Heinzmann Triton CPM 500 User manual

Copyright 2017 by Heinzmann GmbH & Co. KG. All rights reserved.

This publication may not be reproduced by any means whatsoever or passed on to any third parties.

8018 Manual SF 17 001-e / 05-17

Heinzmann GmbH & Co. KG

Engine & Turbine Management

Am Haselbach 1

D-79677 Schönau

Germany

Phone +49 7673 8208 - 0

Fax +49 7673 8208 - 188

E-mail info@heinzmann.de

www.heinzmann.com

V.A.T. No.: DE145551926

HEINZMANN

Engine & Turbine Management

Safety Systems

CPM 500

Electronic

Peak Pressure Indicator

Operating manual

Software Release l.0.7.8 2017-03-22

Contents

Page 2 of 46

Content

1Scope of supply ________________________________________________________ 4

2Important information __________________________________________________ 5

2.1 Use of the operator manual__________________________________________________5

3Description ___________________________________________________________ 6

3.1 Introduction ______________________________________________________________6

3.2 Measure functions _________________________________________________________6

3.3 Functional description______________________________________________________6

4Operation_____________________________________________________________ 7

4.1 Operator push buttons _____________________________________________________7

4.2 Operating functions________________________________________________________8

4.3 Installation of visualisation- and USB driver software____________________________9

4.4 Select COM port of PC _____________________________________________________9

4.5 Charge battery ___________________________________________________________10

4.6 Change battery___________________________________________________________11

4.7 Mounting instructions on marine engines _____________________________________11

4.8 Measuring with CPM 500 __________________________________________________12

5Visualisation software release 1.0.7.8 _____________________________________ 13

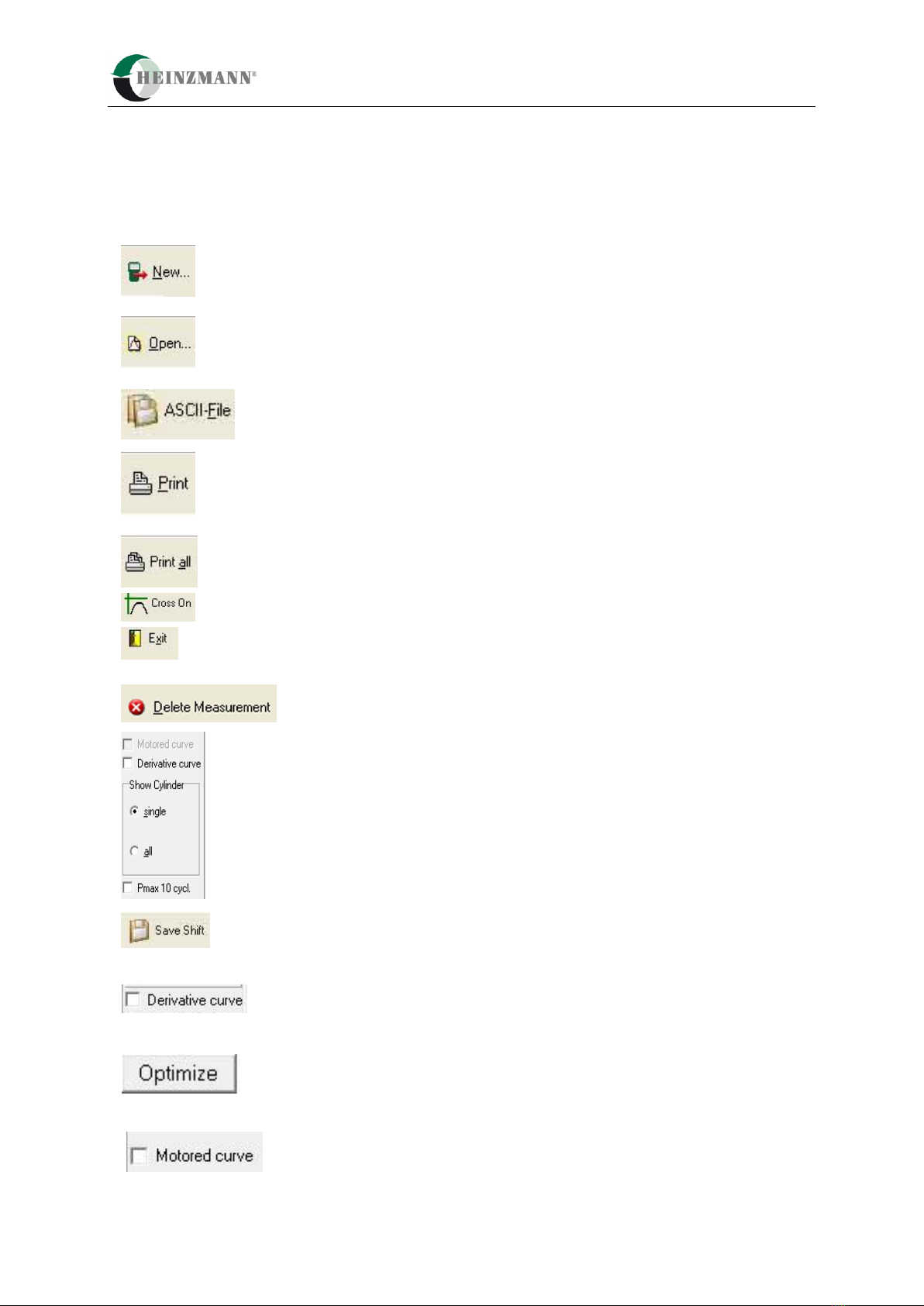

5.1 Main tool bar buttons _____________________________________________________13

5.2 Load measured data from CPM 500 to PC ____________________________________15

5.3 Load measured data from hard disc to PC ____________________________________15

5.4 Monitoring of combustion data _____________________________________________16

5.4.1 Screen page “Cylinder pressure curve” _____________________________________________16

5.4.1.1 Indication of all cylinders ___________________________________________________16

5.4.1.2 Cross On function _________________________________________________________17

5.4.1.3 Save to ASCII ____________________________________________________________18

5.4.1.4 Optimize function for application on two-strokes_________________________________18

5.4.1.5 Save Shift _______________________________________________________________20

5.4.1.6 Automatic Pcomp calculation on four-strokes ___________________________________21

5.4.1.7 Additional functions _______________________________________________________22

5.4.2 Screen page “Pmax diagram” _____________________________________________________23

