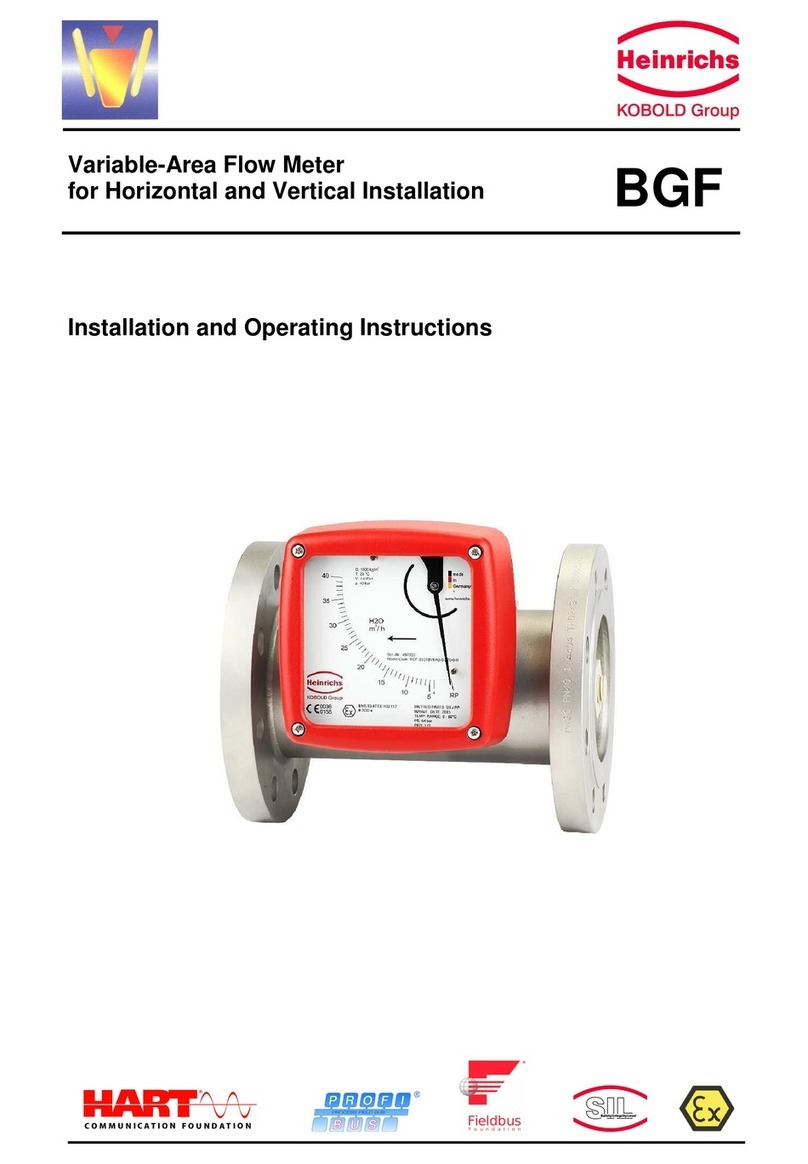

Heinrichs Messtechnik BGF Installation and Operating Instructions

10 Indicator unit

- Analog indicator approx. 90° with pointer

- Customized product scale

- ES transmitter with freely programmable user interface

- Parameters may be changed based on the ES

Operating Instructions.

11 Auxiliary power

see Electrical connection

12 CE mark

The measuring system meets the statutory requirements of

the following EU directives: Directive 94/9/EC (Equipment

and Protective Systems for Use in Potentially Explosive

Atmospheres), the Electromagnetic Compatibility (EMC)

Directive 89/336/EEC and the Pressure Equipment Directive

97/23/EC.

Heinrichs Messtechnik confirms compliance with the

directives by attaching the CE mark.

13 Order information

Please include the following information in your order:

product data, specific weight, temperature, pressure,

viscosity, material design, connection size, measuring range,

direction of flow, desired accessories, required approvals

and material certificates. See Device selection by model

code.

