Heatrae Sadia Accolade Guide

20

Heatrae Sadia

Hurricane Way,

Norwich,

Norfolk NR6 6EA.

www.heatraesadia.com

Due to continuous improvement and updating, specifications may be altered without prior notice.

Service

Tel: (01603) 420330

Fax: (01603) 420349

email: [email protected]

Sales

Tel: (01603) 420110

Fax: (01603) 420149

email:[email protected]

The quality name in water heating

APPROVED SPARES STOCKISTS

Electric Water Heating Co.,

2 Horsecroft Place, Pinnacles,

Harlow, Essex CM19 5BT

Tel: 0845 0553811

E-mail: [email protected]

Eyre & Elliston

Unit 9 & 10, Chantry Gate Business Centre,

Springfield Road, Hayes,

Middlesex

Tel: 020 8573 0574

Parts Center

Network 65 Business Park, Bentley Wood Way,

Burnley, Lancashire BB11 5ST

Tel: 01282 834403

www.partscenter.co.uk

Newey & Eyre

Specialists Products Division

Please contact your local branch.

UK Spares Ltd.,

Tower Lane, Warmley,

Bristol BS30 8XT

Tel: 0117 961 6670

William Wilson Ltd.,

Unit 3A, 780 South Street,

Whiteinch, Glasgow G14 0SY

Tel: 0141 4341530

1

ELECTRIC SHOWER

INSTALLATION and USER INSTRUCTIONS

ref. 36 00 5641 issue 4

PLEASE READ AND UNDERSTAND THESE INSTRUCTIONS BEFORE

COMMENCING INSTALLATION

PLEASE LEAVE THESE INSTRUCTIONS WITH THE USER

START

STOP

USER

PROTECT

HIGH

LOW FLOW

MEDIUM

INSPECT

HANDSET

LOW

PHASED

SHUTDOWN

2

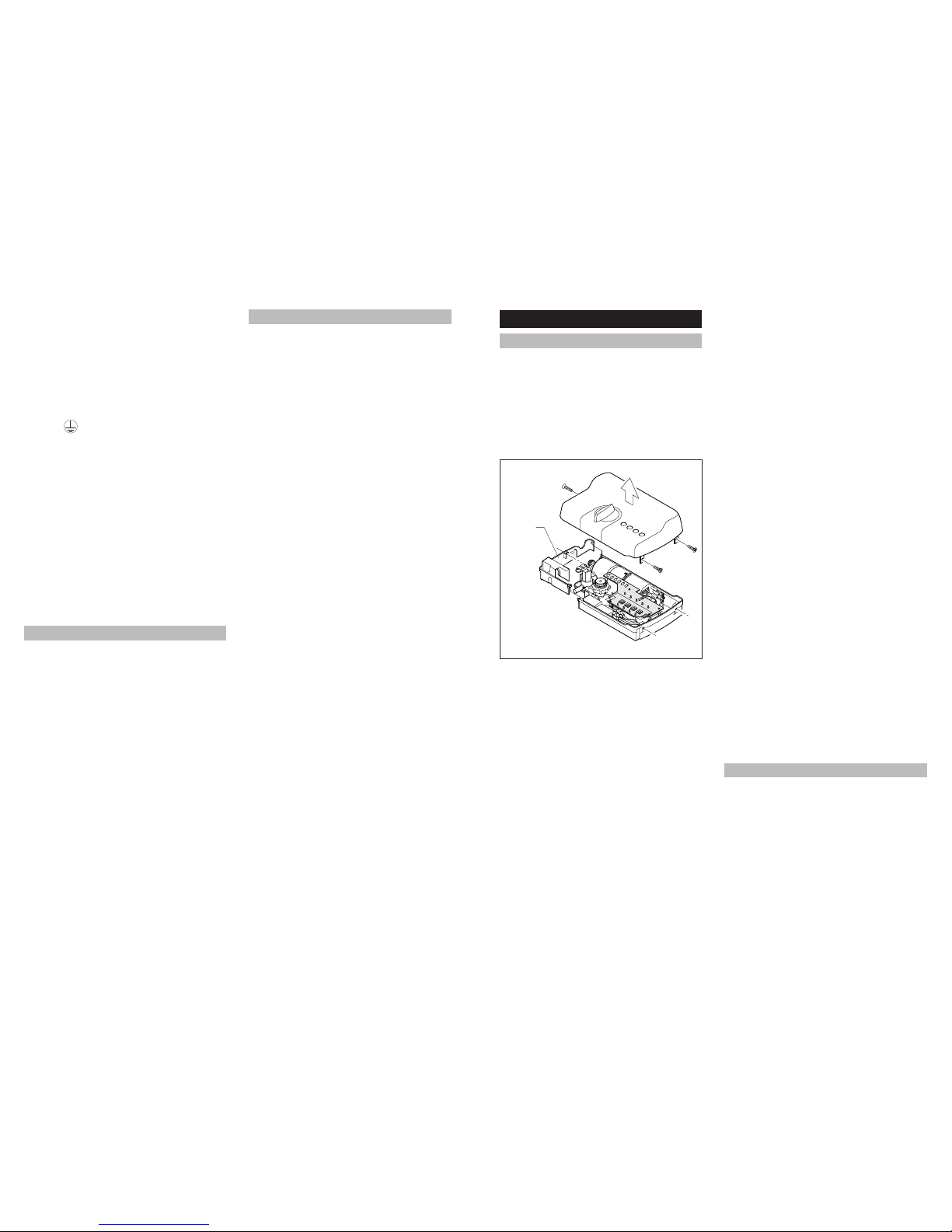

Figure 1 Internal components

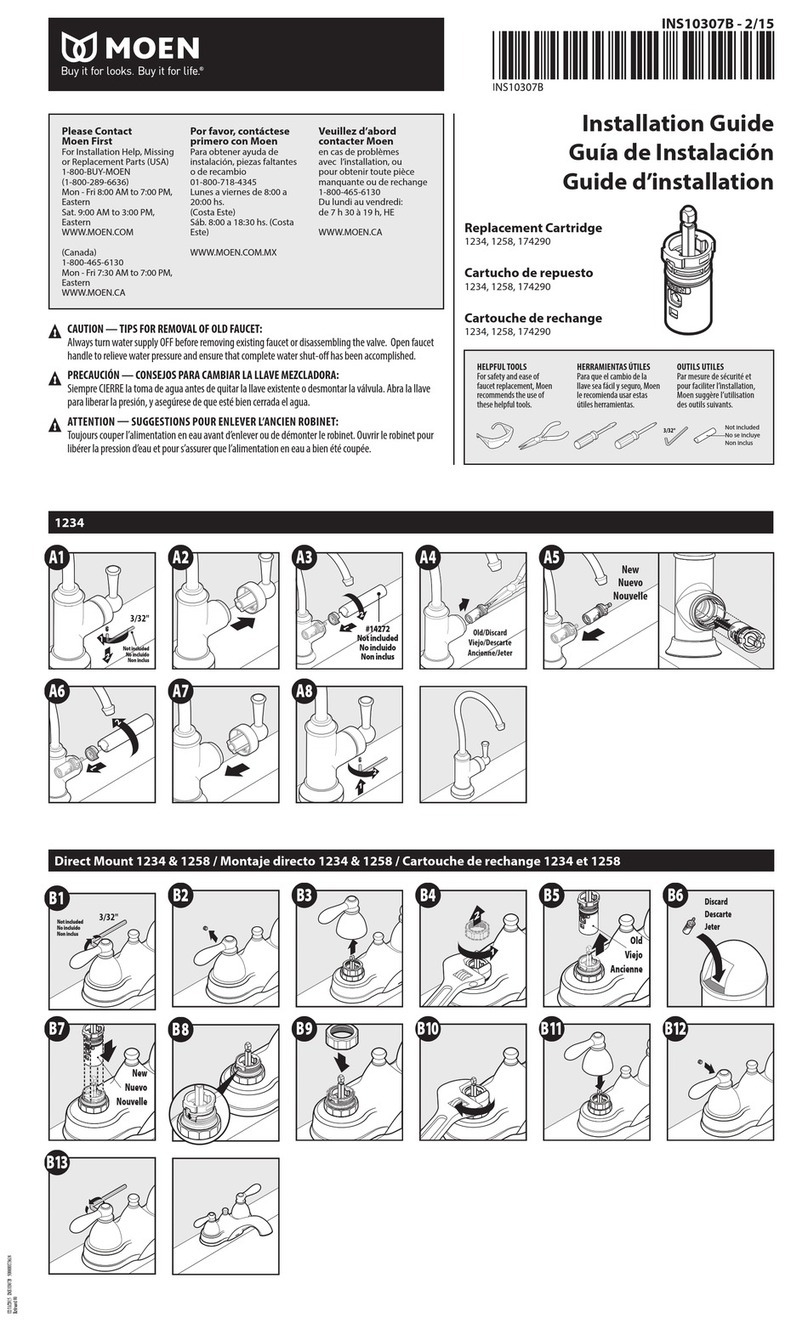

Figure 2 Wiring diagram

Fixing Lugs

Thermal cutout

Printed Circuit

Board (PCB)

Front cover

Heat

exchanger

Water

control valve

Outlet pipe

Pressure relief device

Removable

bottom

section

Inlet spigot

Fixing lug

Alignment

post

Drain slot

Solenoid

valve

L & N

terminal

block

