Heatrae Sadia HI-MAX STORE User manual

703034483_issue_02

HI-MAX STORE

Installation, operation and maintenance manual

page 1

Contents

1. Introduction

1.1 General

1.2 Symbols used

1.3 Abbreviations

1.4 Liabilities

2. Safety

2.1 General safety warnings

2.2 Recommendations

2.3 Specific safety instructions

3. Technical specifications

3.1 Product features

3.2 Dimensions and weight

3.3 Dimensions and features

3.4 Hydraulic diagrams

3.5 Hydraulic diagrams legend

3.6 Wiring Diagram

4. Before Installation

4.1 Installation regulations

4.2 Installation requirements

4.3 Transport and storage

4.4 Standard delivery

4.5 Positioning and access

4.6 Installation guidelines

5. Installation

5.1 HIU installation.

5.2 Cylinder and frame installation

5.3 Cylinder and HIU installation

5.4 Modesty panel installation

5.5 Modesty panel fitting instructions

6. Components

6.1 District control valve

6.2 Safety valve

6.3 Strainer

6.4 Plate heat exchanger

7. Commissioning

7.1 Commissioning district heating system

7.2 Filling the system

7.3 Product installation & service documentation.

8. Service

8.1 General

8.2 Fault finding

9. Spare parts

9.1 Spare parts - HI-MAX STORE

9.2 Spare parts - HI-MAX STORE HIU

10. Warranty

10.1 Warranty

page 2

1. Introduction

1.1 General

The following instructions are offered as a guide to the user and installer.

The installation must be carried out by a competent plumbing and electrical installer in

accordance with Building Regulations, The Building Standards (Scotland) Regulations 1990,

The Building Regulations (Northern Ireland), UK Water Regulations and IEE Electrical

Regulations.

The heating and hot water to your home are provided by the HI-MAX STORE HIU and

unvented cylinder.

Heat is supplied to the HI-MAX STORE HIU from the central boiler(s) installed elsewhere

in the building. The central boiler will provide heat to your HIU for your central heating and

domestic hot water.

The unit works in conjunction with an indirect domestic hot water cylinder to provide heating

and hot water to your taps. As such you must read these instructions in conjunction with

those for the cylinder.

The cylinder frame arrangement permits the cylinder to sit above a washing machine. The

HI-MAX STORE HIU is wall mounted and can be supplied with a first fix rail for ease of

installation.

The unit is supplied complete with all the necessary safety and control devices needed to

allow connection to the community heating system and the apartment's central heating and

hot water systems.

This appliance complies with the requirements of the CE marking directive.

The following instructions are offered as a guide to installation which must be carried out

by a competent plumbing and electrical installer in accordance with Building, Electrical and

Water Regulations.

1.2 Symbols used

In these instructions various risk levels are employed to draw the user's attention to particular

information. In doing so we wish to safeguard the user, avoid hazards and guarantee the

correct operation of the appliance.

DANGER

Risk of a dangerous situation causing serious physical injury.

WARNING

Risk of dangerous situation causing slight physical injury.

CAUTION

Risk of material

damage.

1.3 Abbreviations

#DHW - Domestic Hot Water

#T&P - Temperature & Pressure relief valve

#PRV - Pressure Reducing Valve

#Prv - Pressure relief valve

#Stv - Safety Tempering Valve

#HIU - Heat Interface Unit

#PICV - Pressure Independent Control Valve

1.4 Liabilities

Manufacturers liability

Our products are manufactured in compliance with the requirements of the various applicable

European Directives. This appliance complies with the requirements of the CE marking

directive and is Kiwa approved to show compliance with Building Regulations (part G,

section G3). In the interest of UK customers we are continuously endeavouring to make

improvements in product quality. All the specifications stated in this document are therefore

subject to change without notice.

Our liability as the manufacturer may not be invoked in the following cases:

#Failure to abide by the instructions on using the appliance.

