Helios Power Solutions TDK-Lambda PFE700SA Series User manual

C275-04-11C

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

PFE700SA Series

Instruction Manual

BEFORE USING THE POWER SUPPLY UNIT

Be sure to read this instruction manual thoroughly before using this product. Pay attention to all cautions and warnings before

using this product. Incorrect usage could lead to an electrical shock, damage to the unit or a fire hazard.

DANGER

Never use this product in locations where flammable gas or ignitable substances are present. There are risks of igniting these

substances and exploding by an arcing.

WARNING

·Do not touch this product or its internal components while circuit is live, or shortly after shut down.

There may be

high voltage or high temperature present and you may receive an electric shock or burn.

·While this product is operating, keep your hands and face away from it as you may be injured by an unexpected situation.

·Do not make unauthorized changes to this product, otherwise you may receive an electric shock and void your warranty.

·Do not drop or insert anything into the product. It might lead to a failure, fire and electric shock.

·Do not use this product under unusual condition such as emission of smoke or abnormal smell and sound etc.

It might lead fire and electric shock, In such cases, please contact us. Do not attempt repair by yourself, as it is dangerous for

the user.

·Do not operate these products in the presence of condensation. It might lead to fire and electric shock.

CAUTION

·This power supply is designed and manufactured for use within an end product such that it is accessible to

SERVICE ENGINEERS only.

·Confirm connections to input/output terminals and signal terminals are correct as indicated in the instruction manual

before switching on.

·Input voltage, Output current, Output power, ambient temperature, base-plate temperature and ambient humidity should be

kept within specifications, otherwise the product will be damaged.

·Do not operate and store this product in an environment where condensation might occur. In such case, waterproof treatment

is necessary.

·The equipment has been evaluated for use in a Pollution Degree 2 environment.

·Do not use this product in environment with a strong electromagnetic field, corrosive gas or conductive substances.

·For application which requires very high reliability (Nuclear related equipment, medical equipment, traffic control

equipment, etc.), It is necessary to provide a fail-safe mechanism in the end equipment.

·Do not inject abnormal voltages into the output terminal or signal terminal of this product. The injection of reverse voltage or

over voltage exceeding nominal output voltage into the output terminal or signal terminal might cause damage to internal

components.

·Never operate the product under overcurrent or short circuit conditions. Insulation failure, or other damages may occur.

·The output voltage of this power supply unit is considered to be a hazardous energy level (The voltage is 2V or more and the

electric power is 240VA or more). It must not be made accessible to users. Protection must be provided for Service Engineers

against indirect contact with the output terminals and/or to prevent tools being dropped across them. While working on this

product, the AC input power must be switched off and the input, output, +BC, -BC and R terminal voltage should be safe

level.

·The application circuits and their parameters are for reference only. Be sure to verify effectiveness of these circuits and their

parameters before finalizing the circuit design.

·Use a Fast-Blow external fuse to each module to ensure safe operation and compliance with the safety standards to which it is

approved. The recommended input fuse rating within the instructions is as follows: 15A, 250V fast acting fuse. The breaking

capacity and voltage rating of this fuse may be subject to the end use application.

www.heliosps.com

C275-04-11C

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

CAUTION

· This model is considered non-SELV. End equipment manufacturers must provide protection against inadvertent contact by a

Service Engineers.

· This information in this document is subject to change without prior notice. Please refer to the latest version of the data sheet,

etc., for the most up-to date specifications of the product.

· No part of this document may be copied or reproduced in any form without prior written consent TDK-Lambda.

Note : CE MARKING

CE Marking, when applied to a product covered by this handbook, indicates compliance with the low voltage directive.

