Pag.7

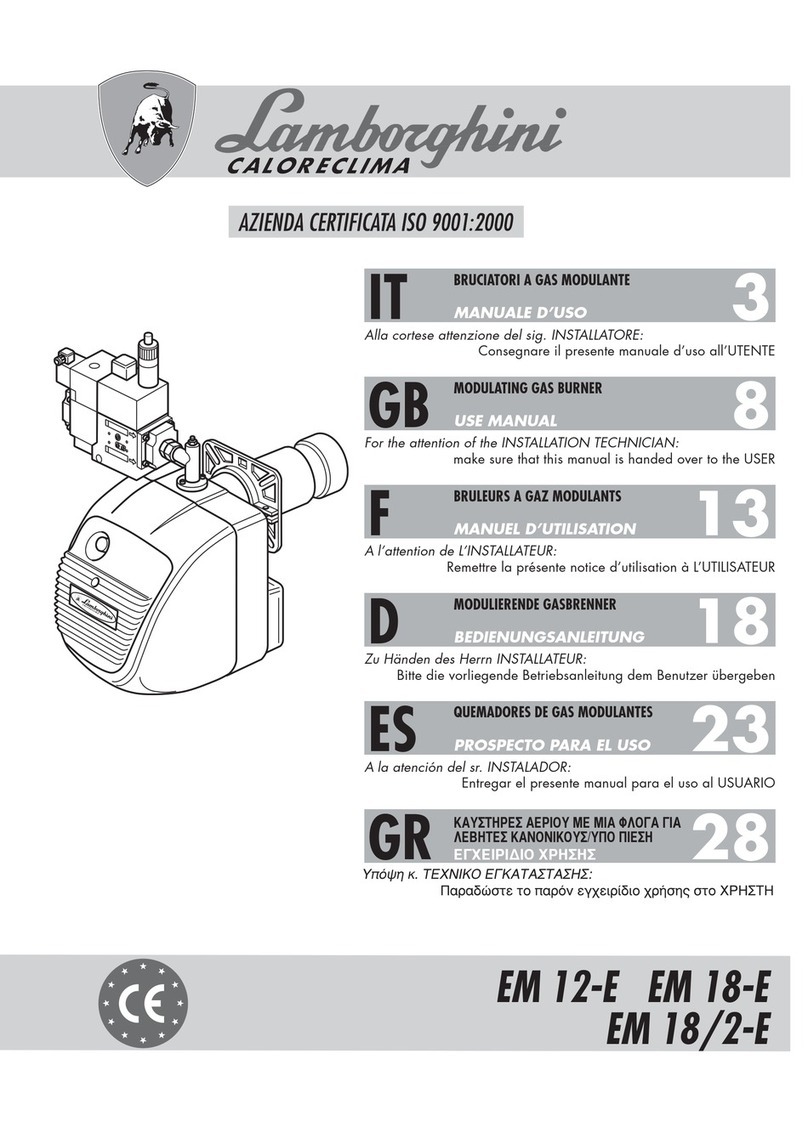

2.3 Connection to the gas pipe

Place the basic unit in its intended position and then mount the surround. Adjust the basis unit to ensure that the

mounting holes in the surround and the unit are aligned (do not attach yet). Having done this, you can decide on

the position of the gas pipe at the same time. Punch-out covers have been made on both the right and left sides of

the surround for feeding the gas pipe through, so that you can choose for yourself on which side of the appliance

you wish to have the inlet for the gas pipe. Ensure that the control equipment does not become twisted during

connection and that no excessive tension develops. There are diverse connecting points which must be accessible

for the various components. Check the connections for gas tightness after installation. Use a ½” gas cock with

coupling in the supply pipe and make sure that the gas pipe is free of dirt and sand.

2.4 Power supply for gas regulation equipment and remote control.

The regulation equipment is supplied with power by a battery in the signal receiver (see diagram 2-F on page 13),

which is located in the bottom of the appliance at the right-hand side, diagonally behind the gas regulator block.

This battery holder/signal receiver is secured with a cable tie to prevent damage in transit. Cut through the cable

tie with pincers and take the battery holder/signal receiver out of the appliance. Remove the cover of the battery

holder and place the 4 batteries supplied with the appliance in the battery holder as shown. Close the cover and

replace the battery holder/signal receiver in the bottom of the appliance. Ensure that the receiver eye is placed in

a position where it is able to receive the signal from the remote control properly. Also insert the batteries into the

remote control (see diagram 2-B on page 13). Open the cover of the remote control. Connect the battery to the

plug, place it in compartment and close the cover again.

3. Details gas control. (see page 13 diagram 2)

A. Gas combination control F. Receiver and battery housing

A1. On/Off knob F1. Led (green)

A2. Temperature knob F2. Batteries 4 x 1.5V AA

B. Remote Transmitter F3. Battery cover

B1. Battery 9V block G. Ignition cable

B2. Battery cover H. Gas supply inlet

B3. Display I. Gas supply outlet to main burner

B4. Auto button J. Pilot flame tube

B5. Timer button K. Thermocouple connection

B6. Mode button up L. Burner pressure nipple

B7. Mode button down M. Pre-pressure nipple

C. Servomotor remote control N. Min. rate screw

D. Connectors power supply servomotor O. Adjusting screw burner pressure (high setting)

E. Power cable servo motor

3.1 Gas technical details

Gas category :Natural gas or Butane/Propane

Type :C11 / C31

Safety :Thermo -electrical

* Nominal output depends on duct situation used.

Type of gas Natural gas

Cat. I2L Natural gas

Cat. I2ELL Natural gas

Cat. I2E+-I2H Propane

cat I3 P

G25 G20 G25 G20 G25 G31 G30/31

Position min. max. min. max. Min. max. Min. max. min. max. min. max. min. max.

Burner injector -2,3 -2,3 -2,3 -2,3 -2,3 -1,1 -1,1

Pipe pressure in mbar 25 25 20 20 20 20 20 20 25 25 50 50 30 30

Burner pressure in mbar 5,2 12,8 3,5 85,2 12,8 3,5 85,2 12,8 20 36 15 29

Nom. load in kW HS 3,7 6,1 3,9 6,1 3,7 6,1 3,9 6,1 3,7 6,1 3,7 5,1 3,7 5,1

Nom. load in kW HI 3,3 5,5 3,5 5,5 3,3 5,5 3,5 5,5 3,3 5,5 3,33 4,6 3,3 4,6

Nom. output in kW* -4-4-4-4-4-3,5 -3,5

Gas consumption in L/hr 0,4 0,67 0,37 0,57 0,4 0,67 0,37 0,57 0,4 0,67 0,13 0,18 0,1 0,14

Butane

cat I3 B/P