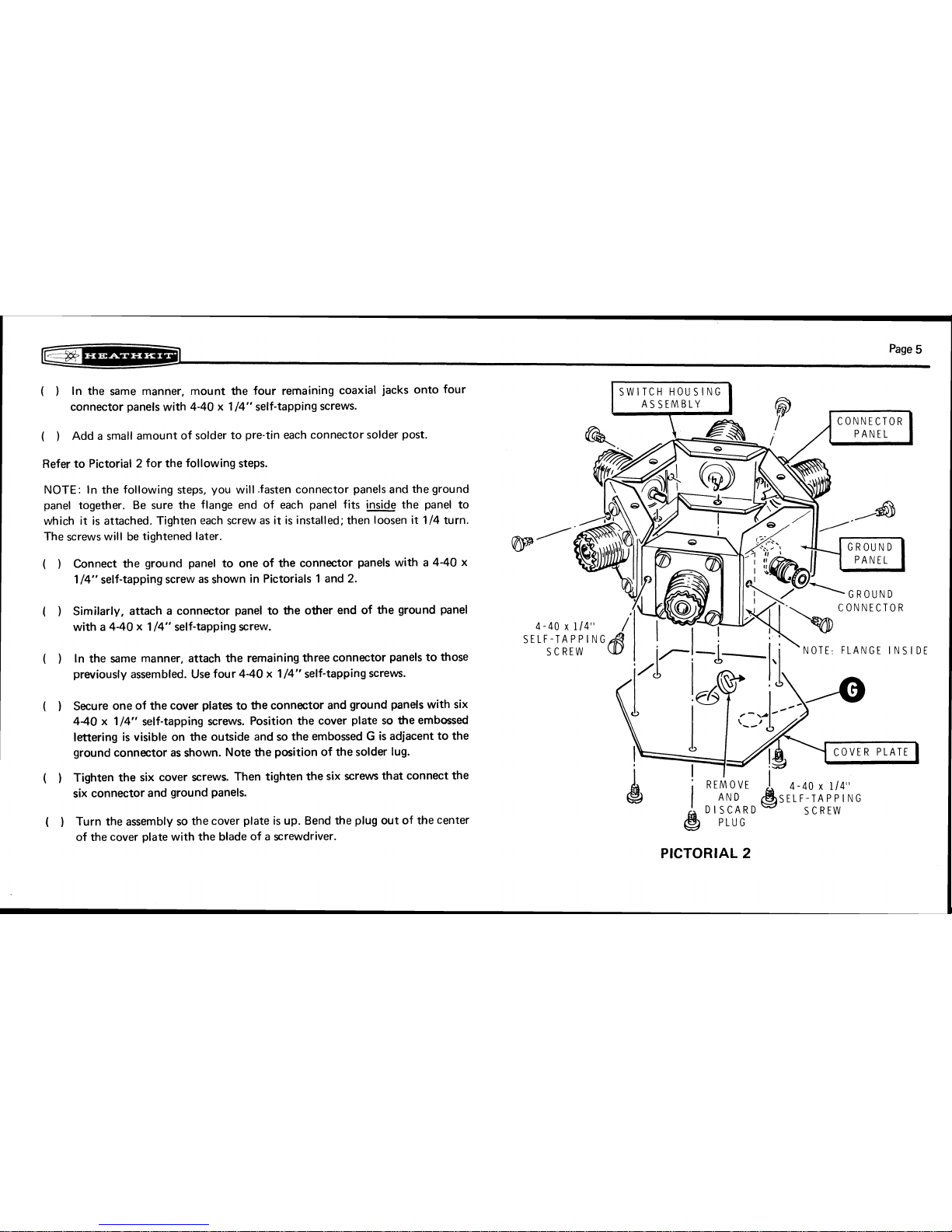

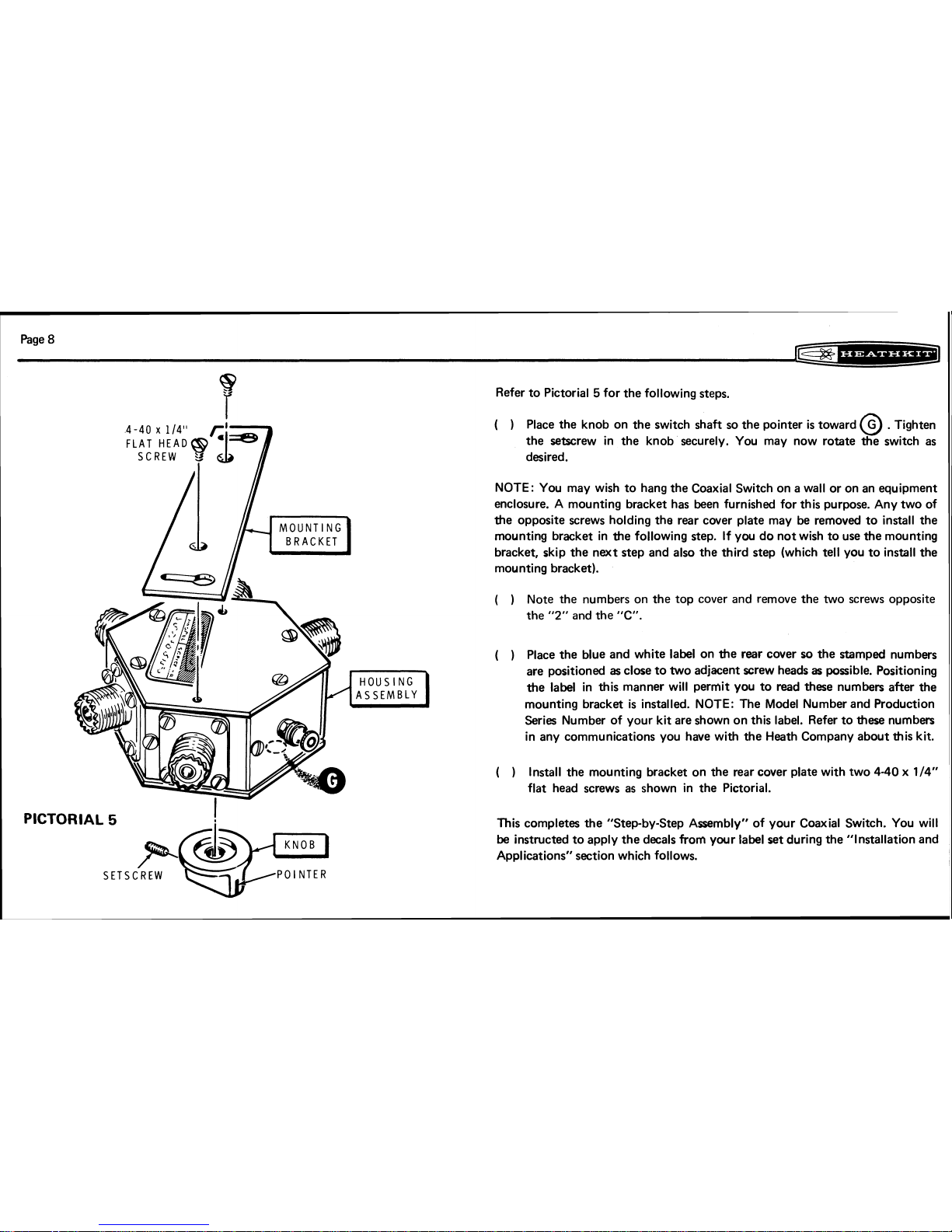

Refer to Pictorial

2

for the following steps.

NOTE:

In the following steps, you will .fastenconnector panels and the ground

panel together. Be sure the flange end of each panel fits wethe panel to

which it is attached. Tighten each screw as it is installed; then loosen it 114 turn.

The screws will be tightened later.

(

)

Connect the ground panel to one of the connector panels with a 4-40 x

114" self-tapping screw as shown in Pictorials

1

and

2.

(

)

Similarly, attach a connector panel to the other end of the ground panel

CONNEClOR

with

a

4-40 x 114" self-tapping screw.

SELF-TAPPING

( )

In the same manner, attach the remaining three connector panels tothose

NOTE. FLANGE

IhSI

DE

previously assembled. Use four 4-40x 1/4" self-tapping screws.

(

)

Secure one of the cover plates to the connector and ground panels with six

4-40 x 114" self-tapping screws. Position the cover plate so the embossed

lettering is visible on the outside and so the embossed

G

is adjacent tothe

ground connector as shown. Notethe positionof thesolder lug.

( )

Tighten the six cover screws. Then tighten the six screws that connect the

six connector and groundpanels.

( )

Turn the assembly so the cover plate is up. Bend the plug out of the center

of the cover plate with the blade of ascrewdriver.

PICTORIAL

2