Trejon MULTIFOREST V Series Guide

TREJON FÖRSÄLJNINGS AB

Företagsvägen 9

SE-911 35 VÄNNÄSBY

SWEDEN

Tel: + 46 (0)935 39 900

Web: trejon.se

Instruction Manual

and Maintenance

Directions

Knuckle boom crane

Parallel crane

Issue: 20-05

Important!

Read the Instruction Manual

thoroughly before use

Instruction Manual MULTIFOREST Cranes (2005)

2

Mount the widening

wing inside the

machine

Instruction Manual MULTIFOREST Cranes (2005)

3

Mount the widening

wing inside the

machine

LIST OF CONTENTS

1Introduction............................................................................................................. 8

1.1 Getting Started................................................................................................... 8

1.2 Description......................................................................................................... 8

1.3 Detailed description, V-series............................................................................. 9

1.4 Detailed description, P-series............................................................................. 9

1.5 Technical specifications, V-cranes ................................................................... 11

1.6 Technical specifications, P-cranes ................................................................... 12

1.7 Right and Left Hand ......................................................................................... 12

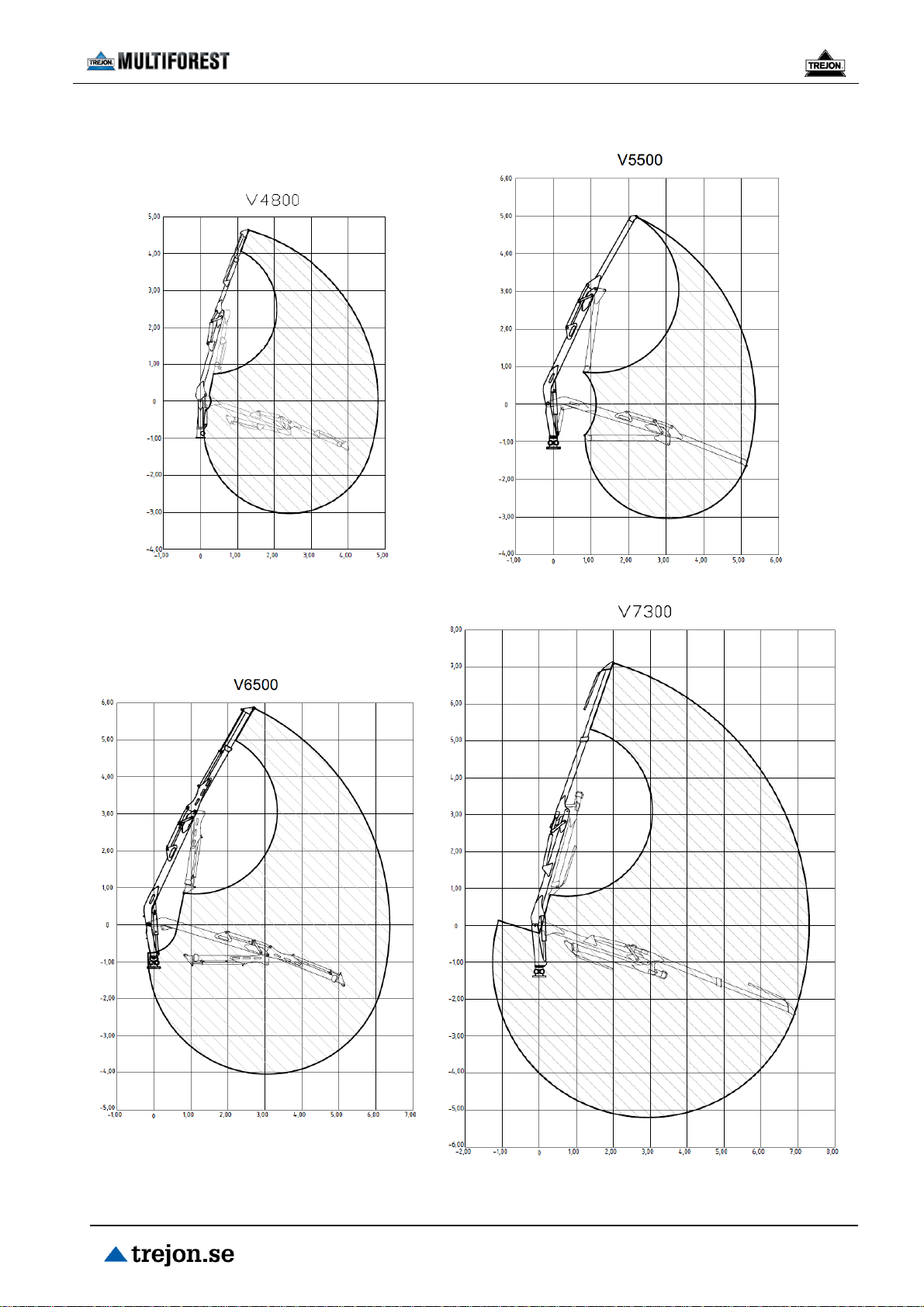

1.8 Lift diagram, work area, V-cranes..................................................................... 13

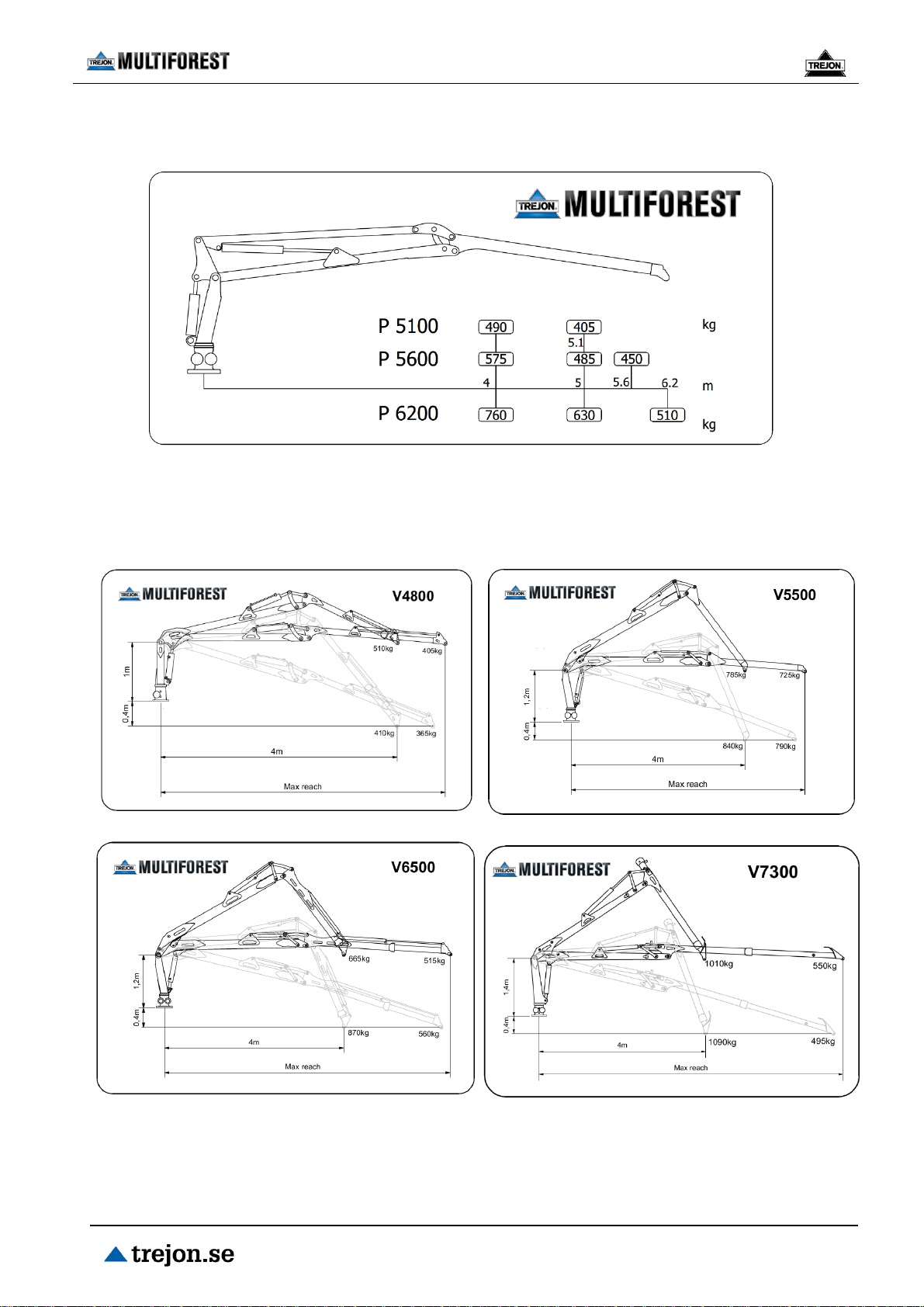

1.9 Lift diagram, work area, P-cranes..................................................................... 14

1.10 Lifting capacity decals, P-cranes...................................................................... 15

1.11 Lifting capacity decals, V-cranes...................................................................... 15

2Safety Instructions ............................................................................................... 16

2.1 Safety Regulations........................................................................................... 16

2.2 Safety Symbols................................................................................................ 19

3Using the Machine................................................................................................ 20