#Faulty or insufficient maintenance of the appliance.

#Failure to abide by the instructions on installing the appliance.

Installer's liability

The installer is responsible for the installation and the commissioning of the appliance. The

installer must respect the following instructions:

#Read and follow the instructions given in the manuals provided with the appliance.

#Carry out installation in compliance with the prevailing legislation and standards.

#Perform the initial start up and carry out any checks necessary.

#Complete the commissioning checklist.

#Explain the installation to the user.

#If maintenance is necessary, warn the user of the obligation to check the appliance

and maintain it in good working order.

#It is the installers responsibility to ensure that all joints made in the factory are sound

after installation.

#Leave all the instruction manuals with the user.

Users liability

To guarantee optimum operation of the appliance, the user must respect the following

instructions:

#Read and follow the instructions given in the manuals provided with the appliance.

#Call on qualified professionals to carry out installation and initial start up.

#Ask the installer to explain the installation.

#Have the required checks and services carried out annually.

#Keep the instruction manuals in good condition and close to the appliance.

page 3

2. Safety

2.1 General safety warnings

DANGER

This unit becomes pressurised when in operation.

The combination of pressurisation and hot water could lead to serious physical injury if the safety

instructions in this manual are not adhered to.

The unit is also designed to work at district heating hydraulic pressures up to 16 bar g and

temperatures up to 90°C, which, if exposed to could lead to serious physical injury.

WARNING

#Only competent persons having received adequate training are permitted to work on the

appliance and the installation.

#Do not tamper with any of the safety valves or controls supplied with the cylinder.

#Before any work, switch off the electrical mains supply to the appliance and the water

mains.

#Do not switch on if there is a possibility that the water in the cylinder is frozen.

WARNING

#Do not adjust the safety tempering valve (Stv). This is factory set to prevent excessive hot

water temperatures reaching the taps in the event of a system failure.

The purpose of this valve should not be confused with that of a point of use mixing valve

which is fitted near to the tap to prevent scalding.

#Do not tamper with any of the safety valves fitted to the system. If a fault is suspected

contact a competent installer.

2.2 Recommendations

WARNING

When handling the unit, take appropriate precautions for the weight of the unit. Weights can be

found in section 3 page 7.

CAUTION

Annual maintenance is recommended by a competent

person.

The HWA Charter Statement requires that all members adhere to the following:

#To supply fit for purpose products clearly and honestly described.

#To supply products that meet, or exceed appropriate standards and building and water

regulations.

#To provide pre and post sales technical support.

#To provide clear and concise warranty details to customers.

page 4

2.3 Specific safety instructions

WARNING

#Under no circumstances should the factory fitted safety valves (Stv and Prv) be removed

by anyone other than a competent person.

The unit must not be run if either of these safety valves have been removed. Doing so will

invalidate any guarantee or claim.

#No control or safety valves should be tampered with or used for any other purpose.

#The Prv discharge pipe should not be blocked or used for any other purpose.

#Where a tundish is fitted, this should not be located adjacent to any electrical components.

CAUTION

Do not operate immersion heaters until the cylinder has been filled with water.

WARNING

#If water discharges from the temperature/ pressure relief valve on the cylinder, shut down

the boiler/immersion heaters.

Do not turn off any water supply.

Contact a competent installer for unvented water heaters to check the system.

#Do not tamper with any of the safety valves fitted to the system. If a fault is suspected

contact a competent installer.

#DO NOT bypass the thermal cut-out(s) in any circumstances.

WARNING

#The heat meter can be installed within the space provided inside the HI-MAX STORE

HIU.

Although most heat meters are now battery powered some are still provided with a mains

power supply.

In these instances it is important that the installer clearly indicates that there are two

power supplies to the HIU.

This appliance can be used by children aged from 8 years and above and

persons with reduced physical sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or instruction concerning use of the

appliance in a safe way and understand the hazards involved. Children shall not play

with the appliance.

