Primes FocusParameterMonitor FPM 60 User manual

Revision 06 EN 02/2023

FocusParameterMonitor FPM

FPM60, FPM100, FPM160

Hardware and software interface PROFINET®/PROFIBUS®

35,0(6

Original Instructions

3

Revision 06 EN 02/2023

35,0(6

IMPORTANT!

READ CAREFULLY BEFORE USE!

KEEP FOR FUTURE USE!

4Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

Inhaltsverzeichnis

1 Basic safety notes 7

2 Symbols and conventions 8

3 About this operating manual 9

4 Device description 10

4.1 Type overview .........................................................................................................................10

4.2 Functional description .............................................................................................................11

4.3 Measuring principle .................................................................................................................12

4.4 Optical displays.......................................................................................................................13

4.4.1 FPM PROFIBUS®.....................................................................................................13

4.4.2 FPM PROFINET®.....................................................................................................13

4.4.3 FPM PROFINET®M12 ..............................................................................................14

4.5 Scope of delivery and optional accessories .............................................................................14

5 Transport and storage 15

6 Mounting 15

6.1 Conditions at the installation site .............................................................................................15

6.2 Installation in the laser system .................................................................................................15

6.2.1 Prepare mounting .....................................................................................................15

6.2.2 Possible mounting positions......................................................................................16

6.2.3 Align the device ........................................................................................................16

6.2.4 Mount the device ......................................................................................................17

6.3 Removal from the laser system................................................................................................19

7 Connections 20

7.1 FPM PROFIBUS®...................................................................................................................20

7.1.1 Interface description PROFIBUS®.............................................................................20

7.1.2 Set PROFIBUS® address .........................................................................................21

7.1.3 Device master file (GSD data)....................................................................................22

7.2 FPM PROFINET®....................................................................................................................23

7.2.1 Interface description PROFINET®.............................................................................23

7.2.2 Device master file (GSDML file) .................................................................................24

7.3 FPM PROFINET®M12.............................................................................................................25

7.3.1 Interface description PROFINET®M12 ......................................................................25

7.3.2 Device master file (GSDML data)...............................................................................27

7.4 Locking device for interlock.....................................................................................................27

7.5 Compressed Air Connection ...................................................................................................28

8 PROFIBUS®-/PROFINET® parameter set 29

8.1 Inputs......................................................................................................................................30

8.2 Outputs...................................................................................................................................33

8.3 Error identifier..........................................................................................................................35

8.3.1 Error identifier hardware ............................................................................................35

8.3.2 Error identifier parameter selection ............................................................................35

8.3.3 Error identifier single plane measurement ..................................................................36

8.3.4 Error identifier caustic................................................................................................36

8.3.5 Warning identifier single plane measurement.............................................................37

8.3.6 Warning identifier caustic ..........................................................................................37

9 Install and configure LDS 38

9.1 System requirements ..............................................................................................................38

9.2 Install software ........................................................................................................................38

5

Revision 06 EN 02/2023

35,0(6

9.3 Ethernet configuration .............................................................................................................39

9.3.1 Set IP address of PC ................................................................................................39

9.3.2 Change IP address of a connected device ................................................................39

9.3.3 Establishing a connection to FPM .............................................................................40

9.3.4 Obtain an IP address automatically with DHCP .........................................................41

10 Description of the LDS 42

10.1 Graphical user interface...........................................................................................................42

10.1.1 The menu bar ...........................................................................................................43

10.1.2 The toolbar ...............................................................................................................44

10.1.3 Menu overview..........................................................................................................45

11 Measurement settings 47

11.1 Warning messages..................................................................................................................47

11.2 Enter measurement parameters with the LDS .........................................................................48

11.2.1 Establish connection.................................................................................................48

11.2.2 Sensor parameters ...................................................................................................48

11.2.3 Measurement window...............................................................................................49

11.2.4 The command line „Command“ ................................................................................50

11.2.5 Creating setups ........................................................................................................51

11.2.6 Checking the beam position .....................................................................................52

11.3 Enter measurement parameters via the PLC ...........................................................................52

11.4 Determine exposure time with the help of the LDS ..................................................................53

11.4.1 Preparation ...............................................................................................................53

11.4.2 Triggering a manual measurement ............................................................................53

11.4.3 Setting the gain.........................................................................................................54

11.5 Determine the exposure time via the PLC................................................................................55

12 Measuring 61

12.1 Measuring procedure ..............................................................................................................61

12.1.1 Measuring procedure power measurement ...............................................................61

12.1.2 Measuring procedure focus measurement (untriggered) ............................................62

12.1.3 Measuring procedure focus measurement (triggered)................................................63

12.1.4 Measuring procedure caustic measurement..............................................................64

12.1.5 Measuring procedure combined measurement .........................................................65

12.2 Timing diagrams .....................................................................................................................66

12.2.1 Timing diagram power measurement ........................................................................66

12.2.2 Timing diagram focus measurement (untriggered).....................................................67

12.2.3 Timing diagram focus measurement (triggered).........................................................69

12.2.4 Timing diagram caustic measurement.......................................................................71

12.2.5 Timing diagram combined measurement ..................................................................72

12.3 Flow Chart combined measurement........................................................................................75

13 Display of a measurement in the web browser 77

14 Maintenance and Service 79

14.1 Maintenance intervals..............................................................................................................79

14.2 Cleaning..................................................................................................................................79

14.3 Spare parts .............................................................................................................................79

14.4 Maintenance of the Protective Window ...................................................................................80

14.4.1 Exchange of the protective window cartridge............................................................81

14.4.2 Exchanging or cleaning of the protective window......................................................82

15 Measures for the product disposal 83

16 Declaration of incorporation for partly completed machine 84

17 Technical Data 85

18 Dimensions 86

6Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

PRIMES - the company

PRIMES is a manufacturer of measuring devices which are used to analyze laser beams. These devices are

employed for the diagnostics of high-power lasers ranging from CO2-, fiber- and solid-state lasers to diode

lasers. A wavelength range from infrared through to near UV is covered, offering a wide variety of measuring

devices to determine the following beam parameters:

• Laser power

• Beam dimensions and position of an unfocused beam

• Beam dimensions and position of a focused beam

• Beam quality factor M²

Development, production and calibration of the measuring devices is performed at PRIMES. This guarantees

optimum quality, excellent service, and a short reaction time, providing the basis for us to meet all of our

customers’ requirements quickly and reliably.

PRIMES GmbH

Max-Planck-Str. 2

64319 Pfungstadt

Germany

Tel +49 6157 9878-0

www.primes.de

7

Revision 06 EN 02/2023

Basic safety notes

35,0(6

1 Basic safety notes

Intended use

The device has been designed exclusively for measurements in the beam of high-power lasers.