3.1 Assembly ......................................................................................................... 20

3.2 Before starting the machine.............................................................................. 22

3.3 Adjustments ..................................................................................................... 23

3.4 Operating the Machine..................................................................................... 24

3.5 Transporting and Uncoupling ........................................................................... 30

4Service and Maintenance..................................................................................... 31

4.1 General............................................................................................................ 31

4.2 Maintenance Schedule..................................................................................... 32

4.3 Before season start.......................................................................................... 33

4.4 At End of Season............................................................................................. 33

4.5 Hydraulic System ............................................................................................. 33

4.6 Turret ............................................................................................................... 34

Instruction Manual MULTIFOREST Cranes (2005)

4

Mount the widening

wing inside the

machine

4.7 Rotator............................................................................................................. 34

4.8 Lubrication Schedule........................................................................................ 35

5Fault Finding......................................................................................................... 36

6Accessories .......................................................................................................... 37

7Spare Parts ........................................................................................................... 37

7.1 Use original spare parts ................................................................................... 37

EC certificate of conformity ....................................................................................... 39

Instruction Manual MULTIFOREST Cranes (2005)

5

Mount the widening

wing inside the

machine

SAFETY SYMBOLS

NB! You will find this general warning symbol throughout this Instruction Manual to make you aware

of safety instructions concerning yourself, your employees and other persons coming into contact

with the machine. Neglecting these instructions may lead to serious injury and even death.

This symbol has the following meaning:

WARNING!

LOOK OUT!

YOU ARE IN DANGER!

Warning Labels

Be aware of the warning text WARNING! and NOTE! (NOTE!) in safety texts. These words have

been chosen based on the following guidelines:

Warning!

Warns of dangerous situations which, unless avoided, could lead to serious injury or even death.

This also includes dangers that can occur when protective equipment and/or protective screens

are removed. Warning labels can also be used to warn of hazardous use.

NB!

Highlight risky situations where slight or minor injuries can result if they are not avoided. Used

also to warn of machine damage that can arise if the directions are not followed.

Instruction Manual MULTIFOREST Cranes (2005)

6

Mount the widening

wing inside the

machine

Dear customer,

Thank you for choosing a TREJON MULTIFOREST product –we hope you will be pleased.

Reading this manual and following its recommendations will ensure you get the longest possible

service life and an efficient use of the machine.

We have produced this manual to give you a good overview of how the machine works and what

safety and maintenance directions that must be followed when working with it.

If any questions should arise in its use or when reading this manual, you are always welcome to

contact us.

TREJON AB

Företagsvägen 9

SE-911 35 Vännäsby

Sweden

Tel: + 46 (0)935 399 00

e-mail: inf[email protected]

Website: www.trejon.se

Instruction Manual MULTIFOREST Cranes (2005)

7

Mount the widening

wing inside the

machine

Dear Dealer,

In order for the warranty to come into force and all legal requirements to be met, we would like

you to complete the warranty certificate together with the customer and register at trejon.se.

The warranty will come into force on the same day as the machine is transferred to the customer.

Delivery inspection checklist:

Check for any transport damage. Report to carriers

Inspect the equipment thoroughly before use and make sure all packing material

has been removed. Dispose of all packing materials in an environmentally

responsible manner.

Check that the delivery is complete in accordance with the machine order/packing

note.

