Heckert Solar NeMo 4.1 80 M User manual

Installation and operating manual

PV-Module NeMo 4.1 80 M

www.heckert-solar.com

Status 08/2022

Standard 11 years

product warranty

Produced with

green energy

Made in Germany

www.heckert-solar.com

Version dated 07/2022

Installation and operating manual

This operating manual is addressed to suppliers, installers and operators of PV systems with monocrystalline high-

performance solar modules manufactured by Heckert Solar GmbH. It aims to ensure that the installed PV systems

produce optimum yields through the entire running time. Non-compliance may render the warranty invalid. Please read

the following instruction manual thoroughly.

Heckert Solar brand modules may only be installed by qualified specialist companies. Please observe the relevant

standards and regulations for the installation and operation of photovoltaic plants, such as VDE requirements, DIN

standards, the VDEW Guideline, the Technical Connection Conditions of the relevant network operators, as well as the

rules of the employers' liability insurance associations on accident prevention, in particular IEC 62446 on operation and

maintenance. Non-compliance may result in considerable personal injuries and material damage. The standards and

laws applicable in Germany form the basis of the information contained in this installation and operating manual.

This installation manual should form part of the plant documentation, and should be available to the plant operator at

any given time.

Heckert Solar reserves the right to amend the present document at any time without prior notice. Please use the most

current copy, which can be found on our homepage at

https://www.heckertsolar.com/service/

This installation and operating manual is in accordance with IEC 61730-1:2016.

Overview

1. Risks & safety precautions

2. General information on PV plants

3. Delivery & handling of the modules

4. Information on the module

5. Module installation

6. Connecting the modules

7. Returns & recycling

8. Product and service warranty

9. Disclaimer

1. Risks & safety precautions

Solar modules generate electricity as soon as they are exposed to light. It is hazardous to touch a module with a voltage

of 30 volts or more. Each serial or parallel connection of modules increases the voltage or current. By connecting more

than two solar modules in series, hazardous voltages may occur!

Danger of death due to electric shock!

Although touch protection is provided in the form of the fully insulated plug contacts, please ensure that when handling

the solar modules

no electrically conductive parts are inserted into the plugs or sockets!

solar modules and cables are not installed with wet plugs and sockets!

all works on the cables are undertaken with extreme caution!

high contact voltages may still be present inside the inverter even when the unit is switched off!

as a rule, caution is exercised when performing any work on the inverter and cables!

Heckert Solar brand modules correspond with Class II.

2

Risk of death by electric arc!

A deadly electric arc can result when opening a closed section (e.g. when separating the DC cable from the inverter

under load):

Never separate the solar generator from the invertor if the latter is connected to the grid!

Working on the roof

Please observe the applicable accident prevention regulations. Do not carry out installation work when there are strong

winds. Secure yourself and other persons from falling down. Prevent objects from potentially falling down. Secure the

work area so that no other persons can be injured.

2. General information on PV plants

Orientation

The solar module achieves the highest yield when oriented to the south (towards the north when in the southern

hemisphere). The optimum angle of inclination outside the tropics can be estimated using the following equation:

Angle of inclination = latitude of the installation site - 20°

Deviations from the optimum orientation and inclination of the modules lead to a reduction in yield.

The minimum inclination is 3°.

Angle of inclination >75° may lead to regional restrictions.

Location

The area planned for the installation should be as free as possible from shade of any kind (houses, trees, branches,

chimneys, dormers, antennas, satellite dishes, cables, etc.), because shade can significantly reduce the efficiency of the

solar modules. Core shadows should be avoided. Even partial shading will lead to a significant reduction in yield. A

module is considered “shade-free” when the entire surface is shade-free all year round and, even on the most

unfavourable days of the year when the sun is low, receives unobstructed sunlight for several hours.

Rear ventilation

The output of solar modules decreases considerably as the modules heat up. Rear ventilation avoids yield-impairing

heat accumulation. The so-called “chimney effect” (draught behind the modules) should not be impeded if possible

(e.g. roof windows, collectors).

Cleaning/Maintenance

With a sufficient inclination of the modules (>20°), there is a self-cleaning effect from rain and snow. Cleaning the

modules is generally unnecessary. In the case of a smaller inclination, the self-cleaning effect is only limited.

However, the soiling of the modules is strongly dependent on the surrounding environment and should be checked once

a year. In case of heavy soiling, it is recommended that the modules be cleaned after cooling down (e.g. in the morning)

using plenty of lukewarm, de-mineralised water and a gentle cleaning device, as sharp-edged items might lead to

scratches on the surface or to destruction of the anti-reflective (AR) coating. Clean, lint-free cotton, microfibre cloths

or paper towels should be used for cleaning. Fatty or oily deposits can be removed with isopropyl or isopropyl/water

mixtures. You should also refrain from using strong acids, alkalis, benzine-based cleaning agents or hot cleaning agents,

as well as cleaning agents containing silicone oil, fluorides or wax, polishes, alkaline cleaning agents and cleaning agents

with abrasive chemical products or high-pressure cleaners. Any methods, means or conditions which can exchange Na

ions from the glass surface are unsuitable for cleaning glass. All abrasive cleaning agents and utensils are also

unsuitable. Please note that too great differences in temperature can lead to tension in the glass, which may damage

the module.

If other cleaning methods or means are used, the anti-reflective coating may be damaged or become dirty down to the

pores, which can lead to visual changes and/or a loss of performance.

3

Please make sure that the earthing is not interrupted or destroyed when carrying out

cleaning and maintenance work!