Use for any other purpose is considered as not intended and is strictly prohibited. Furthermore, intended use

requires that all information, instructions, safety notes and warning messages in this operating manual are

observed. The specifications given in chapter17 „Technical Data“ on page85 apply. Any given limit values

must be complied with.

If not used as intended, the device or the system in which the device is installed can be damaged or

destroyed. In addition, there is an increased risk to health and life. Only use the device in such a way that

there is no risk of injury.

This operating manual is an integral part of the device and must be kept in the immediate vicinity of the place

of use, accessible to personnel at all times.

Every person who is responsible for the installation, start-up or operation of the device must have read and

understood the operating manual and, in particular, the safety instructions.

If you still have questions after reading this operating manual, please contact PRIMES or your supplier for

your own safety.

Observing applicable safety regulations

Observe the safety-relevant laws, guidelines, standards and regulations in the current editions published by

the state, standardization organizations, professional associations, etc. In particular, observe the regulations

on laser safety as well as machine safety and comply with their requirements.

Before commissioning, it must be ensured that the entire machine in which the device is installed meets

these safety requirements. Otherwise the commissioning of the device is prohibited.

Necessary safety measures

The device measures direct laser radiation, but does not emit any radiation itself. However, during the mea-

surement the laser beam is directed at the device. This produces scattered or directed reflection of the laser

beam (laser class 4). The reflected beam is usually not visible.

Protect yourself from direct and reflected laser radiation while working with the device by taking the following

measures:

• Wear safety goggles adapted to the power, power density, laser wavelength and operating mode of the

laser beam source in use.

• Wear suitable protective clothing or protective gloves if necessary.

• If possible, also protect yourself from direct laser radiation and scattered radiation by using separating

protective devices that block or attenuate the radiation.

• If the device is moved from its aligned position, increased scattered or directed reflection of the laser

beam occurs during measuring operation. Mount the device in such a way that it cannot be moved unin-

tentionally, i.e. by bumping or pulling the cables.

• Install safety switches or emergency safety mechanisms that allow the laser to be switched off immedi-

ately.

• Use suitable beam guidance and beam absorber elements which do not emit any hazardous substances

when irradiated.

Employing qualified personnel

The device may only be operated by qualified personnel. The qualified personnel must have been instructed

in the installation and operation of the device and must have a basic understanding of working with high-

power lasers, beam guiding systems and focusing units.

8Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

Conversions and modifications

The device may not be modified in terms of design or safety without the explicit consent of the manufacturer.

The same applies to unauthorized opening, dismantling and repair. The removal of covers is only permitted

within the scope of the intended use.

Liability disclaimer

Manufacturer and distributor exclude any liability for damages and injuries which are direct or indirect con-

sequences of using the device not as intended or modifying the device or the associated software without

authorization.

2 Symbols and conventions

Warning messages

The following icons and signal words indicate possible residual risks in the form of warnings:

DANGER

Means that death or serious physical injuries will occur if necessary safety precautions are not

taken.

WARNING

Means that death or serious physical injuries may occur if necessary safety precautions are not

taken.

CAUTION

Means that minor physical injury may occur if necessary safety precautions are not taken.

NOTICE

Means that property damage may occur if necessary safety precautions are not taken.

Product safety labels

The following icons are used on the device itself to indicate imperatives and possible dangers:

General warning sign

Read and understand the operating manual before using the device!

Labeling according to WEEE directive:

The device must not be disposed of with household waste, but in a separate WEEE collection

in an environmentally friendly way.

9

Revision 06 EN 02/2023

About this operating manual

35,0(6

Further icons and conventions in this operating manual

Here you will find useful information and helpful tips.

Indicates a single instruction.

If several of these instructions appear one below the other, the order in which they are executed is

irrelevant or they represent alternative courses of action.

1.

2.

...

A numbered list identifies a sequence of instructions that must be executed in the specified order.

Indicates the result of an action to explain processes that take place in the background.

Indicates an observation prompt to draw attention to visible feedback from the device or the software.

Observation prompts make it easier to check whether an instruction was executed successfully.

Often they also guide to the next instruction.

Points to a control element that is to be pressed/clicked.

Points to an element described in the text (for example an input field).

3 About this operating manual

This manual describes working with the FocusParameterMonitor FPM and its settings both

• via a system using a PLC

• as well as with the LaserDiagnosticsSoftware LDS 2.98.

The FocusParameterMonitor FPM is intended to be used with a PLC for fully automated operation. Manual

operation with a PC is not recommended.

However, since the FocusParameterMonitor FPM is designed for measuring short-term exposure and does

not automatically adjust the exposure time, the appropriate exposure time must be determined for the

various beam configurations. The LaserDiagnosticsSoftware LDS 2.98 can be used for setup.

The LaserDiagnosticsSoftware LDS 2.98 is available free of charge on the PRIMES website at:

https://www.primes.de/de/support/downloads/software.html.

In these operating manual, the abbreviations FPM and LDS will be used in the following.