Make sure the machine has been lubricated as described under “Service and

Maintenance”

Check oil level in turret housing

Check tightness of all screw unions.

With the assistance of the Instruction Manual, run through and explain

commissioning, use and maintenance of the machine with accessories for the

customer.

Carry out a function check.

Explain the switch between working mode and transport mode.

EHC and radio-controlled valves must be calibrated by the dealer with the crane

coupled to the customer’s tractor.

Instruction Manual handed over to customer.

Complete the warranty certificate together with the customer and register on

trejon.se.

Enter the type and serial number of the machine

into the box on the right.

Type:

S/N:

Instruction Manual MULTIFOREST Cranes (2005)

8

Mount the widening

wing inside the

machine

1 Introduction

1.1 Getting Started

Thank you for choosing this TREJON MULTIFOREST product. We have concentrated on

making a powerful and good machine that will serve you for many years. As the service life of

the machine does not wholly depend on us, but also you, the user, we have compiled an

instruction manual in which we describe its correct care and use. So read through these

directions thoroughly. Always get in touch with the dealership where you bought your machine

when ordering spares or other service. The dealer is your natural service partner. When

ordering spares, always specify the correct model, type and serial number found on the name

plate on the chassis.

1.2 Description

This MULTIFOREST product is an all-round crane for small-scale forestry, agriculture and light

work in the construction sector, where flexible and simple lifting machinery is required.

MULTIFOREST cranes are available both as parallel (P-series) and knuckle boom (V-series)

types, each of which has its own specific advantages.

The crane is supplied with suitable flow and pressure from an external hydraulic system (see

Technical Specifications).

It is available as a separate machine or mounted on a MULTIFOREST trailer. When mounting a

separate crane, it is the buyer’s responsibility to make sure the carrying vehicle is of a suitable

size and stability. This is to avoid tipping the machine or in any other way putting people or

nearby equipment in harm’s way. It is also the buyer’s responsibility to ensure that the

coupling to the carrier vehicle is dimensioned with good safety margins so it can handle the

stresses involved.

Instruction Manual MULTIFOREST Cranes (2005)

9

Mount the widening

wing inside the

machine

1.3 Detailed description, V-series

1. Turret

7. Telescopic boom

2. Crane post

8. Telescopic cylinder

3. Lift arm, boom

9. Link

4. Lift cylinder

10. Rotator

5. Outer boom, front boom

11. Grapple

6. Tilt cylinder

12. Grapple cylinder

1.4 Detailed description, P-series

1. Turret

7. Tilt cylinder

2. Crane post

8. Outer boom, front boom

3. Lift arm, boom

9. Link

4. Lift cylinder

10. Rotator

5. Lift link

11. Grapple

6. Parallel arm

12. Grapple cylinder

1

2

4

3

6

5

8

7

10

12

11

2

4

3

10

9

11

7

6

9

1

5

8

12

Instruction Manual MULTIFOREST Cranes (2005)

10

Mount the widening

wing inside the

machine

Controls

Low-pressure servo valve package PCL ERGO - EHC

1. Crane slew and

boom cylinder lever

6. Crane slew and boom

cylinder lever

2. Rotator and lift

cylinder lever

7. Rotator and lift

cylinder lever

3. Right support leg

lever/button (if

equipped)

8. Extension control

buttons/roller (if

equipped)

4. Left support leg

lever/button (if

equipped)

9. Grapple cylinder

control buttons/roller

5. Grapple cylinder

lever

Standard package

Lightweight package

1

2

3

4

5

6

7

8

9

9

7

front

3 & 4

front

7

6

9

8

4

6

9

3

8

3 & 4

front

Instruction Manual MULTIFOREST Cranes (2005)

11

Mount the widening

wing inside the

machine

1.5 Technical specifications, V-cranes

Specifications/Model

V4800

V5500

V6500

V7300

Range [m]

4.8

5.5

6.5

7.3

Hydraulic extension [m]

0.6

-

1.0

1.9

Slew cylinder (qty)

2

4

4

4

Torque [kNm]

5.3

12.2

12.2

13.4

Slew radius [°]

420

360

360

360

Rec. pump capacity [l/min]

20–40

25–55

25–55

35–55

Max. operating pressure [bar]

