11

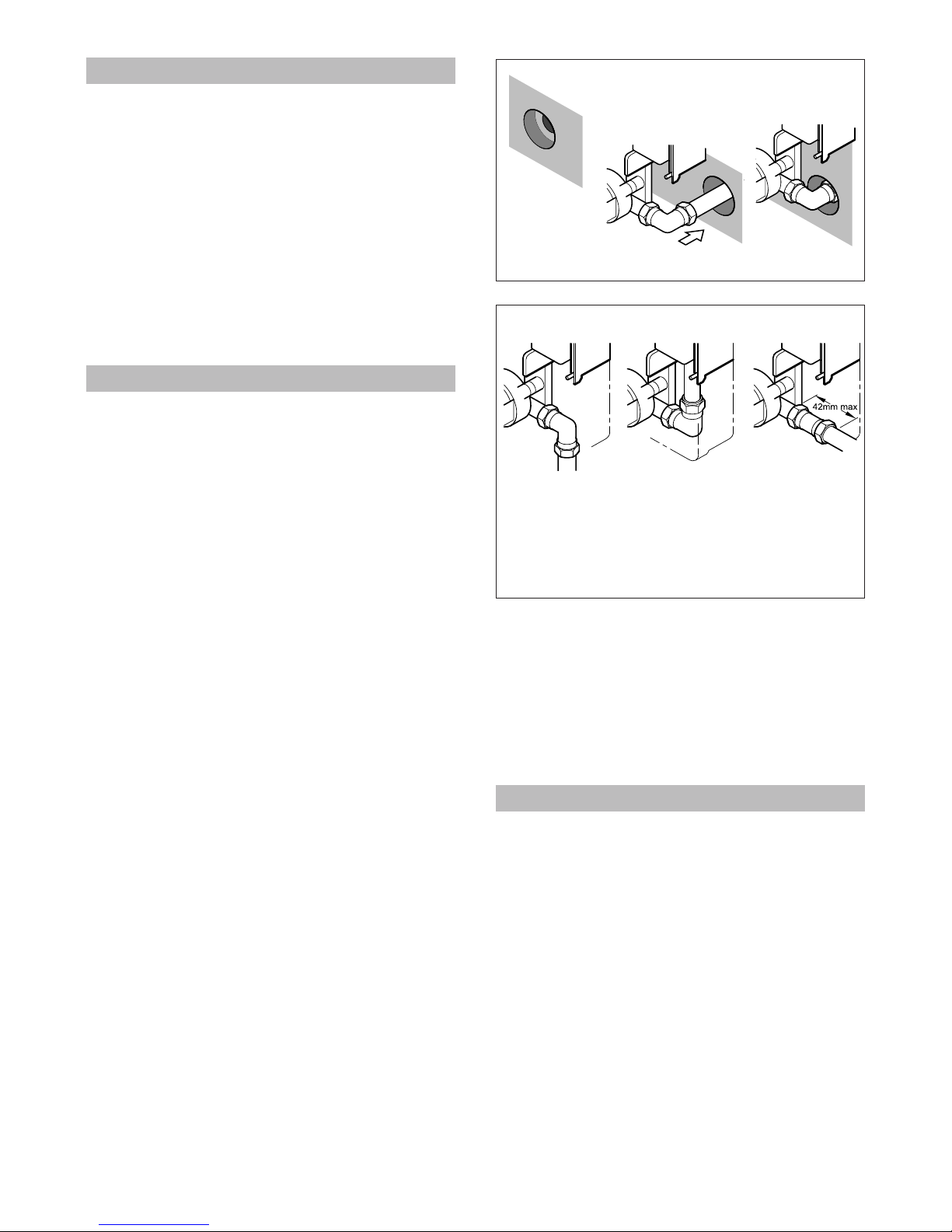

5.17 Carry out any cutting with pipe cutters

in preference to a hacksaw, to minimise

swarf. Use 15mm compression fittings,

preferably with copper compression rings

(olives), for the connection to the shower

heater.

5.18 Remember to incorporate a servicing

valve and, if required, a double-check

valve - see 3.8 & 3.14.

5.19 Locate your stop cock and turn off

the water supply. Check that the pipe

you intend tapping into no longer carries

water, by opening a tap that the pipe

supplies.

5.20 Make your connection to the pipe. If it

is on a low-lying loop there may be some

water left in the pipe, so be prepared for

some flow of water. Make all joints except

that to the shower heater before flushing.