10 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

4 Device description

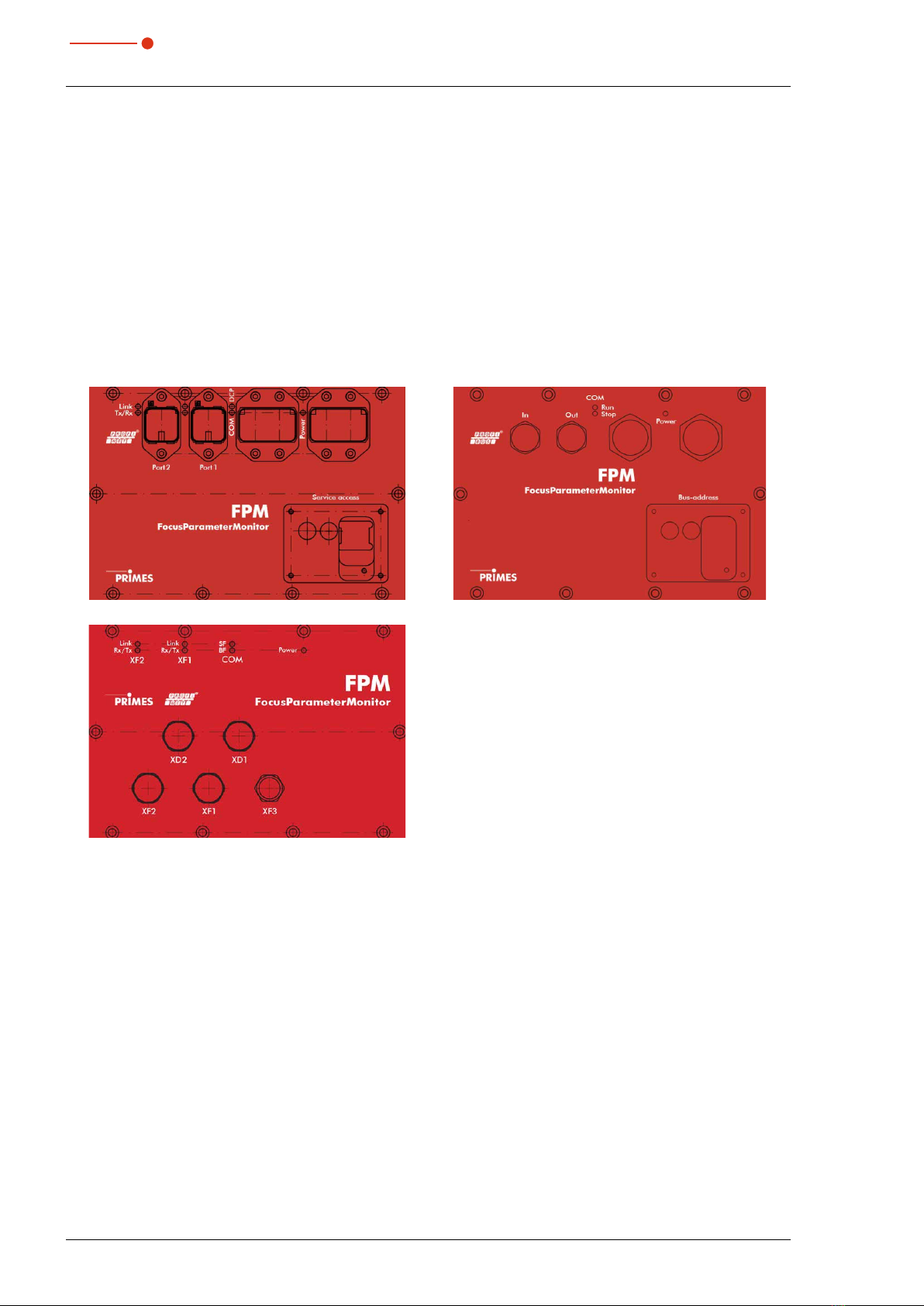

4.1 Type overview

The digits in the name indicate different types. These differ in their maximum permissible divergence as well

as the imaging scale.

• FocusParameterMonitor FPM 60 with a maximum divergence of 60 mrad and a 1:1 image

• FocusParameterMonitor FPM 100 with a maximum divergence of 100 mrad and a 5:1 image

• FocusParameterMonitor FPM 160 with a maximum divergence of 160 mrad and a 3:1 image

The FPM is optionally equipped with a PROFIBUS®or a PROFINET®interface. For this purpose the following

connection fields are available:

PROFINET®PROFIBUS®

PROFINET®M12

The following variants of the FPM are available:

• FPM 60 PROFIBUS®

• FPM 60 PROFINET®

• FPM 100 PROFIBUS®

• FPM 100 PROFINET®

• FPM 100 PROFINET®M12

• FPM 160 PROFIBUS®

• FPM 160 PROFINET®

• FPM 160 PROFINET®M12

Devices with PROFINET

®

and PROFIBUS

®

connection field are available with an openly accessible or a con-

cealed Ethernet port.

For PROFINET®M12 devices, the Ethernet port XF3 is always freely accessible.

11

Revision 06 EN 02/2023

Device description

35,0(6

4.2 Functional description

The FPM is designed for laser beam measurement. The beam quality is controlled by means of periodic

measurements which ensures the process quality. The following parameters are measured:

• Laser power

• Power density distribution

• Beam position and beam geometry

• Caustic of laser beams

The FPM consists of three main components: the power measuring unit, the beam analysis unit and the

PROFIBUS®or PROFINET®interface. These components are included in a stable aluminium housing.

An electrically operated shutter protects the beam entrance from pollution.

In addition, an exchangeable protective window is integrated. It is constantly surrounded by compressed air.

The compressed air is required to create an overpressure in the housing, which prevents the penetration of

dirt particles.

PROFIBUS®/

PROFINET®

Interface

FocusParameterMonitor FPM

+24 V

Beam Analysis

Power

Measurement

Control

Data

Fig. 4.1: Block diagram of the FPM

12 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

4.3 Measuring principle

The device determines the laser power in the power measuring unit according to the calorimetric principle.

For this purpose the absorber of the power measuring unit is irradiated with the laser for a defined time.

Using the known absorber mass and the specific heat capacity of the absorber material, the introduced

energy can be calculated by the measured temperature increase. The measured exposure time can then be

used to calculate the power.

The beam geometry and the power density distribution are measured by the camera-based beam analysis

unit using a CCD sensor. The measurement of beam parameters require an external z-axis.

The measurement data is transmitted to the system control via a PROFIBUS®or PROFINET®interface.

The beam coming from the laser is transmitted through the beam entrance to deflection mirror 1 and from

there to a beam splitter.

The lagest part of the beam enters an absorber which is part of the power measurement unit.

The attenuated beam reaches the beam analysis unit (CCD sensor) via deflecting mirror 2.

The power measuring unit is used to determine the power and the beam analysis unit is used to measure the

beam position and geometry, the caustic and the power density distribution.

Shutter

Measuring Position

Measurement level

Entrance level

Deflection Mirror 1

Protective Window

Cartridge

Beam Splitter

Deflection

Mirror 2

Absorber

CCD-Sensor Beam Entrance

Fig. 4.2: Beam path inside FPM

Please note that the measuring plane in the FPM is below the entrance plane, depending on the

magnification and the configuration. (see chapter17 „Technical Data“ on page85).

