Helac POWERTILT PT Series Operating instructions

S W I N G

•

A T T A C H M E N T

INSTRUCTION, MAINTENANCE

AND REPAIR MANUAL

PT, PTB. TT, TTB AND TBB SERIES

®

®

2

INTRODUCTION 3

DANGER 3

SAFETY 3

MODIFICATION OF THE POWER

TILT

3

OPERATION 3

OTHER PRECAUTIONS 3

BASIC POWER

TILT

CONFIGURATIONS 4

MAINTENANCE 4

MAXIMUM RECOMMENDED BUCKETS 4

POWER

TILT

SERIES IDENTIFICATION 5

INSTALLATION AND MOUNTING 5

INSTALLING THE POWER

TILT

ONTO THE CARRIER 5

MOUNTING A BUCKET ONTO THE POWER

TILT

6

REMOVING A BUCKET FROM THE POWER

TILT

6

HYDRAULIC REQUIREMENTS AND PLUMBING 7

TYPICAL POWER

TILT

CIRCUIT 7

SUGGESTED HOSE ROUTINGS 7

TOOL CIRCUIT REQUIREMENTS 8

TROUBLESHOOTING GUIDE 9

TESTING AND TROUBLESHOOTING 10

OPERATING CONCEPT 10

EXPLODED VIEW 11

DISASSEMBLY 12

PARTS INSPECTION 13

REASSEMBLY 13

PT SERIES ASSEMBLY DRAWING 15

TT SERIES ASSEMBLY DRAWING/SINGLE COLLAR DESIGNS 16

TT SERIES ASSEMBLY DRAWING/TWO COLLAR DESIGNS 17

TTB SERIES ASSEMBLY DRAWING/SINGLE COLLAR DESIGNS 18

PT AND TTB SERIES ASSEMBLY DRAWING/TWO COLLAR DESIGNS 19

TBB SERIES ASSEMBLY DRAWING/SINGLE COLLAR DESIGNS 20

PTB AND TBB SERIES ASSEMBLY DRAWING/TWO COLLAR DESIGNS 21

DETAIL DRAWINGS — SEAL, BEARING, AND PISTON PARTS 22

PARTS LIST 24

SPARE PARTS 25

WARNING DECAL FOR CAB 25

TORQUE SPECIFICATIONS 26

END CAP TORQUE SPECIFICATIONS 26

POWER

TILT

SPECIFICATIONS 26

WARRANTY INFORMATION 27

Table of contents

INSTRUCTION, MAINTENANCE AND REPAIR MANUAL

3

INTRODUCTION

Thank you for choosing the Power

Tilt

Bucket and

Tool Swing Attachment. Helac Corporation has en-

gineered and manufactured this product to provide

you with a long life of safe, reliable service when

used and maintained as recommended.

DANGER

Power

Tilts

contain several pinch points with poten-

tialforsevereinjuries-keephandsandfingersclear.

RemainclearofthePower

Tilt

whenthemachineisin

operation.

SAFETY

Read and understand all written instructions in the

carrier operator’s manual, the Power

Tilt

Instruction,

Maintenance and Repair Manual, the bucket and/or

quick-coupler manufacturers' instructions, and on the

warning and maintenance decals which are attached

to the carrier, Power

Tilt,

bucket and/or quick-coupler.

It is the owner's responsibility to be sure all safety

equipment is in place and operating properly at all

times. If safety decals fade, are damaged, or be-

come unreadable in any way, they should be re-

placed immediately.

Obey Safety Rules

Checktherulesandregulationsatyourlocation.The

rules may include an employer’s work safety pro-

gram. Regulations may identify hazards such as

working around utility supply lines or hazardous

slopes.

New operators must familiarize themselves with the

equipment in an area without bystanders until they

are proficient in the use of all the controls and have

full control of the machine and all related compo-

nents and attachments under the conditions of the

work area.

Know the Work Conditions

Theoperatormustknowanyprohibitedusesorwork

areasforthemachine.Forexample,excessiveslopes

and poor or dangerous terrain conditions.

Make sure all the controls (levers and pedals) are in

the neutral position before starting the carrier.

Operate the carrier, Power

Tilt

, and/or quick-coupler

from the operator's seat

ONLY

. Make sure the seat

belt is fastened snugly before activating any con-

trols.

Machine stability is important! Do not exceed the

stabilitylimitsestablishedbythemanufacturerofthe

basemachine.OnlyusethePower

Tilt

inconjunction

with attachments which do not adversely affect the

stabilityofthemachine.Thecombinedweightsofthe

attachments and Power

Tilt

may require additional

counterweights. Consult the carrier manufacturer

and observe all local health and safety require-

ments.

Make certain that no other personnel are within the

arc described by the movement of the stabilizers,

frontbucket,attachment,boom,dipperstick,orother

moving parts.

Keephandsandfeetonthecontrolsatalltimeswhen

the machine is running.

When learning to operate a machine and related

equipment, do so at a slow pace.

Before leaving the operators seat, always lower the

loaderarmsandtheboomtoastablepositiononthe

ground.

Never

leave the machine with the engine running.

ALWAYS ENGAGE THE PARKING BRAKE.

Stop the engine before attempting to make any

repairs or adjustments to the carrier, the Power

Tilt,

or any other attachment.

MODIFICATION OF THE POWER

TILT

AnymodificationofthePower

Tilt

whichcouldchange

the function or reliability of the Power

Tilt

is done at

the owner’s risk and voids the warranty and CE

endorsement.

OPERATION

The Power

Tilt

should only be used to perform tasks

for which it was designed. Abusing the product and/

or using it for purposes for which it was not intended

can expose the operator and others to hazards as

well as result in damage to the Power

Tilt,

carrier,

and/or other attachments.

Please read this manual carefully and observe all

safety precautions.

Before operating the Power

Tilt

and bucket or other

attachment, make sure neither the attachment nor

thePower

Tilt

interferes withthebasemachine.Only

use attachments in con-

junctionwiththe Power

Tilt

that do not interfere with

the base machine or

operator’s area.

OTHER

PRECAUTIONS

The Power

Tilt

should be

treatedwiththesamecare

as a hydraulic cylinder.

The body should not make direct contact with hard

surfaces. Do not weld directly to the Power

Tilt

as

4

seals and other internal

componentscanbedam-

aged. Neveruseaquick-

coupler or the Power

Tilt

for lifting or craning of

materials. The Power

Tilt

increases the swing ra-

diusofbucketsandtools.

This can result in dam-

aging contact with the

boom, boom cylinder

and/or operator's area,

particularly in the fully

curled position. A de-

crease in breakout force

maybeexperienceddue

to the increased swing

radius and the added

weight of the Power

Tilt

to the stick. Do not ex-

ceed maximum recommended bucket widths —

refer to the chart to the right for more information.

MAINTENANCE

Daily

Grease the thrust washers at the two grease fittings

(Items 122 on Assembly Drawings) with a high quality

NLGI-2lithiumbasedgreasetoflushcontaminantsout

oftheseals.Continueapplyinguntilcleangreaseflows

fromthegreasereliefs(Items123onAssemblyDraw-

ings). Severe operating conditions such as abrasive

dust or prolonged submersion in water may require

more frequent grease applications.

Make sure the grease reliefs are functioning properly.

Never replace the grease relief valves

with grease

fittings or plugs and do not operate the Power

Tilt

if the

grease reliefs are not functioning. Open or replace

non-functioning grease reliefs immediately.

Mounting pins should be greased upon installation

and then according to equipment manufacturer’s

instructions.

Inspect the Power

Tilt

for loose, worn, or damaged

components and replace or repair immediately.

Weekly

Hydraulic fluid should be flushed weekly from the

Power

Tilt.

