Heatrae Sadia CAMEO ELECTRIC SHOWER Instruction Manual

1

Fitting Instructions and User Guide

CAMEO ELECTRIC SHOWER

2

INTRODUCTION

Thank you for purchasing a Heatrae Sadia Cameo. The Cameo electric

shower is manufactured to the highest standards and has been designed to

meet all the latest relevant safety specications.

This Cameo electric shower must be installed (sections 3.0-5.0),

commissioned (section 5.0) and maintained (section 6.0) by a competent

person. Please read and understand these instructions prior to installing

your Cameo electric shower. Particular attention should be paid to the

section headed IMPORTANT INFORMATION (section 2.0). Following

installation and commissioning the operation of the heater should be

explained to the user (section 6.0) and these instructions left with them for

future reference.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning the use of the appliance by a person responsible for their

safety. Childern should be supervised to ensure that they do not play with

the appliance.

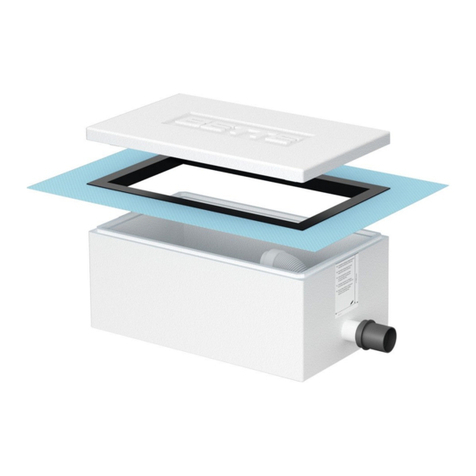

PACK CONTENTS

Heater.

Fixing screws and plugs.

Installation and user instructions.

Handset and riser rail kit.

3

1.0 TECHNICAL SPECIFICATION

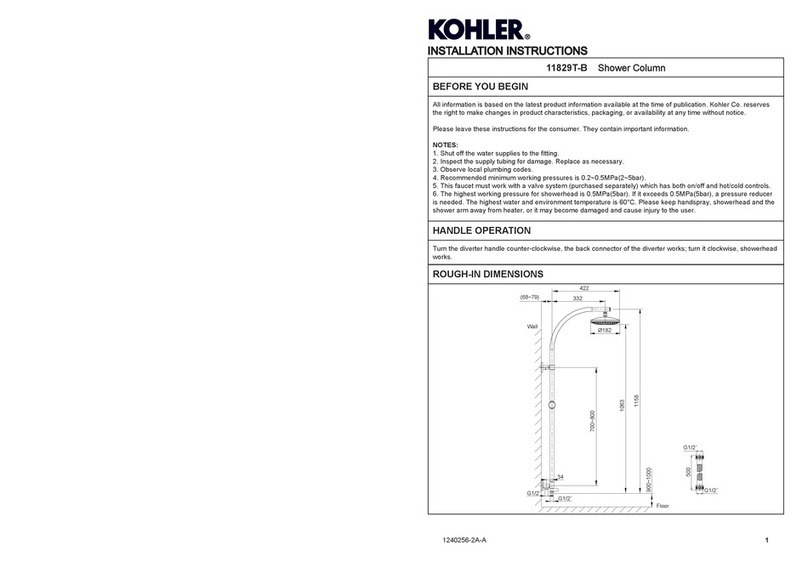

1.1 CONNECTIONS

Inlet connection -15mm ext. diameter (copper or push t stem elbow)

Water entry point - bottom and rear

Cable entry point - bottom and rear

1.2 ELECTRICAL

Nominal Power Rating

1.3 MATERIALS

Backplate, cover and control knob- ABS

Element(s) - Copper sheathed rod type.

1.4 DIMENSIONS

Height - 235mm

Width - 151mm

Depth - 85mm

1.5 STANDARDS AND APPROVALS

Complies with the requirement of EN 60335-2-35.

British Electrotechnical Approvals Board (BEAB) approved.

Complies with European Community Directives (CE).

Complies with uk water regulations, kiwa approved.