3. Delivery & handling of the modules

The goods must be checked immediately upon delivery to ensure completeness and integrity. Only damages which are

noted on the driver’s delivery receipt and are immediately communicated in written form to Heckert Solar can be

recognised as transport damages.

In general, our brand modules are packed upright on a one-way pallet of up to 30 or max. 19 modules. Take care when

unpacking, transporting and storing the modules. We recommend keeping the modules in their packaging until ready

for installation. Always set the pallets on a reinforced level ground and do not stack them under any circumstances.

Standard

packaging

Picking

packaging

Number of modules/

pallets

20-30

1-19

External dimensions

(W x L x H)

1.2 m x 1.16 m x 1.94 m

1.2 m x 1.16 m x 1.94 m

Weight of full pallet

660 kg

430 kg

Quantity per truck

22 pallets * 30 modules = 660 pcs.

22 pallets * 19 modules = 18 pcs.

The packaging is not film-wrapped and is therefore not resistant to rain!

Please be sure to observe the unpacking instructions on the packaging! Never remove

the rear retaining strap from pallets with 30 modules!

4

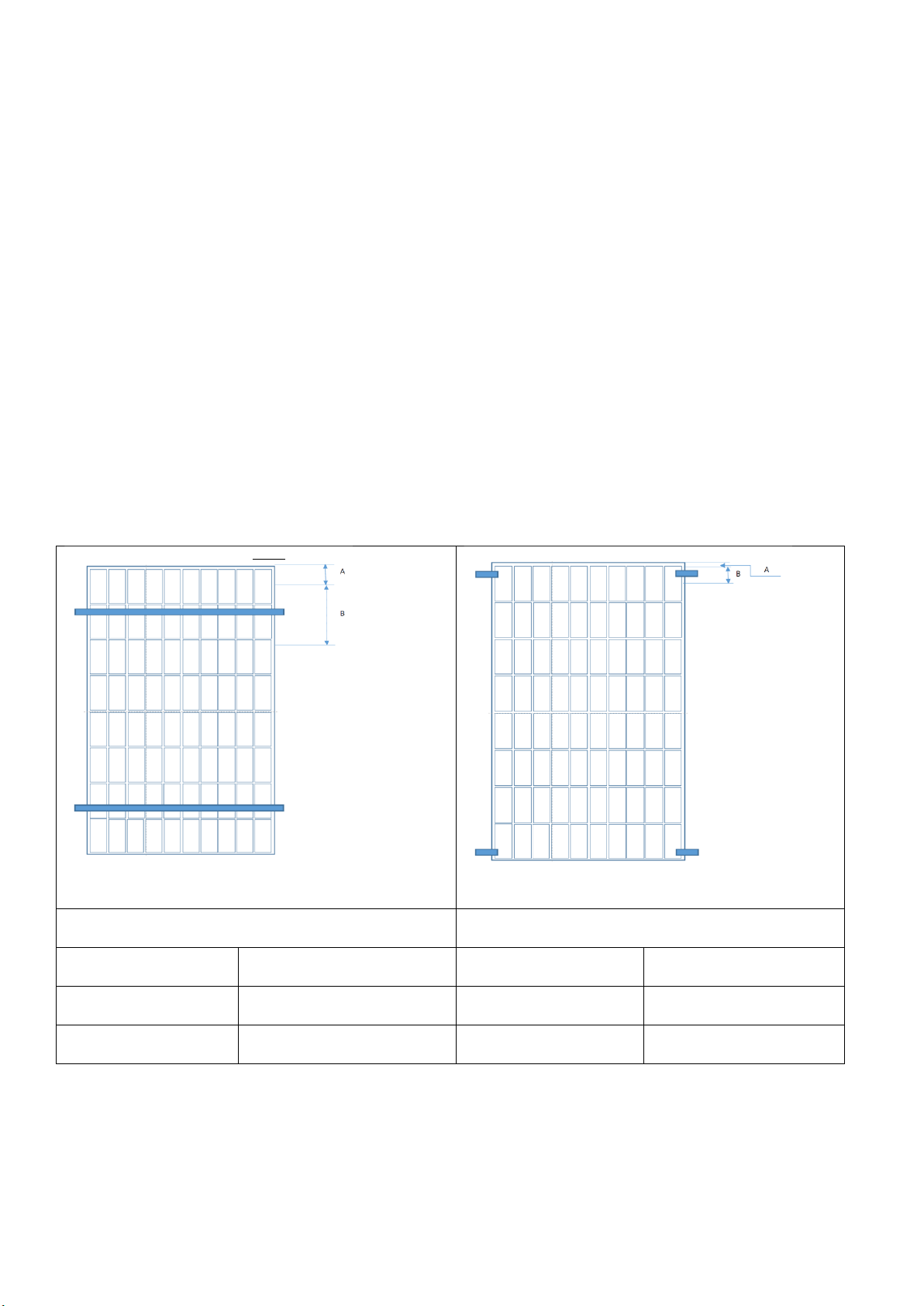

Figure 1: Standard packaging: Pallet with 30 modules

Figure 2: Picking packaging: Pallet with 19 modules or fewer

Exercise caution when working with the modules!

Carry the modules with both hands. Do not use the connection sockets or cables(s) as a handle. During the

transport and installation, take care that no pressure or tension is exerted on connection sockets and cables.

Protect the modules from any hard knocks! Do not set the modules down roughly on hard ground. Do not set

the modules down on their corners. Do not place the modules on top of each other unprotected. Do not place

any objects on the modules. Never stand on the modules! Do not allow the modules to fall or use hard or

pointed objects on them.