Cleaning and user maintenance shall not be made by children without supervision.

Children must be supervised to ensure they do not play with the appliance.

#Water may drip from the discharge pipe of the pressure-relief device and this

pipe must be left open to the atmosphere.

#The pressure-relief device is to be operated regularly to remove lime deposits

and to verify that it is not blocked

#How hot water can be drained. (See Systemfit manual for more details)

#The type of characteristics of the pressure-relief device and how to connect it.

(See Systemfit manual for more details)

#A discharge pipe connected to the pressure-relief device is to be installed in a

continuously downward direction and in frost free environment.

Details on how to set the temperature controls for both immersion heaters and boiler

controls can be found in the Systemfit manual supplied.

page 5

3. Technical Specification

3.1 Product features

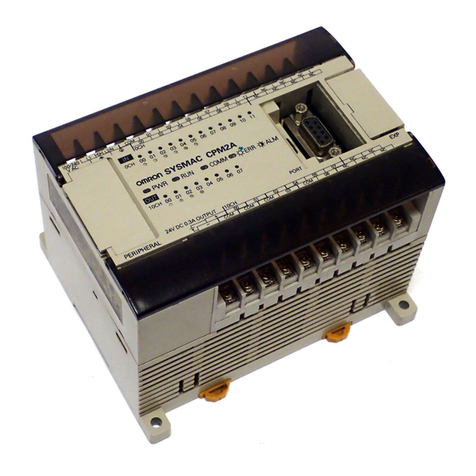

Fig 1. Product Features and Components for the HI-MAX STORE HIU

page 6

1. First fix rail bracket

2. 4 No. Fixing holes for first fix rail (Ø 7mm)

3. HIU mounting studs (M6) x 2. Supplied with HIU

4. 15mm central heating system safety valve 3 bar g

5. 230V on/off thermo actuator

6. DN 15 Frese Optima Compact pressure independent balancing and control valve

7. Brazed stainless steel plate heat exchanger

8. Test point to measure the pressure drop across the district control valve

9. Plate heat exchanger support bracket

10. Wall mounting bottom fixing holes Ø7mm (2 No.)

11. Test point to measure the pressure drop across the district control valve

12. Volume flow meter (for heat meter) spool piece 3/4" bsp x 110mm centres EN1434

13. 3/4"#bsp male Y strainer

14. Position of 1/4"# bsp heat meter flow sensor pocket (supplied by heat meter company)

15. Earth stud (M4)

16. Community (district) heating return - 3/4"# bsp male

17. Community (district) heating flow - 3/4" #bsp male

18. HWS primary return connection - 3/4" #bsp male

19. HWS primary flow connection - 3/4"# bsp male

20. Safety valve discharge pipe Ø15 mm

21. M12 cable gland (2 No.)

22. Actuator Cable Connector block

3.2 Dimensions and Weight

Fig 2. HI-MAX STORE HEAT INTERFACE UNIT

Unit Dry Weight (kg) Wet Weight (kg)

HI-MAX STORE 1st fix rail 1.6 1.6

HI-MAX STORE WITH CASINGS 11.2 13.0

Note: All dimensions are for reference only.

page 7

3.3 Dimensions and features - HI-MAX STORE

Fig 3. HI-MAX STORE Two heating zone model detailed

Cylinder size** 125i 145i 170i 210i 250i 300i

Dimension (mm)

A 2096 2217 2379 1584* 1855* xxxx

B 900 900 900 - - -

C 700 700 700 630 xxxx xxxx

D 700 700 700 700 xxxx xxxx

*Floor standing cylinder height (no frame).

Available depth for washing machine frame 580mm.