13

Revision 06 EN 02/2023

Device description

35,0(6

4.4 Optical displays

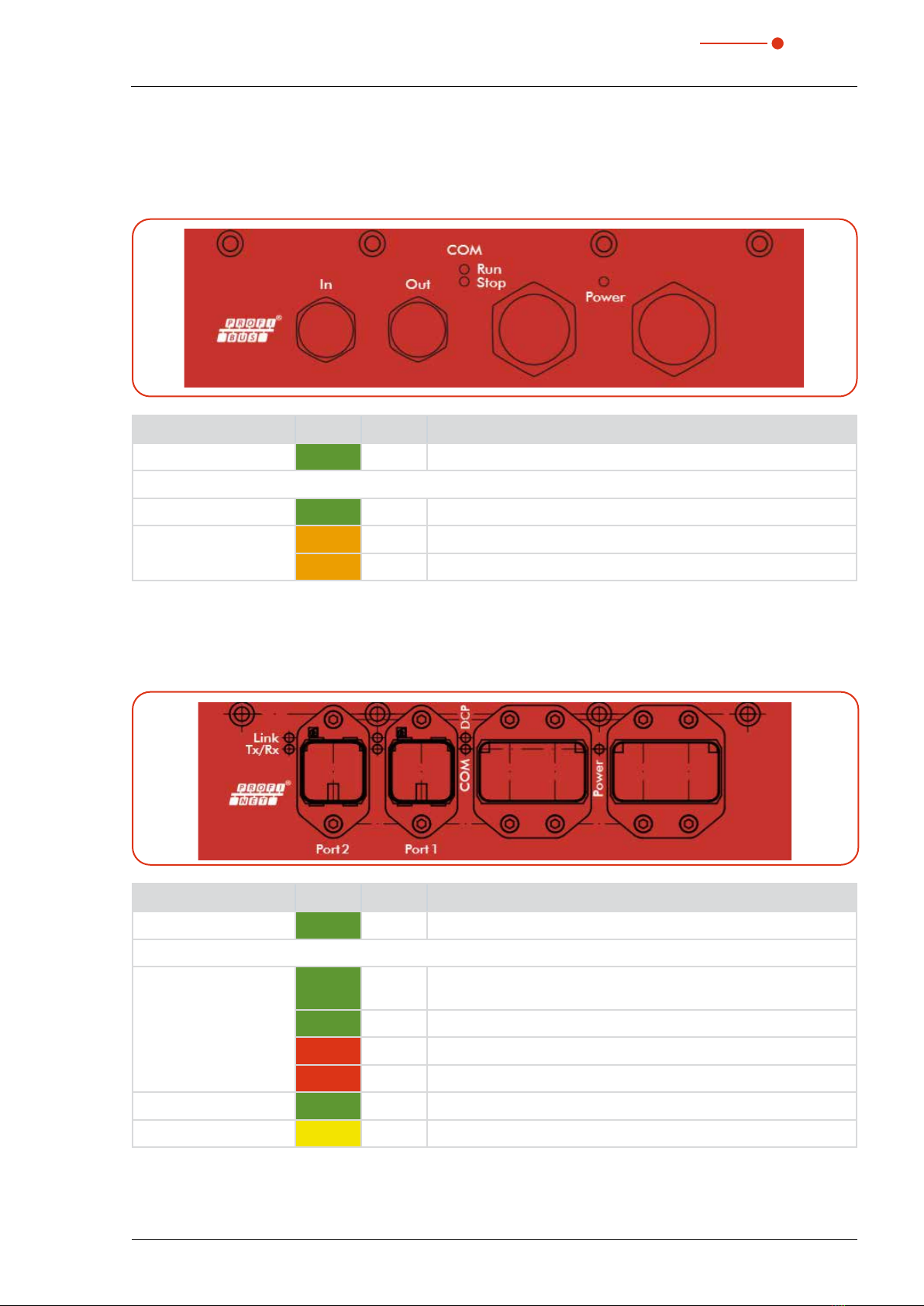

4.4.1 FPM PROFIBUS®

LED Color State Meaning

Power Green On Supply voltage applied.

COM Run Green On Communication takes place on the bus.

COM Stop

Orange On There is a connection, but no data is exchanged.

Orange Blinks The measuring device has no physical connection to the bus.

Tab. 4.1: Light signals and colors PROFIBUS®

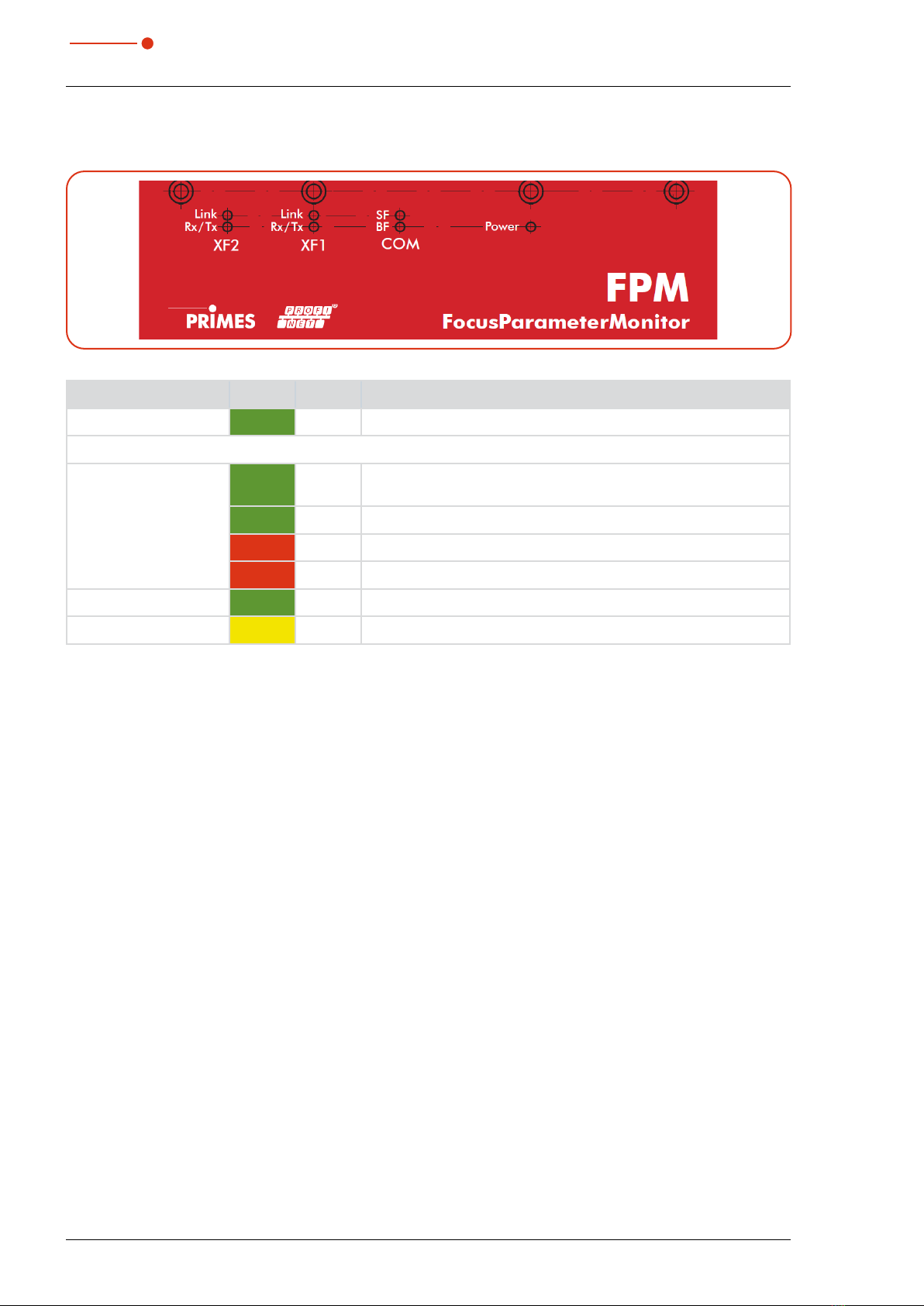

4.4.2 FPM PROFINET®

LED Color State Meaning

Power Green On Supply voltage applied.