Model 240v 230v

7.2kW 7.2kW

30 amp

6.6kW

28.75 amp

Cut

Out

red

red

red

red

NL

black

green/yellow

red

Terminal

block

Pressure

switches

Inner

container

7.2kW

Figure 1 Wiring diagram

Neon

4

2.0 IMPORTANT INFORMATION

2.1 Your shower is designed and tested to the very highest standards

and complies fully with all of the relevant British and European

standards for safety and reliability. The shower is manufactured in

an ISO 9001: 2000 -registered factory - your assurance of a quality

product.

2.2 To ensure correct use and maintenance of the shower, please read

and adhere to the following warnings and guidelines.

FOR INSTALLERS

2.3 Do not attempt any of the electrical or plumbing work necessary to

install this product unless you have good practical experience and

a competent understanding of the IEE Wiring Regulations and Water

Regulations.

2.4 WARNING: THIS APPLIANCE MUST BE EARTHED.

2.5 The installation must be carried out in accordance with the relevant

requirements of:

• The appropriate Building Regulations either The Building

Regulations, The Building Regulations (Scotland) or Building

Regulations (Northern Ireland).

• The Water Fittings Regulations or Water Byelaws in Scotland.

2.6 Before removing the front cover always ensure your shower heater

is isolated from the electrical mains.

2.7 This product is splash proof and is approved for use in shower

cubicles and over baths. However, do not install the Shower

heater in a position where the handset, in its normally-parked

position, will consistently direct the spray over it.

FOR USERS

2.8 If water emerges from anywhere other than the spray head

outlets, do not use your shower, TURN OFF ELECTRICITY

& WATER and refer to the Fault Finding section.

2.9 IT IS IMPORTANT TO CLEAN THE SPRAY PLATE OR SPRAY

ASSEMBLY REGULARLY, particularly in hard water areas,

where this may be necessary as often as once a week. Failure

to do so will affect the performance of the shower and in

extreme cases may cause the pressure relief device (PRD) to

operate - see Fig. 2 and Fault Finding (p17).

Refer to the user instructions in handset kit for maintenance.

2.10 The shower heater outlet, hose and handset act as a vent.

They must not be blocked, obstructed, or have connected to

themanyttingnotapprovedbythemanufacturers.Theuse

of unapproved accessories may affect the performance and

safety of the unit.

5

2.11 WARNING! DO NOT USE the shower if the HOSE IS

DAMAGED in any way; for instance if the outer covering has

parted to reveal the inner tube.

A damaged hose can suddenly restrict the ow and result in

extremely hot water being emitted from the showerhead.

A damaged hose could completely block the outlet of the shower;

the resulting increase in pressure could burst a weakened or

damaged hose.

2.12 Do not install the shower in a situation where the water in it could

freeze. Any damage caused by freezing will not be covered by the

guarantee.

WARNING. If you suspect the shower of being frozen, DO NOT

SWITCH ON. If you have switched on, SWITCH OFF

IMMEDIATELY. Refer to Fault Finding (p16).

2.13 Do not leave the inrm, disabled users, or young children

unattended in the shower.

2.14 Before stepping into the shower, always test the temperature of the

spray with your hand.

2.15 Switch off at the isolating switch after showering.

2.16 As with all electrical appliances, it is advisable to have your shower

and installation checked at least every two years by a competent

electrician, to ensure that there is no deterioration due to age and

usage.

Thermal

cut-out

Front

cover

Inner

container

Pressure switch

Flow control valve

anticlockwise

Rating label

Cable clamp

Pressure relief device (PRD)

Outlet spout

Terminal block

To close: turn

Figure 2 Internal components

Neon

6

3.0 SITING AND PLUMBING

3.1 Spend some time planning exactly where to site the shower heater

and riser rail. Bear in mind the height of people who will be using it.

THINGS YOU MUST DO

3.2 Check that the water pressure to the shower is adequate. If in

doubt, consult a competent plumber.

Maximum 0.7MPa (7bar - 100 psi)

Minimum 0.1MPa (1bar - 14.5psi)

The use of other services connected to the water pipe supplying

the shower heater may cause the water pressure to drop below the

minimum. Therefore this should be taken into account.

The following conversions may

be useful:

1 bar = 14.5 lbf/in² = 33.3 ft

head of water.

1 lbf/in² = 2.3 ft head.

