Heinrichs TMU User manual

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

May 2021

Coriolis Mass Flow Meter

TMU

2nd Generation

Installation and operation manual with UMC3

Please read the instructions carefully and store them in a safe place

Heinrichs Messtechnik GmbH

Page 2 of 122

OPERATING MANUAL TMU / UMC3

Contents

INTRODUCTION................................................................................................................................5

I. Shipping and storage; product inspection................................................................................................ 5

II. Warranty ................................................................................................................................................. 5

III. Maintenance, Repair and Hazardous substances..................................................................................... 5

IV. Disposal ................................................................................................................................................... 5

V. Supplementary operating instructions..................................................................................................... 5

VI. Operating manual of explosion-proof flowmeters................................................................................... 5

1. IDENTIFICATION......................................................................................................................5

2. STEPS PRIOR TO OPERATION...................................................................................................7

2.1 Safety advisory for the user ..................................................................................................................... 8

2.2 Hazard warnings ...................................................................................................................................... 8

2.3 Proper use of the device .......................................................................................................................... 9

2.4 Installation and servicing......................................................................................................................... 9

2.5 Returning your flowmeter for servicing or calibration ............................................................................10

2.6 Replacement of the transmitter electronics............................................................................................10

2.7 Maintenance...........................................................................................................................................11

Transmitter.............................................................................................................................................. 11

Coriolis mass flow sensor ........................................................................................................................11

3. THE TMU SENSOR .................................................................................................................12

3.1 Application domain of the TMU sensor...................................................................................................12

3.2 Mode of operation..................................................................................................................................12

Measuring principle ................................................................................................................................12

System configuration ..............................................................................................................................12

Acquisition............................................................................................................................................... 12

3.3 Performance characteristics of the TMU sensor......................................................................................13

Reference conditions .............................................................................................................................. 13

TMU flow ranges .....................................................................................................................................13

Density measurement.............................................................................................................................14

Accuracy ..................................................................................................................................................15

Pressure loss TMU...................................................................................................................................16

Environmental Conditions....................................................................................................................... 17

3.4 Operating conditions ..............................................................................................................................18

Installation...............................................................................................................................................18

Installation Orientation ...........................................................................................................................19

Pressure surges .......................................................................................................................................21

Using the device with hazardous fluids...................................................................................................21

Vibration stability .................................................................................................................................... 22

Process conditions................................................................................................................................... 22

Gas content .............................................................................................................................................22

Process pressure range ...........................................................................................................................23

Outlet pressure .......................................................................................................................................23

Connection to the transmitter ................................................................................................................23

3.5 Construction details................................................................................................................................24

Dimensions and weight...........................................................................................................................24

Dimensions of the sensor types TMU 006 to TMU 050 ..........................................................................26

Dimensions of the sensor types TMU 080 to TMU 300 ..........................................................................28

Dimension drawings for sensors with heating ........................................................................................31

Material...................................................................................................................................................32

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 3 of 122

4. UMC3 TRANSMITTER ............................................................................................................33

4.1 Application domain of the UMC3 transmitter.........................................................................................33

4.2 Mode of Operation.................................................................................................................................33

4.3 System configuration..............................................................................................................................33

4.4 UMC3 performance characteristics.........................................................................................................33

4.5 Operating conditions ..............................................................................................................................34

Installation conditions and cable glands ................................................................................................. 34

NPT cable glands ..................................................................................................................................... 34

Environmental conditions .......................................................................................................................35

Process conditions................................................................................................................................... 36

4.6 DSB data memory module......................................................................................................................36

4.7 Input measured variables .......................................................................................................................37

Measured Values.....................................................................................................................................37

Measuring range .....................................................................................................................................38

4.8 Outputs ..................................................................................................................................................38

Output circuits......................................................................................................................................... 38

Current outputs.......................................................................................................................................39

4.9 Construction details UMC3 .....................................................................................................................41

Mounting / Dimensions...........................................................................................................................41

Weight.....................................................................................................................................................42

Material...................................................................................................................................................42

5. ELECTRICAL CONNECTIONS UMC3........................................................................................43

5.1 Mains connections and their protection classes......................................................................................43

Wiring diagrams ......................................................................................................................................43

The output terminals............................................................................................................................... 44

Sensor connection...................................................................................................................................46

6. CERTIFICATES AND APPROVALS ............................................................................................49

6.1 Conformity to CE Directives ....................................................................................................................49

6.2 Explosion protection...............................................................................................................................49

6.3 Custody transfer applications .................................................................................................................49

6.4 Patents ...................................................................................................................................................49

7. OPERATION...........................................................................................................................50

7.1 Control unit BE4......................................................................................................................................50

Introduction ............................................................................................................................................50

Operating modes.....................................................................................................................................51

Operator interface ..................................................................................................................................51

The keys and their functions ................................................................................................................... 52

Functional classes, functions and parameters ........................................................................................53

Heinrichs Messtechnik GmbH

Page 4 of 122

OPERATING MANUAL TMU / UMC3

7.2 UMC3 transmitter functional classes ......................................................................................................55

MEASURED VALUES functional class.......................................................................................................56

PASSWORD functional class .................................................................................................................... 61

COUNTER functional class.......................................................................................................................63

MEASUREMENT PROCESSING functional class........................................................................................ 65

FLOW functional class .............................................................................................................................68

DENSITY functional class ......................................................................................................................... 73

TEMPERATURE functional class...............................................................................................................80

PULSE OUTPUT functional class ..............................................................................................................83

STATUS functional class...........................................................................................................................86

CURRENT OUTPUTS functional class ....................................................................................................... 90

SIMULATION functional class .................................................................................................................. 95

SELF-TEST functional class.......................................................................................................................99

UMC3 TRANSMITTER SETTINGS functional class ..................................................................................102

SENSOR SETTINGS functional class........................................................................................................107

7.3 Density calibration................................................................................................................................110

Conditions .............................................................................................................................................110

Procedure..............................................................................................................................................110

8. TROUBLE SHOOTING...........................................................................................................112

8.1 Self-help Checklist.................................................................................................................................112

8.2 UMC3 transmitter error messages........................................................................................................113

Standard operating mode .....................................................................................................................113

Custody transfer mode..........................................................................................................................113

List of error messages ...........................................................................................................................113

8.3 Returning the Meter.............................................................................................................................117

Declaration of Decontamination...........................................................................................................118

9. DECLARATION OF CONFORMITY .........................................................................................119

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 5 of 122

Introduction

I. Shipping and storage; product inspection

Shipping and storage

The device is to be safeguarded against dampness, contamination (especially the inside of the flow meter),

impact and damage. Open the packaging with caution to prevent unintentional damage.