Special care must be taken to connect the modules in accordance with the instructions and should not be

forced. Keep all electrical contacts clean and dry.

A dry, well-ventilated room should be used to store the modules.

For the system documentation, it is advisable to make a note of the serial number and address of the place of

installation on the installation plan.

Do not install any damaged modules.

5

Please observe the specific instructions for handling solar modules with AR glass.

Compared with non-coated glass, the surface of AR glass has a similar resistance to mechanical influences. The

resistance to corrosion and chemical influences is considerably higher than with non-coated glass. The AR layer should

be handled with the same care to avoid any damage to it. Due to its special reflective properties, light soiling is more

noticeable than on non-coated glass. In particular, fats/oils are visible even in small amounts and change the reflection

and thus also the appearance of the module. In order to avoid these marks, the modules should only be touched with

clean gloves or suction cups with covers.

4. Information on the module

Certification and Performance Data

For the performance data and instructions on certificates for our brand modules, please refer to the datasheets for

the respective series.

Use

Please observe the following points in particular for the use of our brand modules:

Installation or operation of the solar modules is permissible up to an altitude of max. 2000 m above sea level.

The function of the modules is tested at an ambient temperature of -40 to +40°C or an operating temperature

of -40 to +85°C. This area should be adhered to.

The solar module is not suitable for use in seawater.

When installing in salty air, functional earthing must be provided.

The module must not be subjected to unusual chemical loads (e.g. emissions from manufacturing plants).

Do not immerse the solar module in liquid.

Do not install the module in the immediate vicinity of air-conditioning units.

Do not use any lenses or mirrors to concentrate light (risk of overheating).

Avoid damage to the module from using carbide or diamonds.

Protect solar modules from overvoltage, e.g. voltage peaks from battery-charging devices, generators or

alternators etc. (Please ask your specialist retailer in case of any doubt).

If solar modules are connected to energy-storage devices, the safety instructions of the respective manufacturer

must be followed.

Keep children away from solar modules.

In southern regions, a PV module can supply greater power and/or a higher voltage than stated for the standardised

test conditions (standard test conditions). Therefore, to determine the voltage ratings of components, current ratings

of conductors, sizes of fuses connected to the output of PV modules, the values of Isc and Uos indicated on the module

should be multiplied by a factor of 1,25. The highest rated value for overcurrent protection (reverse current resistance)

is 20 A.

5. Module installation

General instructions on module installation

All modules can be fitted both horizontally and vertically independent of the connector sockets.

The modules must not be subject to stress during installation. The modules cannot be used as a rigid linking or fixing

element.

Please be advised that the holes in the frame and in the corners must remain free in order to allow condensed water

to flow out.

Load on the modules

The load capacity of standard solar modules is independent of the installation situation and the system used. Please

observe the installation situations in the following table and the resulting maximum load capacity of the modules.

The values shown (Fig. 3) correspond to the design load in accordance with IEC 61215: 2016. The cyclical load test is

carried out according to the standard of a 1.5 times higher test load.

6

Default situation for continuous mounting rails

Please note that the module can bend under high loads and can strike the mounting rails. Ensure that the mounting rail

displays a sufficient stability and the fixing points are set with sufficient frequency to prevent the mounting rail from

bending. (tested with Heckert Solar rails and a support spacing of max. 1m)

Ensure that the maximum mechanical load is not exceeded, in particular while also taking into account the site-

dependent loads, e.g. wind and snow (DIN 1055-4/5).

Do not use any fixing material that might damage the module e.g. due to pointed, sharp or uneven structures. Please

note that the module bends under load and can strike the supporting surface/ mounting rails. Ensure that the connector

sockets and cables, when necessary, are not damaged or exert pressure on the cells.

The total snow load on the ground sk in kN/m² results from the respective snow load zone, the building site and the

ground height above sea level. The total wind load for the project site must be determined from the wind zone map,

which takes into account the site situation as well as wind zones. For buildings up to a height of 25 m, the total wind

load may be determined through a simplified procedure. Independent of building heights, the wind load is specified as

velocity pressure q in kN/m2.

2 continuous rails under module 4 fixing points

A = 250; B = 150

4 fixing points in the corners (internal clearance)

A = 10; B = 200

Test load

Design load

Test load

Design load

Pressure 6000 Pa

Pressure 4000 Pa

Pressure 2400 Pa

Pressure 1600 Pa

Suction 2400 Pa

Suction 1600 Pa

Suction 2400 Pa

Suction 1600 Pa

7

Positioned linearly on the long side

High load capacity with 3rd rail

A = 315; B = 868

The middle rail must run above the connector sockets,

cables go in the other direction

Test load

Design load

Test load

Design load

Pressure 3600 Pa

Pressure 2400 Pa

Pressure 8100 Pa

Pressure 5400 Pa

Suction 2400 Pa

Suction 1600 Pa

Suction 2400 Pa

Suction 1600 Pa

Clamp short side

A = 150; B = 150

4 fixing points in the corners (internal clearance)

A = 10; B = 200

Test load

Design load

Test load

Design load

Pressure 5400 Pa

Pressure 3600 Pa

Pressure 2400 Pa

Pressure 1600 Pa

Suction 2400 Pa

Suction 1600 Pa

Suction 2400 Pa

Suction 1600 Pa

Figure 3: Load capacity depending on the installation situation

8

The maximum load capacity of the modules can only be achieved by clamping the

specified area and complying with all conditions!

Please note that the planning and execution of the project is the sole responsibility of

the installation company, and in some cases, it is necessary to prepare property statics!