3.3 Electric shower heaters are

normally plumbed into the

mains water (except for special

low pressure versions).

However, the shower heater

may be fed from a storage tank

where there is a sufcient head

of water, i.e. over 10m.

3.4 Mount the shower heater on a

at vertical wall with the outlet,

to which the hose is connected,

pointing downwards.

3.5 DO NOT place the shower

heater where it will be in the

direct spray from a normally-

parked handset.

3.6 Allow room around the shower

heater for removal of the front

cover - see Fig. 7&8.

3.7 Position the riser rail close to

the heater, not necessarily on

the same wall (but bear in mind

paragraph 3.5) so that in the

Figure 3 Siting of riser rail and heater

Lowest positon

handset position

Bath/Shower tray

25mm minimum

Hose - retaining ring

Lowest position

305mm (12”) 610mm (24”)

Riser rail

Highest position

7

3.13 A Water Regulations Advisory

Service listed servicing valve should

be tted in the water supply pipe to

the shower. This is to allow the

shower heater to be serviced without

turning off the water supply to other

appliances.

3.14 DO NOT use plumber’s paste on any

joints as this may damage the

shower.

3.15 DO NOT use a blow-torch or other

form of heat close to the shower

heater as this may damage the non-

metallic parts.

3.16 DO NOT use excessive force, but

do ensure adequate support, when

making connections.

3.17 Before making the nal water

connections to the shower heater,

the pipe-work MUST BE FLUSHED

THOROUGHLY to remove brick

dust, swarf etc. which could severely

damage the shower itself - see Fig. 5.

highest parked position, the handset is not more than 610mm above

the bottom of the heater and in its lowest position it is no lower than

305mm -see Fig. 3.

3.8 If the handset can reach to within 25mm (1”) of the spillover level of

the bath, shower tray, wash basin, WC or bidet, then to prevent the

possibility of back-siphonage of used water (Water Regulations

Guide G15.14/R15.14) you must either:

1. Install a hose-restraining ring - see Fig. 3.

2. Fit a double-check valve in the pipe work to the shower.

3.9 Decide from which direction your inlet pipe will enter the shower

heater. There is a choice of entry from bottom or rear - see Fig. 12.

It is advised to use rear entry when possible, as this gives a neater

installation.

3.10 Ensure there are no services such as gas, water pipes, electrical or

telephone cables beneath the surface of the wall before drilling.

Special hand-held testers are available from hardware stores.

3.11 The water connection to the shower heater should be made using

standard 15mm outside diameter copper tube or a push t stem

elbow. The ends of the pipe should be cut square and be free from

internal and external burrs and deep scratches.

3.12 Cut all necessary pipe work to length with a pipe cutter and not a

hacksaw, to minimise swarf - see Fig. 4.

Figure 4 Cutting pipes

Figure 5 Flushing the pipework

8

4.5 The shower heater must be

connected to its own

independent electrical circuit.

It MUST NOT be connected

to a ring main, spur, socket

outlet, or lighting circuit,

otherwise the circuit will

overload - see Fig. 6.

4.6 Check that your consumer

unit (main fuse box):

1. has a main switch rating

of 80A or above and

2. has a spare fuse way which

will take the fuse/mcb you

need to t - see Fig. 6. If so,

you can wire the shower

direct to the spare fuse of

your consumer unit - see

Fig. 6.

Note that not all consumer

units accept a 35/40/45A

sized fuse.

4.7 If point 4.6, 1 and 2 are not achievable, the installation is not

straightforward, since it could involve installing a new consumer

unit to serve the whole house or just the shower. You will need to

call in your Regional Electricity Company to check the circuit and

make the connections to the meter or service connector block.

They will also check the earth bonding of items in the bathroom.

4.8 All exposed metallic parts in the bathroom must be bonded

together using cable of at least 4mm² CSA (cross sectional area).

These parts include metal baths, radiators, water pipes (including

the feed to the shower), taps and waste ttings.

4.0 ELECTRICAL INSTALLATION

WARNING

4.1 This appliance must be earthed.

4.2 The installation, supply cable and circuit protection must conform to

BS7671 ‘Requirements for electrical installations’ (IEE Wiring

Regulations).