Adhere to the temperature limits during storage.

Product inspection

Upon receipt of the product, check the contents of the box and the product particulars against the

information on the delivery slip and order form so as to ensure that all ordered components have been

supplied. Notify us of any shipping damage immediately upon receipt of the product. Any damage claim

received at a later time will not be honoured.

II. Warranty

Your flowmeter was manufactured in accordance with the highest quality standards and was thoroughly

tested prior to shipment. However, in the event any problem arises with your device, we will be happy to

resolve the problem for you as quickly as possible under the terms of the warranty, which can be found in

the terms and conditions of delivery. Your warranty will only be honoured if the device was installed and

operated in accordance with the instructions for your device. Any mounting, commissioning and/or

maintenance work is to be carried out by qualified and authorized technicians only.

III. Maintenance, Repair and Hazardous substances

When used in the intended manner no special maintenance is required. However, the flowmeter should be

checked within the context of routine maintenance of the facility and the pipelines. Should a repair,

calibration or maintenance become necessary, be sure to clean the device thoroughly and follow the steps in

section 8.3, “Returning the Meter” before returning the device to Heinrichs Messtechnik.

The operator is liable for any substance removal or personal damage costs arising from inadequate cleaning

of a device sent for repair.

IV. Disposal

Observe the regulations applicable to disposal in the country of installation!

V. Supplementary operating instructions

Supplement operating manuals are available for special features, interfaces and operations relating to your

device, request your copy from our service department.

VI. Operating manual of explosion-proof flowmeters

For installation of the flowmeter within hazardous areas read the operation manual of explosion-proof

flowmeters. It contains all the EX-relevant information for your flowmeter.

Warning!

Only devices designated as EX-certified on their rating plates may be used in areas of

potentially explosive atmospheres!

The use of standard equipment in EX-hazardous areas is strictly prohibited.

Heinrichs Messtechnik GmbH

Page 6 of 122

OPERATING MANUAL TMU / UMC3

1. Identification

Manufacturer:

Heinrichs Messtechnik GmbH

Robert-Perthel-Strasse 9

D-50739 Cologne

Germany

Product type:

Mass flow-rate meter for liquid and gaseous products

Product name:

Sensor type: TMU 2nd Generation

Transmitter type: UMC3

File name:

tmu_umc3_ba_21.02_en.docx

Version:.

21.02, dated, 19 May 2021

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 7 of 122

2. Steps prior to operation

It is essential that you read these operating instructions before installing and

operating the device. The device is to be installed and serviced by a qualified

technician only. The UMC transmitter is to be used exclusively to measure mass

and volume flow, as well as liquid and gas density and temperature, in conjunction

with a Heinrichs Messtechnik TM, TME, TMR, TMU, TM-SH or HPC sensor.

Downloading of the present document from our web site www.heinrichs.eu and printing out this

document is allowed only for the purposes of using our mass flowmeters. All rights reserved. No

instructions, wiring diagrams, and/or supplied software, or any portion thereof, may be produced, stored,

in a retrieval system or transmitted by any means, electronic, mechanical, photocopying or otherwise,

without the prior written permission of Heinrichs Messtechnik GmbH.

Although the materials in the present document were prepared with extreme care, errors cannot be

ruled out. Hence, neither the company, the programmer nor the author can be held legally or otherwise

responsible for any erroneous information and/or any loss or damage arising from the use of the

information enclosed.

Heinrichs Messtechnik GmbH extends no express or implied warranty concerning the applicability of the

present document for any purpose other than that described.

We plan to optimize and improve the products described and in so doing will incorporate not only our

own ideas but also, and in particular, any suggestions for improvement made by our customers. If you

feel that there is any way in which our products could be improved, please send your suggestions to the

following address:

Company:

Heinrichs Messtechnik GmbH

HM-EE (R&D Department)

Robert-Perthel-Strasse 9

D-50739 Cologne

Germany

or:

via fax : +49 (221) 49708-178

Note:

We reserve the right to change the technical data in this manual in the light of any

technical progress that might be made.

For updates regarding this product, visit our website at www.heinrichs.eu, where you

will also find contact information for the Heinrichs Messtechnik distributor nearest you.

For information regarding our own sales operations, contact us at info@heinrichs.eu.

Heinrichs Messtechnik GmbH

Page 8 of 122

OPERATING MANUAL TMU / UMC3

Safety advisory for the user

The present document contains the information that you need in order to operate the product described

herein properly. This document is intended for use by qualified personnel. This means personnel who are

qualified to operate the device described herein safely, including:

electronics engineers,

electrical engineers, or

service technicians

who are conversant with the safety regulations pertaining to the use of electrical and automated

technical devices and with the applicable laws and regulations in their own country.

Such personnel must be authorized by the facility operator to install, commission and service the product

described herein, and must have read and understood the contents of this operating instructions before

working with the device.

Hazard warnings

The purpose of the hazard warnings listed below is to ensure that device operators and maintenance

personnel are not injured and that the flow meter and any devices connected to it are not damaged.