5.4.3 Screen page “Engine report” _____________________________________________________23

5.4.4 Screen page “Pmax balance” _____________________________________________________24

5.4.5 Screen page “Remarks” _________________________________________________________24

5.4.6 Screen page “Engine data” _______________________________________________________24

5.5 Delete measurement on CPM 500 ___________________________________________24

5.6 Open *.csv files with Excel _________________________________________________25

5.7 620-66-002-00 IPOWER- and IMEP calculation _______________________________26

5.7.1 Overview of additional functions __________________________________________________26

5.7.1.1 Power calculation function __________________________________________________26

5.7.1.2 Indication of cylinder pressure (single) versus volume_____________________________28

Contents

Page 3 of 46

5.7.1.3 Indication of all cylinder pressure (all) versus crank angle__________________________28

5.7.2 Screen page “Pcomp Balance” ____________________________________________________29

5.7.3 Screen page “IMEP”____________________________________________________________29

5.7.4 Screen page “IMEP balance” _____________________________________________________30

5.7.5 Screen page “Engine data” _______________________________________________________30

5.7.6 Screen page “Engine report” _____________________________________________________31

5.7.7 Screen page “Trending” _________________________________________________________31

6Accuracy check _______________________________________________________ 33

6.1 Connection of CPM 500 to pressure calibrator_________________________________34

6.2 Generate pressure at pressure calibrator _____________________________________35

6.3 Example of displayed CPM 500 values during pressure check ____________________36

6.4 Disconnect CPM 500 from pressure calibrator_________________________________36

7Cleaning ____________________________________________________________ 37

7.1 Periodically cleaning ______________________________________________________37

7.2 Cleaning in case of hard deposit_____________________________________________37

7.3 Cleaning procedure of adaptor______________________________________________38

7.4 Cleaning procedure of cylinder pressure sensor _______________________________38

8Basic check for fault finding ____________________________________________ 39

9Nomenclature ________________________________________________________ 40

10 Technical data________________________________________________________ 41

11 Thomson Adapter _____________________________________________________ 42

Please note:

(*) IPOWER- and IMEP calculation functionality

is only available with Dongle 620-66-002-00

1 Scope of supply

CPM 500 Electronic Peak Pressure Indicator 4

1 Scope of supply

Fig.1: Instrument case with all components

2 Important information

CPM 500 Electronic Peak Pressure Indicator 5

2 Important information Please study this manual carefully before using the

equipment. This will ensure that you will receive maximum

benefits from using this engine performance tuning tool with

its versatile functionality and it will guarantee optimum

benefits over its lifetime.