The following notes are for guidance only:

4.3 The shower heater must only be connected to a 230/240V ac

supply.

4.4 Before making any electrical connections within the installation,

make sure that no terminal is live. If in doubt,SWITCH OFF the

whole installation at the consumer unit or switch fuse (where tted).

Figure 6 Schematic of typicalelectrical layout

Shower unit

(use rear entry when it is

possible)

80A or 100A main switch

Meter

Meter ‘tails’

Consumer unit

RCD (can be part of the

consumer unit)

Double pole isolating switch:

pull cord or wall mounted in accordance

with IEE regulations

9

4.9 For all installation arrangements work back from the shower to the

consumer unit. Before making the nal connections, check the

circuit for continuity and insulation resistance.

4.10 It is recommended that a residual current device (rcd), formerly

known as an earth leakage circuit breaker (elcb), with a tripping

current of 30mA, is incorporated in the circuit. This removes the need

to check your earth loop impedance.

4.11 A double-pole isolating switch rated at 30A or greater, with a

contact separation of at least 3mm in each pole, must be incorpo

rated in the circuit. This must have a mechanical indicator showing

when the contacts are open. An indicator lamp alone is not sufcient.

It is recommended that only cord operated switches are tted

in bathrooms. The switch must be located so that the body is more

than 2.25m above the inside of the bottom of the bath or shower tray

and more than 600mm outside the showering area. It should be

readily accessible (you should switch off the shower at the isolating

switch after showering).

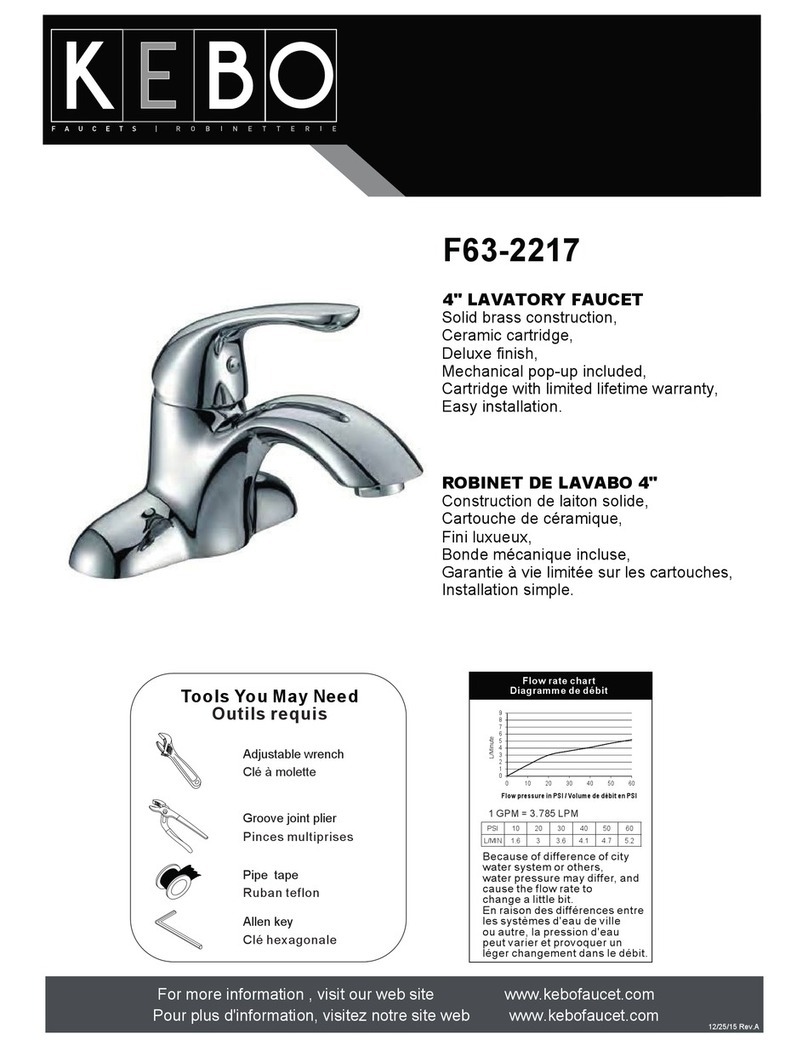

4.12 Choosing cable and fuse sizes

The nominal current of your shower is 30A at 240V - see 1.2. The

current rating of your cable must be at least that of the shower itself.