The safety advisories and hazard warnings in the present document that aim to avoid placing operators

and maintenance personnel at risk and to avoid material damage are prioritized using the terms listed

below, which are defined as follows in regard to these instructions herein and the advisories pertaining

to the device itself.

Warning

means that failure to take the prescribed precautions could result in injury, substantial

material damage or even death. Always comply to these warnings and proceed with

caution.

Caution

means that failure to take the prescribed precaution could result in material damage or

destruction of the device. We advice always to abide to these instructions!

Note

means that the accompanying text contains important information about the product,

handling the product or about a section of the documentation that is of particular

importance.

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 9 of 122

Proper use of the device

The Coriolis Mass Flow Sensor is intended for the sole use of direct and continuous mass flow

measurement of liquids and gases.

To ensure safety for people and the environment adhere to the installation and operational instructions

and warning in this manual.

Warning

The operator is responsible for ensuring that the material used in the sensor and

housing are suitable and that such material meets the requirements for the process

medium and the ambient site conditions.

The manufacturer accepts no responsibility for the selection of unsuitably materials.

Warning

Only sensors marked as EX-certified on their rating plates may be used in EX hazardous

locations. Standard equipment is not permitted for installation and use in EX hazardous

locations.

For installation within hazardous areas read the Ex-supplementary manual. It contains

all EX-relevant parameters for the sensor and the UMC transmitter.

Caution

To ensure the device performs correctly and safely, it must be shipped, stored, set up,

mounted, operated and maintained correctly.

Installation and servicing

The devices described in this manual are to be installed and serviced only by qualified technical

personnel such as a qualified Heinrichs Messtechnik electronics engineer or service technician.

Warning

Before servicing, the device must be completely de-energised and disconnected from all

peripheral devices. The technician must also ensure that the device is completely

disconnected from any live circuits.

Only original replacement parts are to be used.

Heinrichs Messtechnik GmbH accepts no liability for any loss or damage of any kind arising from

improper operation of any product, improper handling or use of any replacement part, or from

external electrical or mechanical effects, overvoltage or lightning. Any such improper operation, use

or handling shall automatically invalidate the warranty for the product concerned.

In the event a problem arises with your device, or if you need assistance in diagnosing a problem with

your device, please contact us at one of the following numbers to arrange to have your device repaired:

+49 (0)221 49708-0 +49 (0)221 49708-178

Heinrichs Messtechnik GmbH

Page 10 of 122

OPERATING MANUAL TMU / UMC3

Returning your flowmeter for servicing or calibration

Before sending your flowmeter back to us, for servicing or calibration, make sure it is completely clean.

Any residues of substances that could be hazardous to the environment or human health are to be

removed from all crevices, recesses, gaskets, and cavities of the housing before the device is shipped.

Warning

The operator is liable for any loss or damage of any kind, including personal injury,

decontamination measures, removal operations and the like that are attributable to

inadequate cleaning of the device.

Any device sent in for servicing is to be accompanied by a declaration of

Decontamination, a template of which is provided in section 8.3.1!

When returned, the device is to be accompanied by a document describing the problems encountered.

Please include in this document the name of a contact person whom our technical service department

can contact to enable us to repair your device as expeditiously as possible and minimize the repair costs.

Replacement of the transmitter electronics

Before replacing the transmitter electronics, read the safety instructions in Section 2.3, “Installation and

servicing” on page 9.

The data memory chip (DSB) with the calibrating data of the sensor is an integral component of the

transmitter. Removal and installation of the DSB is described in chapter 4.6, “DSB data memory module”

on page 36.

Should an exchange of the transmitter electronics become necessary, it is essential that the whole

electronic stack is replaced. This comprises of all circuit boards in the electronic compartment and in the

terminal compartment. The overall accuracy of the measurement up to the analogous outputs can only

be guaranteed when all circuit boards are replaced. Only the control unit with the integrated memory for

the calibrating data of the sensor shall remain with the device.

Caution

The complete stack is to be replaced with all of its printed circuit boards (with the

exception for the display unit containing the memory module). This is particularly

important for the explosion-proof transmitter. The specified precision of the

electronics is only guaranteed if the complete stack is replaced.

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 11 of 122

Maintenance

Transmitter

The transmitter is maintenance-free.

We recommend cleaning the viewing-glass of the transmitter at regular intervals; check the enclosure for

corrosion damages and the solid seat of the cable glands.

Warning!

In the event an enclosure lid O-ring gasket is damaged, humidity may enter the

enclosure and cause damage to the internal electronic circuits.

Indications of such are:

Visible discolouration’s or condensation on the viewing-glass of the transmitter,

corrosion damages to the enclosure

Coriolis mass flow sensor

The sensor is largely maintenance-free. When handled correctly its functionality will only be impaired by

corrosion or deposits inside of the measuring tubes. Therefore, both should be implicitly avoided. Remove

deposits in the tubes and in or around the splitter on a regularly basis by means of a suitably washing

method. Failure to do so may result in a loss of measurement precision.

Warning!

In the event of a tube rupture, e.g. due to corrosion or damage, medium will leak into

and fill the enclosures body, which can lead to subsequent damage to the external

housing, particularly at high process pressures!

Heinrichs Messtechnik GmbH

Page 12 of 122

OPERATING MANUAL TMU / UMC3

3. The TMU sensor

Application domain of the TMU sensor

The TMU sensor is intended for use solely for direct and continuous mass flow measurement of liquids and

gases, irrespective of their conductivity, density, temperature, pressure, or viscosity.

The sensor can be utilised for the direct and continuous mass flow measurement of chemical fluids,

suspensions, molasses, paint, varnish, lacquer, pastes and similar materials.