Load restraints

To prevent the modules from slipping on sloped surfaces during installation and to facilitate installation, our module

frames are fitted with holes for load restraints. Screws with hexagon socket head caps are fixed in these holes in the

module frame. The screws are fastened with a washer and nut or using a self-locking nut. An M5x10 VA screw and the

corresponding toothed washer and nut is recommended for the load restraints.

6. Connecting the modules

The solar modules from Heckert Solar are equipped with Original MC4 connectors (Stäubli –MultiContact)

Only connectors in accordance with DIN EN 62852 (VDE 0126-300) may be used.

Please note that only the proper tool may be used for the crimping of connectors.

Defective crimped connections may cause significant damage to the modules and could even cause the plant to burn

down.

The modules are connected to the strings in series. This adds the voltage of the modules to the string. Please note that

the permissible system voltage of 1000V may not be exceeded even at very low temperatures.

Please note that it is imperative to avoid tensile force on the connection cables.

Please note that only the manufacturer’s connectors may be connected. Even

“compatible” connectors can loosen the connection and cause an electric arc. This is

especially important to consider when using power optimizers!

Please ensure that the connectors are not in water for prolonged periods of time (cable

ducts, roof surfaces)!

Any change in the connector socket can lead to the warranty being rendered null and

void, and therefore may only be carried out by trained and skilled personnel.

No damaged modules may be installed!

Both connector sockets are fitted with a cable (900 mm in length) and connectors. The socket (+) is located on the

right-hand side, and the plug on the left-hand side (-) (Fig. 4). The connectors are each designed in such a way as not

to create confusion.

9

Figure 4: Configuration of the connector sockets

The individual solar modules in a string can be interconnected effortlessly.

Please ensure the correct connection of the plugs and sockets!

Figure 5: Connected MC4 modules

The string cables are connected to the MC4 connectors on the first or last module in the string.

The connectors comply with IEC 62852.

Please be sure to observe the requirements set out in DIN VDE 0298-3 for cable routing, in particular the smallest

permissible bending radii (Figure 6; R>5 x cable Ø) and the guidelines for cable fastening and routing.

Figure 6: Bending radii

10

The connectors have a protection class of IP68 after connecting to the plug; the connector socket has a

protection class of IP65. Both components are permanently protected against environmental influences.

Figure 7: Protection class

Pleasure be sure to observe the instructions and installation instructions of the respective manufacturer. See

Annex. The Multicontact instructions can also be found on our homepage

(https://www.heckertsolar.com/service/).

Cable routing

Per string, 2 cables are required per string, that connect the solar generator to the inverter. Please use solar cables

that comply with the standard EN 50618 class 5 and the respective requirements. The minimum cross-section is

4mm². Cable losses should be < 1%. At greater distances, the cable cross-section must be adjusted accordingly.

Please be sure to observe the requirements set out in DIN VDE 0298-3 for cable routing.

The strings (+ and - cables) are fed into the inverter and connected to the DC inputs. The module connectors are

marked. To avoid conductor loops, the strings (+ and -) should be laid together.

When connecting the strings to the inverter, ensure that its polarity is correct. The + and - cables must not be

interchanged. Using a multimeter/voltmeter, the polarity and voltage of the individual strings should be verified before

connecting them to the inverter.

Only certified, suitable connectors are approved for the connection of the solar cables to the inverter. The installation

or connection of the inverters should be carried out in accordance with the manufacturer's instructions.

The inverter manufacturer’s instructions are binding.

Pleasure ensure that there is no tension when routing the cables and that the plug and

crimp are properly connected!

Depending on the module performance and inverter type, different length strings are

possible. Make absolutely sure that the permissible system voltage cannot be achieved

at full-load (VOC) and at low temperatures.

Parallel boarding of PV modules

When wiring our brand modules, it should be noted that string fuses (safety fuse 16 A) must be used for the parallel

boarding of more than 2 strings.

The maximum reverse current load capacity is 25 A. Where more than two strings are connected in parallel, this may

be exceeded in the case of a fault.

11

Electrical installation

Connection of the inverter to the public electricity network must be carried out by an authorised specialised company.

Even at low solar radiation, there is high DC voltage. Never touch unprotected + and -

cables that are in operation!

Equipotential bonding

The requirements for the lightning and surge protection are dependent on the local conditions. Where there is already

an external lightning protection system in place or planned for the building, the PV system must be integrated in the

protection system against a direct lightning strike.

When using transformer-less inverters, due to the galvanic isolation, equipotential bonding may be required for reasons

of personal safety. Country-specific laws shall apply.

The responsibility for a professional equipotential bonding of the module frame lies with the installing company. Country-

specific standards must be adhered to.