Use Table 1 to choose a fuse or mcb. DO NOT use rewirable fuses.

If the cable is to be:

1. bunched with others

2. in an ambient of above 30°C

3. in an insulating wall or within thermal insulation, e.g. loft

insulation

IF IN DOUBT ALWAYS SEEK ADVICE FROM A COMPETENT

ELECTRICIAN.

TABLE 1

4mm² cable

6mm² cable

(Values are in

Amperes)

Clipped

direct ¹

Enclosed in

trunking ²

Enclosed in

insulating wall ³

Clipped

direct ¹

Enclosed in

trunking ²

Enclosed in

insulating wall ³

Cable rating

36

30

46

38

32

Fuse rating

30

30

30

30

30

MCB rating

32

32

32

32

1. Clipped direct means cable clipped onto wall without a covering, or embedded directly in masonry

concrete or plaster etc.

2. Enclosed in trunking means cable is on its own in a plastic or metal conduit fixed to the wall or ceiling.

3. Enclose in insulating wall, where cable is enclosed in a plastic or metal conduit within a thermally

insulated wall where heat can only escape through the insulating material.

Use 6mm

²

Use 6mm

²

Use 6mm

²

Use 6mm

²

10

5.0 CONNECTING TO SERVICES

PREPARATION

5.1 Remove the xing screw which holds the front cover onto the

backplate of the shower heater. Carefully remove the cover.

5.2 The control knob is an integral part of the cover - do not attempt to

remove it see Fig. 7.

5.3 The unit must be mounted on a at surface, which covers the full

width and length of the backplate. It is important that the wall

surface is at otherwise difculty may be encountered when tting

the cover.

5.4 DO NOT t the shower to the wall and tile up to the case. It must be

tted on to a nished at and even wall surface.This allows removal

for servicing.

5.5 You should leave at least 130mm around the shower heater for

tting the front cover in place and for tting the cover-xing

screws - see Fig. 8.

130mm

130mm

Figure 8 Positioning shower

Figure 7 Removing Cover

11

CABLE ENTRY

5.6 Cable entry can be from the

rear (preferred see g. 9) or

from the bottom. The

backplate has cut out

positions to suit 2 sizes of

cable. When opting for

bottom entry make cut out

to suit cable before tting

backplate to the wall - see

Fig. 10.

PIPE ENTRY

5.7 Plumbing entry can be from

the rear (preferred) see

Fig. 9 or from the bottom.

The backplate has a cut out

position to suit 15mm pipe.

Figure 9 Unit layout - Dimensions (mm)

19.5

74

29

86

196.5

151

235

Cable

Clamp

Inlet water

connection

Terminal

Block

Rear entry access

area for electricity

and inlet water

supply

When opting for bottom entry make cut out before tting backplate to

the wall - see Fig 11.

5.8 Fix the shower heater loosely to the wall. The wallplugs provided are

suitable for most brick walls (use a 6.5mm diameter masonry drill),

but if your wall is plasterboard or soft building block, you should use

special wallplugs and an appropriate drill, obtainable from most

hardware stores.

Make cut-out

using sharp knife

Figure 11 Plumbing cut-out

Flexible

cord Fixed

wire

4mm cable

2

Make cut-out

using sharp

knife

Figure 10 Cable cut-out

12

PLUMBING

5.9 Decide where to connect to the water mains for your feed to the

shower. Ensure that the pipe you have selected is not a gas pipe

(they can look similar) or a hot water pipe or from a cold water

storage tank (unless you have sufcient head - see point 3.2 & 3.3).

5.10 Cut the necessary pipe work to length, assemble and offer up to

the installation before making any soldered joints. Ensure that the

pipe is the correct length, as shortening it can be difcult once joints

have been made.

5.11 Carry out any cutting with pipe cutters to minimise swarf.

5.12 Remember to incorporate a servicing valve and, if required, a double

check valve - see point 3.8 & 3.13.