Earth

terminal

block

Back plate

NL

red

green/yellow

black

Cut

Out

Terminal

block

red

Inner

container

brown

white

black

red

white

red

red

red

red

brown

LH RH

white

Pressure switches

PCB

Solenoid

black

19

REMEDY

A. Switch off shower and isolating switch. Renew fuse or

reset mcb. If they operate a second time, contact a

qualified electrician.

B. Follow the same procedure as above. If this has

happened with a ‘split load’ consumer unit on initial

installation, check that the neutral core of the shower

feed cable is connected to the ‘protected’ neutral bar

of the unit.

A. Descale handset as described in 8.5. Reset the timer

as described in 5.56.

POSSIBLE CAUSE

A. Cartridge fuse or

miniature circuit

breaker (mcb) has

operated in your

fusebox (or

consumer unit) or

switch fuse.

B. Residual current

device (rcd) (or

earth leakage

circuit breaker)

has operated.

A. Handset needs

descaling.

SYMPTOM

6. “Low Flow”

indicator not lit.

Isolating switch

“On” but its

neon not lit .

7. ‘Inspect Handset’

warning light

flashes.

Where a fault cannot be corrected by

either yourself or your installer, contact our

Service Department, (address and phone

number below), who will try to help over

the phone. If necessary, they can arrange

a visit by one of our service engineers.

We find that the vast majority of problems

can be solved by reference to these fitting

instructions or by discussion over the

phone. In the event that our engineer is

called and finds that the fault is caused by

faulty installation or usage, or lack of

reasonable maintenance, a call-out

charge will be made.

18

SYMPTOM

1.

continued

2. Flow adequate

but water too

cold.

3. Water too hot.

4. Water runs from

around hose.