190

190

190

190

Weight crane (empty)* [kg]

320

565

610

695

Lifting torque, gross [kNm]

25.5

48

48

56

Max payload* - A, 4 m [kg]

510

785

665

1010

Max payload* - B, max range [kg]

405

725

515

550

Max payload* - C, 4 m [kg]

410

840

870

1090

Max payload* - D, max range [kg]

365

790

560

495

Dimensions Z[m]

1

1.2

1.2

1.4

Dimensions Y[m]

0.4

0.4

0.4

0.4

* (without grapple and rotator)

Due to a policy of continuous development, the technical data specified in our document is not binding and may be changed without

prior notice. Information specified in the table above may also show equipment that is not standard.

The equipment level may vary depending on user country.

Instruction Manual MULTIFOREST Cranes (2005)

12

Mount the widening

wing inside the

machine

Right

Left

1.6 Technical specifications, P-cranes

Specifications/Model

P5100

P5600

P6200

Range [m]

5.1

5.6

6.2

Slew cylinder (qty)

4

4

4

Torque [kNm]

12.2

12.2

12.2

Slew radius [°]

360

360

360

Rec. pump capacity [l/min]

20–25

25–30

30–35

Max. operating pressure [bar]

190

190

190

Weight crane (empty)* [kg]

520

660

740

Lifting torque, gross [kNm]

26

34

46

Max payload*, 4 m [kg]

490

575

760

Max payload*, max range [kg]

405

450

510

* (without grapple and rotator)

Due to a policy of continuous development, the technical data specified in our document is not binding and may be changed without

prior notice. Information specified in the table above may also show equipment that is not standard.

The equipment level may vary depending on user country.

1.7 Right and Left Hand

In this Instruction Manual, the terms right and left hand apply as looking toward the rear of the

tractor, i.e. seen from behind in the direction of machine travel.

Instruction Manual MULTIFOREST Cranes (2005)

13

Mount the widening

wing inside the

machine

1.8 Lift diagram, work area, V-cranes

Instruction Manual MULTIFOREST Cranes (2005)

14

Mount the widening

wing inside the

machine

1.9 Lift diagram, work area, P-cranes

Instruction Manual MULTIFOREST Cranes (2005)

15

Mount the widening

wing inside the

machine

1.10 Lifting capacity decals, P-cranes

All values in kg without grapple and rotator.

1.11 Lifting capacity decals, V-cranes

All values in kg without grapple and rotator.

Instruction Manual MULTIFOREST Cranes (2005)

16

Mount the widening

wing inside the

machine

2 Safety Instructions

2.1 Safety Regulations

Read the manual. All machine operators should read and understand the entire contents of this

manual and the safety regulations so there is no uncertainty as to the use of the machine/tool

before it is taken into service. Get in touch with your dealer if you have any questions.

Use of the machine is strictly forbidden if the operator is not aware of the risks involved in

conjunction with the use of the machine and cannot act correctly if a risk situation should arise.

Read, observe and understand the meaning of all safety, operating, warning and positioning

decals on the machine and in the manual.

Actions may occur when using this equipment that cannot be prevented in its design or with the

use of mechanical protection.

Unfortunately, human carelessness may cancel the function of our integrated safety features.

Accordingly, the prevention of accidents and operating safety features are dependent on the

responsible use of the equipment and its integrated safety features.

Only trained personnel should use this equipment.

The machine is intended for outdoor use only.

Operation. Learn and practise the machine’s working methods and controls before it is used.

Coupling the Machine. Connect the machine in the correct manner and keep away from the

area between the tractor and the machine when coupling.

Make sure the equipment is correctly mounted, adjusted and in working order.

Safe Work Area. Keep unauthorized persons, especially children, away from the working zone

of the machine or when it is being repaired.

Observe the risk of injury from material that can be thrown from the machine while work is in

progress and clear away any stones, twigs and other foreign objects in the work zone that may

cause personal injury or damage to property.

Moving parts of this equipment are designed and tested to handle tough use but driving on

heavy, solid objects may damage the machine. In order to avoid any material damage, personal

injury and even death, make sure never to drive over such obstructions.

The Machine’s Safety Equipment. The machine may only be used if all the manufacturer’s

original safety equipment for moving mechanisms are positioned correctly and in working order.