COM

Green On Watchdog timeout or „Channel, generic or extended diagnostics

present“ or system error.

Green Blinks DCP signal service is triggered via the bus.

Red On

No configuration or slow physical connection or no physical connection.

Red Blinks No data exchange.

Link (Port 1 and Port 2)

Green On The device has a connection to the Ethernet.

Tx/Rx (Port 1 and Port 2)

Gelb Flickers The device sends/receives Ethernet frames.

Tab. 4.2: Light signals and colors PROFINET®

14 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

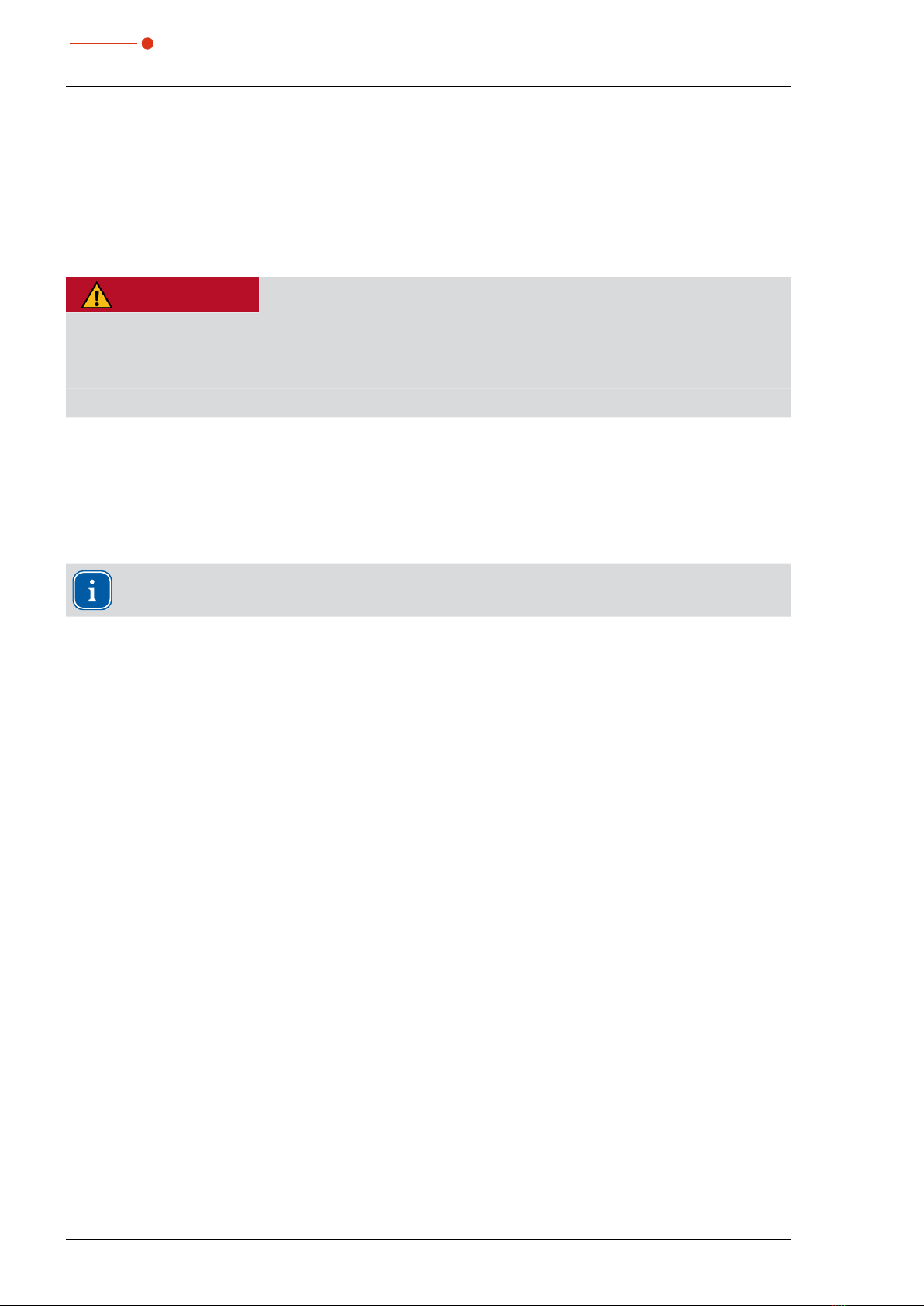

4.4.3 FPM PROFINET®M12

LED Color State Meaning

Power Green On Supply voltage applied.

COM

Green On Watchdog timeout or „Channel, generic or extended diagnostics

present“ or system error.

Grün Blinks DCP signal service is triggered via the bus.

Red On

No configuration or slow physical connection or no physical connection.

Red Blinks No data exchange.

Link (XF 1 and XF 2) Green On The device has a connection to the Ethernet.

Rx/Tx (XF 1 and XF 2) Gelb Flickers The device sends/receives Ethernet frames.

Tab. 4.3: Light signals and colors PROFINET®M12

4.5 Scope of delivery and optional accessories

The scope of delivery includes:

• FPM

• USB flash drive

• Operating manual (printed version)

The following accessories are optional:

• Transport and storage case

• Maintenance hatch with passage for Ethernet

15

Revision 06 EN 02/2023

Transport and storage

35,0(6

5 Transport and storage

NOTICE

Damage/destruction of the device

Hard impacts or dropping can damage the optical components.

Handle the measuring device carefully during transport and installation.

6 Mounting

DANGER

Serious eye or skin injury due to laser radiation

A

n improper installation by unqualified personnel can lead to material damage or even personal injury.

Have the device installed by qualified personnel only. Qualified personnel must have basic knowledge

about working with high-power lasers, beam delivery systems and focusing units.

6.1 Conditions at the installation site

• The device must not be operated in a condensing atmosphere.

• The ambient air must be free of gases and aerosols that interfere with the laser radiation (e.g. organic

solvents, cigarette smoke, sulfur hexafluoride).

• Protect the device from splashes of water and dust.

• Operate the device in closed rooms only.

6.2 Installation in the laser system

The FPM is intended for the installation into a laser system. Therefore neither constructive nor safety related

modifications may be made to the FPM unless we have given our explicit written consent. In case of any

modifications, we do not accept any liability for resulting damages.