5.13 Locate your stop cock and turn off the water supply. Check that the

pipe you intend tapping into no longer carries water by opening a tap

that the pipe supplies.

5.14 Make your connection to the

pipe. If it is on a low-lying

loop there may be some

water left in the pipe, so be

prepared for some ow of

water. Make all joints except

that to the shower heater

before ushing.

5.15Itisessentialtoushthe

pipe in order to clear

debris, particles or solder

and swarf prior to

connecting to the shower

- see Fig. 5.

5.16 Turn the water off after ushing, either at the

stop cock or by using your servicing valve.

5.17 Connect the cold water supply pipe to the

inlet of the shower, this is a push t

connection - see Fig. 12.

5.18 Fit top and bottom screws and secure the

backplate to the wall ensuring that it is level.

5.19 Close the shower ow control valve by

turning the gear fully anticlockwise.

5.20 Turn the sevicing stop valve on slowly and

check for leaks in all pipework and rectify as

necessary.

5.21 Turn off the servicing valve.

35mm

Figure 12 Pipe connection

Bottom entry

Rear entry

Copper compression fitting

shown - push fit stem

elbow can be used.

Close

Figure 13 Valve closed

13

FITTING THE HOSE

5.22 Secure one end of the hose to

the handset and screw the other

end of the hose to the shower

heater outlet. Ensure that the

black sealing washers are tted.

ELECTRICS

5.23 Design your system as outlined

on pages 6 to 10. Lay the cable

in your chosen route, ensuring

that you have ample length.

5.24 Leave the connection to the

consumer unit or switch-fuse

until last.

5.25 Remember, when working on

electrical components, ensure

they are not switched on

electrically. If in any doubt, switch

off at your main switch at the fuse

board or consumer unit.

5.26 The cable entry should have

been decided before tting the backplate - see point 5.6.

5.27 Remove the screws and clamping bar from the cable clamp - see

Fig.16.

5.28 Feed the cable in the backplate (unscrew backplate for easy

feeding if necessary).

5.29 Strip the outer sheath of the cable to a point about 5mm above the

clamp, thus ensuring that the cable is clamped across its outer

sheath.

5.30 Strip the insulation from the cores and make connections - see Fig.

16.

5.31 Make sure that all the terminal block screws are tightened FIRMLY.

5.32 Ret the clamp bar (for a 10mm² cable, the clamp bar is not required).

If cable enters from the rear DO NOT use the cable clamp.

FITTING THE COVER

5.33 The hose must be tted - see point 5.22.

5.34 Check that the ow control valve is fully closed by turning the gear

fully anticlockwise - see point 5.19.

Figure 15 fitting the hose

Hose

Sealing washer

Handset

red or brown to 'L'

green & yellow to

blue or black to 'N'

Cable clamp

Figure 16 Electrical connection

14

5.35 Turn control knob in the cover until the indicator is

between ‘START’ and ‘STOP’.

5.36 Place the cover onto the backplate.

5.37 Secure the cover to backplate using screws provided.

COMMISSIONING

NOTE: The rst operation of the shower is intended to ensure the

heater unit contains water before the unit is switched on.

5.38 Secure the handset on the riser rail, in a position where it can spray

safely.

5.39 Before turning on the electricity and mains water to the shower,

ensure the control knob is turned fully clockwise.

5.40 Turn on the main water supply at the servicing stop valve and

slowly turn the control knob anticlockwise (it will take approximately

30 seconds for a smooth ow of water to be obtained whilst any air

is being dispersed from the shower).

5.41 Stop the water ow by rotating the control knob clockwise.

5.42 Turn on the electrical supply at the isolating switch.

5.43 Rotate the control knob half a turn anticlockwise. After

approximately 15 seconds, the water will start to heat.

5.44 To obtain warmer water turn the control knob clockwise and for

cooler water turn anticlockwise.

5.45 Shut off the shower by turning the control knob clockwise. The unit

is now ready to use.

15

6.0 USER INFORMATION

6.1 To turn on and set temperature:

1. Turn on your isolating switch.

2. Turn water control knob anticlockwise to allow water to

ow until “power on” neon illuminates; the shower is then heating.

WARMER - DECREASE FLOW - TURN KNOB CLOCKWISE.

