HEDÜ FRE201 User manual

besser-messen.de

HEDÜ Rotationslaser FRE201

Art.-Nr. R154

Ersatzteilliste & Serviceanleitung

HEDÜ Rotary Laser FRE201

Art.-No. R154

Part List & Service Manual

Koffer

Case

Art.-Nr. / Art.-No.

R154-1. . . . . . . . . . . . . . . . . . . . . 30,00 €

4 Akkus Typ C NiMH 1.2 V 3800 mAh

4 rechargeable batteries

Art.-Nr. / Art.-No.

R154-2. . . . . . . . . . . . . . . . . . . . . 46,00 €

Ladegerät

Charger

Art.-Nr. / Art.-No.

R154-3. . . . . . . . . . . . . . . . . . . . . 39,00 €

ALB, AND, AUT, BGR, BIH, CHE, DEU,

DNK, ESP, FIN, GRC, HRV, HUN, ITA,

LUX, MCO, MDA, MKD, NLD, NOR, POL,

PRT, ROU, SVN, SWE, TUR

Ladegerät (französische Version)

Charger (french version)

Art.-Nr. / Art.-No.

R154-17. . . . . . . . . . . . . . . . . . . . 39,00 €

BEL, CZE, FRA, SVK

2

Gehäuse Oberschale

Top cover set

Art.-Nr. / Art.-No.

R154-5. . . . . . . . . . . . . . . . . . . . . 18,00 €

Oberer Dichtungsring

Upper gasket

Art.-Nr. / Art.-No.

R154-6. . . . . . . . . . . . . . . . . . . . . . 2,30 €

Gehäuse mit Griff, Tastatur und Kabel

Housing unit with handle, panel and cable

Art.-Nr. / Art.-No.

R154-7. . . . . . . . . . . . . . . . . . . . . 49,60 €

3

Gehäuse Unterschale

Underpan

Art.-Nr. / Art.-No.

R154-8. . . . . . . . . . . . . . . . . . . . . 28,00 €

Unterer Dichtungsring

Lower gasket

Art.-Nr. / Art.-No.

R154-9. . . . . . . . . . . . . . . . . . . . . . 2,30 €

4

Fernbedienung

Remote control

Art.-Nr. / Art.-No.

R154-4. . . . . . . . . . . . . . . . . . . . . 48,00 €

Steuerungsplatine

Mainboard

Art.-Nr. / Art.-No.

R154-11. . . . . . . . . . . . . . . . . . . 132,00 €

Antriebsmotor mit Halteblech, Zahnrad

und Kabel

Driving motor with stabilizing board, gear

and cable

Art.-Nr. / Art.-No.

R154-12. . . . . . . . . . . . . . . . . . . . 98,00 €

Lichtschranke

Light barrier

Art.-Nr. / Art.-No.

R154-13. . . . . . . . . . . . . . . . . . . . 32,00 €

5

Batteriedeckel

Batteriy cover

Art.-Nr. / Art.-No.

R154-10. . . . . . . . . . . . . . . . . . . . . 6,70 €

Nivelliermotor, links

X-leveling motor

Art.-Nr. / Art.-No.

R154-14. . . . . . . . . . . . . . . . . . . . 46,00 €

Nivelliermotor, rechts

Y-leveling motor

Code 25PM15-02-SZ

Art.-Nr. / Art.-No.

R154-15. . . . . . . . . . . . . . . . . . . . 46,00 €

Nivelliermotor

leveling motor

Code 2510-02-SZ2

Art.-Nr. / Art.-No.

R154-19. . . . . . . . . . . . . . . . . . . . 46,00 €

Pendel mit Prisma, Befestigungsring,

Rasterscheibe, Tilt-Sensor

Pendulum with prism, ring holder, raster,

self-alarm PCB

Code FRE101-101-Pendulum

Art.-Nr. / Art.-No.