Mode of operation

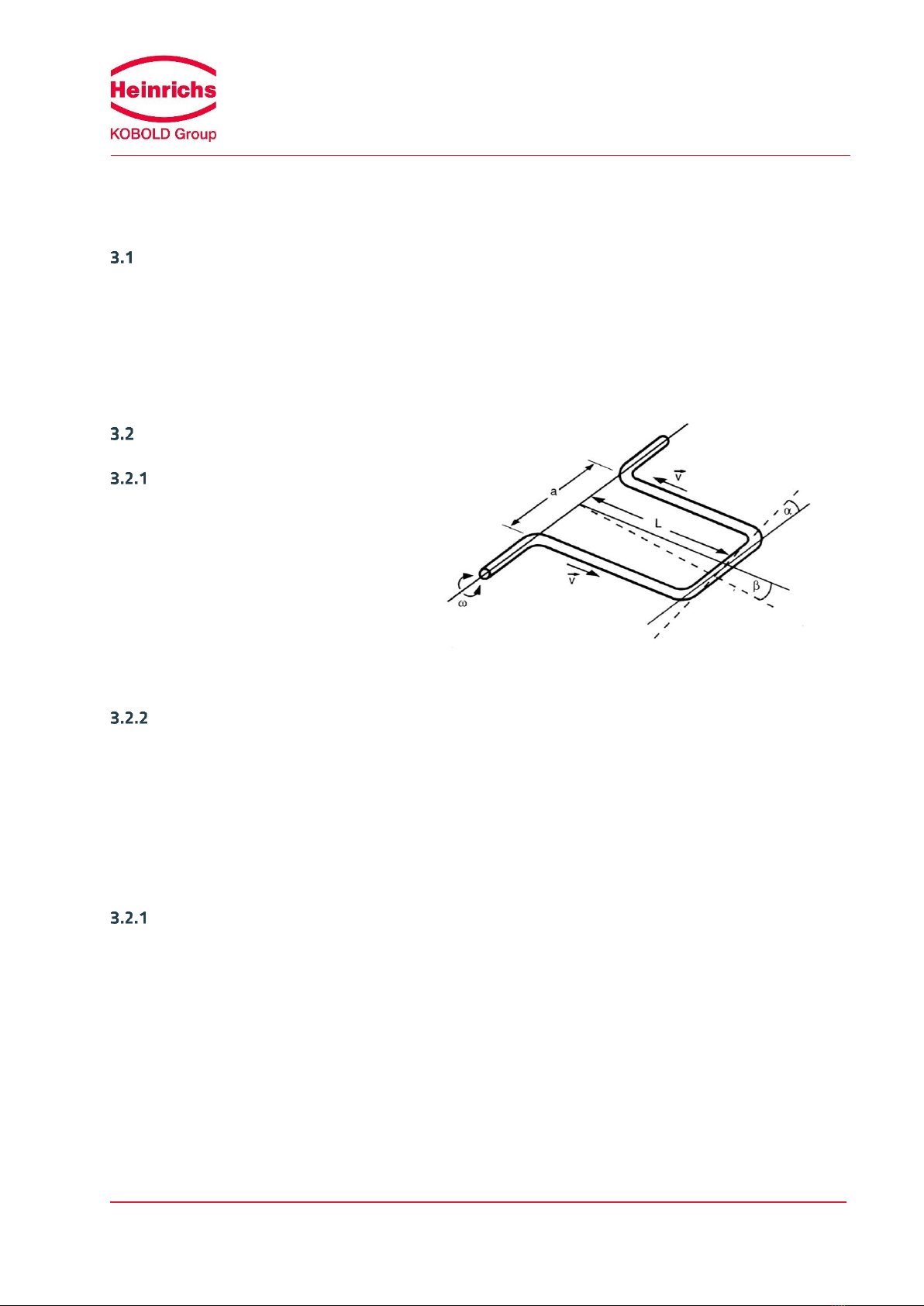

Measuring principle

The Coriolis mass flowmeter is based on the

principle whereby in a rotating system a force

(known as the Coriolis force) is exerted on a

mass at a rotation point that is moving towards

or away from this point.

System configuration

The flowmeter consists of a sensor that is mounted in a pipe, and a transmitter (see Section 4.1 Application

domain of the UMC3 transmitter on page 33), that can be directly mounted on the sensor or installed

separately (e.g. on a wall).

The transmitter oscillates the flow tubes in the sensor over an excitation coil and picks up, via the sensor coil,

the measuring signal, which is proportional to the mass flow. After being temperature compensated, the

measuring signal is converted into an analog output signal that is consistent with the measuring range setting.

Acquisition

Measured variables: Mass flow,

Density,

Temperature

Calculated variables: Volume flow

mFC2

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 13 of 122

Performance characteristics of the TMU sensor

Reference conditions

Established flow profile

Inlet section has to correspond to mounting length

Control valves always positioned downstream

Measurement is to be performed with a liquid containing no gas bubbles

Flow tubes are to be kept clean at all times

Process temperature is to be regulated as specified in Section 3.4.6, “Process conditions” on page 22

Process pressure is to be regulated as specified in Section 3.4.8, “Process pressure range” on page 23

Ambient temperature is to range from + 10 °C to + 30 °C (50 °F to 86 °F)

Warm-up period: 15 minutes

Standard calibration is to be performed at 20 %, 50 % and 100 % (two times each)

High-frequency interference is to be regulated according to the EMC standards stated in section 9,