2.1 Use of the operator manual We strongly recommend you to read the complete manual

before using the equipment. If you already have experience

with HEINZMANN systems you may only read the

relevant chapters for the required information.

It was our intention to structure this manual in a clear

layout, to enable you to get easy and instant access to the

information you are looking for. Please keep this manual in

a safe place where it is always available for easy access.

We ask for your understanding, that we will reserve the

right to change information and instructions in this manual

if necessary without giving notice in advance.

3 Description

CPM 500 Electronic Peak Pressure Indicator 6

3 Description

3.1 Introduction The electronic indicator CPM 500 is a handy, battery powered,

portable device to measure and evaluate cylinder pressure on

diesel engines at speed up to 1500 RPM.

The CPM 500 collects 10 consecutive pressure measure-

ments (cycles) and calculates peak pressure and engine

speed. The measured data are displayed in numerical format

on the LCD screen and can be stored in memory.

Up to 20 measurement data sets can be stored in the

CPM 500. The stored data can be downloaded via USB-

interface to a personal computer for evaluation.

The scope of supply includes software for Windows which

allows additional evaluation and visualization of the

collected data.

3.2 Measure functions Pmax: average maximum pressure of 10 cycles

Pcomp: compression pressure

RPM: engine speed

A complete individual pressure curve average over the 10

cycles will be stored in the CPM 500 memory with each

measurement.

3.3 Functional description The cylinder pressure will be measured with the CPM 500

unit incl. high temperature pressure sensor at the indicator

cock on marine diesel engines.

Memory : for 20 data sets

Application 2 –stroke: 40 –300 RPM

Application 4 –stroke: 200 –1500 RPM

The battery must be re-charged after approximately one

hour of continuous operation.

4 Operation

CPM 500 Electronic Peak Pressure Indicator 7

4 Operation

4.1 Operator push buttons

Remarks: After switching “On“, the CPM 500 automatically starts in 2-stroke mode. For converting to initial 4-

stroke mode, the user must connect the CPM 500 via USB cable to a powered up PC.

When connected, press “Read“ and “Measure“ simultaneously. The display starts to toggle between 4- and 2-

stroke start mode.

After display of the desired mode, immediately unhand the push buttons to store the selected start mode.

The same procedure can be used for switching from 4-stroke start mode to 2-stroke.

Fig. 2: Push buttons

Arrow up ““

Arrow down ““

On/Off

Start measurement

Read measurement

Selection of

2- or 4-stroke engine

4 Operation

CPM 500 Electronic Peak Pressure Indicator 8

4.2 Operating functions

Function

Key board

push button

Display

Notes

Switch On/Off

Basic settings will be dis-

played after switching on:

Cyl:1 = cylinder no.1

2 stroke = 2 stroke engine

4 stroke = 4 stroke engine

Pmax in bar ; RPM: speed

Selection of 2 -stroke or 4

–stroke engine

Push key “2/4“to change

the mode of operation to

the desired value (4 or 2

stroke application).

Battery check

Push key “2/4“two times

to check the battery status.

Also temperature at mea-

suring element will be dis-

played.

Sensor check

Push key “2/4“three

times to check the sensor

status at 0 bar.

Selection of cylinder

Push arrow key ““and

change the displayed value

to the number of the

selected cylinder.

Start measurement

During measurement the

following information

“Recording cylinder” will

be indicated.

Display indication (1-2 s)

of measured cylinder

values. Then CPM 500

unit automatically

switches to the next

cylinder.

Read Pmax

The measured value for

Pmax of the selected

cylinder will be displayed.

Read Pcomp (only on two

stroke engines)

Press 2x

The measured value for

Pcomp of the selected

cylinder will be displayed.

