09/04 30484 Rev Q 3

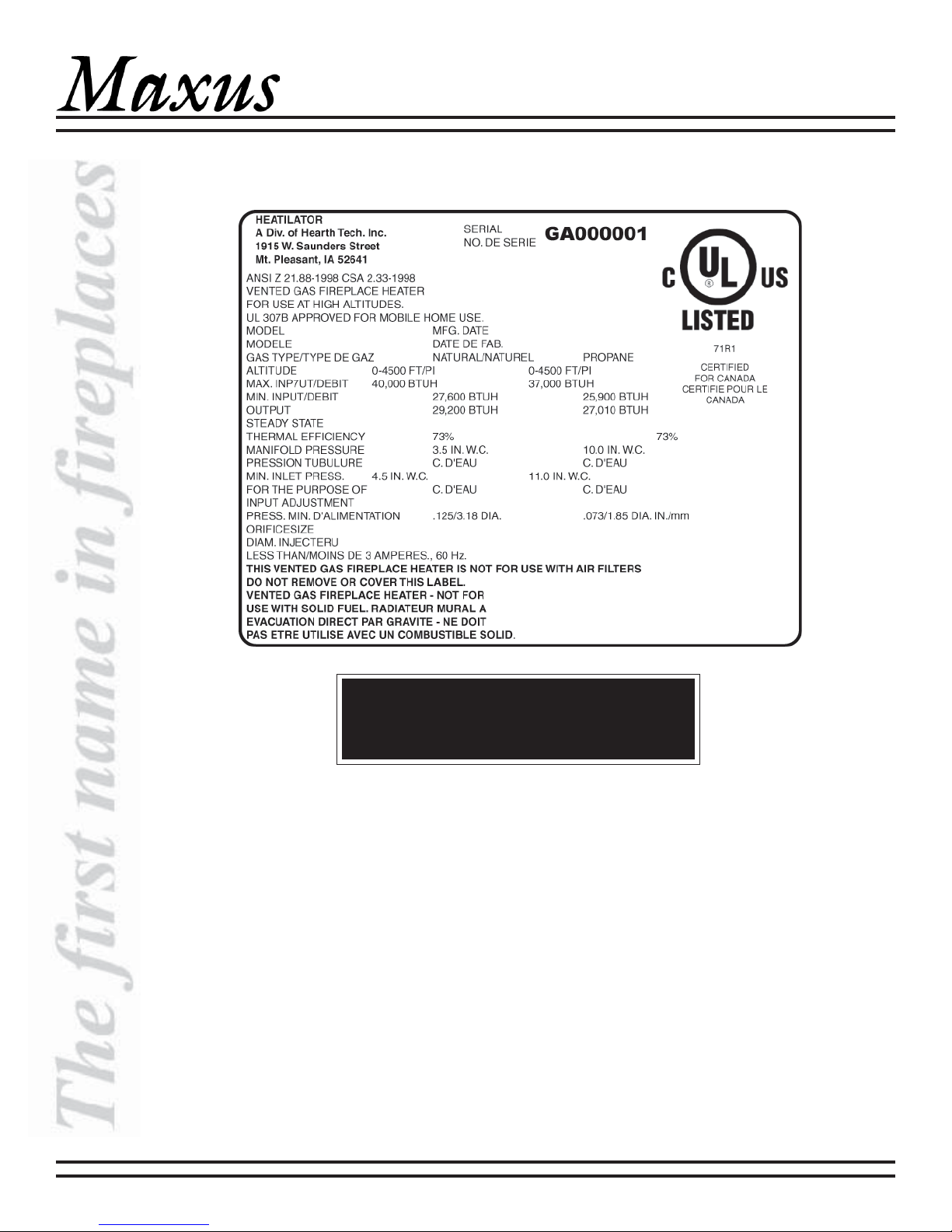

MAXUS DIRECT VENT HEATER

A. LISTINGS AND CODE APPROVALS

1. U.S. and Canadian Certification

The Maxus Series Gas Appliance has been tested in

accordance with the ANSI standard Z21.88-1998, CSA

2.33-M98, and has been listed by UL for installation

and operation as described in these installation and

operating instructions. All components are AGA, CGA,

CSA or UL safety certified.