“Declaration of Conformity” on page 119

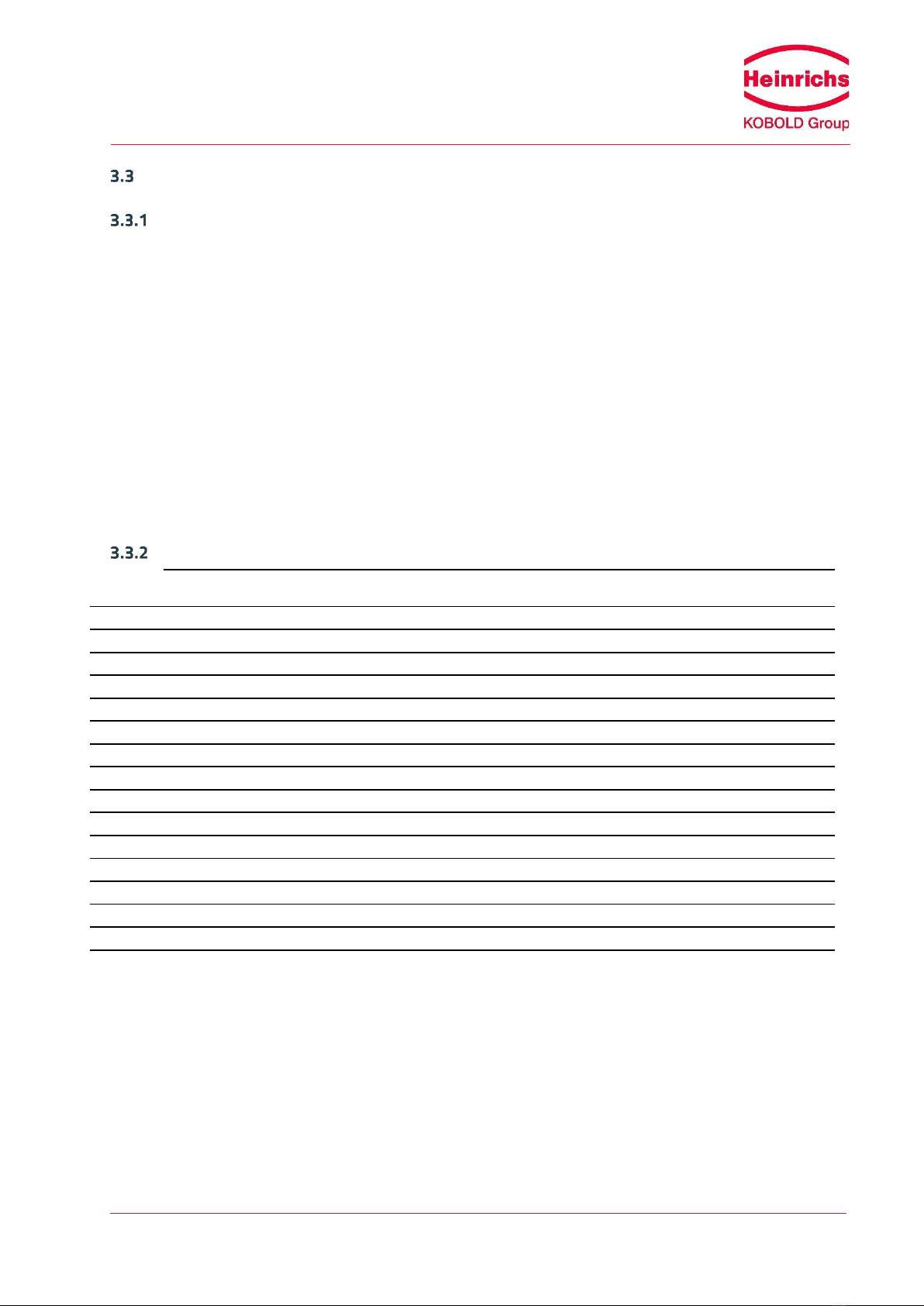

TMU flow ranges

Model kg/h [lbs/min] kg/h [lbs/min] kg/h [lbs/min] kg/h [lbs/min]

TMU-x008 60 [2,2] 600 [22,0] 330 [12,1] 0,03 [0,001]

TMU-x010 250 [9,2] 2500 [91,9] 1150 [42,3] 0,125 [0,005]

TMU-x012 800 [29,4] 8.000 [293,9] 3.650 [134,1] 0,4 [0,015]

TMU-x015 1200 [44,1] 12000 [440,9] 5250 [192,9] 0,6 [0,022]

TMU-x020 2.500 [91,9] 25.000 [918,6] 14.250 [523,6] 1,25 [0,046]

TMU-x025 3000 [110,2] 30000 [1102,3] 20000 [734,9] 1,5 [0,055]

TMU-x040 6000 [220,5] 60000 [2204,6] 55000 [2.020,9]* 3[0,110]

TMU-x050 20000 [734,9] 80000 [2939,4] 74000 [2.719,0] 4[0,147]

TMU-x080 25000 [918,6] 120000 [4409,2] 118000 [4.335,7]** 12 [0,4]

TMU-x100 30000 [1102,3] 200000 [7348,6] 200000 [7.348,6]*** 20 [0,7]

TMU-x150 60000 [2204,6] 460000 [16901,8] 460000 [16.901,8]*** 46 [1,7]

TMU-x200 150000 [5511,5] 700000 [25720,2] 700000 [25.720,2]**** 70 [2,6]

TMU-x250 300000 [11022,9] 1500000 [55114,6] 1350000 [49.603,2] 150 [5,5]

TMU-x300 400000 [14697,2] 2200000 [80834,8] 1900000 [69.811,9] 220 [8,1]

* (Dp=0,87bar)

** (Dp=0,95bar)

*** (Dp=0,93bar)

**** (Dp=0,66bar)

Zero point stability

(of range)

Max.

measuring range

Nominal

(Dp=1bar)

Min.

measuring range

Table 1: Flow ranges

Reference conditions: in conformity with IEC 770:

Temperature: 20 °C, relative humidity: 65 %, air pressure: 101.3 kPa

Fluid: water

Heinrichs Messtechnik GmbH

Page 14 of 122

OPERATING MANUAL TMU / UMC3

Density measurement

The attainable accuracy depends on the type of performed density calibration, selected during the ordering

process.