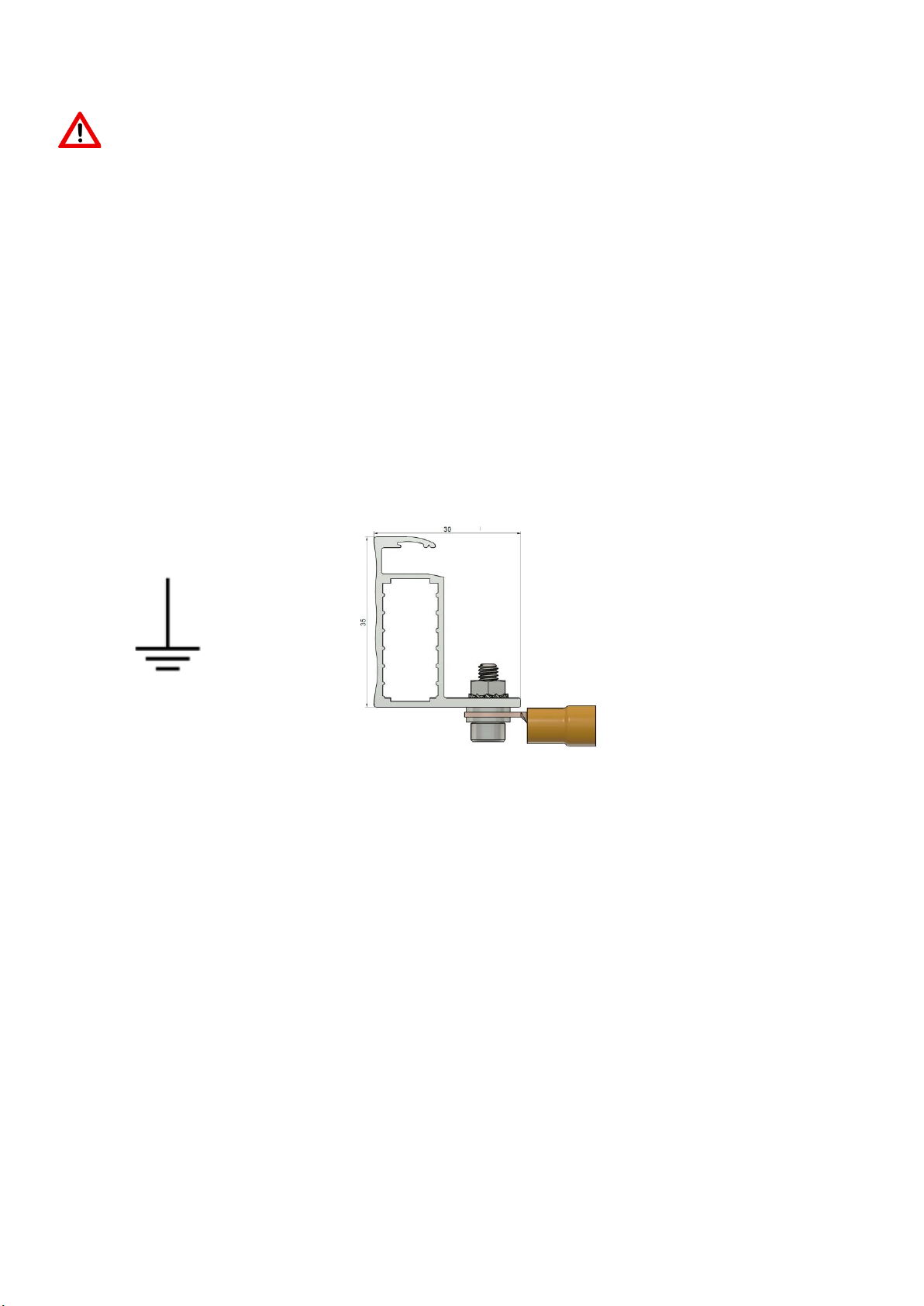

A hole is drilled in the middle of the short sides of the module frame for equipotential bonding, and is marked with the

corresponding symbol (Figure 8).

An M4 screw is required for equipotential bonding. The fixing must be carried out using a spring washer or toothed

washer to ensure that the anodized layer is penetrated.

Figure 8: Equipotential bonding symbol and execution

Functional earthing

Functional earthing is required in the following cases:

-installation in tropical regions (23.5°N –23.5°S)

-Module inclination <5°

-Installation near the sea

It must be ensured with functional earthing that the voltage difference between the negative generator pole and earth

potential (substructure, protective earth PE of the inverter) is ≥0V on the individual strings in operating mode.

Please observe the inverter manufacturer’s installation instructions. Only earthing kits approved by the manufacturer

may be used

Fire protection

The installation of on-roof systems can affect the fire safety of a building; improper installations can result in a hazard

in case of fire. Please observe LBO Building Law requirements. In the event of on-roof systems, the Heckert Solar brand

modules must be installed above a fire-resistant surface (“hard roofing” in accordance with DIN 4102-4). The module

is “non-explosion-proof operating equipment”. It may not be installed near highly-flammable gasses and vapours (e.g.

petrol stations, gas containers or spraying systems). The module may not be installed near open flame or flammable

materials.

-Cable clamp

-Screw

-Toothed washer

-Nut

12

The Heckert Solar modules were verified for their fire behaviour in accordance with IEC 61730-1:2004 und ISO 11525-

2:2014. Our modules are considered to be flame retardant (Fire-resistance class C). Heckert Solar does not accept any

warranty claims for inadequate supporting surfaces, in particular roof covering.

A clear labelling of the PV system and installation diagram, on the domestic junction box and the main building

distribution board, are normative.

7. Returns & recycling

Returns & recycling of solar modules are governed by the WEEE ElektroG2 Directive. Please observe country-specific

regulations. Where applicable, notification may be required in the respective country.

EAR registration number DE42676826

8. Product and service warranty

Information and terms for our product and service warranties can be found on our homepage under www.heckert-

solar.com .

9. Disclaimer

These installation and operating instructions apply to general installations. All information is supplied without guarantee.

Heckert Solar GmbH shall assume no liability for the usability and functionality of the system if there are deviations from

the instructions contained in this user information. Given that neither compliance with this user information, nor the

conditions, use and methods of installation, nor system operation, nor maintenance of the modules can be checked or

monitored by Heckert Solar GmbH, the latter shall assume no liability for damage resulting from unintended use,

incorrect installation, operation, use or maintenance.