Positionthe Power

Tilt

sothat thehydrau-

lic ports are facing downward. Swing the bucket to

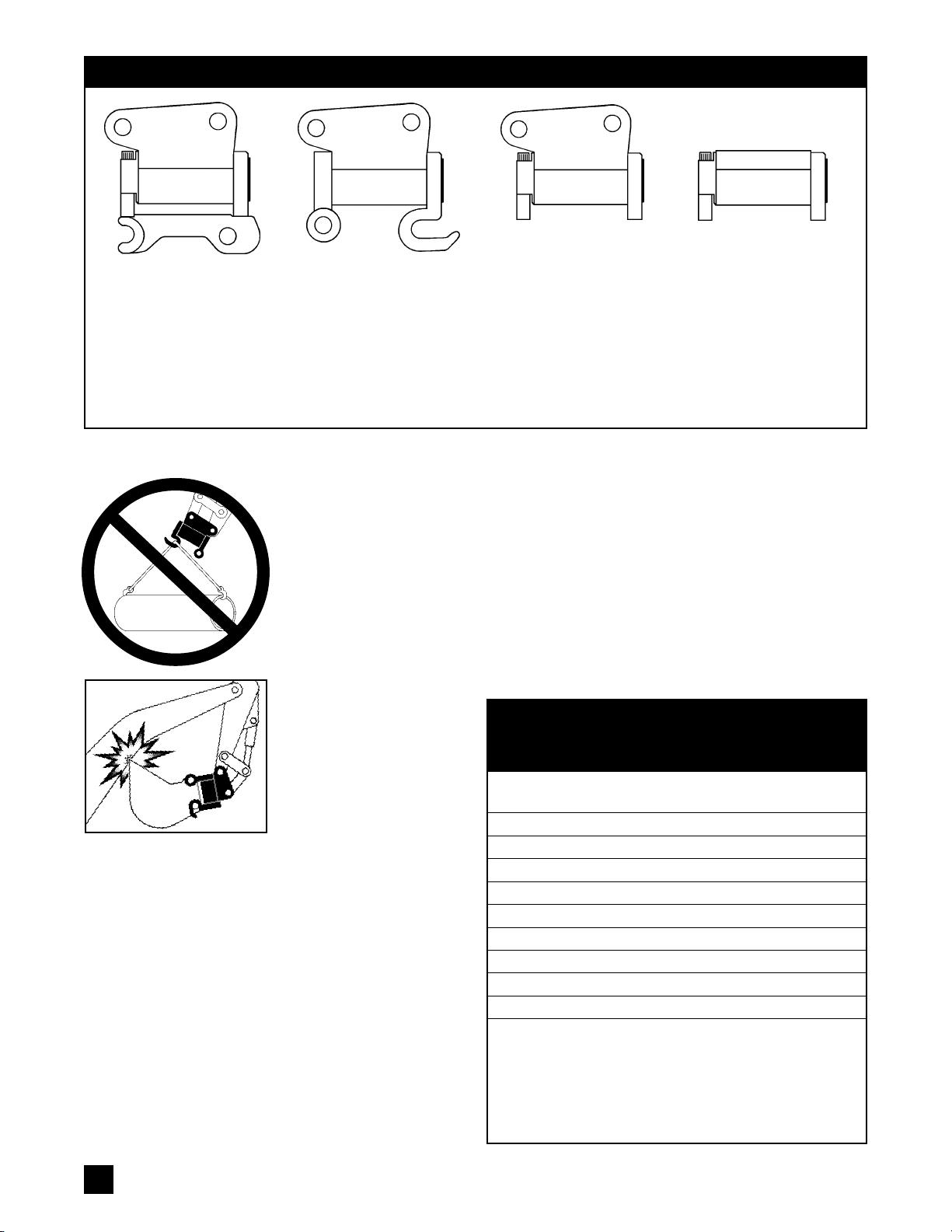

TT SERIES

Integral upper bracket

comes from the factory

readytopinmounttoaspe-

cificcarrier.Thelowershaft

bracketincorporatesahalf-

hitch quick coupler with

hook away from the opera-

tor and is designed to use

the carrier's OEM buckets.

PTB/TBB SERIES

The upper surface is de-

signed with a drilled and

tapped surface to permit

easy bolt-mounting of the

customer's brackets. The

lower shaft brackets are

unfinished.

PT (without coupler)

and TTB SERIES

Integral upper bracket

comes from the factory

ready to pin mount to a

specific carrier.The lower

shaftbrackets areshipped

unfinished to permit cus-

tomization in the field.

BASIC POWER

TILT

CONFIGURATIONS

POWER

TILT

MAXIMUM

MODEL BUCKET WIDTH

05 40" (100 cm)

06 42" (110 cm)

07 48" (120 cm)

08 55" (140 cm)

8.5 60" (150 cm)

09 60" (150 cm)

10 72" (180 cm)

11 75" (190 cm)

12 78" (200 cm)

MAXIMUM RECOMMENDED BUCKETS

FOR USE WITH THE POWER

TILT

FOR

LIGHT DUTY APPLICATIONS*

* Maximum recommended bucket widths above

are intended for light duty applications only.

Applyingthe full bucketcylinder capacitytothe

cornerofawidebucket(i.e.cornerdiggingwith

awidebucket)maycauseprematurewearand/

or reduced equipment life.

PT SERIES

Integral upper bracket

comes from the factory

readytopinmounttoaspe-

cificcarrier.Thelowershaft

bracketincorporatesahalf-

hitch quick coupler with

hook towards the operator

and is designed to use the

carrier's OEM buckets.

5

the end of rotation and then run the

Power

Tilt

circuitoverreliefforoneminute

to completely flush out all hydraulic fluid

and any contaminants which may have

settled in the Power

Tilt.

Reverse the fluid

direction and repeat so that both sides of

thepistonarepurged.Thisprocedurewill

contribute to reduced wear of internal

metalcomponents. The Power

Tilt

cannot

be flushed if the circuit pressure is below

3000 psi

(210 bar)

because the relief

valvesare set toopen between 3000 and

3200 psi

(210 and 220 bar).

Monthly

Check shaft endplay once a month. If endplay ex-

ceeds .015"

(.38 mm),

the end cap must be tight-

ened.

The end cap should not be tightened more

than 1/2 turn total over the life of the thrust

washers.

Tightening beyond1/2turncancausethe

endcaptogalltotheshaftaswellasindicatethatthe

thrust washers (Item 344 and/or 345) should be

replaced.Theendcapcanbetightenedusingeither

of the methods outlined below. For more detailed

instructions, refer to the appropriate sections of the

Disassembly and Reassembly instructions.

Torque wrench With the lockring removed (Item

05), torque the end cap with a torque wrench to the

values specified in the End Cap Torque Specifica-

tionsChartonpage26. If theendplayisbelow.015"

(.38mm),

reassembleandtorqueallfastenerstothe

values specified in Torque Specifications Chart on

page 26.

Hydraulic pressure With the lockring removed

(Item 05), torque by holding the end cap stationary

and hydraulically pressurizing Port P2 to the values

specified in the End Cap Torque Specifications

Chart on page 26. If the endplay is below .015"

(.38

mm),

reassemble and torque all fasteners to the

values specified in Torque Specifications Chart on

page 26.

POWER

TILT

SERIES IDENTIFICATION

There are four basic Power

Tilt

configurations as il-

lustrated on the top of page 4.Though the different

external configurations require slightly different in-

stallation and mounting procedures, all Power

Tilts

are essentially identical internally. The Series can

also be identified by the first two or three charac-

ters of the model number on the ID Tag. Detailed

Assembly Drawings for each Series' can be found

on pages 15-21.

INSTALLATION AND MOUNTING

PT and TT Series Models

EachPower

Tilt

iscustomizedfora specific backhoe

or excavator and is designed to be pin mounted

directly to the machine. Two sets of pins are re-

quired: one set to mount the Power

Tilt

to the

dipperstick,andasecond set tomountthebucketor

attachment to the Power

Tilt

.

Installing the Power

Tilt

onto the carrier

All Power

Tilt

models should be mounted to the

carrier according to the instructions outlined below.

Referring to the illustration above, position the

Power

Tilt

close to the carrier boom to ensure easy

useoftheliftingreachandrangeofthecarrierboom.

Lower the dipper to approximately 2-3" (50-75 mm)

above the Power

Tilt

. Roll out the bucket cylinder to

lowerthelinkbarstothePower

Tilt

.AlignthePower

Tilt

and link bar holes and install the link pin. Slowly lift

the Power

Tilt

to a safe height with the bucket and

boom cylinders. Curl the bucket cylinder until the

Power

Tilt

and dipper holes align and install the

bucket pivot pin.

The above mounting procedure should be com-

pleted without excessive force.

Rotatethepinsasnecessaryandinstalltherequired

retainers.

Do not attach a bucket or attachment to the

Power

Tilt until the hydraulic tool circuit is in-

stalled and operating correctly.