Note:

Without calibration no density measurement is possible and the empty pipe

recognition is not available.

Model without Calibration 3-Point 5-Point

TMU-x008 5 g/l 2 g/l

TMU-x010 5 g/l 2 g/l

TMU-x012 5 g/l 1 g/l

TMU-x015 5 g/l 1 g/l

TMU-x020 5 g/l 1 g/l

TMU-x025 5 g/l 1 g/l

TMU-x040 5 g/l 1 g/l

TMU-x050 5 g/l 2 g/l

TMU-x080 5 g/l 2 g/l

TMU-x100 5 g/l 2 g/l

TMU-x150 5 g/l 2 g/l

TMU-x200 5 g/l 2 g/l

TMU-x250 5 g/l 2 g/l

TMU-x300 5 g/l 2 g/l

Density accuracy

No

Density

measurement

possible

Table 2: Density accuracy

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 15 of 122

Accuracy

Mass flow

Fluids

Accuracy TMU-x008 bis TMU-x050

± 0.1 % of actual flow ± zero point stability (1)

Accuracy TMU-x080 bis TMU-x300

± 0.15 % of actual flow ± zero point stability (1)

Repeatability error

± 0.05 % of actual flow (sensor with transmitter) ± ½ zero point

stability (1)

Mass flow

Gases

Accuracy TMU-x008 bis TMU-x050

± 0.5 % of actual flow ± zero point stability (1)

Accuracy TMU-x080 bis TMU-x300

± 0.5 % of actual flow ± zero point stability (1)

Repeatability error

± 0.25 % of actual flow (sensor with transmitter) ± ½ zero point

stability (1)

Additional measured values

Volume flow

± 0.2 % of actual value + zero point stability

Temperature

± 0.5 °C

Hysteresis

Not applicable

Settling time

1 to 15 seconds

Startup drift

15 minutes

Long-term drift

± 0.02 % of upper-range value per year

Influence of ambient temperature

± 0.005 % per K

Influence of fluid temperature

Compensated

Influence of fluid pressure

For fluids: too small to be relevant

(1) Refer to section 3.3.2, “TMU flow ranges” for detailed information on flow ranges.

Table 3: Measurement Deviation

Heinrichs Messtechnik GmbH

Page 16 of 122

OPERATING MANUAL TMU / UMC3

Pressure loss TMU

Model

Min.

measuring range

Max.

measuring range

60 kg/h 150 kg/h 300 kg/h 450 kg/h 600 kg/h

0,03 bar 0,15 bar 0,55 bar 1,18 bar 2,01 bar

250 kg/h 625 kg/h 1250 kg/h 1875 kg/h 2500 kg/h

0,05 bar 0,28 bar 1,02 bar 2,20 bar 3,78 bar

800 kg/h 2000 kg/h 4000 kg/h 6000 kg/h 8000 kg/h

0,05 bar 0,29 bar 1,06 bar 2,32 bar 4,02 bar

1200 kg/h 3000 kg/h 6000 kg/h 9000 kg/h 12000 kg/h

0,05 bar 0,29 bar 1,08 bar 2,38 bar 4,16 bar

2500 kg/h 6250 kg/h 12500 kg/h 18750 kg/h 25000 kg/h

0,04 bar 0,21 bar 0,84 bar 1,78 bar 3,29 bar

3000 kg/h 7500 kg/h 15000 kg/h 22500 kg/h 30000 kg/h

0,03 bar 0,16 bar 0,62 bar 1,38 bar 2,43 bar

6000 kg/h 15000 kg/h 30000 kg/h 45000 kg/h 60000 kg/h

0,01 bar 0,06 bar 0,23 bar 0,50 bar 0,89 bar

20000 kg/h 35000 kg/h 50000 kg/h 65000 kg/h 80000 kg/h

0,09 bar 0,22 bar 0,49 bar 0,73 bar 1,09 bar

25000 kg/h 48750 kg/h 72500 kg/h 96250 kg/h 120000 kg/h

0,05 bar 0,17 bar 0,36 bar 0,62 bar 0,95 bar

30000 kg/h 72500 kg/h 115000 kg/h 157500 kg/h 200000 kg/h

0,02 bar 0,13 bar 0,31 bar 0,58 bar 0,93 bar

60000 kg/h 160000 kg/h 260000 kg/h 360000 kg/h 460000 kg/h

0,02 bar 0,12 bar 0,30 bar 0,58 bar 0,93 bar

150000 kg/h 287500 kg/h 425000 kg/h 562500 kg/h 700000 kg/h

0,03 bar 0,11 bar 0,25 bar 0,43 bar 0,66 bar

300000 kg/h 600000 kg/h 900000 kg/h 1200000 kg/h 1500000 kg/h

0,05 bar 0,21 bar 0,47 bar 0,87 bar 1,30 bar

400000 kg/h 850000 kg/h 1300000 kg/h 1750000 kg/h 2200000 kg/h

0,05 bar 0,20 bar 0,47 bar 0,85 bar 1,34 bar

Model

Min.

measuring range

Max.