1. Domestic hot water flow 22mm

2. Cold feed connection (¼ turn isolation valve) 22mm

3. Balanced cold feed 22mm

4. Cylinder drain cock

5. Hepvo dry trap 32mm

6. Washing machine waste pipe 40mm

7. Immersion heater run back timer

8. Main 3kW immersion heater and thermostat enclosure IPX4

9. Temperature and pressure relief valve 10bar / 90-95°C

10. Tundish 15mm x 22mm

11. Combined expansion relief valve / check valve 8bar

12. Pressure reducing valve 3bar

13. Earth stud M4 22mm

For further information on the range of Megaflo Systemfit models please go to:

www.heatraesadia.com

Maximum Working Pressure:

Primary Side (Community / District Heating): 16 bar g

Secondary Side (Apartment Heating): 3 bar g

Maximum Working Temperature:

Primary Side (Community / District Heating): 90 deg C

Secondary Side (Apartment Heating): 85 deg C

Primary Side Pressure drop 30 kPa

page 8

3.4 Hydraulic Diagrams

Fig 4. HI-MAX STORE Heat Interface Unit with a Megaflo Systemfit cylinder- One Heating

Zone

See Page 10 for a legend of symbols

page 9

3.5 Hydraulic diagrams legend

Fig 5. Schematics Table

page 10

3.6 Wiring diagram

NOTES

1. ALL EARTH CONNECTIONS MUST BE LINKED BACK TO THE EARTH

TERMINALS IN THE WIRING CENTRE

2. ALL NEUTRAL CONNECTIONS MUST BE LINKED BACK TO THE NEUTRAL

TERMINALS IN THE WIRING CENTRE

3. ASSUMES BASIC BOILER

4. THE 22 MM MOTORISED VALVES DO NOT HAVE A WHITE WIRE

5. THE ABOVE DIAGRAM IS FOR GUIDANCE ONLY, THE MANUFACTURER

ACCEPTS NO LIABILITY FOR ANY LOSS OR DAMAGE ARISING FROM

ANY ERRORS OR OMISSIONS THAT MAY BE INADVERTENTLY CONTAINED

WITHIN THIS DIAGRAM.

THE VARIOUS EQUIPMENT MANUFACTURERS SHOULD BE CONSULTED TO

CONFIRM THE CORRECT OPERATION OF THEIR PRODUCTS WITHIN THE

SYSTEM

page 11

4.0 Before installation

4.1 Installation regulations

WARNING

Installation of the appliance must be carried out by a competent person in accordance with

prevailing national regulations as listed below.

#Building Regulations

#The Building Standards (Scotland)

#The Building Regulations (Northern Ireland)

#I.E.E Electrical Regulations UK Water Regulations

4.2 Installation requirements

Limitations

The HI-MAX STORE HIU should not be used in association with any of the following:

#Situations where maintenance is likely to be neglected or safety devices tampered

with.

#Water supplies that have either inadequate pressure or where the supply may be

intermittent.

#Situations where it is not possible to safely pipe away any discharge from the safety

valves.

#In areas where the water consistently contains a high proportion of solids, e.g.

suspended matter that could block the strainer, unless adequate filtration can be

ensured.

#In areas where the water supply contains chloride levels that exceed 150mg/l. For

information or advice regarding any of the above contact Technical Enquiries on:

0344 871 1535.

4.3 Transport and Storage

If the unit has to be stored prior to installation, it must be in a secure area free from frost,

excessive dampness and humidity.

4.4 Choice of location

The HI-MAX STORE HIU is a wall mounted HIU with a floor/frame standing cylinder.

Although location is not critical, the following points should be considered:

#The Megaflo unvented cylinder should be sited to ensure minimum dead leg

distances, particularly to the point of most frequent use.

#Avoid siting where extreme cold temperatures will be experienced. All exposed

pipework should be insulated.

#The discharge pipework from the heating system safety valve should have a

continuous fall.

#Access to associated controls must be available for the servicing and maintenance of

the system.

#Ensure that the wall that the Heatrae Sadia HI- MAX STORE is mounted on is level

and capable of permanently supporting the weight when the unit is full of water.