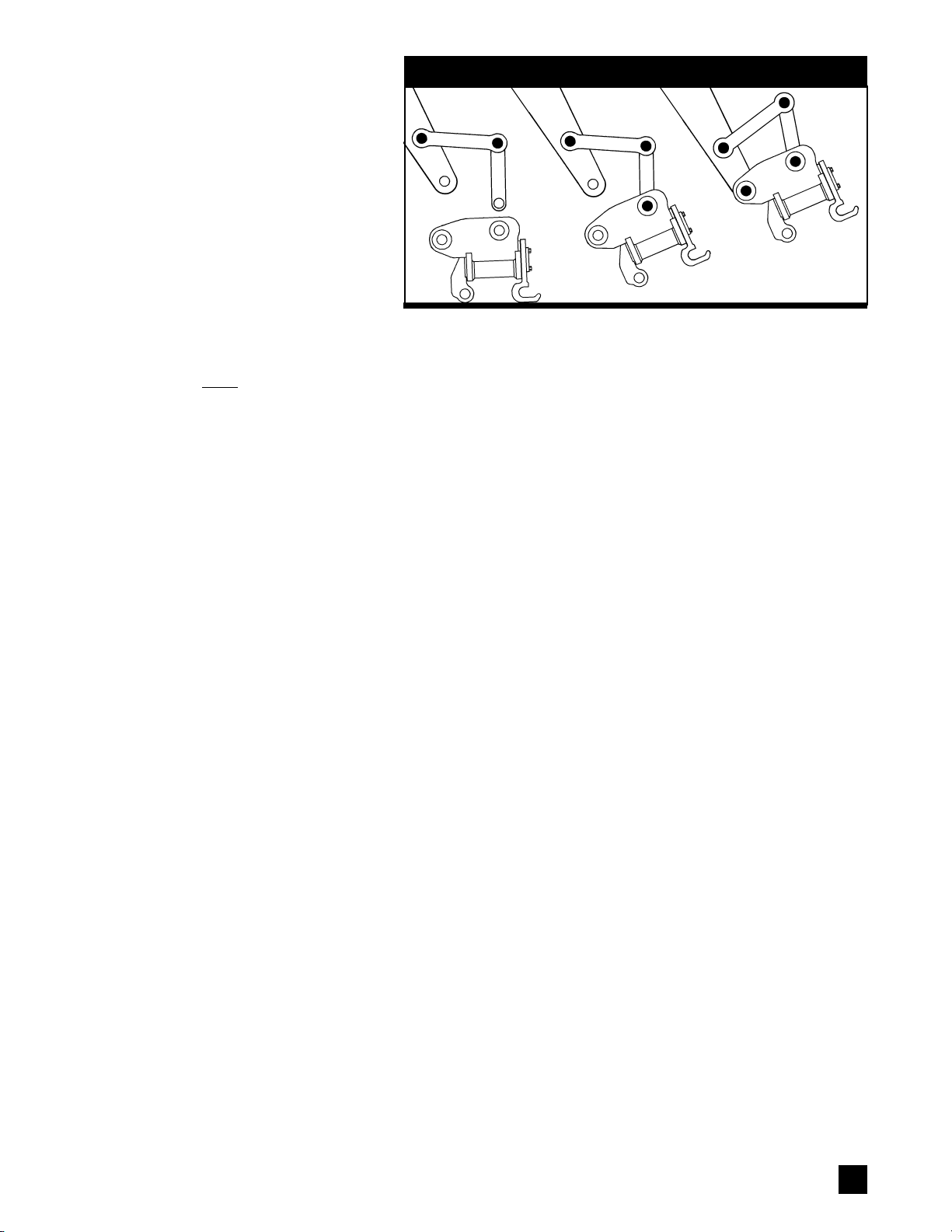

Mounting a bucket

or attachment to the Power

Tilt

Referring to the illustrations appropriate for your

Power

Tilt

modelat thetopofpage6,installthehook

pin in the bucket and position the bucket so the pin

can be easily reached with the Power

Tilt's

hook as

shown. Hook the bucket pin being sure the hook is

properlyalignedtoavoiddamagingthehook.Liftthe

bucketofftheground,thencurlthebucketcylinderto

pivotthePower

Tilt

untilthesecondholeofthebucket

aligns with the Power

Tilt's

coupler pin hole. Install

the second pin and retain properly.

PTANDTTMODELSWITHJACKINGBOLTS:

After

mounting the bucket for the first time, the jacking

bolts(Item 125) onthe back sideof the hookrequire

adjustment. Loosen the jam nut (Item 126) and

thread the bolt until it just contacts the pin, then

tighten the jam nut to lock the bolt in place. Proper

adjustment will make it easier to align the mounting

pins when changing buckets.

TT MODELS ONLY:

If the second pin cannot be

inserted because the Power

Tilt's

shaft bracket and

hook are not correctly aligned, the idler hook (Item

INSTALLING THE POWER

TILT

ONTO THE CARRIER

6

06)mustbeadjusted.Theidlerhookis

clamped in place by the lockring (Item

05). Loosen the lockring cap screws

(Item 120) and position the idler hook

asnecessary.Torquethelockringcap

screws to the values specified in

Torque Specifications Chart on page

26. After both pins are inserted, there

should be a gap of no more than 5/16"

(8 mm) between the hook and its pin.

If this distance is exceeded, please

consult the factory.

Removing a bucket

or attachment from the Power

Tilt

Refer to the illustrations appropriate for

your Power

Tilt

model at the bottom left.

PT MODELS:

With the bucket just

abovethe ground,remove thecoupler

pin (the pin furthest from the cab).

Gently place the bucket on the ground

andmove thePower

Tilt

awayfromthe

bucket to disengage completely, use

the curl cylinder if necessary to make

disengagement easier. Be careful not

to damage the Power

Tilt's

hook.

TT MODELS:

Lift the bucket slightly

and remove the coupler pin (the pin

closesttothecab).Withthebucketjust

contacting the ground, curl the

Power

Tilt

in until the bucket disen-

gages and drops free. Do not curl in

with the bucket on the ground — the

Power

Tilt's

hook can be damaged if

the full force of the curl cylinder is

applied.

PTB, TTB and TBB Series Models

Each PTB, TTB and TBB Series

Power

Tilt

is designed for a specific

backhoe or excavator weight class.

The TTB upper housing brackets are

customizedtopinmountthe Power

Tilt

directly to the dipperstick while the

torque foot (Item 07) and idler foot

(Item06)are designedtobe fittedwith

lower mounting bracket assemblies

specific to the application and/or cus-

tomer. TBB units are designed to be

fittedwithbothupperandlowermount-

ing bracket assemblies specific to the

carrier and/or customer application.

Toassistattachmentdesignersinprop-

erly sizing the mounting brackets and

hardware, Helac can provide an Engi-

neering Design Guide. Contact Helac

Corporation for more information.

Important: The top mounting bracket

must include rotational shaft stops to

prevent the bottoming of the internal

PT SERIES MODELS

TT SERIES MODELS

REMOVING A BUCKET FROM THE POWER

TILT

PT SERIES MODELS

TT SERIES MODELS

MOUNTING A BUCKET ONTO THE POWER

TILT

7

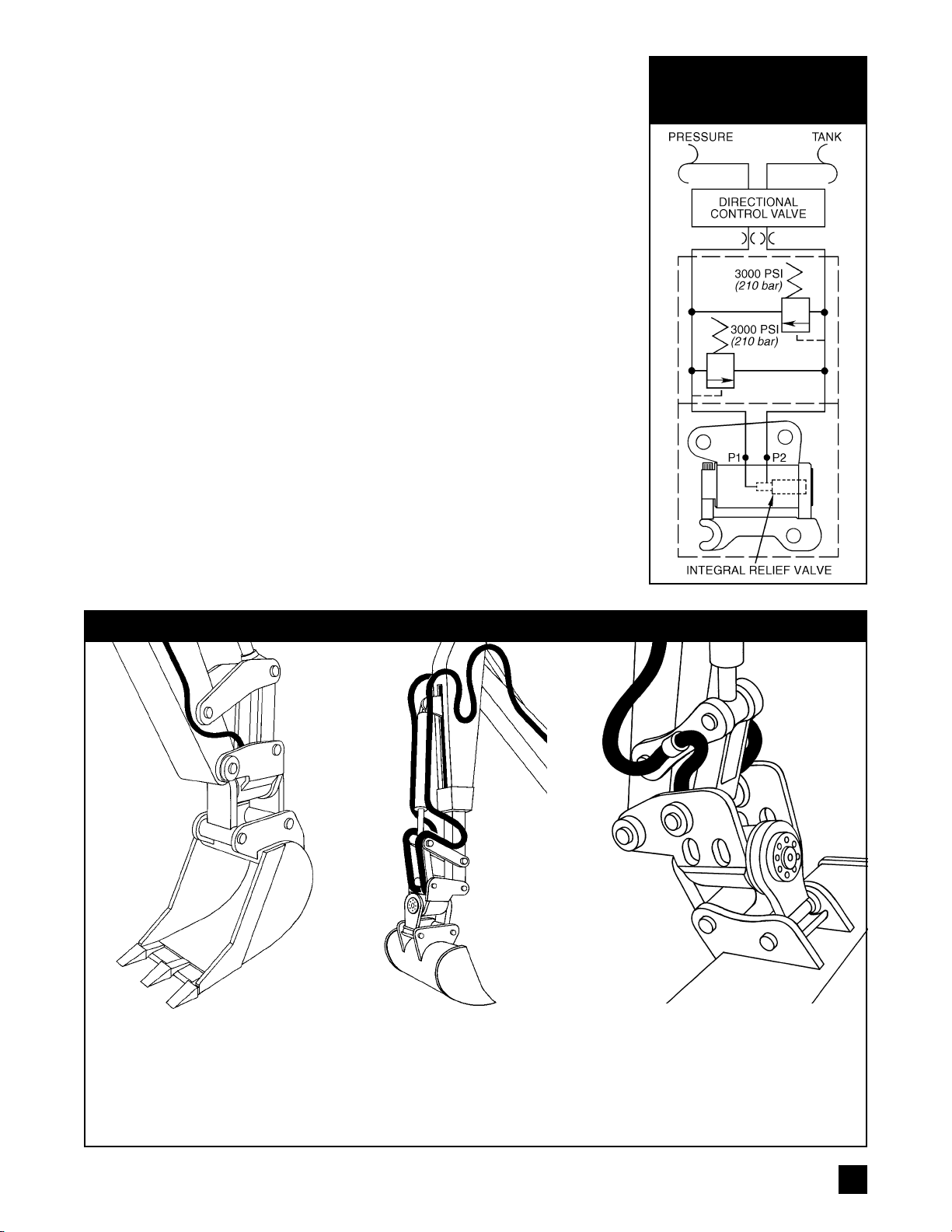

TYPICAL

POWER

TILT

CIRCUIT

(PT Model Shown)

piston.ThePower

Tilt

shouldbemounted on thecarrierwiththetorque foot

(Item 07) oriented towards the carrier.