Pressure relief

device (PRD)

has operated

due to excess

pressure build-

up.

5. Temperature

varies while

showering,

cycling hot/

cold.

POSSIBLE CAUSE

F.

continued

A. Shower heater is on

the ‘LOW’ power

setting.

B. Water flow too high.

A. Water flow too low.

B. Sprayplate blocked

with scale and

debris.

C. Water pressure too

low.

A. Handset Blocked.

B. Hose damaged or

kinked.

A. Thermal cut-out is

operating, normally

making a ‘click’ as it

does so.

B. Input pressure is

below the minimum

required (see 3.2).

Flow is unstable.

REMEDY

4. Release ‘LOW’ and ‘START/STOP’ buttons.

5. Press ‘START/STOP’, the shower will be reset to

previous settings.

A. Ensure that the shower is on ‘HIGH’ setting, where

applicable.

B. Reduce the flow by turning the water control knob

clockwise slowly. NOTE: If the knob is turned too far

clockwise, the safety pressure switch inside the shower

will turn off the heating elements. This is apparent

when the ‘reduce temp’ light starts flashing. If this

happens, turn the knob anticlockwise until the light

stops flashing.

A. Increase the flow by turning the water control knob

anticlockwise slowly.

B. Clean the handset sprayplate.

C. Switch to ‘LOW’ setting, if applicable.

A. Clean out the sprayplate as in ‘Maintenance’ Section 8.

Call a service engineer to remove the front cover and

reset the PRD by removing the bent bracket, pushing

the black outlet boss back into the heat exchanger, and

refitting a new bracket.

If the fault occurs again without the hose being

damaged or the handset blocked, contact our Service

Department.

B. Replace kinked or damaged hose and be careful not to

turn water control knob too far anticlockwise. Reset as

in ‘A’.

A. Increase the flow by turning the water control knob

anticlockwise. Clean the handset and sprayplate.

B. Ensure that your stop cock and servicing valve are fully

open. If they are, ask your installer or the local water

company to check that the running pressure is above

the minimum required (see 3.2).

3

1 TECHNICAL SPECIFICATIONS

1.1 CONNECTIONS

Inlet connection -15mm ext. diameter

spigot for

compression fitting.

Water entry point - Top,bottom, rear and

right hand side.

Cable entry point - Top, bottom and rear

1.2 ELECTRICAL

Nominal Power Rating

1.3 MATERIALS

Backplate, cover

and control knob - ABS

Elements - Copper sheathed rod

type

1.4 DIMENSIONS

Height - 297mm

Width - 186mm

Depth - 86mm

1.5 STANDARDS AND APPROVALS

Complies with the requirements of

EN 60335-2-35.

British Electrotechnical Approvals Board

(BEAB) approved.

Complies with European Community

Directives (CE).

CONTENTS

Internal components .......................... p2

Wiring diagram .................................. p2

TECHNICAL SPECIFICATIONS ........ p3

IMPORTANT INFORMATION ............ p4

How an instant electric shower works p5

SITING AND PLUMBING .................. p6

Things you must do ........................... p6

Things you must not do ..................... p7

ELECTRICAL INSTALLATION ........... p8

CONNECTING TO SERVICES ......... p9

Preparation ........................................ p9

Cable entry ........................................ p9

Pipe entry ........................................ p10

Plumbing ......................................... p11

Electrics ........................................... p11

Fitting the front cover ....................... p12

Commissioning ................................ p12

User Protect System........................ p13

Inspect Handset light ....................... p13

Setting the Descale Time ................. p13

Setting Descale Timer to zero.......... p14

GUARANTEE & SERVICE POLICY p14

ENVIRONMENTAL INFORMATION p14

USER INFORMATION ..................... p14

Maintenance .................................... p16

Inspection ........................................ p16

FAULT FINDING ..................... p17 - p19

Address and phone numbers........... p20

Approved Spares Stockists .............. p20

ledoM gnitarrewoP

V042@

gnitarrewoP

V032@

14612059)A53(Wk5.8)A43(Wk8.7

84512059)A14(Wk8.9)A93(Wk0.9

94512059)A54(

Wk8.01)A34(Wk9.9

4

2 IMPORTANT INFORMATION

2.1 Your shower is designed and tested

to the very highest standards and complies

fully with all of the relevant national/

international standards for safety and

reliability. The shower is manufactured in

a BS EN ISO 9001:2000 -registered

factory - your assurance of a quality

product.

2.2 To ensure correct use and

maintenance of the shower, please read

and adhere to the following warnings and

guidelines.

FOR INSTALLERS

2.3 The Installation must comply with the

Building Regulations Part P and the Water

Regulations. Where there is a new

installation, or a replacement product is

not identical to the one being replaced, the

cable sizes, circuit protective devices,

bonding and other requirements of the

Building Regulations must be assessed

by a (registered) qualified and competent

electrician, who should carry out the

installation taking into account the site

conditions.

2.4 WARNING: THIS APPLIANCE

MUST BE EARTHED.

2.5 Before removing your shower heater

cover always ensure your shower heater

is isolated from the electrical mains.

2.6 This product is splash-proof and is

approved for use in shower cubicles and

over baths. However, do not install the

shower heater in a position where the

handset, in its normally-parked

position, will consistently direct the

spray over it.

2.7 To comply with the Water

Regulations a servicing valve must be

fitted in the pipework to the shower, in an

accessible place. This will be of great

benefit if any maintenance work or

complete replacement of the shower is

required later on.

2.8 This shower is designed for domestic

use and is not vandal-resistant. If it is

installed in an institutional or commercial

situation, frequent inspection may be

necessary, and our guarantee may be

affected.