measuring range

2,2 lbs/min 5,5 lbs/min 11,0 lbs/min 16,5 lbs/min 22,0 lbs/min

0,03 bar 0,15 bar 0,55 bar 1,18 bar 2,01 bar

9,2 lbs/min 23,0 lbs/min 45,9 lbs/min 68,9 lbs/min 91,9 lbs/min

0,05 bar 0,28 bar 1,02 bar 2,20 bar 3,78 bar

29,4 lbs/min 73,5 lbs/min 147,0 lbs/min 220,5 lbs/min 293,9 lbs/min

0,05 bar 0,29 bar 1,06 bar 2,32 bar 4,02 bar

44,1 lbs/min 110,2 lbs/min 220,5 lbs/min 330,7 lbs/min 440,9 lbs/min

0,05 bar 0,29 bar 1,08 bar 2,38 bar 4,16 bar

91,9 lbs/min 229,6 lbs/min 459,3 lbs/min 688,9 lbs/min 918,6 lbs/min

0,04 bar 0,21 bar 0,84 bar 1,78 bar 3,29 bar

110,2 lbs/min 275,6 lbs/min 551,1 lbs/min 826,7 lbs/min 1102,3 lbs/min

0,03 bar 0,16 bar 0,62 bar 1,38 bar 2,43 bar

220,5 lbs/min 551,1 lbs/min 1102,3 lbs/min 1653,4 lbs/min 2204,6 lbs/min

0,01 bar 0,06 bar 0,23 bar 0,50 bar 0,89 bar

734,9 lbs/min 1286,0 lbs/min 1837,2 lbs/min 2388,3 lbs/min 2939,4 lbs/min

0,09 bar 0,22 bar 0,49 bar 0,73 bar 1,09 bar

918,6 lbs/min 1791,2 lbs/min 2663,9 lbs/min 3536,5 lbs/min 4409,2 lbs/min

0,05 bar 0,17 bar 0,36 bar 0,62 bar 0,95 bar

1102,3 lbs/min 2663,9 lbs/min 4225,5 lbs/min 5787,0 lbs/min 7348,6 lbs/min

0,02 bar 0,13 bar 0,31 bar 0,58 bar 0,93 bar

2204,6 lbs/min 5878,9 lbs/min 9553,2 lbs/min 13227,5 lbs/min 16901,8 lbs/min

0,02 bar 0,12 bar 0,30 bar 0,58 bar 0,93 bar

5511,5 lbs/min 10563,6 lbs/min 15615,8 lbs/min 20668,0 lbs/min 25720,2 lbs/min

0,03 bar 0,11 bar 0,25 bar 0,43 bar 0,66 bar

11022,9 lbs/min 22045,9 lbs/min 33068,8 lbs/min 44091,7 lbs/min 55114,6 lbs/min

0,05 bar 0,21 bar 0,47 bar 0,87 bar 1,30 bar

14697,2 lbs/min 31231,6 lbs/min 47766,0 lbs/min 64300,4 lbs/min 80834,8 lbs/min

0,05 bar 0,20 bar 0,47 bar 0,85 bar 1,34 bar

TMU-x250

11022,9 lbs/min

55114,6 lbs/min

TMU-x300

14697,2 lbs/min

80834,8 lbs/min

TMU-x150

2204,6 lbs/min

16901,8 lbs/min

TMU-x200

5511,5 lbs/min

25720,2 lbs/min

TMU-x080

918,6 lbs/min

4409,2 lbs/min

TMU-x100

1102,3 lbs/min

7348,6 lbs/min

TMU-x250

300000 kg/h

1500000 kg/h

TMU-x300

400000 kg/h

2200000 kg/h

TMU-x150

60000 kg/h

460000 kg/h

TMU-x200

150000 kg/h

700000 kg/h

TMU-x080

25000 kg/h

120000 kg/h

TMU-x100

30000 kg/h

200000 kg/h

TMU-x008

60 kg/h

600 kg/h

2500 kg/h

TMU-x010

250 kg/h

80000 kg/h

TMU-x050

20000 kg/h

60000 kg/h

TMU-x025

TMU-x040

6000 kg/h

3000 kg/h

30000 kg/h

2204,6 lbs/min

TMU-x040

220,5 lbs/min

TMU-x025

1102,3 lbs/min

110,2 lbs/min

918,6 lbs/min

TMU-x008

2,2 lbs/min

22,0 lbs/min

TMU-x010

9,2 lbs/min

91,9 lbs/min

440,9 lbs/min

TMU-x015

44,1 lbs/min

2939,4 lbs/min

Pressure loss [water (20°C), 1 mPas]

Pressure loss [water (20°C), 1 mPas]

TMU-x050

734,9 lbs/min

TMU-x012

29,4 lbs/min

293,9 lbs/min

TMU-x020

91,9 lbs/min

TMU-x012

800 kg/h

8000 kg/h

TMU-x020

2500 kg/h

25000 kg/h

12000 kg/h

TMU-x015

1200 kg/h

Table 4: Pressure losses

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 17 of 122

Environmental Conditions

Ambient temperature

−40 °C to + 60 °C (-40 °F to 140 °F), as special version up to 80 °C (176 °F).

Special cables and cable glands are required for temperatures below −20 °C (-4 °F) and above +70 °C (158 °F).

Storage temperature

−25 °C to + 60 °C (-13 °F to 140 °F), − 40 °C (-40°F) available as special version.

Climatic category

In conformity with IEC 654-1. Unsheltered class D locations with direct open-air climate.

Ingress protection

Sensor: IP 67 (NEMA 6), Transmitter: IP68 / 1 m for 24 hours (NEMA 6P) acc. to DIN EN 60529 with mounted

and sufficiently tightened approved cable glands.

Heinrichs Messtechnik GmbH

Page 18 of 122

OPERATING MANUAL TMU / UMC3

Operating conditions

Installation

The sensor is to be protected, wherever possible, against valves, manifolds and similar fittings that generate

turbulence. The sensor is to be installed in accordance with the following instructions.

Diagram showing flowmeter installation

Flowmeter installation: A = sensor, B = valve, C = pipe clamps and supports.

The sensor is not to be used to support a pipe or

other pipe components.

Do not install the sensor in suspended pipes.

Do not adjust the position of a pipe by pulling or

grasping the sensor.