Delete measurements

+

Push “Read” and ““

at the same time for 2s to

delete the currently dis-

played measurement.

4 Operation

CPM 500 Electronic Peak Pressure Indicator 9

4.3 Installation of visualisation- and USB driver software

The scope of supply includes the HEINZMANN visualisation software on CD-ROM for displaying and

analysing the measured data in numeric and graphic format.

Hardware requirements:

IBM PC Pentium or 100 % compatible, USB port

Windows 7, XP

Main memory minimum 16 MB RAM,

Monitor with minimum resolution of 1024 x 768.

Install CD ROM on your Personal Computer. Open directory “software”and make a double click at setup.exe

for installation of visualisation- and necessary USB driver software.

The program will automatically install a new directory and places an icon on the desktop of your computer.

USB driver will be installed automatically

Press enter to finalize USB driver installation

4.4 Select COM port of PC

For selection of COM Port the CPM 500 should be

connected via USB cable to PC

Switch on CPM 500

Connect USB port of PC via USB cable to CPM 500

Run “Visualisation software“ by double click on

the desktop icon.

Fig.3: CPM 500 connected via USB cable to PC

For selection of COM Port the CPM 500 should be connected via USB cable to PC and visualisation software

should be started by double click on desktop icon.

With mouse click on “Tools” and selection “Interface” the COM port of PC will be selected.

4 Operation

CPM 500 Electronic Peak Pressure Indicator 10

4.5 Charge battery

The CPM 500 has a re-chargeable battery. The battery

charging will start automatically after the CPM 500 unit

has been connected via USB cable from USB port to PC

(fig. 4,5,6,7)

Fig. 4: USB-port of CPM 500

Note: At first usage please connect CPM 500 via USB cable to PC.

Charge battery for 2h continuously without disconnecting from PC !

Fig. 5: CPM 500 connected via USB cable to PC

Fig. 6: Indication during charging process Fig. 7: Indication charging process completed

Do not change battery during charging process while CPM 500 is connect via USB cable to PC.

When the indicator is connected by USB, the battery charging runs automatically. The indicator can detect the

charging status and continues charging until the battery is fully loaded. Then the charging process stops

automatically. It is not recommended to interrupt the charging process before it is automatically stopped. The

charging process is finished when the display message "CPM 500 charging..." has disappeared.

If the battery status is low and the charging process stops after 5-10 minutes, then the user can manually force

the unit to charge the battery for 90 minutes by pressing both arrows + at the CPM 500 unit

for 2 seconds (Forced Charging Mode).

Note: It is not recommended to use the Forced Charging Mode when the battery charge condition is more than

40%, due to the risk of overcharging. Please see chapter 5.2 for a description how to check the charge state.

USB port

4 Operation

CPM 500 Electronic Peak Pressure Indicator 11

4.6 Change battery

Note: Please only use re-chargeable battery E-block type “ANSMANN 250 mAh NiMH”

For changing the re-chargeable battery the battery cover on the back side of CPM 500 must be opened

(fig.9,10,11). Do not change battery during charging process while CPM 500 is connect via USB cable to PC.

Fig.8: Battery cover Fig.9: Re-chargeable E-block battery type:Ansmann

Fig.10: Battery installed on backside of CPM 500

Note: If battery of standard NiMh 250 mAh type Ansmann can not be charged or is not available, then the

operator can use for measurements Alkaline battery 9V only for a short time. In this case please immediately

disconnect the CPM 500 unit after transferring data to PC !

4.7 Mounting instructions on marine engines

Measuring at the indicator valve

Before mounting the adapter, please clean the indicator valve by opening (1-2s).

To avoid measurement distortion:

Check adaptor and sensor periodically for dirtiness and clean it if necessary.

+ Pol

The battery should only be installed by

correct pole of battery !

DANGER!

The indicator valve ejects hot gas under high

pressure. Danger of sparks and burning.

Hot gases and particles may be ejected.

Wear gloves and safety glasses!

- Pol

4 Operation

CPM 500 Electronic Peak Pressure Indicator 12

4.8 Measuring with CPM 500

Charge battery

Charging time: min. 2 hours

Start measurements on the engine

2-and 4 stroke application

Open indicator cock and close. Install sensor with adaptor at cylinder no.1 and open indicator cock

Press “On” at CPM 500

Press “Measure” and wait about 5-10 s

Fig.11: Indication during measurement on cylinder

Fig.12: Indication (1-2 s) of measured values from cylinder

After indication of measured cylinder values (1-2s) the display switches automatically to next cylinder.