2. Local Codes

This installation must conform with local codes or, in

the absence of local codes, with the National Fuel

Gas Code, ANSI Z223.1-latest edition in the U.S.A.,

and the CAN/CGA B149-latest edition in Canada.

The Maxus Series gas appliance has been tested

and listed for use in manufactured housing (mobile

homes). These installation instructions conform with

the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or when such a

standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1.

3. Glass Specifications/Certifications

Heatilator gas appliances manufactured with

tempered glass may be installed in hazardous

locations such as bathtub enclosures as defined by

the CPSC. The tempered glass has been tested and

certified to the requirements of ANSI Z97.1-1984 and

CPSC 16 CFR 1202. (Safety Glazing Certification

Council SGCC# 1595 and 1597. Architectural Testing,

Inc. Reports 02-31919.01 and 02-31917.01.)

This statement is in compliance with SPCS 16 CFR

Section 1201.5 “Certification and labeling

requirements” which refers to 15 USC 2063 stating,

“…Such certificate shall accompany the product or

shall otherwise be furnished to any distributor or

retailer to whom the product is delivered.”

Some local building codes require the use of tempered

glass with permanent marking in such locations.

Glass meeting this requirement is available from the

factory. Please contact your dealer or distributor to

order.

4. Efficiency

The efficiency rating of the appliance is a product

thermal efficiency rating determined under continuous

operating conditions and was determined

independently of any installed system.

If any assistance is required during installation please

contact your local dealer or contact the Heatilator

Technical Services Department, Hearth & Home

Technologies Inc., 1915 W. Saunders St., Mt. Pleasant,

IA 52641, 1-800-927-6841.

This appliance is approved for installation in

bedrooms and manufactured housing (mobile

homes) in the United States and Canada.