FOR USERS

2.9 If water emerges from anywhere

other than the spray head outlets, do not

use your shower, TURN OFF

ELECTRICITY and refer to the Fault

Finding section.

2.10 IT IS IMPORTANT TO CLEAN THE

SPRAY PLATE REGULARLY, particularly

in hard water areas, where this may be

necessary as often as once a week.

Failure to do so will affect the

performance of the shower and in

extreme cases may cause the pressure

relief device (PRD) to operate - see Fig.

1 and Fault Finding (p18).

Refer to the handset user instructions for

handset maintenance information.

2.11 The shower heater outlet, hose

and handset act as a vent. They must

not be blocked, obstructed, or have

connected to them any fitting not

approved by the manufacturers. The

use of unapproved accessories may

invalidate the guarantee and affect the

performance and safety of the unit.

2.12 WARNING! DO NOT USE the

shower if the HOSE IS DAMAGED in any

way; for instance if the outer covering has

parted to reveal the inner tube.

A damaged hose can suddenly restrict the

17

SYMPTOM

1. No flow or not

enough flow.

POSSIBLE CAUSE

A. Electrical supply to

shower heater off.

B. Water control knob is

turned fully

clockwise.

C. Water turned off at

mains or servicing

valve.

D. SHOWER HEATER

SUSPECTED OF

BEING FROZEN.

E. There may be an

outlet blockage.

F. ‘User Protect’ system

has been activated

(temp indicators and

‘START/STOP’ light

flashing).

REMEDY

A. Ensure that the electrical supply to the shower is

switched on.

B. Turn water control knob anticlockwise.

C. Ensure water is fully turned on at the mains and at

servicing valve in circuit.

D. If so, DO NOT USE.

1. Switch off immediately at isolating switch.

2. Turn water off at servicing valve (if fitted) or at stop

cock.

3. Contact our Service Department.

E. Disconnect handset from hose and run the shower.

1. If water flows, then handset is blocked with scale or

debris. Remember that disturbances to plumbing

elsewhere in your house, or in the street, can dislodge

debris which can find its way to the shower. Clean the

handset and spray rings/plate thoroughly.

2. If the water does not flow, remove hose from the

shower outlet.

2a If the water flows then the hose is blocked. This could

be due to damage, severe kinking or even an

obstruction. Replace with a new hose.

2b If the water does not flow, there is a blockage in the

plumbing to the shower, or the shower itself. Contact

our Service Department if the shower is considered to

be the problem.

F. Position the handset where it can spray safely and

purge the heater of the hot water as follows:-

1. Press and hold in ‘START/STOP’ button.

2. Press and hold in ‘LOW’ button. Water will flow from

handset.

3. When temperature has reduced to a safe level, Low

flow and flashing lights will go out.

9 FAULT FINDING

In the unlikely event of a problem, consult the trouble shooting chart below.

For your particular symptom follow the suggested remedies in the order given. If you

are unable to remedy the problem, CONTACT YOUR INSTALLER IN THE FIRST

INSTANCE. Do not attempt any electrical or plumbing work unless you are competent

to do so.

16

MAINTENANCE

‘Inspect Handset’ warning

8:4 This light will flash when it is advised

that the handset may need descaling.

Remove the handset and clean following

the instructions below. To reset the

‘INSPECT HANDSET’ warning, follow the

instructions given in 5.56.

Cleaning the Handset

Also refer to instructions supplied with

handset.

8:5 To obtain the best performance from

your shower, the handset must be cleaned

regularly, maybe as often as once a week

in hard water areas.

8:6 This is because the fine outlet holes

can become blocked with scale and this

will affect the pattern of the spray and

cause the heater to perform poorly.

8:7 The easiest and most effective

method of cleaning your handset,

regardless of which type you have with

your shower, is to soak it in a proprietary

descalant. For best results the handset

should be left to soak overnight.

8:8 The handset with rubber spray outlets

can be cleaned by simply rubbing one’s

hand over them firmly to dislodge the

scale.

INSPECTION

8:9 We recommend that in the interests

of safety the shower and its electrical

installation is checked by a qualified

electrician at least every two years.

5

Heating

element

Pressure

switch

Cold

water

inlet

Flow

control

Start/

stop

button

Electrical

terminals

LN

flow and result in extremely hot water

being emitted from the spray head.

A damaged hose could completely block

the outlet of the shower; the resulting

increase in pressure could burst a

weakened or damaged hose.

2.13 Do not install the shower in a situation

where the water in it could freeze. Any

damage caused by freezing will not be

covered by the guarantee.

WARNING. If you suspect your shower

is frozen, DO NOT SWITCH ON. If you

have switched on, SWITCH OFF

IMMEDIATELY. Refer to Fault Finding

(p17).

2.14 Do not leave the infirm, disabled

users, or young children unattended in the

shower.

2.15 Before stepping into the shower,

always test the temperature of the spray

with your hand.

2.16 Switch off at the isolating switch after

use. This is a safety procedure

recommended with ALL electrical

appliances.

2.17 As with all electrical appliances, it is

advisable to have your shower and

installation checked at least every two

years by a competent electrician, to

ensure that there is no deterioration due

to age and usage.

2.18 Shampoo and shower gel should be

stored using the gel hook and soap dish

(where provided) and must not be placed

on top of the shower unit.

HOW AN INSTANT ELECTRIC

SHOWER WORKS

2.19 When the user starts the shower by

pressing the start/stop button, the flow

control lets in the water. If there is

sufficient water pressure, the pressure

switch will turn on the heating elements.

2.20 The element in the tank will start to

heat the water and this takes typically 10-

20 seconds.