Repeat measuring procedure for all remaining cylinders!

For to change engine mode 2- or 4-stroke press “2/4” to select application on a 2- or 4 stroke engine

Remark: The CPM 500 has a overheating protection of measuring cell for temperature > 300°C

Remark: The CPM 500 turns off automatically after 2 minutes without pressing any push button!

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 13

5 Visualisation software release 1.0.7.8

5.1 Main tool bar buttons

Load new measurement data from EPM-XP

Open stored measurement data set

Save all data to ASCII file

Print screen page

Print all screen pages

Cross On function

Program exit

Delete measurements at EPM-XP

Selection of “Motored curve “ on 4-strokes

Selection of derivative curve

Selection of all cylinder in screen page “Engine diagram”

Selection of Pmax bar graph function

Save value of shifted curves

Function “Derivative curve”

Function for optimizing Pcomp position

Function “Motored curve”

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 14

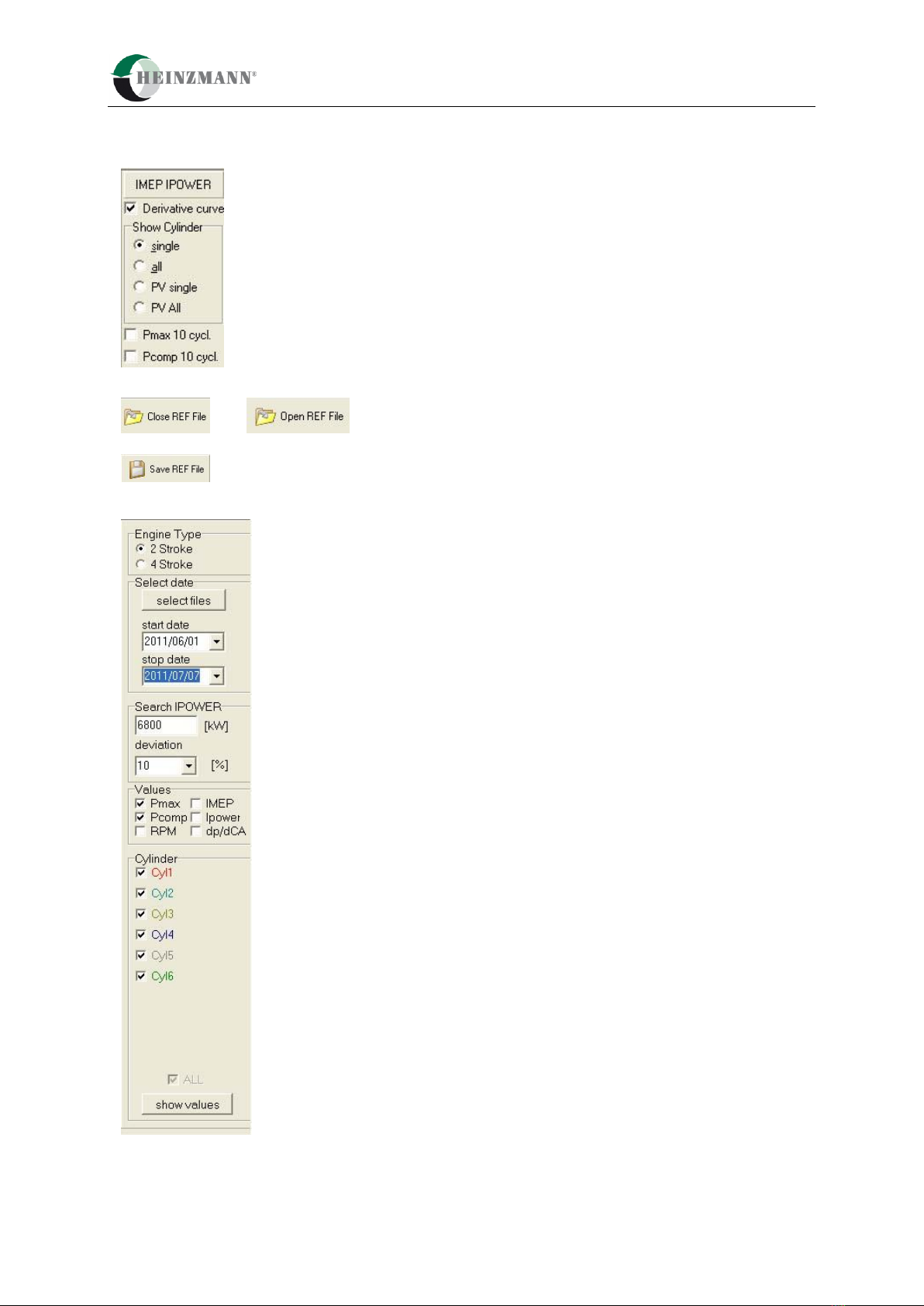

Functions for power calc. function. Only visible with Dongle 620-66-002-00

Selection window of cylinder

Derivative curve

p/alpha, p/v diagram

Indication Pmax 10 cycles

Indication of Pcomp 10 cycles (only on two strokes)

Close and open reference file

Save a reference file

Selection of engine type

Select files (*.ext format)