6.2.1 Prepare mounting

NOTICE

Damaging/destroying the device

Too little space in front of the shutter can damage the device.

Make sure that there is enough free space to open the shutter.

1. Switch off the laser beam.

2. Ensure that moving parts, e.g. robot arms, etc. are at a standstill and that they cannot be set in motion

unintentionally.

3. Check the space available before installing the device, especially the required space for the connection

cables and hoses/shutter.

16 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

6.2.2 Possible mounting positions

The FPM can be mounted both horizontally and vertically. Due to the danger of contamination we recommend

a vertical mounting with a horizontal beam incidence. The plug connections should point downwards and

unused sockets should be covered with the caps supplied.

6.2.3 Align the device

DANGER

Serious eye or skin injury due to laser radiation

If the device is moved from its aligned position, increased scattered or directed reflection of

the laser beam occurs during measuring operation (laser class 4).

Mount the device so that it cannot be moved by an unintended push or a pull on cables.

The device must be aligned to the laser beam. The laser beam must hit the centre of the inlet aperture.

Please mind and adhere to the specifications and limit values given in chapter „17 Technical Data“ on

page 85. The distance between the measurement plane and the entrance plane can be up to 25 mm,

depending on the lens.

The marking on the shutter can be used as an alignment aid. Align the device using the pilot beam with the

shutter closed.

In order to avoid direct reflections into the laser system, the device can be installed offset at an

angle of max. 10mrad to the incoming beam.

17

Revision 06 EN 02/2023

Mounting

35,0(6

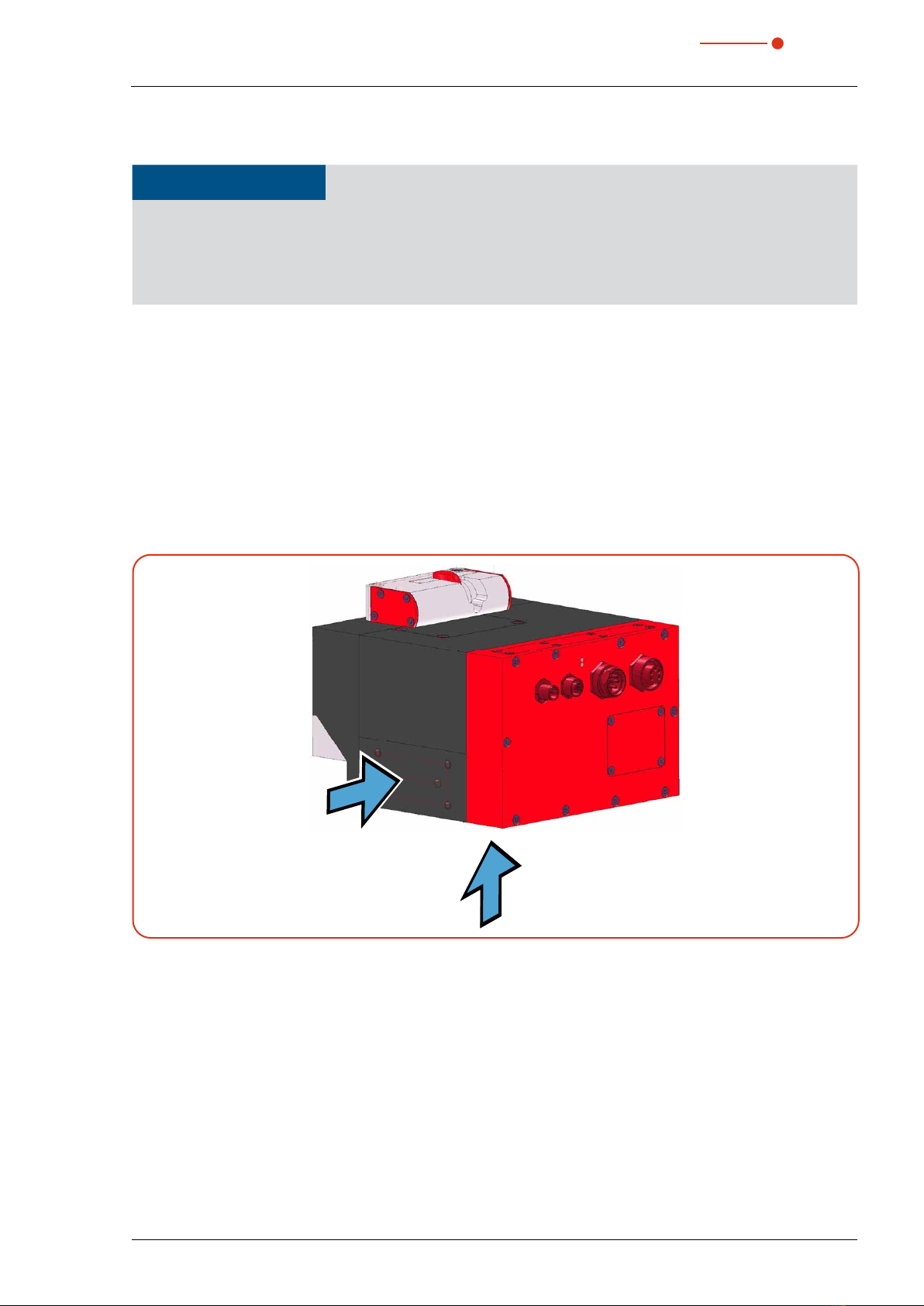

6.2.4 Mount the device

NOTICE

Damaging/destroying the device

Screws which are too long can damage the screw-in thread.

When choosing the mounting screws, please ensure that the maximum extension into the device

does not exceed 12 mm.

• Mount the device securely in order to prevent a relative movement to the beam axis, reducing a danger

posed by scattered radiation.

• Mounting space: Please note that the shutter of the FPM is opened and closed during operation. A com-

plete opening of the shutter has to be ensured. Please make sure that there is enough space to prevent

a collision of the shutter with other parts of the machine as well as to exclude a hazard for the operating

personnel by crushing.

