CONTENTS

A - Description and Installation

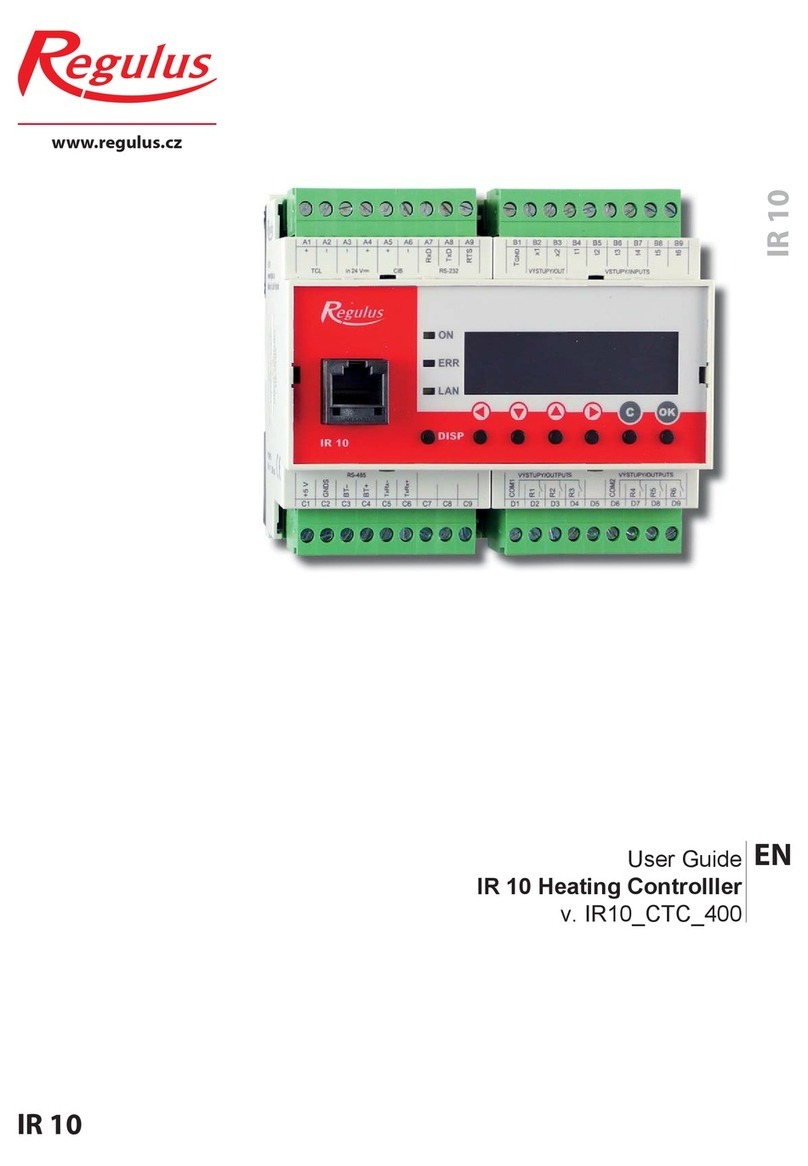

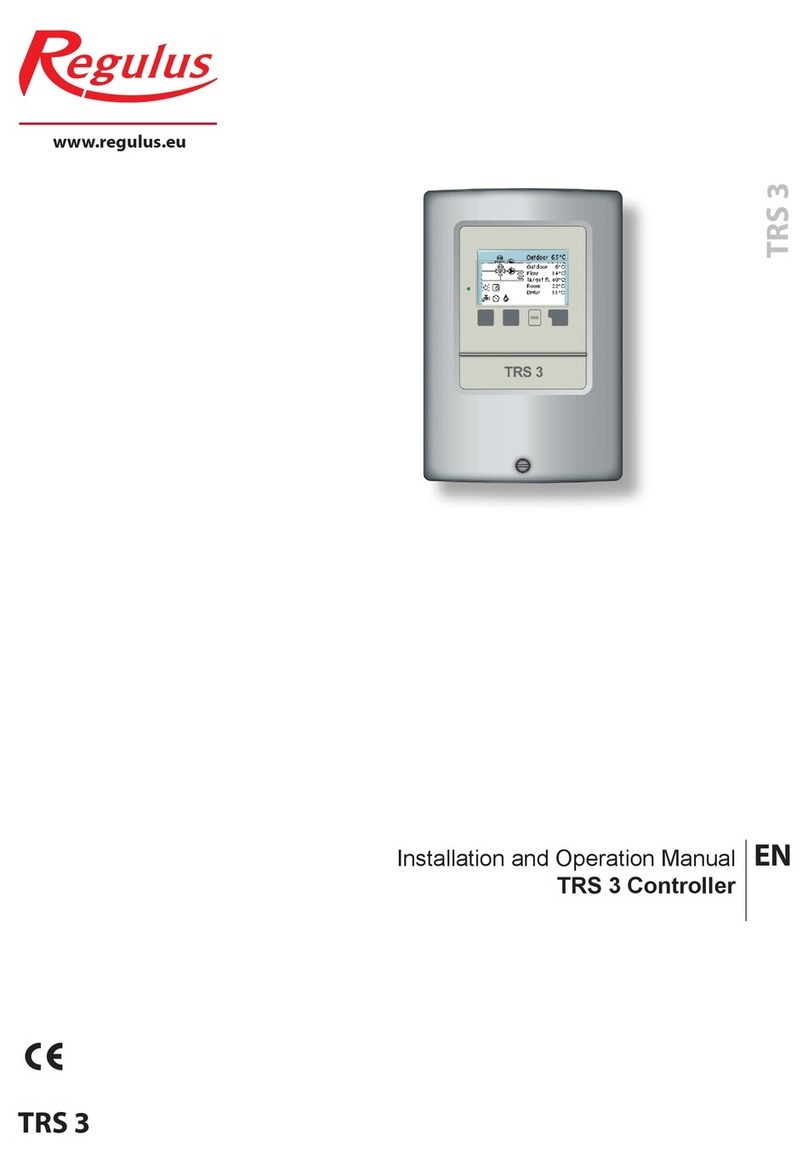

A 1 - Specification ................................................................................................................................ 4

A 2 - Description .................................................................................................................................. 5

A 3 - Scope of supply ........................................................................................................................... 5

A 4 - Explanation of symbols ............................................................................................................... 5

B - Hydraulic variants

C - Installation and Wiring

C 1 - Wall installation ........................................................................................................................... 7

C 2 - Electric wiring .............................................................................................................................. 8

C 3 - Installing the temperature sensors .............................................................................................. 8

D - Electric Wiring of Hydraulic Variants

E - Controller Use

E 1 - Display and input ......................................................................................................................... 10

E 2 - Menu sequence and menu structure ........................................................................................... 11

E 3 - Commissioning help - setup wizard ............................................................................................ 12

E 4 - Free commissioning .................................................................................................................... 12

F - Menu Description

F 1 - Measurements ............................................................................................................................ 13

F 2 - Statistics ...................................................................................................................................... 14

F 3 - Times ........................................................................................................................................... 15

F 4 - Operating modes ......................................................................................................................... 16

F 5 - Settings HC ................................................................................................................................. 18

F 6 - Settings HC 2 .............................................................................................................................. 20

F 7 - Protective functions ..................................................................................................................... 21

F 8 - Special functions ......................................................................................................................... 22

F 9 - Menu lock .................................................................................................................................... 24

F 10 - Service values ............................................................................................................................. 25

F 11 - Language ..................................................................................................................................... 26

G - Defects and Maintenance

G 1 - Error and info messages ............................................................................................................. 26

G 2 - Replacing the fuse ...................................................................................................................... 27

G 3 - Maintenance ............................................................................................................................... 27

G 4 - Useful hints and tricks ................................................................................................................. 28

G 5 - Disposal ...................................................................................................................................... 28