Forinstructionsonproperbucketandattachment mounting anddismount-

ing,pleaserefertothirdpartybucket/attachment/coupler manufacturer(s).

HYDRAULIC REQUIREMENTS AND PLUMBING

The carrier must be fitted with a two-way hydraulic circuit (a typical circuit

schematic is provided to the right). A three position, four way valve is

required to control Power

Tilt

swing. The Power

Tilt

must be protected from

pressures above 3000 PSI (210 bar) by work port or integral cross port

reliefs.AllPower

Tilts

manufacturedsince1997exceptfortheTT-5models

includean integralcross portrelief incorporatedinto theshaft as standard.

Itistheresponsibilityofthedealerand/orcustomertobesurethetool

circuit meets the Power

Tilt

hydraulic requirements.

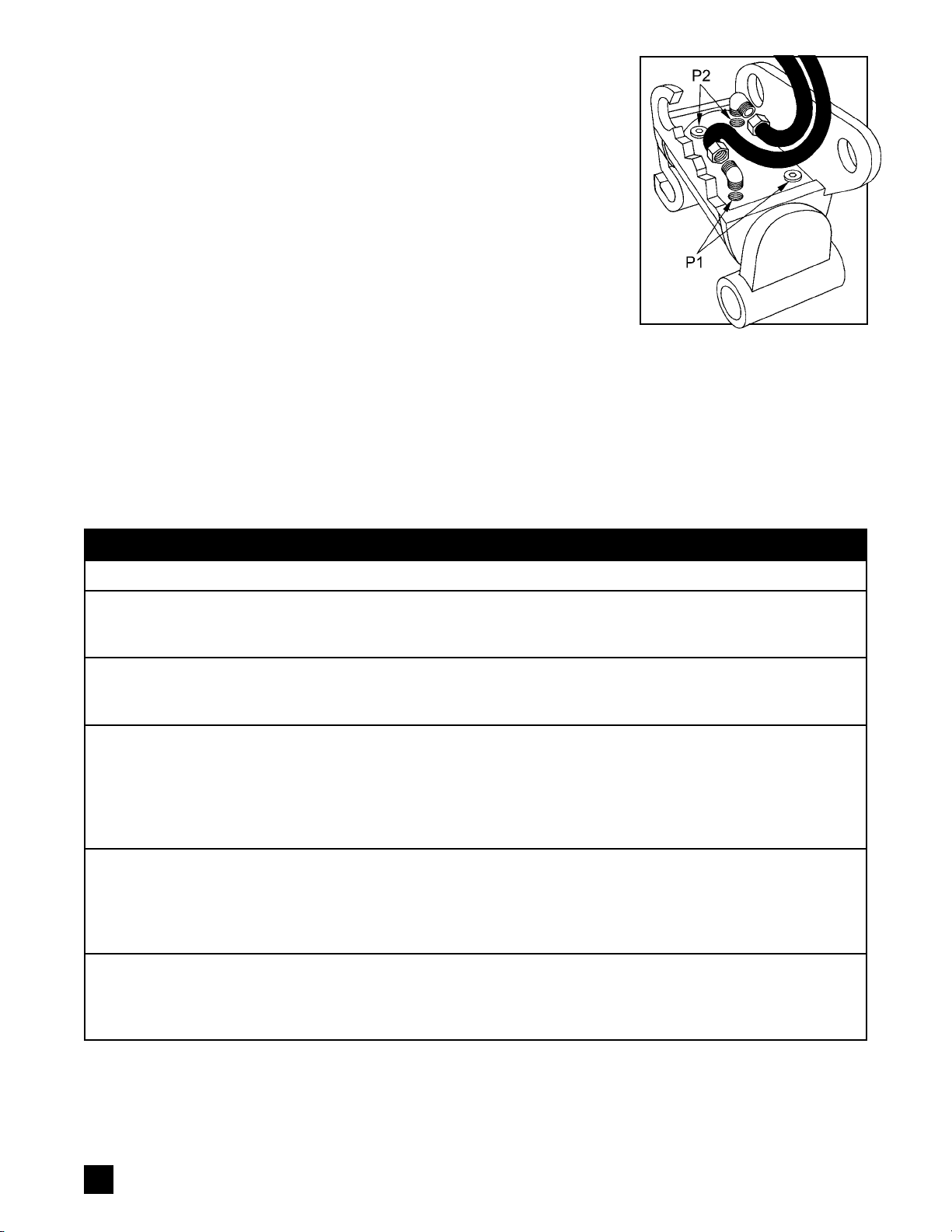

PT, TT and TTB Series: To assist in easy hose routing, each Power

Tilt

modelis manufactured withfour ports:twoPorts P1and two PortsP2 (see

Assembly Drawings and illustration on page 8). One hose should be

attached to either of the P1 ports and the second hose should be attached

toeitheroftheP2ports.Power

Tilts

deliveredtoNorthAmericancustomers

incorporate SAE port configurations at all four ports; Power

Tilts

delivered

tocustomersoutside of NorthAmericaincorporate either BSPPorJIS port

configurations at all four ports.

PTBandTBB Series: Eachmodelisportedonthetopofthehousing.The

ports consist of one Port P1 and one Port P2 (see Assembly Drawings on

pages 20 and 21). Both ports are BSPP.

AllModels:Thesmallestlinesizeandthemostdirectlineroutingwillresult

in the best possible performance of the Power

Tilt

. Hose and tube size

recommendations can be found in the Tool Circuit Requirements chart at

The hoses are routed along the

sides of the dipperstick, around

the link pins and between the

Power

Tilt

housing brackets.

For extendable dipperstick installa-

tions,be sure thereis sufficient hose

when the dipper is fully extended.

The hoses are clamped to the curl

cylinder, along the link bars, then

under the link bars and between the

Power

Tilt's

housing brackets.

The hoses are routed along the

sides of the dipperstick, looped

andclampedtothelinksorrouted

throughguidesonthelinks,then

routedbetweenthelinkbarsand

the Power

Tilt's

housing brack-

ets.

SUGGESTED HOSE ROUTINGS

8

the bottom of page 8. Use high pressure, braided steel hose and/or steel

tubing which meets or exceeds the hydraulic system's rating.

To minimize the possibility of damage to the hydraulic circuit, it is

recommendedthat lines andhoses berouted usingoneof thesuggested

hoseroutingsillustratedatthebottomofpage7.Becauseeachcarrierand

installation is different, the illustrations are intended as general guides

only. Use the routing that is most appropriate for your installation.

Hoses to the Power

Tilt's

ports should be routed between the housing

brackets and not through the openings in the brackets adjacent to the

ports (these are used for the manufacturing process). Depending on the

geometry of the installation, it may be adviseable to cover the hoses with

protective sheathing.

Connect hydraulic hoses to the appropriate ports using 90° elbow fittings

asseenintheillustrationtotheright.Besurethehosesdonotcross,foul,

crush, or chafe when operating the Power

Tilt

or machine. Verify proper

hoseroutingforallpossiblepositionsofthePower

Tilt

andallattachments

whicharetobeusedwiththePower

Tilt

.Repairany oil leaks immediately.

Ifinstallinganewtoolcircuitornewhydrauliclines

,

flushallthetoolcircuit

lines with hydraulic oil prior to connecting the Power

Tilt.

This will remove

any contaminants from the circuit components which may have accumu-

lated during manufacturing and/or installation.