Heinrichs Messtechnik GmbH

OPERATING MANUAL TMU / UMC3

Page 19 of 122

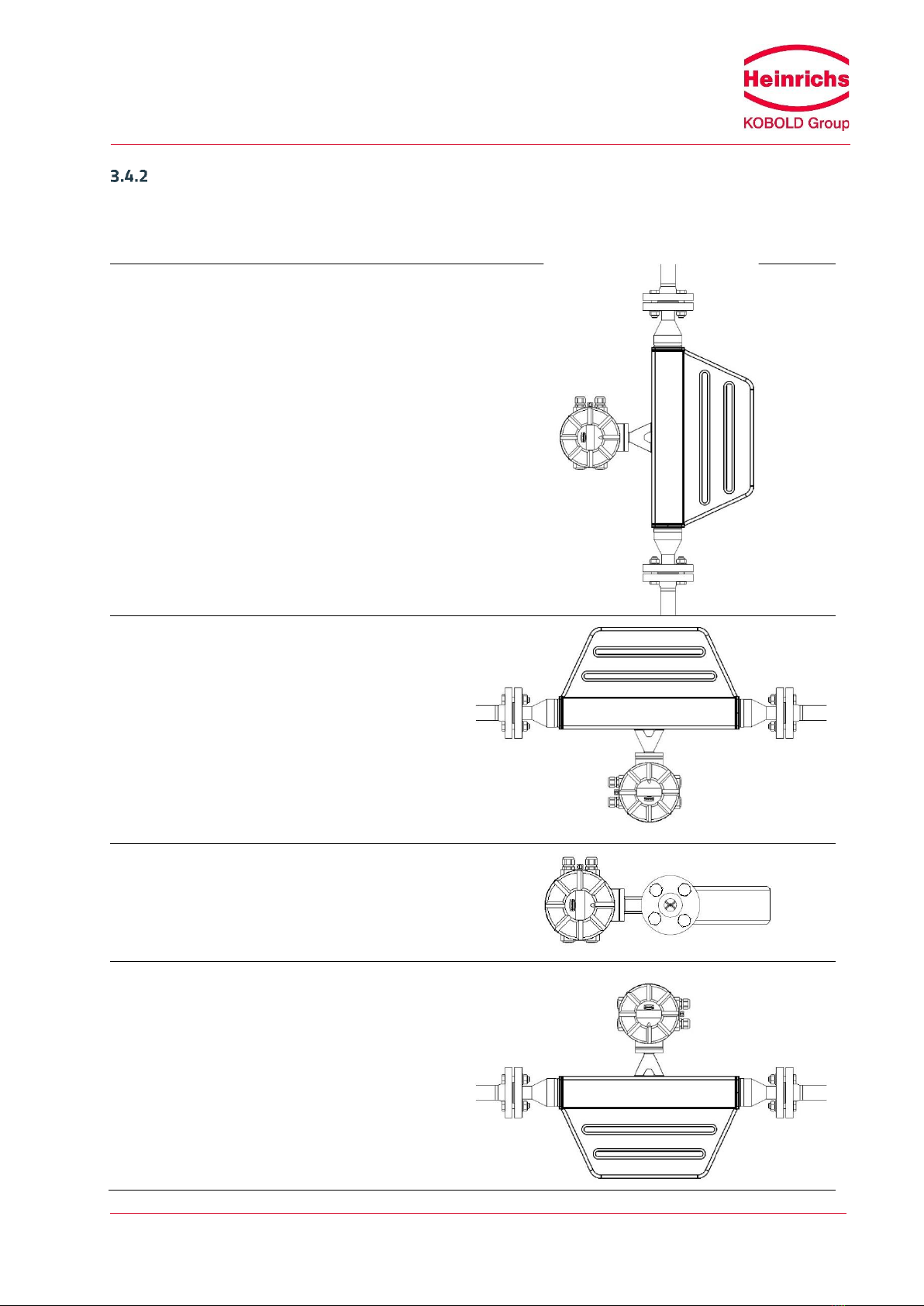

Installation Orientation

Without compromising its accuracy, the TMU can be installed and operated in various orientations. The

following representations show the most common installation positions and provide tips on how the operator

can prevent installation-related influences on the measurement.

Standard installation position

Installation position A

Installation position B

Installation position C

Heinrichs Messtechnik GmbH

Page 20 of 122

OPERATING MANUAL TMU / UMC3

Type of fluid

Position

Assessment

Pure liquids

Standard installation

position

Self-draining flow tubes

Position A or B

OK

Position C

Liquid residue remains in pipe

Liquids containing

homogeneously

dispersed gas

Standard installation

position

Self-draining flow tubes, gas bubbles do not accumulate in

flowmeter

Position A

Not recommended owing to gas bubble accumulation in

flowmeter

Position B

Gas bubbles may accumulate in the presence of low flow

velocities

Position C

No gas bubble accumulation in flowmeter, liquid residues

may remain in device after discharge

Liquids containing

substances that could

form deposits

Standard installation

position

Self-draining flow tubes, no deposit formation

Position A

OK

Position B

Substances in the liquid could form deposits at low flow

velocities

Position C

Not recommended owing to presence in flowmeter of

substances that could form deposits

Liquids containing

homogeneously

dispersed gas, which

may contain

substances that could

form deposits

Standard installation

position

Self-draining flow tubes, no accumulation of gases or

substances that could form deposits

Position A

Not recommended owing to gas bubble accumulation in

flowmeter

Position B

Gas bubbles or substances that could form deposits at low

flow velocities

Position C

Not recommended owing to presence in flowmeter of

substances that could form deposits

Gases that do not

form a condensate

Standard installation

position,

Position A, B or C

Any of these installations positions can be used

Gas, condensate-

forming gas/liquid,

moisture

Standard installation

position

Flow direction should be from top to bottom so that any

condensate that forms can flow out efficiently

Position A

OK

Position B

Condensate might form in flowmeter

Position C

Not recommended owing to condensate accumulation in

flowmeter

This manual suits for next models

14

Table of contents

Other Heinrichs Measuring Instrument manuals