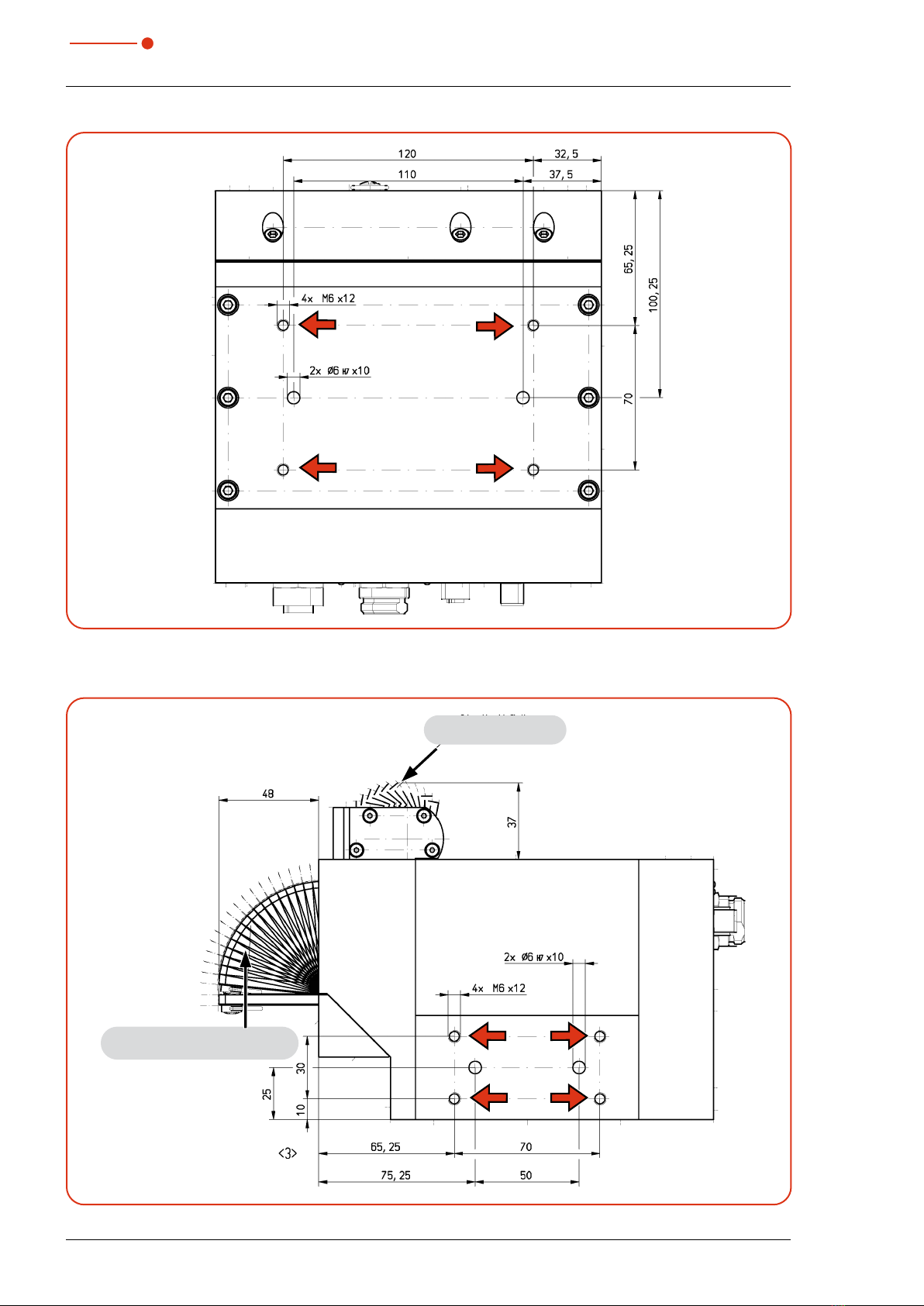

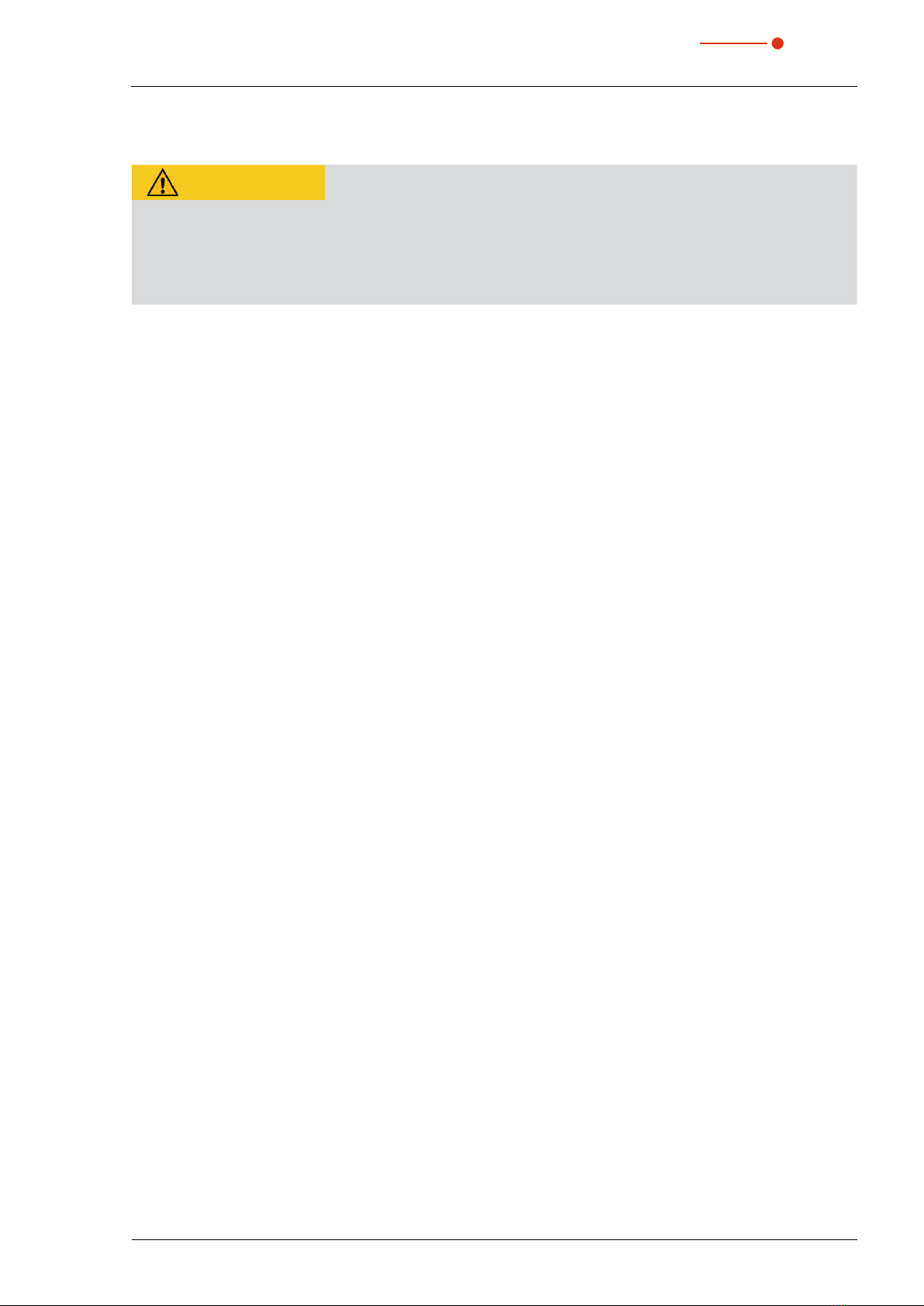

In the base plate of the housing (A) as well as in the side wall (B) there are four fastening threads M6 for

the fixture on a customer specific mounting (see Fig. 6.2 and Fig. 6.3 ). Please mount the housing with four

screws M6. We recommend screws of the strength class 8.8 and a tightening torque of 35N∙m.