Moreover, liability for patent infringements or infringements of other third-party rights resulting from the use of the

modules is excluded unless liability is mandatory by law.

Our technical service department would be happy to answer any other questions you may have and can be reached at:

+49(0)371/458568-0.

Annex: Assembly instructions MC4 connector (Stäubli)

Heckert Solar GmbH • Carl-von-Bach-Straße 11 • D-09116 Chemnitz

13

Excerpt from MC4 crimping instructions (Source: Multi-contact)

Required tool

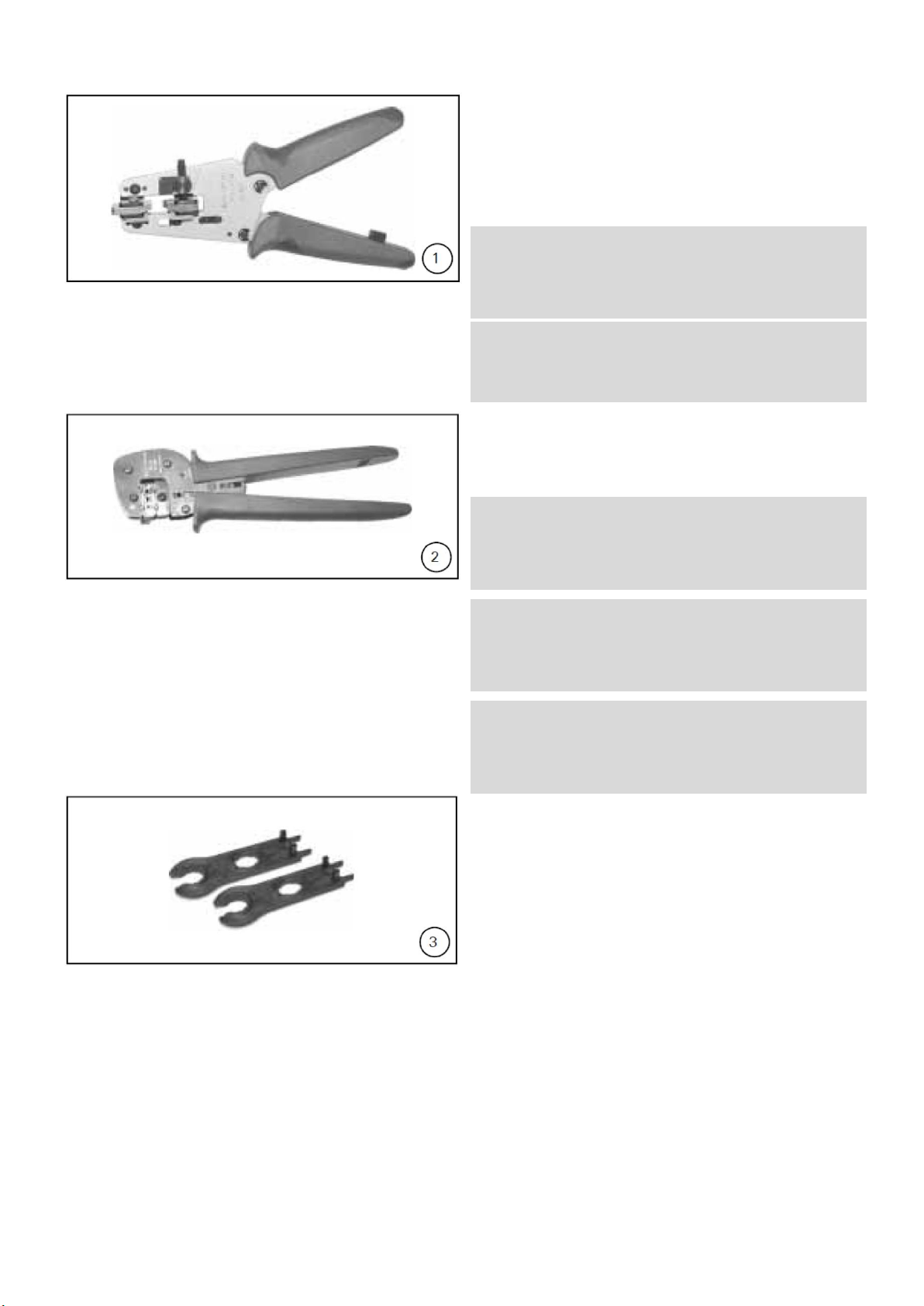

(ill. 1

Stripping pliers PV-AZM... incl built-in

stripping blades and hexagonal spanner,

width across flats 2.5.

Conductor cross-section 1.5 / 2.5 / 4 /

6mm2

Type: PV-AZM-1.5/6

Order no. 32.6029-156

Conductor cross-section 4 / 6 / IO mm2

Type: PV-AZM-4/I0

Order no. 32.6027-410

(ill. 2)

Crimping pliers PV-CZM... incl. locator

and built-in crimping insert.

Crimping range:

1.5/2.5/4 mm2 (14/12 AWG)

Type: PV-CZM-18100

Order no. 32.6020-18100

Crimping range:

2.5/4/6 mm2 (12/10 AWG)

Type: PV-CZM-19100

Order no. 32.6020-19100

Crimping range:

4/IOmm2(12 AWG)

Type: PV-CZM-20100

Order no. 32.6020-20100

(ill. 3)

PV-MS construction spanner. I Set = 2

pieces

Order no.: 32.6024

14

(ill. 4)

PV-WZ-AD/GWD socket spanner

for tightening Order no. 32.6006

(ill. 5)

PV-SSE-AD4 socket spanner for

countering

Order no. 32.6026

(ill. 6)

PV-PST test pin Order no. 32.6028

(ill. 7)

SW 15 Open-ended spanner

(ill. 8)

SW 12 Torque wrench

Preparing the line

Connecting lines with a stranded

wire construction of classes 5 and 6

can be connected.