2.21 By controlling the flow rate of water

over the heating elements, it will be

warmed up to the correct temperature.

Reducing the flow rate will increase the

water temperature and vice versa.

2.22 The shower has high, medium and

low settings that give further control of

temperature.

2.23 The temperature of the incoming

water varies, mains water can be as low

as 5°C in the winter and as high as 20°C

in the summer. This affects the output

temperature of the shower which is only

able to raise the temperature of the water

by a given amount, depending upon the

flow rate.

Figure 3 Schematic of typical electric shower

6

3 SITING AND PLUMBING

3.1 Spend some time planning exactly

where to site the shower heater and riser

rail. Bear in mind the height of people who

will be using it.

THINGS YOU MUST DO

3.2 Check that the water pressure to

the shower is adequate. If in doubt,

consult a competent plumber.

Maximum and minimum pressures are:-

Maximum - 1 MPa

Minimum

- up to and including 9.5kW: 0.09 MPa

- Over 9.5kW: 0.11 MPa

Running pressure with at least 5 l/min

flow rate

The use of other services connected to

the water pipe supplying the shower heater

may cause the water pressure to drop

below the minimum. Therefore this should

be taken into account.

The following conversions may be useful:

1 bar = 14.5 lbf/in²

= 33.3 ft head of water.

= 10m head of water

= 0.1 MPa

1 lbf/in² = 2.3 ft head.

3.3 Electric shower heaters are normally

plumbed into the mains water (except for

special low pressure versions). However,

the shower heater may be fed from a

storage tank as long as there is a sufficient

head of water.

3.4 Mount the shower heater on a flat

vertical wall with the outlet, to which the

hose is connected, pointing downwards,

using three suitable wall plugs and screws.

3.5 DO NOT place the shower heater

where it will be in the direct spray from a

normally-parked handset.

Figure 4 Siting of riser rail and heater

5mm minimum

Lowest possible

handset position

Bath/Shower Tray

610mm ( 4)

Highest Position

Riser rail

Hose-retaining ring

Lowest position

Shower

heater

305mm (1 )

3.6 Allow room around the shower heater

for removal of the front cover.

3.7 Position the riser rail close to the

heater, not necessarily on the same wall

(but bear in mind paragraph 3.5) so that

in its highest parked position, the handset

is not more than 610mm (24”) above the

bottom of the heater, and in its lowest

position it is no lower than 305mm (12”)

below the heater - see Fig. 4.

3.8 If the handset can reach to within

25mm (1”) of the spillover level of the bath,

shower tray, wash basin, WC or bidet, then

to prevent the possibility of back-

siphonage of used water (Water

Regulations Guide G15.14/R15.14) you

must either:-

1. Fit a hose-restraining ring - see Fig. 4.

15

Make adjustments carefully. Give the

shower a few seconds after each

adjustment to stabilise, then check the

temperature by hand before stepping into

the shower. Note the number of

temperature indicators lit, this will aid in

setting your ideal temperature when next

using the shower.

4. The ‘MED’ and ‘LOW’ power settings

allow you to choose the power used

by your shower heater. These settings

use less power and can be used in

the warmer periods when incoming

water temperature is higher. They can

also be used to obtain a cooler spray

without adjusting the water control

knob.

A cold shower cannot be obtained.

8.2 To turn off the shower:

1. Press the ‘START/STOP’ button.

Water will continue to flow and the

‘PHASED SHUTDOWN’ light will flash

for a few seconds. This feature

purges the hot water from the heater

can to ensure there is no hot ‘slug’ of

water if the shower is used again

shortly after.

2. Turn off your isolating switch.

8.3 Warning Lights

1. ‘LOW FLOW’. If the water control

knob is turned too far clockwise, the

pressure switch will turn off the heating

elements and the ‘LOW FLOW’ light

will flash. Turn the water control knob

anticlockwise until the indicator stops

flashing.

2. ‘USER PROTECT’. This feature

prevents the spray temperature

reaching harmful levels. Refer to

sections 5.51 and 5.52.

Please note that this shower is not

thermostatic, it will not keep spray

temperature constant whatever the

change in external influence.

Figure 12 External features of shower

START

STOP

USER

PROTECT

HIGH

LOW FLOW

MEDIUM

INSPECT

HANDSET

LOW

PHASED

SHUTDOWN

Stop /Start button

and indicator light

Power setting buttons

and indicator lights

Water Control Knob

Temperature

Indicator display

User protect

Low flow

Inspect handset

Phased shutdown

Indicator lights

14

8 USER INFORMATION

8.1 To turn on and set temperature:

1. Turn on your isolating switch.

2. Press the ‘START/STOP’ button. The

water will flow and the elements set

to the power setting last used. The

‘START/STOP’ and power setting

indicators will light. The shower can

also be turned on by pressing one of

the power setting buttons.

3. Allow the shower approximately 30

seconds to heat up and check the

water temperature with your hand.

Adjust as necessary by turning the

water control knob.

WARMER - DECREASE FLOW - TURN

KNOB CLOCKWISE

COOLER - INCREASE FLOW - TURN

KNOB ANTI-CLOCKWISE

SETTING DESCALE TIMER TO

ZERO

5:55 Carry out the following procedure to

stop the ‘Inspect Handset’ light flashing.

The descale timer can only be set to zero

when the ‘INSPECT HANDSET’ light is

flashing.

5.56 Hold down the ‘START/STOP’ button

and then momentarily press the ‘LOW’

button. The descale time will then be set

to zero and the ‘INSPECT HANDSET’ light

will stop flashing.