R154-16. . . . . . . . . . . . . . . . . . . 176,00 €

6

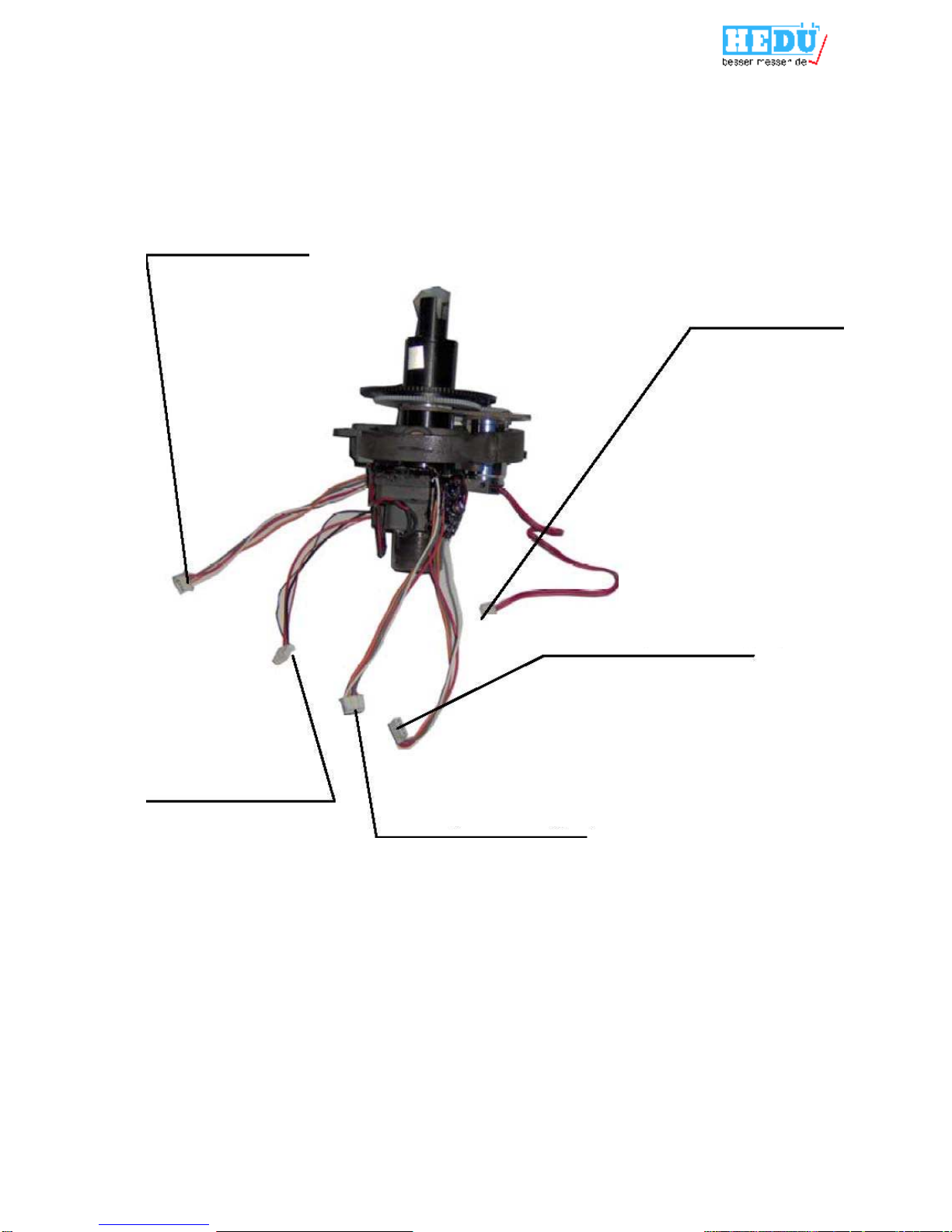

Anschluss Gehäuse Unterschale

Connection underpan

Anschluss Lichtschranke

Connection light barrier

Anschluss Tastatur

Connection panel main housing

Anschlussplan Hauptplatine

Mainboard connection guide

Vertikallibelle

Z-sensor socket

X-Nivelliermotor

X-leveling motor

Y-Nivelliermotor

Y-leveling motor

Rechte Libelle

X-sensor socket

Laser Anschluss

Laser power plug

Linke Libelle

Y-sensor socket

Anschluss Tilt

Selt-alarm PCB

Antriebsmotor

Driving motor

7

Y-axis sensor plug

driving motor plug

Z-axis sensor plug

X-axis sensor plug

laser power plug

Anschlussplan Pendel

Pendulum connection guide

8

Instrument Checking

(1)

(2)

(3)

(4)

Place the instrument at the point of 50m in front of wall (or set a scaleplate at the point of 50m away from

the instrument), and then adjust the level of the base approximately to aim the X1 to the wall (or scaleplate),

as depicted below:

After switching on the power, use the detector measuring the h1 of X1-beam on the wall or scaleplate.