4.5 Positioning and access

Access to the unit and all its components is gained from the front.

It is important that as much access is provided around the unit as is practical. In

the event of a component failure, full access in front of the unit is required for servicing.

Access to all isolation valves and controls is also required for normal operation and

servicing.

CAUTION

Ensure that the HI-MAX STORE HIU is correctly positioned.

Consideration should be given to the access and space requirements for operating and servicing

the unit (See page 13 for guidelines).

WARNING

#Consideration through risk assessments must be made to both the unit siting and routing

of pipework to and from the HIU.

#High pressures associated with the heat networks pose a risk to the health and safety of

anyone who could be within contact of them.

page 12

4.6 Installation guidelines

Access

The unit must be vertically mounted, on a supporting wall. Although location is not critical,

the following points should be considered:

#Avoid siting where extreme cold temperatures will be experienced. All exposed pipe

work should be insulated.

#The discharge pipework from the safety valves must have minimum fall of 1:200

from the unit and terminate in a safe and visible position.

#Access to associated controls and components must be available to provide for the

servicing and maintenance of the system. Please refer to Fig 6 and Fig 7 for minimum

clearance requirements.

#Ensure the first fix rail is installed horizontally, check using a spirit level.

#Ensure the surface to be used will sustain the weight of the unit when full of water.

Fig 6. Fitting the first fix rail (Minimum clearance)

Fig 7. Minimum Clearances

Please note that the clearance dimension detailed above are for guidance. All

dimensions are in mm.

page 13

5. Installation

5.1 HIU Installation

1. Fix the 1st fix rail to the wall using suitable fixings and ensure the rail is level (Fig.

6).

Fig 8. First fix rail mounting details

2. Slide the two studs provided on the 1st fix rail through the slotted holes in the unit

back plate and secure loosely with the M6 nuts provided (Fig. 8)

Insert the washers supplied onto the top of the pipe faces on the HIU and slide upwards until

the washers come in contact with the isolation valves on the 1st fix rail and tighten nuts.

Close all isolation valves before flushing and filling the system.

Fig 9. HIU mounting details

3. Mark out and drill the bottom fixing points and use suitable fixings for the mounting

surface (see Fig 10).

Fig 10. HI-MAX STORE - Bottom Support Fixing Points

4. Fix the casing on by dropping the folds on the casing into the slots on the backplate.

Fix with two screws underneath (Fig.12)

Fig 11. HI-MAX STORE HIU - Casing mounting

Fig 12. HI-MAX STORE - Casing fixing

5. Ensure the actuator cable is fixed tightly in cable gland. (Fig.12) Connect the actuator

cable to the wiring centre. (See page 11 for wiring diagram).

WARNING

#Disconnect from the mains electrical supply before removing any covers.

#DO NOT bypass the thermal cut-out(s) in any circumstances.

#All electrical wiring should be carried out by a competent electrician and be in

accordance with the latest I.E.E Wiring Regulations.

#Each circuit must be protected by a suitable fuse and double pole isolating switch with a

contact separation of at least 3mm in both poles.

#DO NOT operate the immersion heaters until the cylinder has been filled with water.

page 14

5.2 Cylinder and frame installation

1. Place the frame in final position, ensuring the back of the frame is up against the wall.

Secure the frame to the floor and wall using screws through the 8 holes provided.

IMPORTANT Ensure when fixing the frame to the floor that the surface is even

and level.

2. Lift the cylinder on to the frame and push it back to the location ring on the frame

cylinder shelf. Take care not to scratch the shelf by tilting the cylinder back.

For lifting purposes please take note of the cylinder weight detailed in the cylinder

manual and add 5kgs for any ancillary components.

3. Ensure that the front of the cylinder is square with frame. The immersion heater

enclosures should be facing forwards.

4. Fit lower safety valve discharge pipe into the dry trap, manipulate the cylinder if

necessary for alignment and secure in pipe clip.

Table of contents