COOLER - INCREASE FLOW - TURN KNOB ANTICLOCKWISE.

Make adjustments carefully. Give the shower a few seconds after

each adjustment to stabilise, then check the temperature by hand

before stepping into the shower.

A cold shower can be obtained simply by leaving your isolating switch

off and operating the water control knob.

6.2 To turn off:

1. Turn the water control knob fully clockwise.

2. Turn off your isolating switch.

6.3 Power light

ON when water ow activates pressure switch (when heating).

Please note that this shower is not thermostatic, it will not keep spray

temperature constant whatever the change in external inuence.

MAINTENANCE

Cleaning the handset, also refer to instructions supplied with handset.

6.4 To obtain the best performance from your shower, the handset must

be cleaned regularly, maybe as often as once a week in hard water

areas.

6.5 This is because the ne outlet holes can become blocked with scale

and this will affect the pattern of the spray and cause the heater to

perform poorly.

6.6 The easiest and most effective method of cleaning your handset,

regardless of which type you have with your shower, is to soak it in a

proprietary descalant. For best results the handset should be left to

soak overnight.

6.7 The handset with rubber spray outlets can be cleaned by simply

rubbing one’s hand over them rmly to dislodge the scale.

INSPECTION

6.8 We recommend that in the interests of safety the shower and its

electrical installation is checked by a qualied electrician at least

every two years.

16

FAULT FINDING

In the unlikely event of a problem consult the trouble shooting

chart below. For your particular system follow the suggested

remedies in the order given. If you are unable to remedy the

problem CONTACT YOUR INSTALLER IN THE FIRST

INSTANCE. Do not attempt any electrical or plumbing work unless

you are competent to do so.

SYMPTOM POSSIBLE CAUSE REMEDY

1. No flow or not

A. Water control knob is Turn water control knob anticlockwise

enough flow. turned fully

clockwise

B. Water turned off at Ensure water is fully turned on at the mains and at

mains or servicing servicing valve in circuit

valve

C. SHOWER HEATER if so, DO NOT USE

SUSPECTED OF 1. Switch off immediately at isolating switch

BEING FROZEN 2. Turn water off at servicing valve (if fitted) or at stop

cock

3. Contact our Service Department

D. There may be an Disconnect handset from hose and run the shower

outlet blockage 1. If water flows then handset is blocked with scale or

debris. Remember that disturbances to plumbing

elsewhere in your house, or in the street, can dislodge

debris which can find its way to the shower. Clean the

handset and spray rings/plate thoroughly

2. If the water does not flow, remove hose from the

shower outlet

2a. If the water flows then the hose is blocked. This could

be due to damage, severe kinking or even an

obstruction. Renew the hose

2b. If the water does not flow, there is a blockage in the

plumbing to the shower, or the shower itself. Contact

our Service Department if the shower is considered to

be the problem

E. Filter blocked 3. Clean filter in unit: isolate power and water to shower

remove the front cover, remove the two screws which

hold the filter in place. Pull the black filter out and clean.

Replace filter and fixing screws, replace cover and

switch power and water on.

2. Flow adequate A. Electrical power to Ensure that the electrics to the shower are switched on

but water too the shower heater and the neon is lit

cold is off

B. Water flow too high Reduce the flow by turning the water control knob

clockwise slowly. NOTE: If the knob is turned too far

clockwise, the safety pressure switch inside the shower

will turn off the heating elements. This is apparent when

the indicator light on the shower goes out. If this happens,

turn the knob anti-clockwise until the light comes on

17

SYMPTOM POSSIBLE CAUSE REMEDY

3. Water too hot A. Water flow too Increase the flow by turning the water control

low Knob anticlockwise

B. Spray plate Clean the handset spray plate

blocked with scale

or debris

C. Filter blocked Clean filter in unit

4. Temperature A. Pressure switch is

varies while operating,

showering, normally making a

cycling "click" as it does so

hot/cold B. Input pressure is Ensure that your stop cock and servicing

below 1.0 bar valve are opened fully

(14.5psi); flow is

not stable

5. "Power on" A. Cartridge fuse or Switch off shower and isolating switch.

indicator not lit. miniture circuit Turn power of to consumer unit.