5.57 The shower will continue to function

even when the ‘INSPECT HANDSET’ light

is flashing. The system is simply a helpful

reminder that the shower head may

require descaling.

6 GUARANTEE & SERVICE POLICY

This product is guaranteed against faulty

materials and manufacture for a period of

2 years from the date of purchase

provided that:-

6.1 The unit has been installed in

accordance with the Installation and User

Instructions and all relevant Codes of

Practice and Regulations in force at the

time of installation and that all necessary

controls and safety valves have been fitted

correctly.

6.2 Any valves and controls are of

Heatrae Sadia recommended type and

specification.

6.3 The unit has not been modified or

tampered with in any way and has been

regularly maintained as detailed in the

Installation and User Instructions.

6.4 The unit has been used only for

heating potable water.

The unit is not guaranteed against

damage by frost and the inner container

with integral heating element is not

guaranteed against excessive scale build-

up.

This guarantee in no way affects the

statutory rights of the consumer.

The policy of Heatrae Sadia is one of

continuous product development and, as

such, we reserve the right to change

specifications without notice.

7 ENVIRONMENTAL INFORMATION

Heatrae Sadia products are manufactured

from many recyclable materials. At the

end of their useful life they should be

disposed of at a Local Authority Recycling

Centre in order to realise the full

environmental benefits.

7

2. Fit a double-check valve in the

pipework to the shower.

3.9 Decide from which direction your inlet

pipe will enter the shower heater. There

is a choice of entry from top, bottom, right

hand side or rear - see Fig. 9.

3.10 Ensure there are no services such

as gas, water pipes, electrical or telephone

cables beneath the surface of the wall

before drilling.

3.11 The water connection to the shower

heater should be made using standard

15mm outside diameter copper pipe or a

stainless steel pipe. The ends of the pipe

should be cut square and be free from

internal and external burrs and deep

scratches.

3.12 Cut all necessary pipework to length

with a pipe cutter and not a hacksaw, to

minimise swarf - see Fig. 5.

3.13 Before making the final water

connections to the shower heater, the

pipework MUST BE FLUSHED

THOROUGHLY to remove brick dust,

swarf etc. which could severely damage

the shower itself - see Fig. 6.

3.14 A Water Regulations Advisory

Service listed servicing valve should be

fitted in the water supply pipe to the

shower. This is to allow the shower heater

to be serviced without turning off the water

supply to other appliances.

THINGS YOU MUST NOT DO

3.15 DO NOT use plumber’s paste on any

joints as this may damage the shower.

3.16 DO NOT use a blow-torch or other

form of heat close to the shower heater

as this may damage the non-metallic

parts.

3.17 DO NOT use excessive force, but do

ensure adequate support, when making

connections.

Figure 5 Cutting pipes

Figure 6 Flushing the pipework

8

Figure 7 Schematic of typical electrical layout

Double pole isolating switch:

pull cord or wall mounted in accordance

with IEE regulations

Shower unit

(use rear entry when it is possible)

RCD (can be part of the

consumer unit)

Meter

80A or 100A main switch

Consumer unit Meter ‘tails’

4 ELECTRICAL INSTALLATION

WARNING

4.1 This appliance must be earthed.

4.2 The installation must comply with the

Building Regulations Part P. Where there

is a new installation, or a replacement

product is not identical to the one being

replaced, the cable sizes, circuit protective

devices, bonding and other requirements

of the Building Regulations must be

assessed by a (registered) qualified and

competent electrician, who should carry

out the installation taking into account the

site conditions.

The following notes are for guidance only:

4.3 The shower heater must only be

connected to a 230/240V ac supply.

4.4 Before making any electrical

connections within the installation,

make sure that no terminal is live. If in

doubt, SWITCH OFF the whole installation

at the consumer unit or switch fuse (where

fitted).

4.5 It is strongly recommended that a

30mA rcd is incorporated in the circuit,

even if it is not required to comply with BS

7671.

4.6 A double-pole isolating switch with a

contact separation of at least 3mm in each

pole, must be incorporated in the circuit.

This must have a mechanical indicator

showing when the switch is in the OFF

position. A neon lamp alone is not

sufficient.

13

5.48 The ‘MED’ and ‘LOW’ power settings

allow you to reduce the power used by the

heater and can be used at times of the

year when the inlet water temperature is

higher. They can also be used to obtain a

cooler spray without adjusting the water

control knob. A cold shower cannot be

obtained.

5.49 To stop the shower, press the

‘START/STOP’ button. The ‘START/

STOP’ and ‘HIGH’, ‘MEDIUM’ or ‘LOW’

lights will go OFF. Water will continue to

flow for a few seconds and the ‘PHASED

SHUTDOWN’ light will flash. This allows

hot water to be flushed from the can.

When flow stops, turn off the isolating

switch.

USER PROTECT SYSTEM

5.50 The User Protect system is intended

to prevent showering temperatures

reaching harmful levels. To test its

operation, turn on the shower by pressing

‘HIGH’. Turn the water control slowly

clockwise until the ‘USER PROTECT’ light

flashes. This indicates that if the water

temperature is not reduced soon the

shower will automatically switch to the next

lowest power setting. The shower will

remain at the new power setting until reset

by the user.

5.51 If the shower senses that the

temperature is rising too fast to prevent

the spray from becoming very hot, it will

automatically shut off the water flow. All

the temperature indicators and the

‘PHASED SHUTDOWN’ light will flash,

and the ‘USER PROTECT’ light will come

on steady. To reset see section 9 FAULT

FINDING, item 1F.