There are also two dowel pin holes Ø6 H7x10 each in the base and in the side panel for precise and reproducible

alignment of the unit.

A

B

Fig. 6.1: Mounting options on the FPM

18 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

Fig. 6.2: Mounting hole in the base plate (view A)

Movement range

shutter

Movement range

protective window cartridge

Fig. 6.3: Mounting holes in the side wall (view B)

19

Revision 06 EN 02/2023

Mounting

35,0(6

6.3 Removal from the laser system

CAUTION

Damage to hearing

If the compressed air hose is loosened while still under pressure, this generates noise. This can

cause hearing damage.

Only loosen the compressed air hose when there is no longer any pressure.

1. Switch off the laser beam.

2. Ensure that moving parts, e.g. robot arms, etc. are at a standstill and that they cannot be set in motion

unintentionally.

3. Close the shutter.

4. Disconnect the device from the power supply.

5. Switch off the compressed air supply.

6. Disconnect all connections.

7. Unscrew the mounting screws.

8. Remove the device from the laser system.

20 Revision 06 EN 02/2023

FocusParameterMonitor FPM

35,0(6

7 Connections

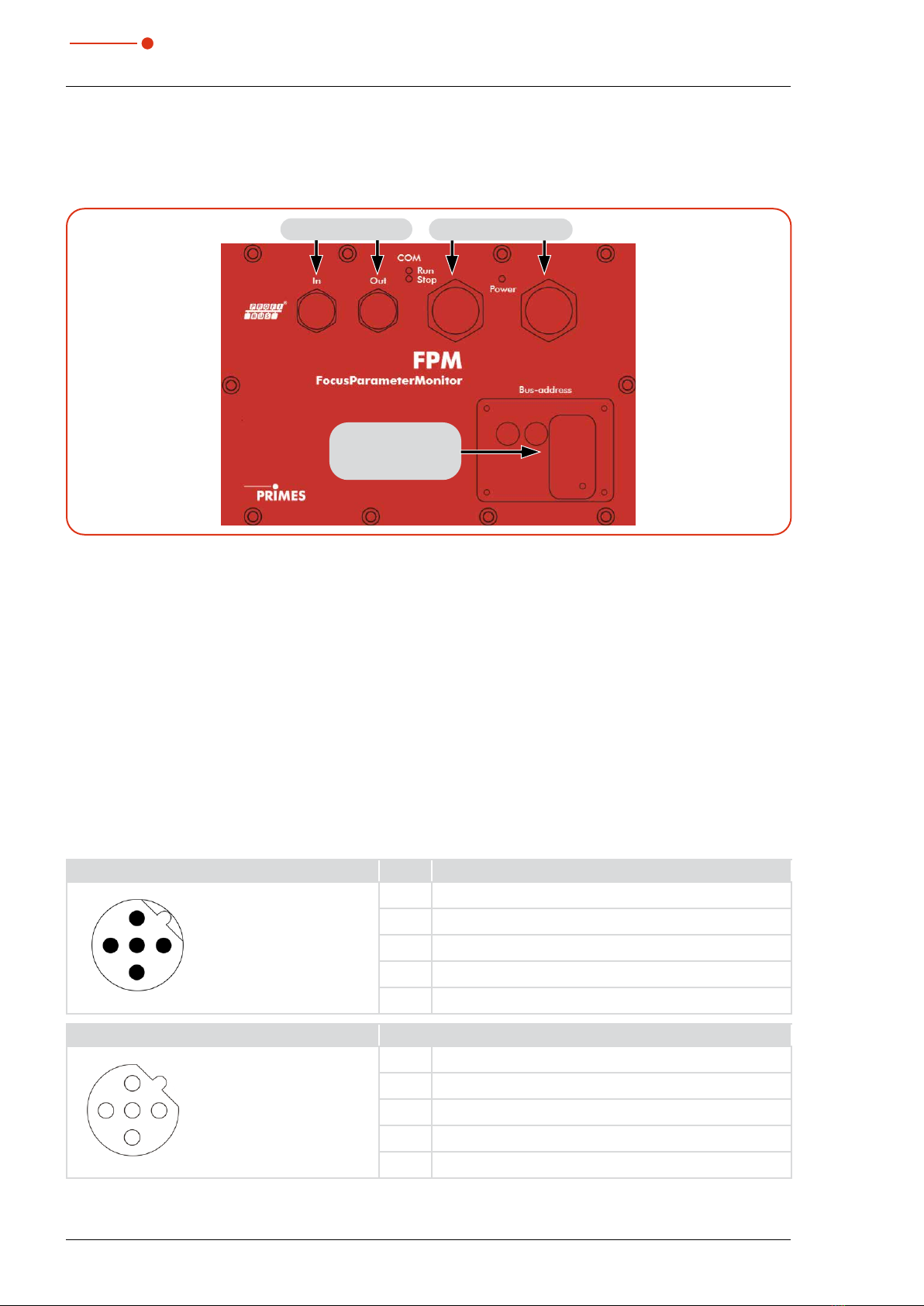

7.1 FPM PROFIBUS®

Fig. 7.1:

Maintenance hatch

with Ethernet port

PROFIBUS In/Out Voltage supply

Connections FPM PROFIBUS®

7.1.1 Interface description PROFIBUS®

Both the bus interface and the power supply are duplicated so that the FPM can be inserted into a line structure.

There are five interfaces in total:

• 2 x PROFIBUS®ports

• 2 x 24V power supplies (24V ± 5%, max. 500mA)

• 1 x Ethernet port

The data are stored in registers in Motorola format. This means that high bytes are stored first and the lower

bytes follow on the next registers.

PROFIBUS®(In/Out)

The plug or socket for PROFIBUS®is a 5-pole, B-coded M12 connector.

Pin assignment plug (top view mating side) Pin Funktion

1

4

2

5

3

1 Not connected

2 Signal A

3 Not connected

4 Signal B

5 Not connected

Pin assignment socket (top view mating side) Pin Function

2

4

1

5

3

1 +5V

2 Signal A

3 ISOGND

4 Signal B

5 Not connected

Tab. 7.1: Connectors PROFIBUS®

This manual suits for next models

2

Table of contents

Other Primes Diagnostic Equipment manuals