TOOL CIRCUIT REQUIREMENTS

MODEL 05 06 07 08 8.5 09 10 11 12

DISPLACEMENT

IN317 32 62 89 106 118 159 215 277

cm3278 525 1060 1458 1740 1934 2600 3515 4540

REQUIRED FLOW

GPM .5-1 .8-1.5 1.5-3 3-5 4-6 6-7 6-8 8-11 9-13

Liters/minute 2-4 3-6 6-12 12-20 16-24 24-28 24-32 32-44 36-52

PORT CONNECTIONS

PT/TT/TTB Series - 4 PORTS (2 EACH P1 & 2 EACH P2)*

SAE 6 4 4** 6 6 6 6 6 6

BSPP ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

PTB/TBB Series -2 PORTS (1 EACH P1 & 1 EACH P2)

BSPP ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼ ¼

HYDRAULIC HOSE & TUBE SIZING

HOSE 3/8"(-6) 3/8"(-6) 3/8"(-6) 3/8"(-6) ½"(-8) ½"(-8) ½"(-8) 5/8"(-10) 5/8"(-10)

TUBE (OPTIONAL) 3/8"(-6) 3/8"(-6) 3/8"(-6) 3/8"(-6) ½"(-8) ½"(-8) ½"(-8) 5/8"(-10) 5/8"(-10)

WHIP HOSE ¼"(-4) ¼"(-4) ¼"(-4) ¼"(-4) ¼"(-4) 3/8"(-6) 3/8"(-6) 3/8"(-6) 3/8"(-6)

(To POWER

TILT)

HYDRAULIC PRESSURES FOR ALL MODELS

OPERATING PRESSURE RANGE 1900-3200 PSI (130-220 bar)

CIRCUIT PRESSURE RANGE 3200-3500 PSI (220-240 bar)

MAXIMUM CIRCUIT BACK PRESSURE*** 600 PSI (40 bar)

* AllPT,TTandTTBSeriesPower

Tilts

manufacturedforNorthAmericancustomersincorporateSAEport

connections. PT, TT and TTB Series Power

Tilts

manufactured for customers outside of North America

and all PTB and TBB Series units incorporate BSPP or JIS port connections.

** Some Model TT-7's incorporate SAE-6 for all ports.

*** Power

Tilts

equipped with factory installed integral cross port relief valves only.

9

TROUBLESHOOTING GUIDE

PROBLEM POSSIBLE CAUSE SOLUTION

Power

Tilt

does not Excessive down pressure This is normal. The integral cross

hold position. applied by excavator causing port relief valve is designed to protect

buildup of pressure in the the Power

Tilt

from excessive internal

Power

Tilt

which is opening pressures that can damage the unit.

the cross port relief valve.

A bi-directional hydraulic Install pilot operated check valves.

motor control valve is being

used without pilot operated

check valves to hold

pressures.

Control valve leaking oil. Test. Repair or replace as needed.

Faulty cross port relief valve. Remove integral cross port relief

valve and visually inspect for

damage or debris. Check pressure

setting of cross port relief valve: non-

adjustable, factory set to open at

2900 to 3200 PSI (197 to 220 bar).

Replace if not within specification.

See Testing and Troubleshooting

on page 10 for testing instructions.

Seals leaking oil. Test. Replace seals as necessary.

See Testing and Troubleshooting

on page 10 for testing instructions.

Power

Tilt

swings in only Single directional control Replace with bi-directional control

one direction. valve is being used. valve.

Cross port relief valve Inspect, test. Replace as needed.

damaged.

Power

Tilt

has spongy Air in Power

Tilt

or Bleed air from circuit.

feel side to side. hydraulic circuit.

Diameter of tubing/hoses Install tubing/hoses with recommended

larger than recommended. diameters.

Install pilot operated check valve in

lines as close as possible to Power

Tilt

.

Forward and backward Worn or missing Tighten end cap (see Maintenance,

movement of shaft in thrust washers. Monthly, page 5). Replace or install

housing (shaft endplay). thrust washers if necessary.

Side to side Some movement is normal Normal movement is 1° to 1½°. If

bucket movement. due to clearance required greater than normal, check shaft

between internal spline endplay; excessive endplay can

teeth. contribute to side to side movement. If

shaft endplay is within acceptable

limits, consult factory.

Power

Tilt

will not accept Grease relief not functioning Clean or replace grease relief valves.

grease at grease fittings. or replaced with grease

fitting or plug.

10

TESTING AND TROUBLESHOOTING

Carrier Hydraulic System Testing

If symptoms of poor performance develop, the chart

on page 9 can be used as a guide. The information

provided is general in nature and does not address

specific applications. When diagnosing faults in

Power

Tilt

operation, it is the responsibility of the

service technician to verify that the carrier and hy-

draulic circuit are operating correctly. Because the

Power

Tilt

receives its power from the carrier, a

thorough check of the carrier hydraulic system is

mandatory before performing any Power

Tilt

service

or adjustments.

Using an accurate flow meter that can operate on a

bi-directional tool circuit, verify correct operation of

the carrier hydraulic system at an operating tem-

perature of at least 80°F (28°C). The flow meter

should be attached first to the hoses that are nor-

mally connected to the Power

Tilt

. In this way, the

entire system from the carrier pump to the Power

Tilt

hoses can be checked for proper performance.

If low performance of the hydraulic system is found,

begin checking upstream of the directional control

valve to verify that the correct input flow and pres-

sureareappliedtothevalve.Iftheflowandpressure

input to the valve are correct, then the problem is in

the valve or the hoses and couplings that lead to the

Power

Tilt

.

Testing the Power

Tilt

Internal leakage

1.Connect a 5000 PSI (350 bar) test gauge into the

line to Port P1. Pressurize until the shaft reaches

theendofrotationandbottomsoutexternally,e.g.

The Power

Tilt

uses Helac's sliding spline

technology which converts linear piston

motion into powerful shaft rotation. The

Power

Tilt

is composed of a housing and

only two moving parts: the central shaft

andtheannularpiston.Helicalsplineteeth

machined on the shaft engage matching

splines on the inside diameter of the pis-

ton. The outside diameter of the piston

carries a second set of splines, of oppo-

site hand, which engage with matching

splinesin thehousing's integralring gear.

As hydraulic pressure powers the piston

back and forth within the housing — simi-

lar to the operation of a hydraulic cylinder

— the splines cause the shaft to rotate.

All working components are protected by

the steel housing. Tough exclusion seals

keep out dirt, water, and other contami-

nants.

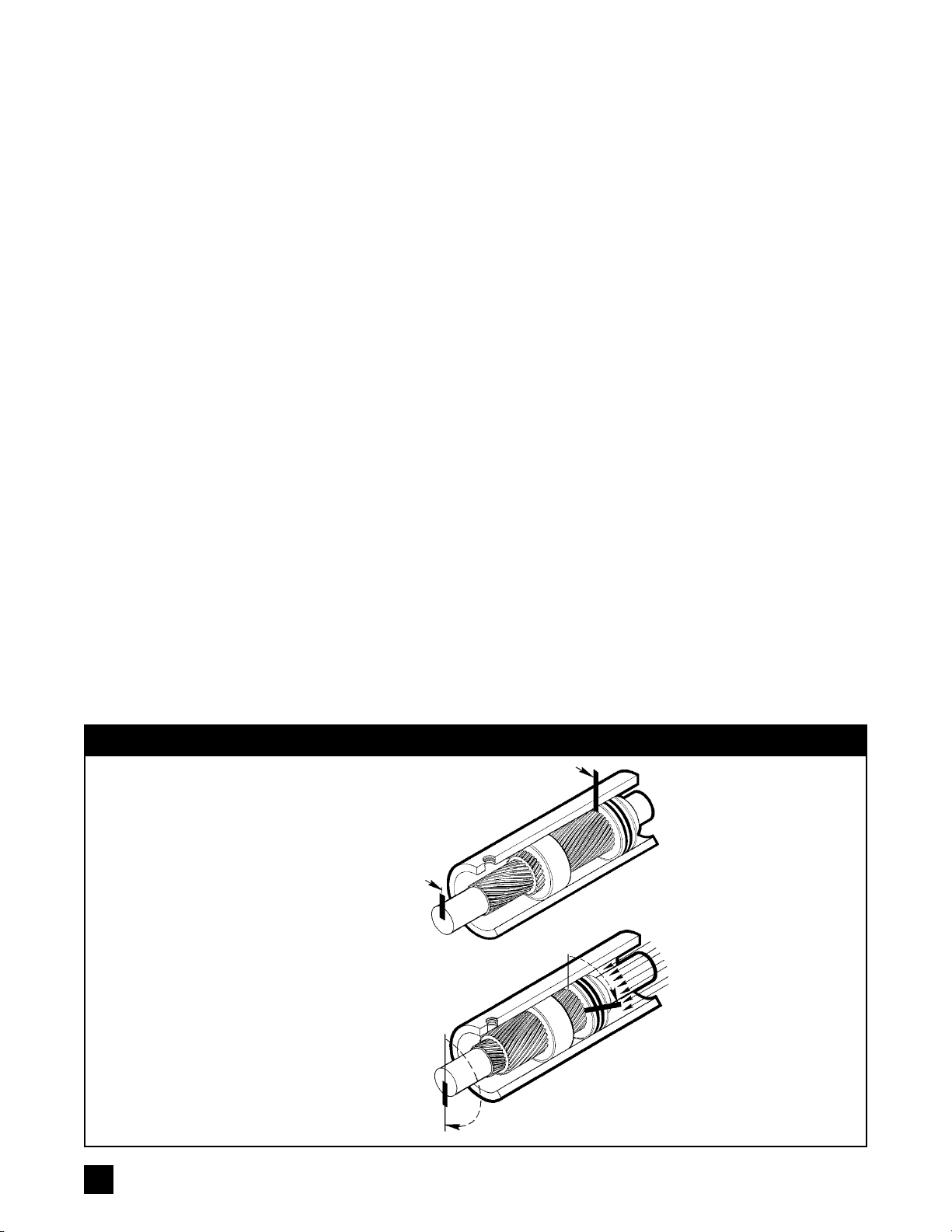

Bars indicate starting

positions of piston and

shaft. Arrows indicate

directions they will rotate.