Loose the screw of the tripod ,and then turn around the instrument 180°to measure the h2 of X2-beam on

the wall or scaleplate. D-value between h1 and h2 ought to be less the 10mm.

Check the Y-beam in the same way.

9

Level adjusting (old model)

(1)

(2)

(3)

(4)

(5)

If the D-value between h1 and h2 is more than 10mm, adjust the instrument as following steps:

Press the key ON/OFF when power indicator lights, automatic leveling of instrument starts up.

Press the key ïand ðsimultaneously for 3 seconds when undervoltage indicator winks, the instrument

enters mode of adjusting.

Press the key ïor ðof X-axis repeatedly and check the position of laser beam when undervoltage

indicator is winking till the D-value between h1 and h2 is less than 10mm.

Press the key ñor òof Y-axis repeatedly and check the position of laser beam when undervoltage

indicator is winking till the D-value between h1 and h2 is less than 10mm.

Press the key ñand òsimultaneously to hold the adjustment when undervoltage indicator goes out.

10

Level adjusting (new model)

Y-axis adjustment

(1)

(2)

(3)

(4)

X-axis adjustment

(1)

(2)

(3)

(5)

Note:

If the D-value between h1 and h2 is more than 10mm, adjust the instrument as following steps:

If the instrument is set horizontally, Y-axis adjustment stands for Z-axis adjustment.

Press the key ON/OFF when power indicator lights, automatic leveling of instrument starts up.

Press the key ïand ðsimultaneously for 3 seconds when mode indicator winks, the instrument enters

mode of adjusting.

Press the key ñor òof Y-axis repeatedly and check the position of laser beam when mode indicator is

winking till the D-value between h1 and h2 is less than 10mm.

Press the key ïand ðsimultaneously to hold the adjustment when mode indicator goes out.

Press the key ON/OFF when power indicator lights, automatic leveling of instrument starts up.

Press the key ïand ðsimultaneously for 3 seconds when undervoltage indicator winks, the instrument

enters mode of adjusting.

Press the key ïor ðof X-axis repeatedly and check the position of laser beam when undervoltage

indicator is winking till the D-value between h1 and h2 is less than 10mm.

Press the key ñand òsimultaneously to hold the adjustment when undervoltage indicator goes out.

If canceling the adjustment, please shut off the instrument and then turn on it.

If the adjusting range exceed range permitted, the power indicator will wink.

11

12

Malfunctions & Eliminations (Rotary Laser)

Failures in starting up

Symptoms

After pressing the Key ON/OFF, power indicator can’t light and also the

instrument doesn’t start up.

Causesa. Poor contact of keys on the panel or panel plug.

b. Poor contact of batteries or power plug, and insufficient power,

c. Troubles of PCB

Eliminations

a. Take off the shell,and renew the panel or connect the power plug with PCB well.

b. Take down the cover of battery case to check whether there are some

dirt or rust between the spring and spring strip,and clear off them if it is

true;Recharge the batteries till power is sufficient and then detach

the shell to connect the power plug with PCB well.

c. Detach the shell to change the PCB.

No spinning of laser head.

Symptoms

The laser beam is being emitted but the laser head doesn’t rotate after instrument

is power on.

Causes

a. Center to center distance of gear is not suitable,gearing is abnormal.

b. Troubles of scanning motor.

c. Laser head has touched the optical coupler.

d. Troubles of PCB.

Eliminations

a. Take off the shell to readjust the center-to-center distance of the gear.

b. Change the scanning motor after taking off the shell.

c. Detach the shell to readjust the space between laser head and optical coupler.

d. Change the PCB.

Malfunctions & Eliminations (Laser Detector)

No responses of detector

Symptoms

Press the Key ON/OFF, the LCD doesn’t display.

Causes

a. Install the batteries according to the wrong electrode.

b. Panel plug drops out.

Eliminations

a. Take off the cover of battery case to install the batteries correctly.

b. Detach the panel cover of detector to insert the plug again.

No sound of buzzer.

Symptoms

There is no sound of buzzer after pressing any keys on the panel.

Causes

Buzzer plug drops out.

Eliminations:

Connect the buzzer plug with the PCB well.

13

Top Cover Set

14

Housing Set

15

Undperpan Set

16

Pendulum

Y-sensor X-sensor

Z-sensor

17

Other manuals for FRE201

1

This manual suits for next models

1

Table of contents

Other HEDÜ Laser Level manuals