Ensure all safety and operating decals are in good order and affixed in the correct manner and

replace them if necessary. Included the model and serial number when ordering new decals.

Moving Parts. Keep arms, legs and other body parts as well as clothing away from any moving

parts of the machine. Do not wear loose fitting clothes.

Leave the machine to work on its own and do not insert hands or fingers in an attempt to give

assistance.

Instruction Manual MULTIFOREST Cranes (2005)

17

Mount the widening

wing inside the

machine

Power Take-Off (PTO) shaft. When changing tractors, always check the length of the power

take-off shaft. If too long, it may damage both tractor and machine.

The use of incorrect power take-off shafts that do not meet with specifications is strictly

forbidden.

Ensure power take-off guards are correctly mounted and in good order and firmly fixed to the

tractor.

The use of damaged or defective power take-off guards is strictly forbidden.

Purchase a new power take-off guard if the old one is defective.

Lifting and lowering of the machine.

Be careful when lifting and lowering the machine/machine part.

Stability. The machine must not be operated with a tractor that does not weigh enough over the

front/rear axle so that tractor stability is affected. At least 20% of the tractor weight shall rest on

the front axle to ensure tractor steering and braking ability.

Mount ballast weights if necessary, see tractor instruction manual.

Apply the support legs when working with the grapple loader (consider retrofitting if not

mounted) and first load the smallest and closest logs so that the trailer attains good stability

before starting to load the heaviest logs.

Operating the Machine. Take great care when working on uneven ground conditions, close to

ditches and fences, look out for hidden dangers and adapt your working rate.

Great care should be observed when working on steep slopes:

Try to drive in the same direction as the incline and not across it.

Avoid fast starts and heavy braking when driving the machine up and down inclines.

If it is absolutely necessary to drive across steep inclines then reduce your speed and watch out

for unevenness, avoid sudden turns and be aware of the shift in centre of gravity that occurs

when lifting mounted tools.

Hold onto the steering wheel tightly if the tractor should overturn.

Operating at Night. The work area must be illuminated when working in the dark.

Driver. Operators who are tired, intoxicated, drugged or under the influence in any other way so

that they cannot control their movements must not use the machine.

The machine may only be operatedby one person sitting inthe tractor, no passengers are allowed.

It is forbidden for people without a tractor driving licence to use the machine.

Personal protective equipment. Protective equipment such as helmets, protective goggles,

protective shoes and gloves are recommended for personnel during assembly, operation,

adjustment and maintenance. Keep the tractor door and windows closed when working in dusty

conditions. Under certain conditions, noise levels may rise above 90dB so keep tractor doors

and windows closed, use hearing protection.

Protective Cab. The machine should only be driven by a tractor equipped with an approved

protective cab. Keep doors and windows close while working.

All moving parts, including engine, must be stationary and the handbrake applied before the

tractor driver leaves the cab. The rear window and the rear side windows of the cab must be

made of safety glass or be equipped with protective bars when working with a grapple loader.

Maintenance. Inspect, adjust and maintain the machine according to the directions.

Regular Inspection. Inspect the entire machine regularly. Locate any loose, worn and damaged

components and leaks.

Instruction Manual MULTIFOREST Cranes (2005)

18

Mount the widening

wing inside the

machine

Safety during maintenance and service. The machine must be standing on firm, even ground

for maintenance and adjustment.

The tractor engine must be shut off, all moving parts stationary, the machine lowered to the

ground and the handbrake applied during all cleaning, inspection, adjustment, maintenance and

repair work.

Clean the machine thoroughly before repair and storage.

Bearing and hydraulic components should not the cleaned with high-pressure jets.

If excessively high pressure is used for general cleaning, this may damage the paint.

After cleaning, the machine must be lubricated according to the lubrication schedule and a short

test run carried out.

Vibration. If any vibration should occur in the machine, it must be shut down immediately and

the cause located. Change any damaged parts.

Hydraulic Hoses. Hydraulic hoses on the machine contain oil at very high pressure. Do not

touch hoses and hydraulic components if the system is pressurised. In case of leaks, oil at high

pressure may penetrate the skin and cause serious injury. In the event of an accident, contact a

doctor immediately.