The housing with integral

ring gear remains

stationary. For the sake of

clarity, bearings, end cap,

brackets, couplers, etc.

are not shown.

As fluid pressure is

applied, the piston is

displaced axially while the

helical gearing causes the

simultaneous rotation of

the piston and the shaft.

Helac's unique double

helix design compounds

rotation: shaft rotation is

about twice that of the

piston.

the shaft bracket or torque foot contacts the

housing or mounting bracket. CAUTION: If the

shaft is not completely bottomed out, hydraulic

fluid will exhaust from Port P2 at a high velocity in

Step 2 below.

2.Remove and cap the line to Port P2. Pressurize

Port P1 to 2500 PSI (175 bar). Check for leakage

atPortP2andfromaroundthemainshaftandend

capseals.Leaksindicatewornordamagedparts.

3.Reconnect the hydraulic line to Port P2 and pres-

surize as in Step 1 above.

4.Check for leaks at Port P1 and around the main

shaft and end cap seals, etc. as in Step 2 above.

Cross port relief valve

Theintegralcrossportreliefvalveventshydraulicoil

aroundtheinternalpistonassemblyofthePower

Tilt

at approximately 3000 PSI (210 bar). To test:

1.Connect a 5000 PSI (350 bar) test gauge into the

line to Port P1. Relieve pressure at Port P2 then

remove hose and cap circuit at Port P2.

2.Slowly pressurize Port P1 noting pressure at

which oil flows from P2. The relief should hold

pressureto approximately 2900to 3200 PSI(200

to 220 bar).

3.Test at Port P2 using the same procedure.

The cross port relief valve is set at the factory and

cannot be adjusted. If test pressure does not meet

specification, the valve must be replaced. If piston

seal leakage is suspected, relief port test plugs are

availablefromthefactory.NOTE:TT-5andTT/TTB/

TBB-8.5modelsdonotincorporateanintegralcross

port relief valve.

OPERATING CONCEPT

11

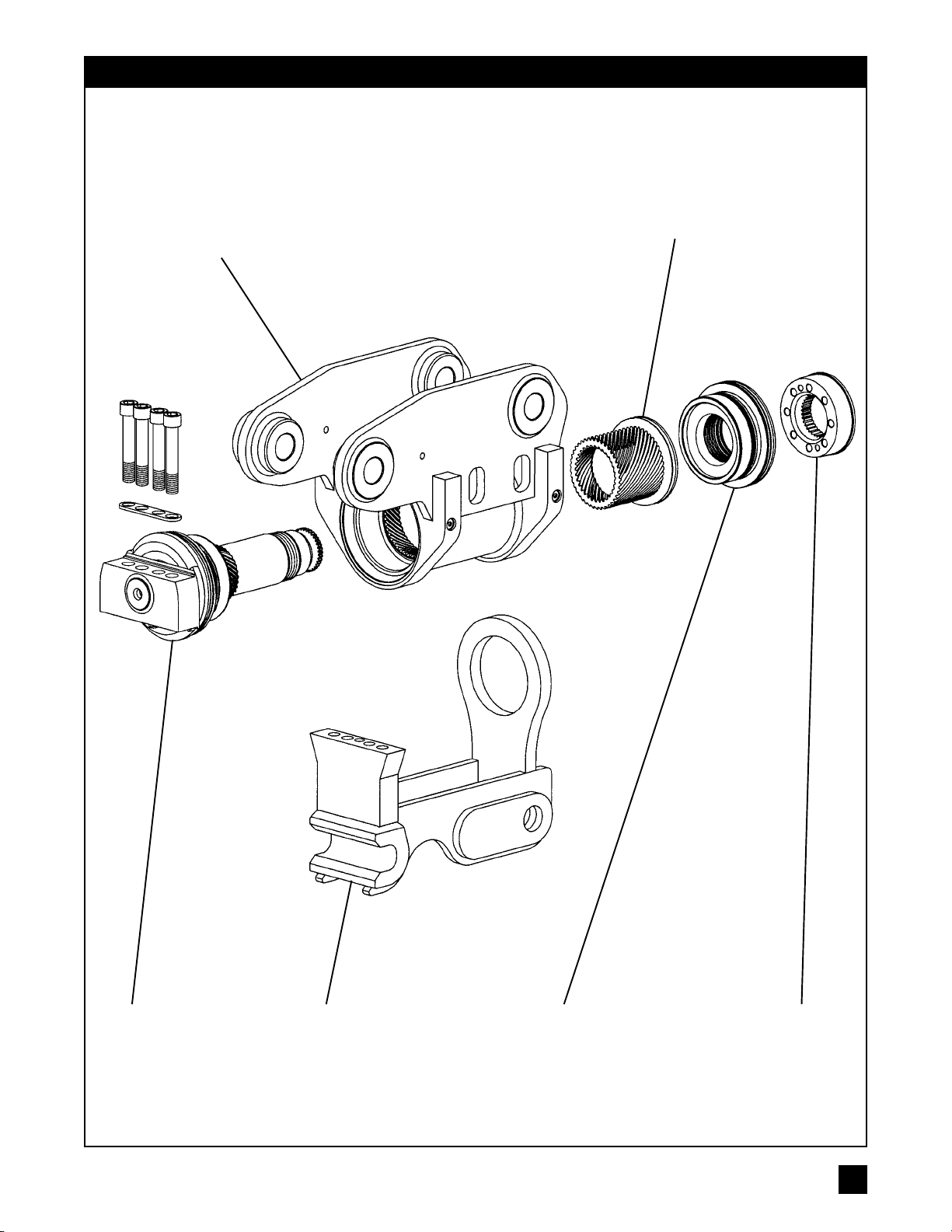

EXPLODED VIEW

PT SERIES MODELS

END CAP

WITH BEARINGS

PISTON

SLEEVE

SHAFT

HOUSING WITH

INTEGRATED

RING GEAR

LOCKRINGSUBFRAME

COUPLER

PHOTO A

PHOTO B

12

DISASSEMBLY

Note: Metric fasteners are used throughout.

1. Removeallhydraulicfittings.PlacethePower

Tilt

onacleanworkbench

with ample room to place the internal parts as they are removed.

2. PT/PTB/TTB/TBB Series - Subframe coupler removal

1) Unthread and remove the torque foot mounting screws (104).

2) Unthread and remove the lockring screws (120) and the lockring

set screws (129).

3) Thread two lockring screws (120) into two diagonally opposed

threaded holes in the lockring (05). Advance the screws equally a

littleatatimeinordertojackthelockringofftheshaft(02)andidler

foot (06).

4) PTSERIESLiftthehousingassemblyoutofthesubframecoupler

(09).Notethereisanalignmentdowelpin(105)betweentheshaft

and subframe coupler. Remove the lockring O-ring (239).

PTB/TTB/TBB SERIES Lift the housing assembly out of the idler

foot (06), torque foot (07) and any associated buckets, attach-

ments, and/or other lower assemblies. Note there is an alignment

dowel pin (105) between the shaft and torque foot.

5) Place the housing assembly on a clean, level work surface.

TT Series - Half-hitch coupler removal

1) Unthread and remove the lockring screws (120) and the lockring

set screws (129).

2) Remove the lockring (05), then the idler hook (06). If the lockring

is difficult to remove, thread two lockring screws (120) into two

diagonally opposed threaded holes in the lockring (05). Advance

the screws equally a little at a time in order to jack the lockring off

the shaft (02) and idler hook (06).

3) Place the housing assembly on a clean, level work surface.

3. Unthread the port plug (101) and remove the cross port relief valve

(413).NOTE:TT-05andTT/TTB/TBB-8.5modelsdonotincorporate

an integral cross port relief valve.

4. Unthread the end cap (04) from the shaft (02) and remove the thrust

washer(344). A considerableamount ofoilmay flowout the housing

when the end cap is removed.