INSPECT HANDSET LIGHT

5.52 This product is fitted with an

electronic ‘descale timer’ which keeps

track of the total time the shower has run

since the timer was last reset. After a

certain number of hours has elapsed, the

‘Inspect Handset’ light will flash, indicating

that the shower head is probably now in

need of descaling. Depending on the

hardness of your water, a different duration

between cleaning will be needed, so there

is a facility to set the time duration after

which the ‘Inspect Handset’ light will go

on. This is called the ‘descale time’.

SETTING THE DESCALE TIME

5.53 The descale time (the time duration

before the ‘INSPECT HANDSET ‘ light

flashes) is set at the factory for hard water

areas, but it can be reset, as follows:-

1. Switch shower isolating switch OFF.

2. Press and hold button as listed below,

3. Turn shower isolating switch ON.

4. Then release the button.

5.54 The settings can be changed at any

time using the above procedure. This

does not automatically set the timer to

zero; if the system is changed to a ‘harder’

setting, then the ‘INSPECT HANDSET’

light may immediately flash on.

To Press and hold in:

Set for VERY SOFT

water (approx. 90 hours) ‘STOP’ button

Set for SOFT water

(approx. 30 hours) ‘LOW’ button

Set for HARD water

(approx. 20 hours) ‘MED’ button

Set for VERY HARD

water (approx. 10 hours) ‘HIGH’ button

12

5.35 Ensure that all three screws hold the

shower backplate to the wall firmly.

5.36 Strip the outer insulation sheath back

as required.

5.37 Strip the insulation from the cores and

make connections to the LIVE (L) (brown

or red), NEUTRAL (N) (blue or black) and

EARTH terminal block. The earth wire

must be sleeved green/yellow. Make sure

that the cores of the cable lie tidily and do

not touch any metallic part of the shower.

They must not be under strain. There is

no cable clamp.

5.38 Ensure that the cable does not foul

the area above the bottom removable

section, where the knob gear will fit when

the front cover is fitted into place.

5.39 Make sure that all the terminal block

screws are tightened very firmly. Replace

the bottom section of the backplate.

FITTING THE FRONT COVER

5.40 Turn the valve fully clockwise (open).

Turn the water control knob in the cover

so that the pointer is at the 7 o’clock

position.

5.41 Carefully fit the cover to the

backplate, ensuring that the lugs slide into

their sockets. You may have to adjust the

water control knob slightly to enable its

gear to mesh with that of the control valve.

NOTE: The alignment post on the

underside of the cover fits into the recess

in the centre of the valve gear to aid the

fitting of the cover.

5.42 Fit the cover fixing screws. The

longer one is for the lower fixing point. You

may have to push the front cover firmly

against the backplate seal, to enable the

screws to locate properly.

COMMISSIONING

NOTE: The first commissioning of the

shower is intended to ensure the heater

unit contains water before the unit is

switched to the high setting.

5.43 Secure the handset on the riser rail

where it can spray safely. Turn on the

water isolating valve (if applicable).

5.44 Turn the water control knob fully

anticlockwise, then half a turn clockwise.

5.45 Turn on the electrical isolating switch.

Press the ‘LOW’ button and check that the

‘LOW’ light comes ON. There may be

gurgling noises as the water fills the heater

can.

NOTE: The shower can be turned on by

pressing either the ‘START/STOP’, (in this

case it turns on at the power setting last

used) or by pressing one of the power

selector buttons.

5.46 Allow water to flow for about 30

seconds, press the ‘HIGH’ button, check

the ‘HIGH’ light comes ON and the ‘LOW’

light goes OFF. Turn the water control

knob clockwise until the lower three lights

of the temperature display are ON. Turn

clockwise for warmer and anticlockwise

for cooler. Allow a few seconds after each

adjustment for the temperature to

stabilise.

5.47 The more indicators ON in the

temperature display, the higher the spray

temperature will be. Continue to turn the

water control knob clockwise; the flow will

reduce and the ‘LOW FLOW’ light will

flash. Turn the water control knob

anticlockwise until the ‘LOW FLOW’ light

goes OFF and the temperature display is

lit as previously.

NOTE: Should the ‘USER PROTECT’

light flash, refer to the User Protect System

section.

9

5 CONNECTING TO SERVICES

PREPARATION

5.1 Remove the three fixing screws

which hold the front cover onto the

backplate. Note that the lower screw is

longer than the upper two.

5.2 Carefully remove the cover which

holds the control knob by pulling directly

away from the backplate.

5.3 Carefully take out the removable

bottom section of the backplate by lifting

its sockets clear of the pegs on the

backplate. This allows greater access for

installing the cable and pipe. Keep it safe,

as it could easily be damaged.

5.4 Decide which entry points you will use

for cable and water pipe - see Fig. 9.

5.5 Decide where to mount the shower,

refer to Section Three for guidance.

Ensure that you leave enough room

around the shower for removal of the front

cover for inspection or servicing at a later

date.

5.6 It is best to mount the shower on top

of any tiling, so that it can be replaced

easily in the future without requiring

Figure 8 Removing cover

re-tiling. If you must tile around the

shower, DO NOT grout right up to the

shower backplate as this makes

subsequent removal difficult. Do not seal

the shower to the wall using bath sealant,

as the shower will not be harmed by water

dripping behind it.

5.7 Remove the relevant areas of the

backplate, which are not knockouts, using

a sharp knife and/or a round file.

WARNING

5.8 The printed circuit board (pcb) is quite

fragile and very expensive. It is positioned

fairly close to the top right-hand mounting

hole of the backplate; if you are in danger

of damaging a board during mounting the

shower, it can be removed temporarily by

carefully pulling it from its four mounting

pegs. The long narrow section of the

board on the left is weak, so ensure that it

is not put under any stress. The board

will still remain attached by its leads and

should not be disconnected; position it

carefully while you fix the shower to the

wall.