Warning:

Do not use bare or already

oxidised conductors. Tin-plated

conductors are advantageous.

All solar cables from MC have

high-quality, tin-plated

conductors.

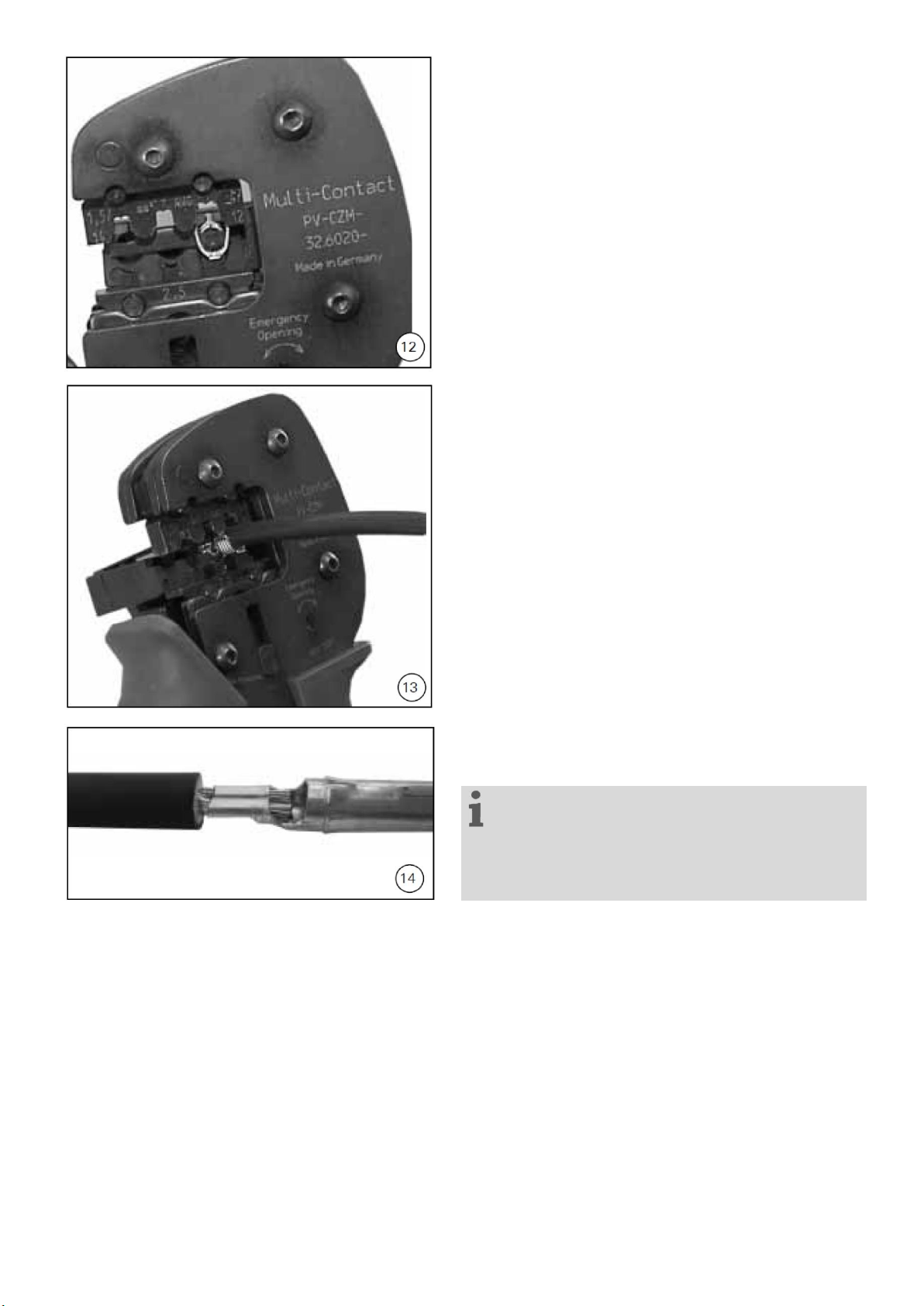

(ill. 9, Tab. 1)

Check the dimensions A and b

according to illustration 9 and table

I.

15

Tab. 1

b Kontrollmass

b- Control dimension

Leitungsquerschnitt

Conductor cross section

A: Ø -Bereich Leitung / A: Ø Range of cable

mm

3.0 –6.0

5.5 –9.0

mm

Mm2

AWG

Typ / Type

~ 3

1.5 –2.5

14

PV-K...T4/...2.5l

PV-K...T4/...2.5ll

~ 5

4 –6

12 / 10

PV-K...T4/...6l

PV-K...T4/...6ll

~ 7.2

10

-

PV-K...T4/...10ll

(ill. 10)

Strip the cable.

Remove the insulation of the cable over

a length of 6.0 to 7.5 mm.

Warning:

Do not cut any individual wires when

stripping!

Note:

1 In order to use the stripping pliers

PV-AZM... and replace the sets of

blades, please refer to the operating

instructions MA267 at www.multi-

contact.com

Crimping

(ill. 11)

Open the clamping bracket (K) and hold it

firmly. Place the contact in the

appropriate cross-section area. Turn the

crimping lugs upwards. Release the

clamping bracket (K). The contact is now

fixed.