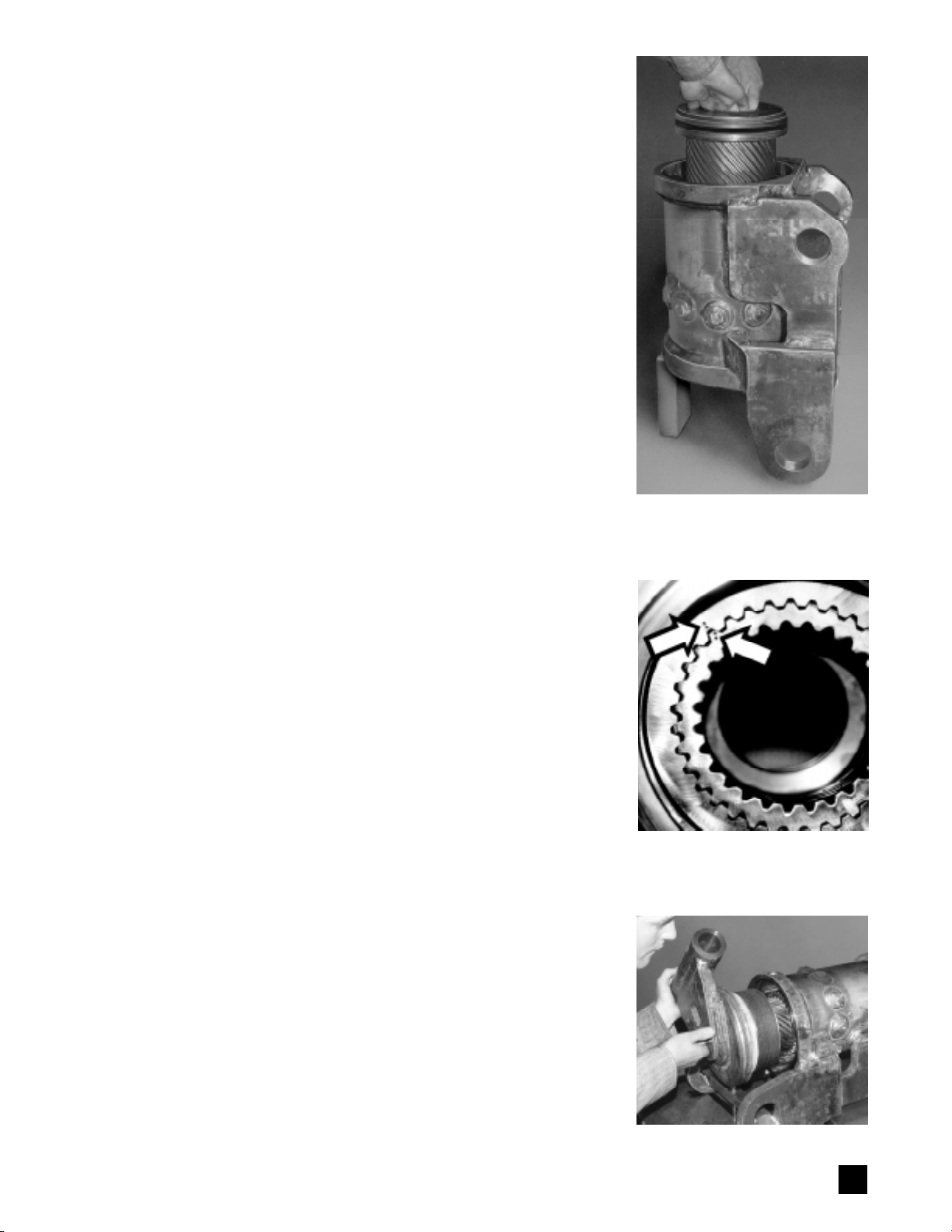

5. Rotate the shaft to slide out of engagement with the piston sleeve

assembly(03).Aconsiderableamountofoilmayflowoutthehousing

when the shaft is removed. Note the orientation between the spline

teeth on the piston sleeve and shaft: small punch marks on the face

ofthesplinedpistonsleeveandtherootofashaftsplinetoothindicate

timing. See Photo A. Correct orientation will assure proper timing

during reassembly. Remove the thrust washer (344 or 345). For PT

andTTSeriesmodels,removetheshaftbracketbushings(116) only

if they exhibit excessive wear.

6. Rotate the piston sleeve assembly (03) out of engagement with the

housing(01).Greatcareshouldbetakentoinsurethatthegearteeth

are not damaged and the housing bore is not scratched when the

piston is removed. Support the piston as it clears the housing to

prevent damage. If seal friction makes it difficult to move the piston,

use a rubber mallet and hard rubber bar as seen in Photo B.

For Models 08, and larger, it is easier to position the Power

Tilt

vertically to remove the piston as seen in Photo C.

7. Depending on the model, the piston sleeve may be a one-piece or

two-pieceassembly. The two-pieceassembly consistsof aseparate

piston and sleeve that are threaded together and cross pinned.

The

piston sleeve does not need to be disassembled unless the O-

ring (232) is suspected of leaking.

To disassemble Models 08/10/

11/12removethepistonbearing(343).ForModels07/8.5/09remove

PHOTO E

PHOTO D

PHOTO C

13

the cross pin retainer (127), either a wire or an O-ring, depending on

the model. If necessary, remove the cross pins (121) and unthread

the piston and sleeve.

8. Remove the grease fittings (122), grease relief covers (107), and

grease reliefs (123).

9. Remove all seals and bearings from their grooves — note orienta-

tions of seal lips prior to removal.

10. Cleanallcomponentsthoroughlywithsolventorinapartswasher. Be

sure to flush all grease and contaminants from grease fitting and

grease relief passages.

PARTS INSPECTION

1. Inspect all parts for wear, damage, cracks, etc.

Housing Inspect the cylinder bore for wear and scratches. The

surface finish should be 32 RMS or better. If the bore requires

rehoning, return the housing to Helac Corporation for rehoning.

Inspectallbearingcontactsurfacesfordamageand/orcontamination

andrepairandcleanasnecessary.Inspecttheexteriorofthehousing

for damage, cracks, integrity of welds, etc.

Bearings Allradialbearings areofa glass-reinforced nylonmaterial.

If the thickness measures less than .123" (3.125 mm), the bearings

should be replaced.

Thrust washers If the thickness measures less than .105" (2.65

mm), the thrust washers should be replaced.

Seal grooves Inspect for damage.

Shaft, end cap, idler hook, and subframe coupler Rough and

groovedbearingjournalsrequirereplacementoftheshaftand/orend

cap. Be sure end cap threads are clean and without burrs. Inspect

external parts for damage, integrity of welds, excessively worn shaft

bracket bushings, etc.

REASSEMBLY

Itisrecommendedthatyoufirstpracticeassemblingthe

Power

Tiltwith

thebearings installed but withoutseals. The sealsare easily damaged

and their increased friction makes assembly more difficult. All seals

must be replaced whenever the

Power

Tilt is reassembled. The thrust

washersshouldbecheckfitpriortoinstallation.Handlethrustwashers

carefullytopreventdamage.Tighten all fasteners to torques specified

in the Torque Specifications chart on page 26.

1. Wash all parts thoroughly, blow dry, and protect from corrosion.

2. Install grease fittings (122), grease reliefs (123), and grease relief

covers (107). Pump a high quality NLGI-2 lithium based grease into

the grease fittings (122) to flush any contaminants out of the fittings

and passages and to insure the fittings are functioning properly.

Replace any nonfunctioning fittings. Wipe off all excess grease.

3. Lightly coat all sealing and working surfaces with a good grade of

hydraulic oil.

4. One piece piston sleeves Install seals (234) (235) on the piston

sleeve (03). Install bearing (342).

Two piece piston sleeves

(Some Models 07, all Models 08 through

12):

InstallO-ring(232)andback-uprings(233)onthepiston.Thread

pistonandsleevetogetheruntilcrosspinholesalign.Insertcrosspins

(121). For Models 07, 8.5 and 09 install the cross pin retainer (127),

either a wire or an O-ring, depending on model. Install seals (234)

(235) on the piston sleeve assembly with the lips oriented as seen in

theDetailDrawings onpages22 and 23.Installbearings (342)(343).

Note: Models 06, 07, 08, 09 and 11 have only one seal each on the ID

and OD of the piston sleeve. Models 8.5, 10 and 12 require one each

P2tothevaluesspecifiedintheEndCapTorque

Specifications chart on page 26.

13. PT/PTB/TTB/TBB Series

Subframe coupler installation

1) Insert the shaft dowel pin (105) into the shaft (02).

2) Check fit the alignment of the lockring (05)

and end cap (04) by threading the lockring

screws (120) into the end cap. If the holes do

not align, thread the end cap in or out slightly

as necessary. After alignment is confirmed,

remove the lockring and cap screws.

NOTE:

Do not rotate the shaft with the lockring re-

moved after torquing the end cap.

3) Coat the exposed diameter of the shaft,

lockring splines (05), and interior surfaces of

PT model subframe coupler (09) and PTB/

TTB/TBB model idler foot (06) with grease.

4) PT SERIES Install the housing/shaft assem-

bly

into the subframe coupler (09).

PTB/TTB/TBB SERIES Install the top mounting

brackets(PTB/TBBSeriesonly).Installthehous-

ing/shaft assembly

into the lower mounting

bracketassemblywhichincludesthetorquefoot

(07), idler foot (06), and any associated lower

buckets,attachments,and/orotherassemblies.

5) Install the lockring (05). Install the lockring

screws (120) and lockring set screws (129).