13.1 Available accessories

- Stainless steel indicator unit, glass window IP 66

- Indicator unit for high or low temperatures pulled

forward by 100 mm

- Fitting with heating or cooling jacket (with Ermeto or

flange connection)

- 1 or 2 inductive limit transducers

- KINAX or ES electric transmitter

- Drainable fitting (pump has been disconnected)

- Magnetic filter

- PROFIBUS PA

14 Standards and directives,

certificates and approvals

- Certified to DIN-EN 9001

- Production in accordance with AD guidelines and HPO

approval (TRB200/TRD201)

- TÜV approval for welding requirements in accordance

with DIN-EN 729-2

- Measuring range rated and converted to other products

according to VDE/VDI guidelines 3513

- Directive 94/9/Ec (Equipment and Protective Systems

for Use in Potentially Explosive Atmospheres)

- EN 50014:1997+A1-A2 - General requirements

- EN 50020:1994 - Intrinsic safety “i”

- Directive 89/336/EEC (EMC Directive)

- EN 61000-6-2:1999 – Immunity industrial environment

- EN 50 081-1 – Emitted interference residential

environment

- EN 55011:1998+A1:1999 – Group 1, Class B

- NAMUR recommendation NE 21

- EN 60529 – Degrees of protection through housing (IP

code)

- EN 61010 – Safety requirements for electrical

measuring, control and laboratory devices

- EN 60947-5-6:2000 – Switchgear and controlgear

- Directive 97/23/EC (Pressure Equipment Directive)

15 Safety instructions

15.1 Intended use

The BGF variable-area flowmeter may be used only for flow

measurements of fluid and gaseous media. The

manufacturer shall not be liable for damages that may result

from unintended or inappropriate use.

When dealing with an aggressive medium, clarify the

material durability of all wetted parts.

When using the device in hazardous areas, follow the

applicable national installation rules.

15.2 Installation, start-up and operating personnel

Only trained specialists authorized by the system operator

may carry out the installation, electrical installations, start-up,

maintenance and operation. They must read and

understand the operating manual and follow its instructions.

The required mounting, electrical installation, start-up and

maintenance work may only be carried out by expert and

authorized persons designated by the plant operator.

Basically, follow the conditions and provisions applicable in

your country.

16 Packaging, mounting and

shipment

Carefully unpack the device to avoid damaging it.

The operability of the measuring cell can be tested by

pressing the measuring body upwards in the direction of flow

using, for example, a wooden stick. The pointer position of

the indicator mechanism must follow the direction of

movement. The resetting spring resets the pointer back to

zero after the magnet carriers are released.

With the help of the delivery note enclosed in the packaging,

check whether all technically relevant data coincide with your

requirements.

Storage and installation must be done in a clean and dry

room so that contamination – especially of the interior of the

fitting – is avoided. Follow the limit values for ambient

temperature. When transporting the device to a remote

mounting location, we recommend that you reuse the

factory-issued packaging and the transport protection.

17 Maintenance

The device requires no maintenance if used according to its

intended purpose. However, if cleaning is necessary to

remove dirt from the measuring ring or the measuring body,

take note of the following aspects:

- Please take note that, with devices with built-in

electrical equipment, removing the indicator cover

restricts the EMC protection.

- Before removing a device, make sure that the pipeline

is free from the product, is pressureless and has cooled

down.

- Fittings with the insides coated may be carefully

cleaned after removal with a brush and the appropriate

cleansing agent. Carefully clean the measuring body

from possible coating. Attention: do not use the

measuring ring/cone and the measuring body with hard

objects (see Removing/installing the measuring body).

- The switching points of the limit transducers are

adjustable. To do this, remove the indicator cover,

unfasten the contact point indicator located on the scale

and readjust it. After the adjustment, reattach the bolts

Page 18 of 29