Check the condition of hydraulic hoses with respect to damage. Chafed and leaking hoses

should be replaced immediately with new that meet the manufacturer’s technical requirements.

When changing tractor, always check the length of the hoses. When hoses are too long or too

short, they may be damaged.

The use of incorrect hydraulic hoses that do not meet with specifications is strictly forbidden.

Hydraulic motors and hoses can get extremely hot while in operation, with a risk of burn injuries.

Do not loosen hoses while the oil is hot, wait for it to cool down.

Welding. Protect bearings, hydraulics and electronic components if welding is being carried out.

Before welding commences, electronic components must be disconnected and the welder’s

ground clamp placed as close to the welding site as possible.

Fire Risk. If overheating of machine parts should occur, the cause must be located and the

machine shut down. Forest residue is very flammable, so remove forest remains and dirty oil.

Keeping a fire extinguisher nearby is recommended.

Smoking in the vicinity of the machine is forbidden.

Electrical Lines. Take great care when working close to electrical lines, maintain a safe

distance with good margin.

If an accident should occur and the crane comes into contact with live lines.

-Keep calm, act rationally so as not to worsen the situation and do not touch any metal parts.

-Warn people in the vicinity and make sure they stay outside the risk zone.

Radio control.If you are using the crane with remote control, you must follow the regulations

and instruction given in the radio control user instructions. You can use the crane only from the

tractor cab in this case, or from outside at a minimum distance of 10 m from the machine.

Spare Parts. Use only original spare parts on the machine.

If you should have any questions concerning the machine or its function, please get in touch

with your dealer or Trejon AB

Instruction Manual MULTIFOREST Cranes (2005)

19

Mount the widening

wing inside the

machine

2.2 Safety Symbols

All warning decals must be clean and legible.

Lost or damaged decals must be replaced. Order new decals from your dealer.

Position of decals on crane

The symbol on the right shows the following:

Warning!

1 - Do not stand in the vicinity of the crane,

maintain a distance of at least 25 m from the

machine when it is running. The operator

must also maintain a good view of the area

while the machine is working.

Warning !

2 - Forbidden lifting point.

Warning !

3 - Decal on crane post showing maximum

lifting capacity in different positions/ranges.

4 - Machine name plate with CE marking.

This includes the machine’s serial number,

weight and model number.

1

2

3

4

Instruction Manual MULTIFOREST Cranes (2005)

20

Mount the widening

wing inside the

machine

3 Using the Machine

3.1 Assembly

Warning!

Crush risk. Do not stand between machine and tractor when coupling. Always apply the

brake on the tractor when leaving the cab during all coupling and uncoupling.

The machine may only be coupled to a tractor/trailer with sufficient weight over the front

and rear axle respectively so that steering and brakes are in working order when the

machine is coupled. Use ballast weights as necessary, see the tractor’s instruction

manual. When working with a grapple loader, use the support legs (consider retrofitting if

not mounted).

The temperature of the hydraulic oil must be checked during operation. If the temperature

rises too high, the reason should be located immediately to avoid serious damage.

If the crane’s valve package is to be mounted inside the tractor cab, protection must be

installed to prevent oil at high pressure reaching the operator, e.g. after a hose rupture.

NOTE!

Ensure no-one is inside the risk area when lifting.

Take care with straps and wires when they are removed as they are tensioned very hard.

They can also be very sharp.

The hydraulic system to which the crane is coupled must be unconditionally fitted with

an efficient filter on the return side.

Trouble-free operation presumes the hydraulic system to be in good condition and that

maintenance has been carried out as recommended.

The crane is normally function tested before delivery. The cylinders may therefore

contain some test oil.

Delivery and return hoses must not be coupled to double-acting outlet.

Instead, the return hose shall be coupled to a separate pressure-free return outlet.

This manual suits for next models

4

Table of contents

Popular Construction Equipment manuals by other brands

KRAUSE

KRAUSE ProTec XS Instructions for assembly

Vahva Jussi

Vahva Jussi 320 Users manual & Spare parts list

Husqvarna

Husqvarna LG 504 Operator's manual

Manitowoc

Manitowoc MLC650 Service maintenance manual

allen

allen WB1224 Assembly & parts manual

Roper Whitney

Roper Whitney MBB 4181 MAGNABEND Operation, parts & maintenance manual