Install the washer plate (106) and the shaft

mounting screws (104). Torque all fasteners

asspecifiedintheTorqueSpecificationschart

on page 26.

TT Series

Half-hitch coupler installation

1) Check fit the alignment of the lockring (05)

and end cap (04) by threading the lockring

screws (120) into the end cap. If the holes do

not align, thread the end cap in or out slightly

as necessary. After alignment is confirmed,

remove the lockring and cap screws.

NOTE:

Do not rotate the shaft with the lockring re-

moved after torquing the end cap.

2) Coat the exposed diameter of the shaft, interior

surfaces of the idler hook (06) and lockring

splines (05) with grease.

3) Installtheidlerhookandtimewiththefrontshaftbracket.

4) Install the lockring (05). Install the lockring

screws (120) and lockring set screws (129).

Torqueall fastenersto the values specified in

the Torque Specifications chart on page 26.

5) Install the shaft bracket bushings (116) if necessary.

14. Grease the thrust washers. Pump a high quality

NLGI-2 lithium based grease into the grease

fittings (122) at both ends of the housing until it

exhausts from the grease reliefs (123).

15. Install hydraulic fittings.

NOTE: The

Power

Tilt should be operated with-

outaloadforonetotwominutes,thenregreased

before going into service. Do not operate

the

Power

Tilt with the lockring removed.

seals (204) and (205) with the O-ring energizers

removedfromthesealsnearestthepistongearing.

5. Apply a thin coat of grease to all piston sleeve

seals, then install the piston sleeve in timed

relation to the housing ring gear. For Models 08

andlarger,itiseasiertoinstallthepistonwiththe

housingpositionedvertically as demonstrated in

Photo C. Time the piston by aligning the punch

marks on the gear faces as seen in Photo D.

Apply firm pressure as the new seals and bear-

ingsenterthehousing and becomecompressed

by the housing chamber; use a rubber mallet if

necessary.Pushthe piston into thehousinguntil

it bottoms out against the housing ring gear.

6. Position the housing horizontally. ForTT-05,TT/

TTB/TBB-06, and TT/TTB/TBB-07 single collar

designs, install the front thrust washer (345) in the

housing. For all other models (two collar designs),

install the front thrust washer (344) on the shaft.

Note: Thrust washers should be installed dry.

Install seals (236 or 237) (238) and bearing (340) on

the shaft (02). Some models have multiple bearing

strips; fill the groove completely with bearing strips.

7. Applyathinfilmofgreasetotheshaftseals,then

install the shaft as seen in Photo E in timed

relation to the piston sleeve by aligning the

punched timing marks as seen in Photo A. Tem-

porarily taping the threaded portion of the shaft

withmaskingtape can make iteasiertoclearthe

piston sleeve seals. Rotate the shaft until it is

completely bottomed out in the housing.

8. Remove the tape from the shaft threads and

apply anti-seize thread lubricant to the threaded

and surrounding areas of the shaft.

9. Install the thrust washer (344) on the end cap.

Note: Thrust washers should be installed dry.

10. Install seals (230) (231) (237) (238) and bearing

(340) on the end cap (04). See Detail Drawings

onpages22 and23for correct sealorientations.

Apply a thin film of grease to the seals, then

thread the end cap onto the shaft to a net fit

where the end cap just begins to clamp against

the thrust washer. For PT and PTB Series mod-

els, install the lockring O-ring on the shaft.

11. Install the relief valve O-ring (201), valve back-

upring(202),andvalveportO-ring(203).Thread

thecrossportreliefvalve(413)intotheshaftand

install the port plug (101). Note Models 05 and

8.5 do not incorporate a cross port relief valve.

12. Torque the end cap using either of the methods

outlined below when new thrust washers are

beinginstalledorwhenthrustwashersarewithin

tolerance specified.

Torque wrench Torque the end cap with a

torque wrench to the values specified in the End

Cap Torque Specifications chart on page 26.

Hydraulic pressure Torque by holding the end

capstationaryandhydraulicallypressurizingPort

14

PT SERIES ASSEMBLY DRAWING

Models PT-06 through PT-12

Configurations of parts may differ between models

15

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➔

16

TT SERIES ASSEMBLY DRAWING

SINGLE COLLAR DESIGNS* — Models TT-05 through TT-07

Configurations of parts may differ between models

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➨➨

➨➨

➨

➔

17

TT SERIES ASSEMBLY DRAWING

TWO COLLAR DESIGNS* — Models TT-06 through TT-12

Configurations of parts may differ between models.

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➔

18

TTB SERIES ASSEMBLY DRAWING

SINGLE COLLAR DESIGNS* — Models TTB-06 and TTB-07

Configurations of parts may differ between models

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➔

19

PT AND TTB SERIES ASSEMBLY DRAWING

TWO COLLAR DESIGNS* — Models PT/TTB-06 through PT/TTB-12

Configurations of parts may differ between models

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➔

20

TBB SERIES ASSEMBLY DRAWING

SINGLE COLLAR DESIGNS* — Models TBB-06 and TBB-07

Configurations of parts may differ between models

ORIENTATION TOWARDS EXCAVATOR/CARRIER WHEN INSTALLED

➔

This manual suits for next models

4

Table of contents

Popular Construction Equipment manuals by other brands

Altrad

Altrad BELLE TDX 650A Operator's manual

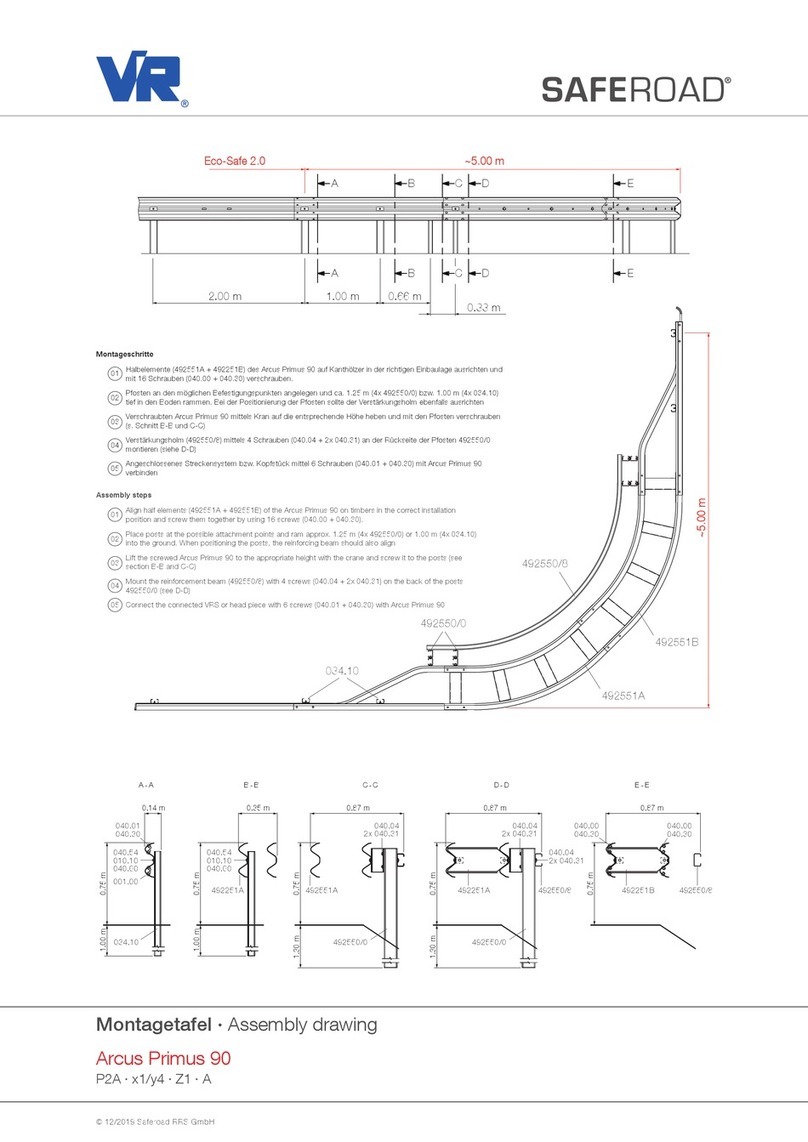

Saferoad

Saferoad VR Arcus Primus 90 Series Installation instruction

UTIFORM

UTIFORM V1 Instruction book

Saferoad

Saferoad VR Arcus Primus 90 Assembly Drawing

Metabo HPT

Metabo HPT VB 3616DA manual

Trejon

Trejon MULTIFOREST V Series Instruction Manual and Maintenance Directions

Dural

Dural Z-FLEX CURVER I operating instructions

E-Z DRILL

E-Z DRILL 210-3 EQ MT maintenance

BE Ag & Industrial

BE Ag & Industrial AGRI EASE DIAMOND HARROW HAR60S Assembly instructions

SPIERINGS

SPIERINGS SK597-AT4 manual

Labounty

Labounty CP 80 Safety, operation & maintenance manual

hymer

hymer 6071 Instructions for use