Isolating switch breaker (mcb) has Renew fuse, reset the mcb. Turn power on to

"ON" but its operated in your consumer unit. If they operate a second time, contact

neon not lit fusebox (or a qualified electrician

consumer unit) or

switch fuse

B. Residual current Follow the same procedure as above. If this

device (rcd) or has happened with a "split load" consumer

(earth leakage unit on initial installation, check that the

circuit breaker) neutral core of the shower feed cable is

has operated connected to the "protected" neutral bar of the unit

6. Water emerges PRD has operated 1. Switch off immediately at isolating switch

from bottom of 2. Isolate water supply to shower unit

the unit 3. Contact Heatrae Sadia Service Department

Water pressure/flow issue

18

7.0 SPARE PARTS

The following comprehensive list of spare parts is available for your He-

atrae Sadia shower. Please refer to the rating label on the side of your

heater before ordering to ensure the correct spare part is obtained.

DO NOT REPLACE WITH PARTS NOT RECOMENDED BY HEATRAE

SADIA, AS THIS WILL INVALIDATE YOUR GUARANTEE AND MAY REN-

DER THE INSTALLATION DANGEROUS.

DESCRIPTION CODE NO.

1. Heat Exchanger Assembly 7.2kW................................. 95 608 004

2. Cut-out - 7.2kW............................................................. 95 612 030

3. Valve/Pressure switch Assembly - 7.2kW..................... 95 605 059

4. Knob..............................................................................95 605 054

5. Cover.............................................................................95 607 097

6. Neon Assembly............................................................. 95 615 057

7. Micro switch.................................................................. 95 613 003

8. Filter.............................................................................. 95 607 107

9. Pressure Relief Device..................................................95 607 108

10. Riser rail kit................................................................. 95 607 098

11. Handset & Hose.......................................................... 95 607 099

6

7

2

3

4

5

8

1

9

11

10

19

Guarantee & Service Policy

This product is guaranteed against faulty materials and

manufacture for a period of two years from the date of purchase

provided that:

1 The unit has been installed in accordance with the Installation and

User Instructions and all relevant Codes of Practice and

Regulations in force at the time of Installation, and that all

necessary controls and safety valves have been tted correctly.

2 Any valves and controls are of the Heatrae Sadia recommended

type and specication.

3 The unit has not been modied or tampered with in any way, and

has been regularly maintained as detailed in the Installation and

User Instructions.

4 The unit has been used only for heating potable water.

The unit is not guaranteed against damage by frost, and the inner

container with integral heating element is not guaranteed against

excessive scale build-up.

This guarantee in no way affects the statutory rights of the

consumer.

The policy of Heatae Sadia is one of continuous product

development and, as such, we reserve the right to change

specications without notice.

Due to continuous improvement and updating, specications may

be altered without prior notice.

Environmental Information

Heatae Sadia products are manufactured from many recyclable

materials.

At the end of their useful life they should be disposed of at a Local

Authority Recycling Centre in order to realise the full environmental

benets.

20 36006024 issue 1

Heatrae Sadia Heating

Hurricane Way, Norwich, NR6 6EA

www.heatraesadia.com

© 2008

Switchboard: 01603 420100

Sales: 08700 603262

Sales Fax: 08700 600403

Service: 08701 600125

Service Fax: 08701 600181

Service Email: heatraesadiaservice@

heateam.co.uk

Spares Stockists

Electric Water Heating Co.

2 Horsecroft Place, Pinnacles

Harlow, Essex, CM19 5BT

Tel: 0845 0553811

E-Mail: [email protected]

SPD

Units 9 & 10 Hexagon Business Centre

SpringeldRoad,Hayes

Middlesex, UB40 0TY

Tel: 020 8606 3567

Parts Center

Tel: 0845 270 9801

www.partscenter.co.uk

Newey & Eyre

Specialist Products Division

Please contact your local branch

UK Spares Ltd.

Tower Lane, Warmley

Bristol, BS30 8XT

Tel: 0117 961 6670

William Wilson Ltd.

Unit 3A, 780 South Street

Whiteinch, Glasgow, G14 OSY

Tel: 0141 434 1530

Table of contents

Other Heatrae Sadia Plumbing Product manuals