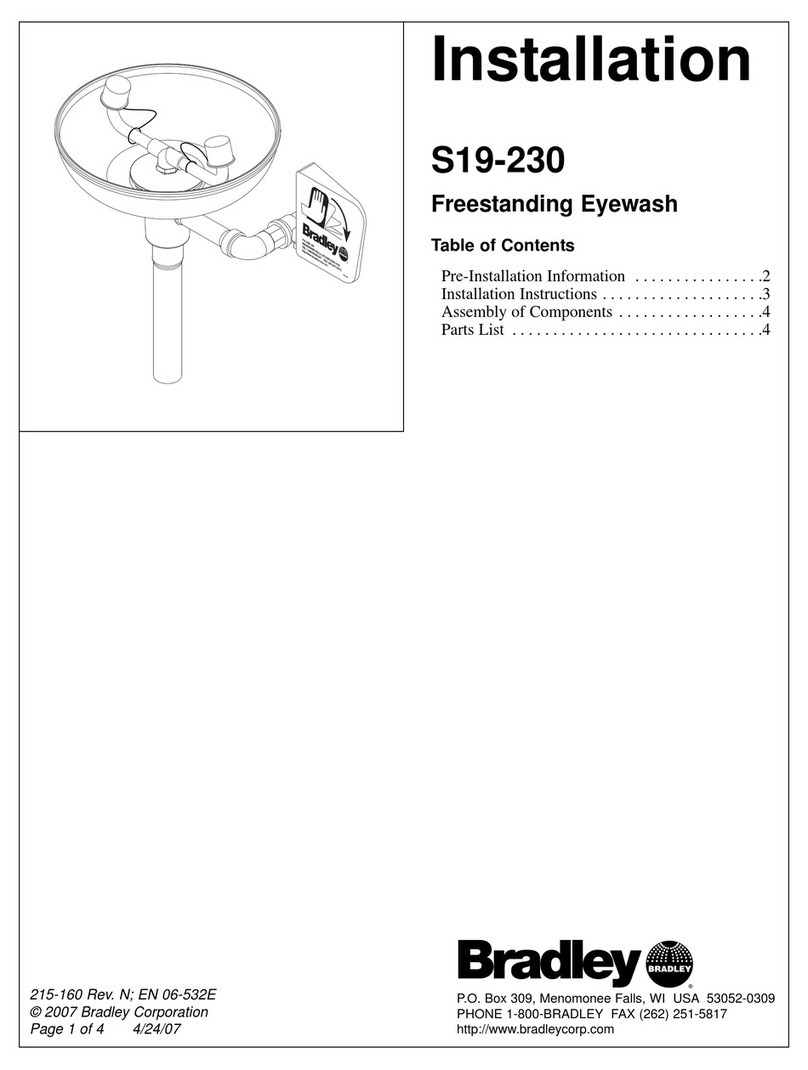

5.21 It is essential to flush the system

in order to clear debris, particles of

solder and swarf which could enter and

damage components within the

shower heater, prior to connecting to

the shower - see Fig. 7. It may be best

to take the shower off the wall to do this.

5.22 Turn the water off after flushing,

either at the stop cock or by using your

servicing valve.

5.23 Remount the shower firmly and make

the final water connection to it. Turn the

water on again.

5.24 No water will flow from the shower

outlet until the electrics are connected, as

the shower incorporates a solenoid valve.

5.25 Check for leaks in all pipework, and

rectify as necessary.

5.26 When the shower fitting is complete

the riser rail and accessories can be fitted,

please refer to separate instructions in

accessory box.

ELECTRICS

5.27 Design your system as outlined in

Section Three. Lay the cable in your

chosen route, ensuring that you have

ample length.

5.28 Leave the connection to the

consumer unit or switch-fuse until last.

5.29 Remember, when working on

electrical components, ensure they are

not live. If in any doubt, switch off at your

main switch at the fuse board or consumer

unit.

5.30 If you find it necessary to increase

access for fitting the cable, the shower can

be unplumbed at its inlet pipe and

temporarily removed from the wall.

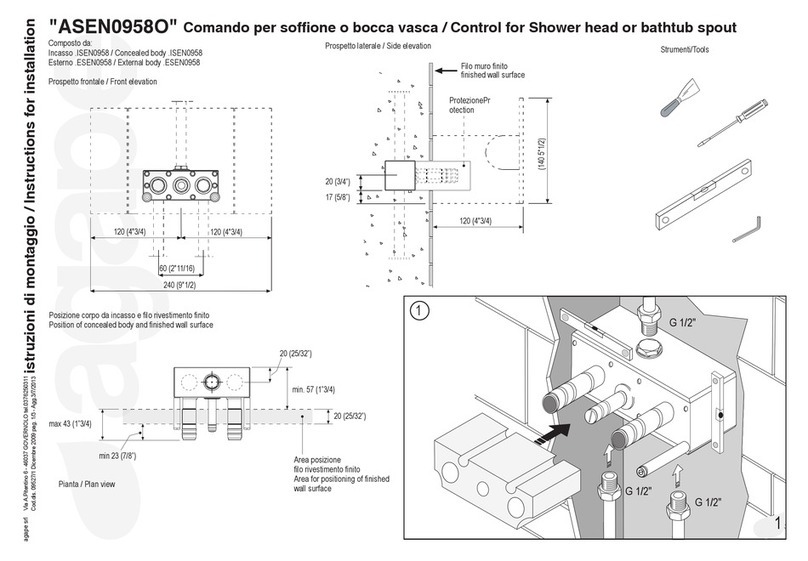

5.31 Feed the cable through the opening

in the backplate below the terminal block.

5.32 Make sure that you route the cable

so that the bottom section of the backplate

will fit in place.

5.33 Ensure that all three screws hold the

shower backplate to the wall firmly.

5.34 Strip the outer insulation sheath back

as required.

5.35 Strip the insulation from the cores and

make connections to the LIVE (L) (brown

or red), NEUTRAL (N) (blue or black) and

EARTH terminal block. The earth wire

must be sleeved green/yellow. Make sure

that the cores of the cable lie tidily and do

not touch any metallic part of the shower.

They must not be under strain. There is no

cable clamp.

5.36 Ensure that the cable does not foul

the area above the bottom removable

section, where the knob gear will fit when

the front cover is fitted into place.