5.9 When repositioning the pcb, ensure

that it fits into place without fouling

anything, with its holes over the mounting

pegs. Then push the board firmly near

the four pegs so that it snaps into place.

CABLE ENTRY

5.10 Available entry points:- top, bottom

and rear (rear is generally the easiest).

Side entry is not possible. The thinned

areas in the backplate and bottom section

are suitable for a cable size up to 16mm².

5.11 For rear entry, cable must emerge

from the wall only in the areas specified in

Fig. 9. You will need at least 280mm of

cable to emerge from the wall to allow

connection to the terminal block.

Bottom

section

10

PIPE ENTRY

5.12 Available entry points:- top, bottom,

rear and right hand side (bottom is

generally the easiest). The inlet spigot is

smooth, 15mm diameter and is designed

to accept a 15mm compression fitting.

This must be an elbow for top, bottom and

rear entry, and a straight connector for side

entry. You should use compression rings

(olives) made of copper rather than brass,

as copper will crush down better onto the

plastic spigot. Push-fit connectors cannot

be used.

5.13 Rear Entry. If the pipework is to

enter from the rear, you must cut away

the wall from around the pipe to allow room

for the nut on the compression elbow to

be recessed into the wall - see Fig. 11.

The pipework must be connected to the

elbow BEFORE the shower is fitted to the

wall; if you were to fix the pipe in place

first, you would not be able to get a

spanner onto the compression nut.

Figure 9 Backplate dimensions (mm)

Figure 10 Connection of pipe to inlet

Figure 11 Pipe fitting

5.14 Depending on the type of

compression elbow used, you may need

to remove a small part of the bottom

section of the backplate in order for it to fit

over the elbow nut.

5.15 Top Entry. You must connect the

ELBOW to the INLET SPIGOT first; if you

were to connect the elbow to the pipe first,

there would not be enough room within

the pipe channel in the shower to

manoeuvre the elbow onto the spigot.

Bottom Top Rear

Use compression fitting

with copper olive

11

5.16 Side Entry. You must use a straight

connector with an overall length (including

nuts and olives) of less than 42mm.

PLUMBING

5.17 Decide where to connect to the water

mains for your feed to the shower. Ensure

that the pipe you have selected is not a

gas pipe (they can look similar) or a hot

water pipe or from a cold water storage

tank (unless you have sufficient head - see

3.2 & 3.3).

5.18 Cut the necessary pipework to length,

assemble and offer up to the installation

before making any soldered joints. Ensure

that the pipe is the correct length, as

shortening it can be difficult once joints

have been made.

5.19 Carry out any cutting with pipe cutters

in preference to a hacksaw, to minimise

swarf. Use 15mm compression fittings,

preferably with copper compression rings

(olives), for the connection to the shower

heater.

5.20 Remember to incorporate a servicing

valve and, if required, a double-check

valve - see 3.8 & 3.14.

5.21 Locate your stop cock and turn off

the water supply. Check that the pipe

you intend tapping into no longer carries

water, by opening a tap that the pipe

supplies.

5.22 Make your connection to the pipe. If

it is on a low-lying loop there may be some

water left in the pipe, so be prepared for

some flow of water. Make all joints except

that to the shower heater before flushing.

5.23 It is essential to flush the system

in order to clear debris, particles of

solder and swarf which could enter and

damage components within the

shower heater, prior to connecting to

the shower - see Fig. 6. It may be best

to take the shower off the wall to do this.

5.24 Turn the water off after flushing,

either at the stop cock or by using your

servicing valve.

5.25 Remount the shower firmly and make

the final water connection to it. Turn the

water on again.

5.26 No water will flow from the shower

outlet until the electrics are connected, as

the shower incorporates a solenoid valve.

5.27 Check for leaks in all pipework, and

rectify as necessary.

5.28 When the shower fitting is complete

the riser rail and accessories can be fitted,

please refer to separate instructions in

accessory box.

ELECTRICS

5.29 Design your system as outlined in

Section Three. Lay the cable in your

chosen route, ensuring that you have

ample length.

5.30 Leave the connection to the

consumer unit or switch-fuse until last.

5.31 Remember, when working on

electrical components, ensure they are

not live. If in any doubt, switch off at your

main switch at the fuse board or consumer

unit.

5.32 If you find it necessary to increase

access for fitting the cable, the shower can

be unplumbed at its inlet pipe and

temporarily removed from the wall.

5.33 Feed the cable through the opening

in the backplate below the terminal block.

5.34 Make sure that you route the cable

so that the bottom section of the backplate

will fit in place.

Table of contents

Other Heatrae Sadia Plumbing Product manuals

Popular Plumbing Product manuals by other brands

Rohl

Rohl PERRIN & ROWE U.1323LS installation instructions

Moen

Moen 1234 installation guide

Helvex

Helvex Vértika E-3008-DX installation guide

Hans Grohe

Hans Grohe Metropol 14400 Series manual

Sanela

Sanela SLSN 23HO Mounting instructions

oventrop

oventrop Multiblock TFU Installation and operating instructions

Hans Grohe

Hans Grohe PuraVida 15132000 Instructions for use/assembly instructions

Hans Grohe

Hans Grohe 27479 Series Assembly instructions

PEERLESS

PEERLESS PTT188740 Series manual

Jacuzzi

Jacuzzi sasha installation manual

Villeroy & Boch

Villeroy & Boch La Belle installation instructions

JADO

JADO Hatteras 842/035 Series installation instructions