Select start and stop date

Input of indicated engine

power and selection deviation

in %

Selection of values

Selection of cylinder

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 15

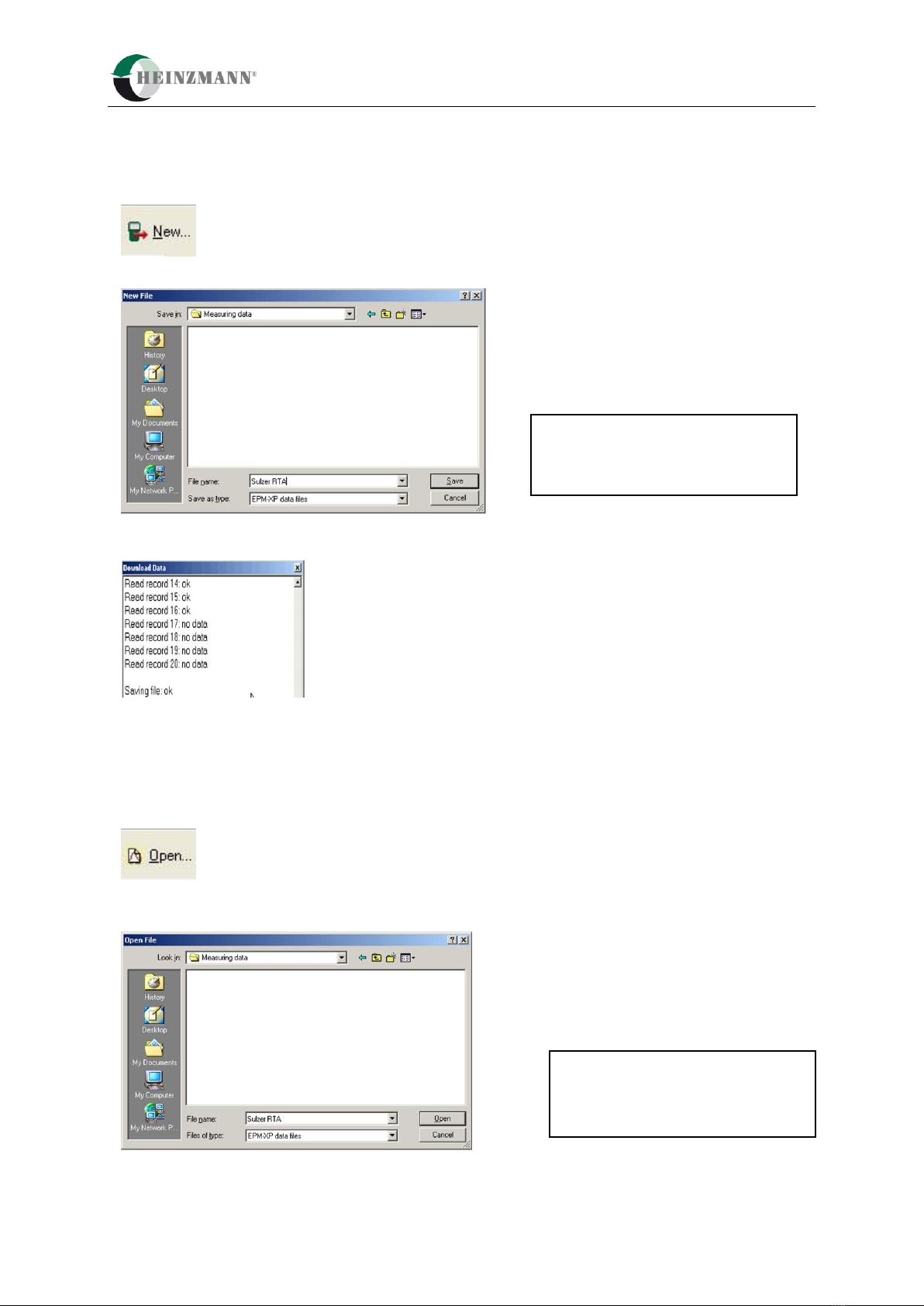

5.2 Load measured data from CPM 500 to PC

At first visualisation software must be started. CPM 500 must be connected via USB cable to PC

Press “New” to load measurement data from CPM 500 to PC

The software opens a window to name the file for storing on PC

After entering a file name and storing the data will be transmitted to PC.

After this procedure the measured data will be monitored at visualisation software.

5.3 Load measured data from hard disc to PC

At first the visualisation software must be started.

Press “Open” to load measurement data from CPM 500 to PC.

The software opened a window for to open a stored file on PC.

After this procedure the selected data file will be monitored at visualisation software.

Remark: The format of data files are

*.ext. The software release 1.0.6.0 or

higher can read and open old data

formats of *.exd

Remark: The format of data files are

*.ext. The software release 1.0.6.0 or

higher can read and open old data

formats of *.exd

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 16

5.4 Monitoring of combustion data

5.4.1 Screen page “Cylinder pressure curve”

5.4.1.1 Indication of all cylinders

Cylinder

selection

Indication of pressure curves of

measured cylinder 1…n.

(n = measured cylinder; max:20)

Indication of

Pmax diagram

Indication of

Engine Report

Indication of

Pmax Balancing

Motored curve

Derivative curve

Indication of all measured

curves overlapped or single

cylinder selection

Remark field

Field „Engine data“

Selection of scav. air

pressure

Pmax bargraph diagram

10 cycles

Arrow function to shift

curves with 0.1 resolution

on 2 strokes.

On 4-strokes shift curves

with 0.5 resolution.

“Optimize“ function“