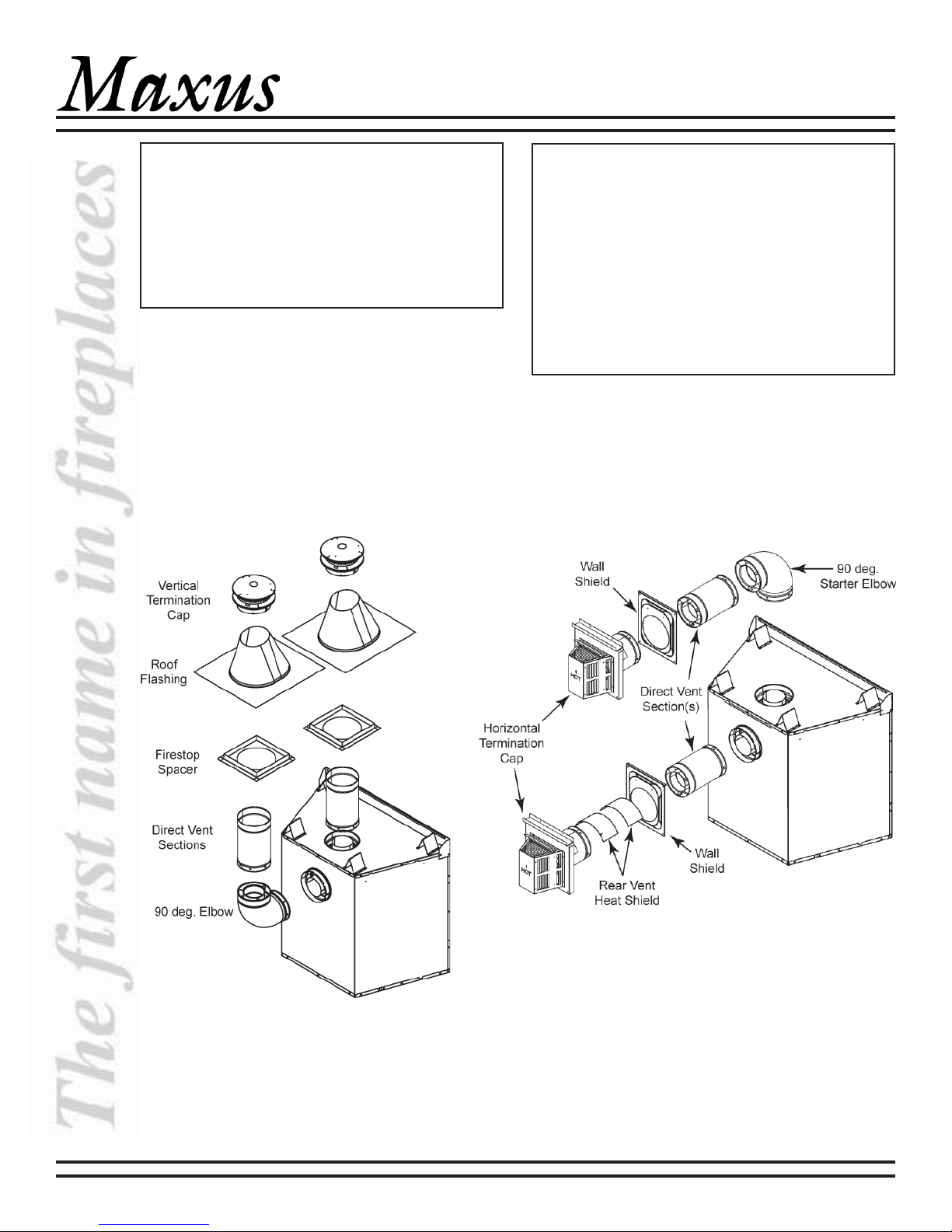

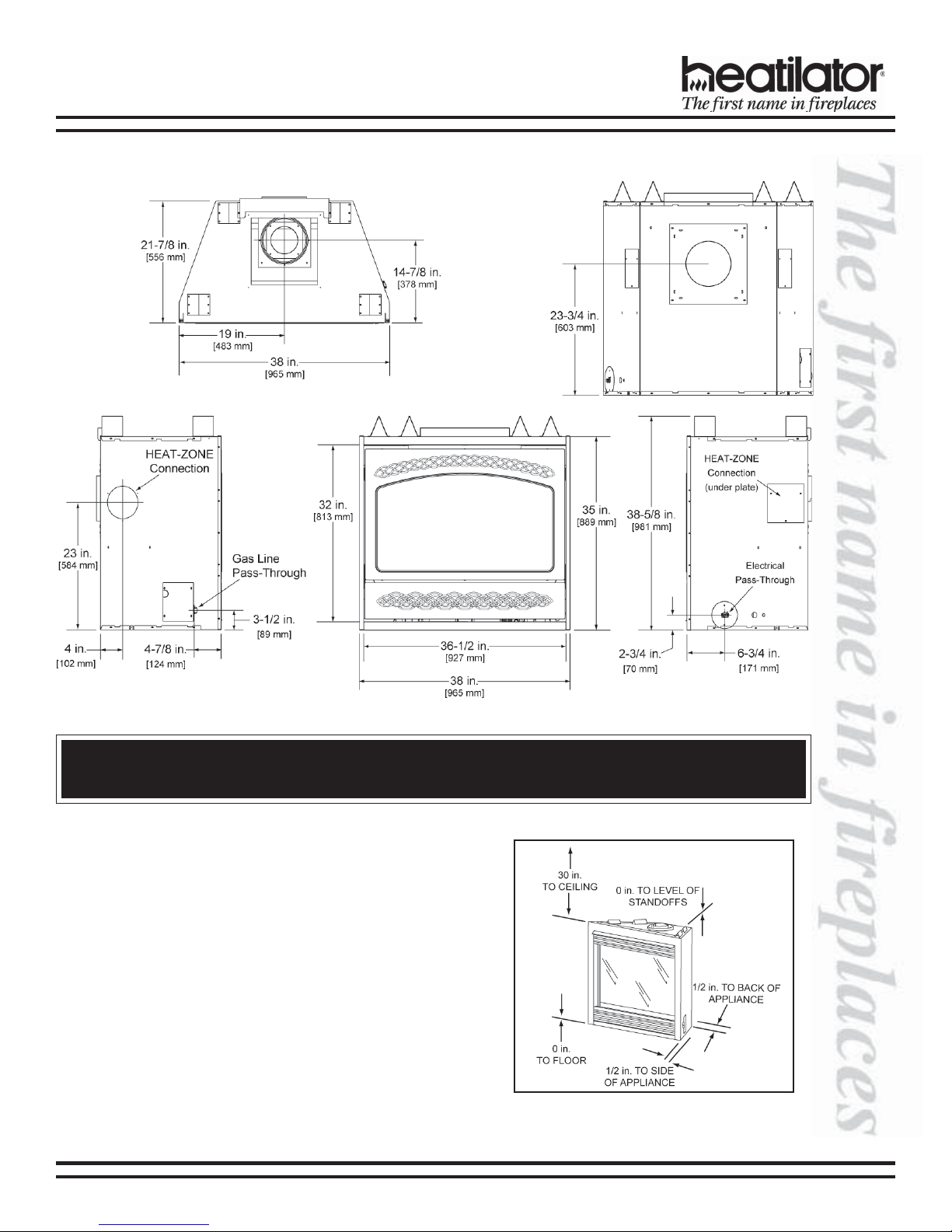

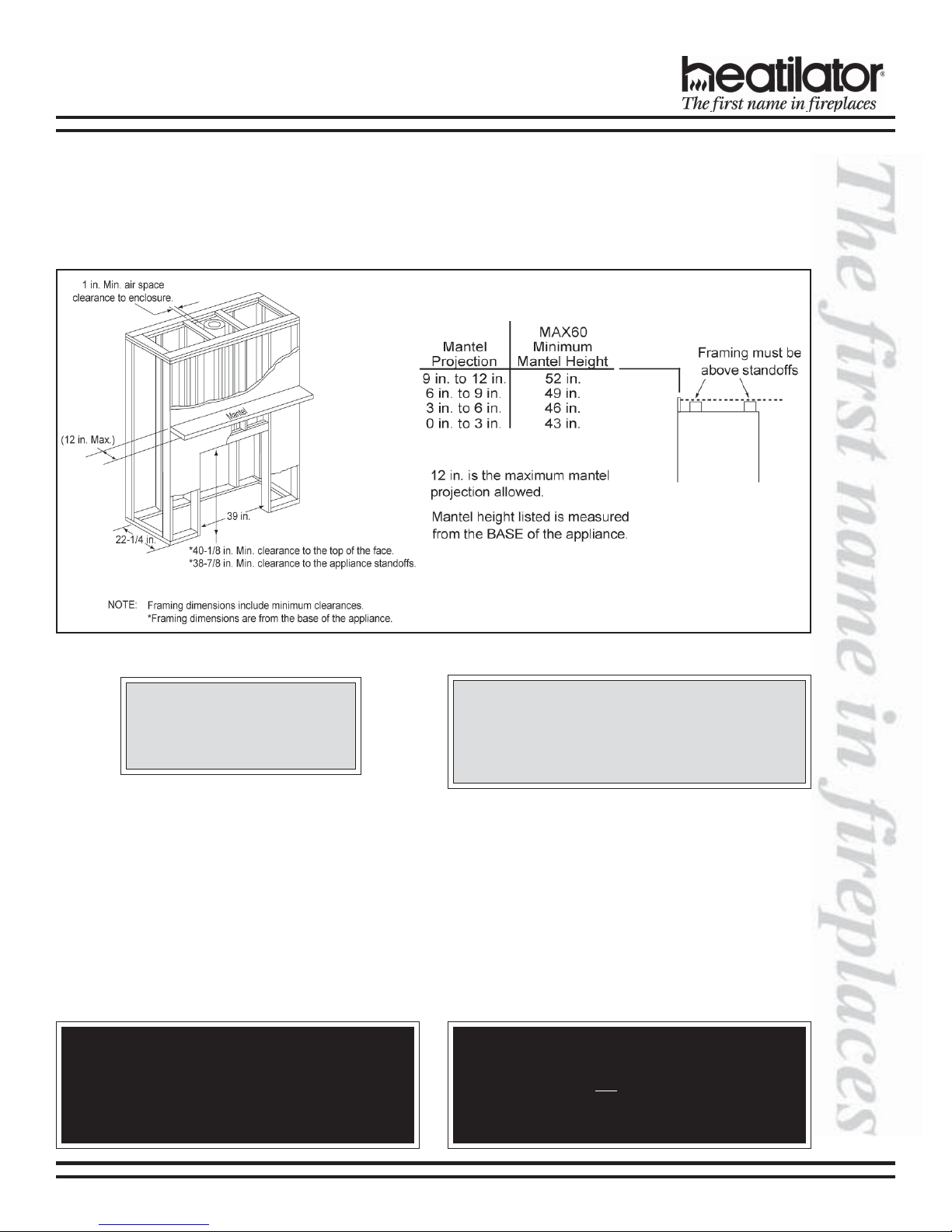

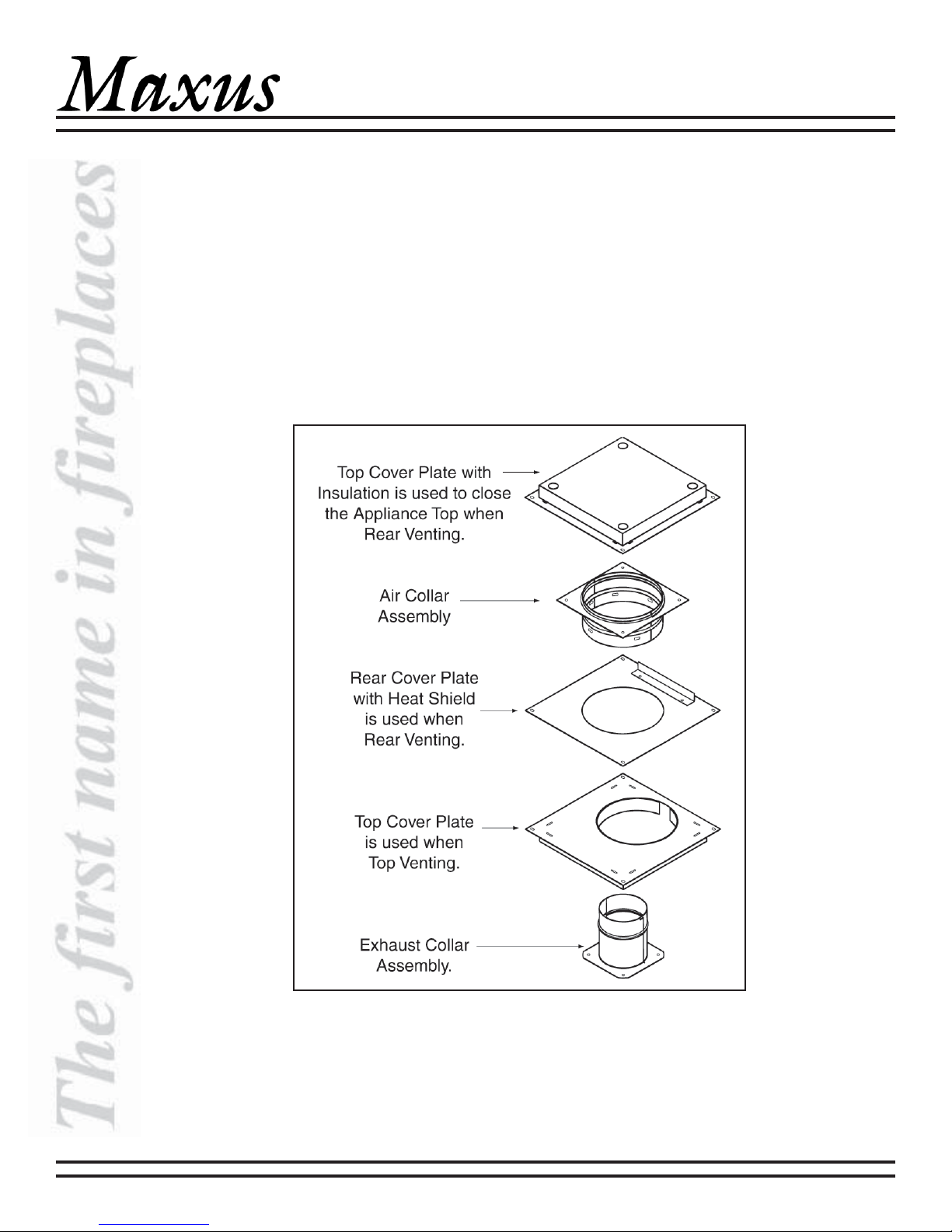

Note: Illustrations throughout these instructions reflect typical installations and are for design purposes only. Actual

installations may vary slightly due to individual design preferences. However, minimum and maximum clearances

must be maintained at all times.

The illustrations and diagrams used throughout these instructions are not drawn to scale.

WARNING!

This appliance is tested and listed for use only with the optional accessories listed in

these instructions. Use of optional accessories not specifically tested for this appliance

could void the warranty and/or result in a safety hazard.