16

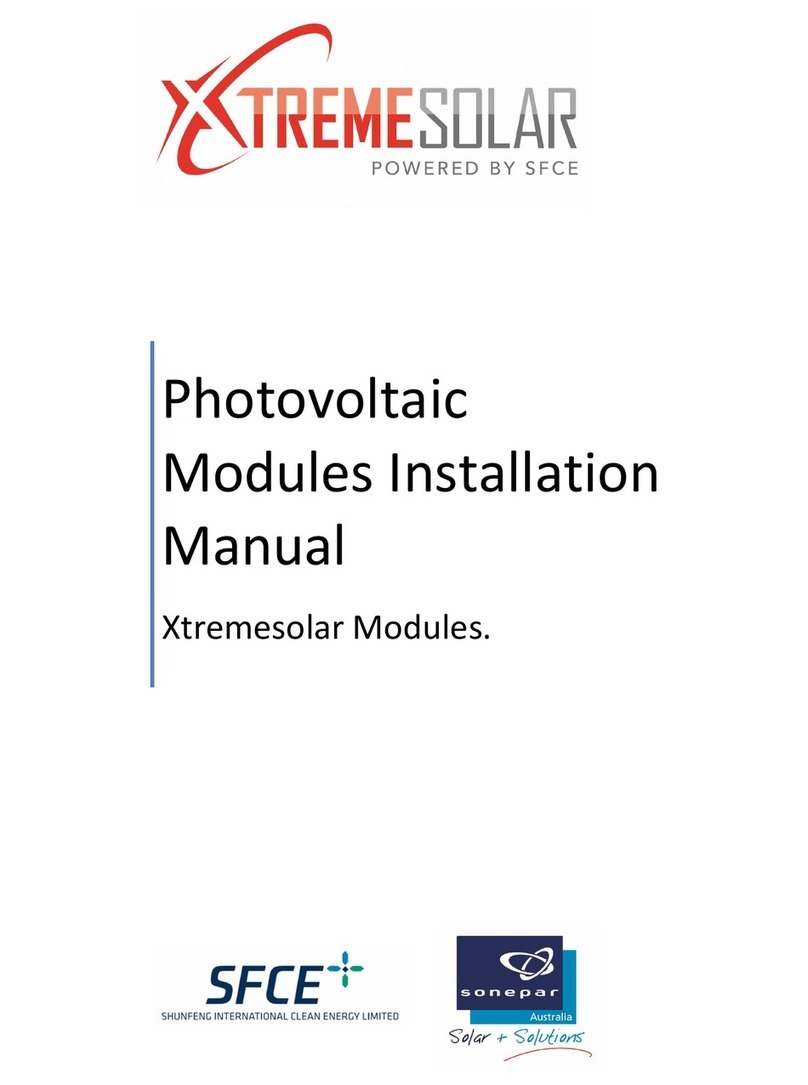

(ill. 12)

Gently squeeze the pliers together until the

crimping lugs are securely inside the crimp

die.

(ill. 13)

Insert the stripped cable. until the insulation

touches the crimp insert. Close the

crimping pliers completely.

(ill. 14)

Visually check the crimping.

Note:

please refer to the operating instructions

MA251 at www.multi-contact.com for

information on how to use the crimping pliers.

17

Mounting inspection

(ill. 15)

Insert the crimped contact from behind into

the plug or socket insulation until it

engages. Check that the metal part is

properly engaged by pulling gently on the

cable.

(ill. 16)

Insert the test pin with the corresponding

side into the socket or plug as far as it will

go. When the contact is correctly mounted,

the white marking on the test pin must still

be visible.

(ill. 17)

Hand-tighten the cable gland with the PV-

MS tools

or

tighten the cable gland with the PV-WZ-

AD/ GWD and PV-SSE-AD4 tools.

In both cases,

the tightening torque must be adjusted to

the specific solar cables used. Typical

values are in the range from 2.5Nm to

3Nm.

Plugging and unplugging the cable

coupling without securing sleeve PV-

SSH4

Plugging

(ill. 18)

Plug the cable coupling together until it

engages. Check that it engages correctly

by pulling on the cable coupling.

18

Unplugging

(ill. 19)

To unplug the contacts, press the

engagement tabs (X) together either by

hand or with the PV-MS tool and pull the

cable coupling apart.

Plugging and unplugging the cable

coupling without securing sleeve

PV-SSH4

Plugging

(ill. 20)

Plug the cable coupling together until it

engages. Check that it engages correctly

by pulling on the cable coupling.

Unplugging

The cable coupling can only be unplugged

with the PV-MS tool. Press the

engagement tabs (X) together with the PV-

MS tool and pull the cable coupling apart.

von Hand

by hand

mit PV-MS

with PV-MS

This manual suits for next models

1

Table of contents

Other Heckert Solar Solar Panel manuals

Popular Solar Panel manuals by other brands

SFC Energy

SFC Energy XTREMESOLAR XTR-S290P Series installation manual

OURASET

OURASET ECOSET 151 instruction manual

Westinghouse

Westinghouse AC System installation guide

ECO-WORTHY

ECO-WORTHY 100W Installation

King Pigeon

King Pigeon SLP1210-P instruction manual

Wolf

Wolf CFK-1 Installation, operating and maintenance instructions

Segway

Segway SP-100 user manual

REC

REC REC320NP installation instructions

UNIRAC

UNIRAC PoleTops 5001 Series installation manual

Southwest Windpower

Southwest Windpower Skystream Hybrid 6 installation manual

Schletter

Schletter SECT installation manual

solarwatt

solarwatt Vision 60P style installation instructions