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 17

Zoom-function

Zoom function on: Hold left mouse button pushed down and draw across the curve from top left down to

right bottom corner.

Zoom function off: Hold left mouse button pushed down and draw across the curve from right bottom up

to top left corner.

5.4.1.2 Cross On function

Cross On: Push with mouse “Cross On” button and move mouse to the position of curve

Cross Off: Push with mouse “Cross Off” button

Indication of pressure

[bar] and crank angle

position [CA]

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 18

5.4.1.3 Save to ASCII

Press “ASCII-File” to save all measurement data to Excel (*.csv) files.

The software opened a window to store data to (*.csv) files.

5.4.1.4 Optimize function for application on two-strokes

IMES algorithm for automatic Pcomp position calculation on two-strokes can be influenced by some noises on

the pressure signal. If Pcomp Position is not exact centred on TDC position than please press button

“OPTIMIZE”

Remarks: Optimum Pcomp position influences also IPOWER and IMEP calculation for application with dongle

620-66-002-00!

1. Check all curves

Some curves should be

checked for optimum

position of Pcomp !

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 19

2. Check lowest position of derivative curve

3. Shift curve into optimum pos. of Pcomp by pressing button “Optimize”. All incorrect curves are shifted

automatically into optimum position of Pcomp.

4. All curves shifted

Lowest point of

derivative curve

is before TDC!

Curve shifted into

optimized Pcomp position

Derivative curve

Select „Derivative curve“

5 Visualisation software release 1.0.7.8

CPM 500 Electronic Peak Pressure Indicator 20

5.4.1.5 Save Shift

After shifting curves the operator has the possibility to save shifted data as *.ext file under new name.

All curves shifted into

optimum Pcomp position

Table of contents