1

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

(*1) /Blank:Standard

/T :Mounting standφ3.3

(Non-threaded through hole)

⑥

⑦

⑨

⑧

⑩

⑪

⑤

④③

①

②

Name plate

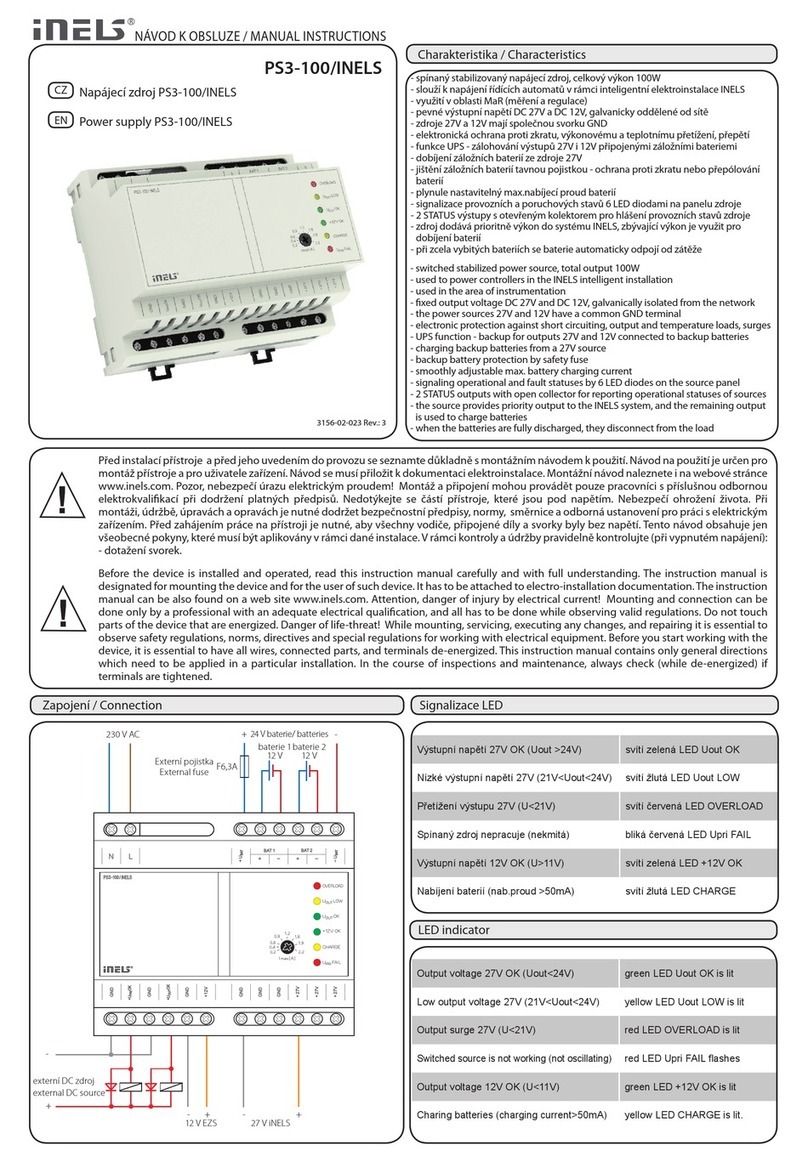

1. Model name identification method

PFE 700 SA – 48 /□

Option (*1)

Rated Output Voltage

Simple function

Output Power type

Series Name

2. Terminal Explanation

- Base-plate can be connected to FG through M3 mounting tapped holes.

- Consider contact resistance when connecting AC(L), AC(N), R, +BC, –BC, +V, –V.

- Note that +BC and –BC terminal are primary voltage with high voltage (375VDC).

Do not connect load from these terminals.

- Do not make external connection to NC terminal.

① : Input terminal neutral line

② : Input terminal live line

③ : External inrush current limiting

④ resister terminal

⑤ : +Boosted voltage terminal

⑥ : -Boosted voltage terminal

⑦ : -Output voltage

⑧ : +Output voltage

⑨ : -Output monitor terminal

⑩ : +Output monitor terminal

⑪ : Make no external connection

⑫ : Power on signal terminal

① AC(N)

② AC(L)

③

R

④ +BC

⑤ -BC

⑥ -V

⑦ +V

⑧ -VM

⑨ +VM

⑩ NC

⑪ ENA

2

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

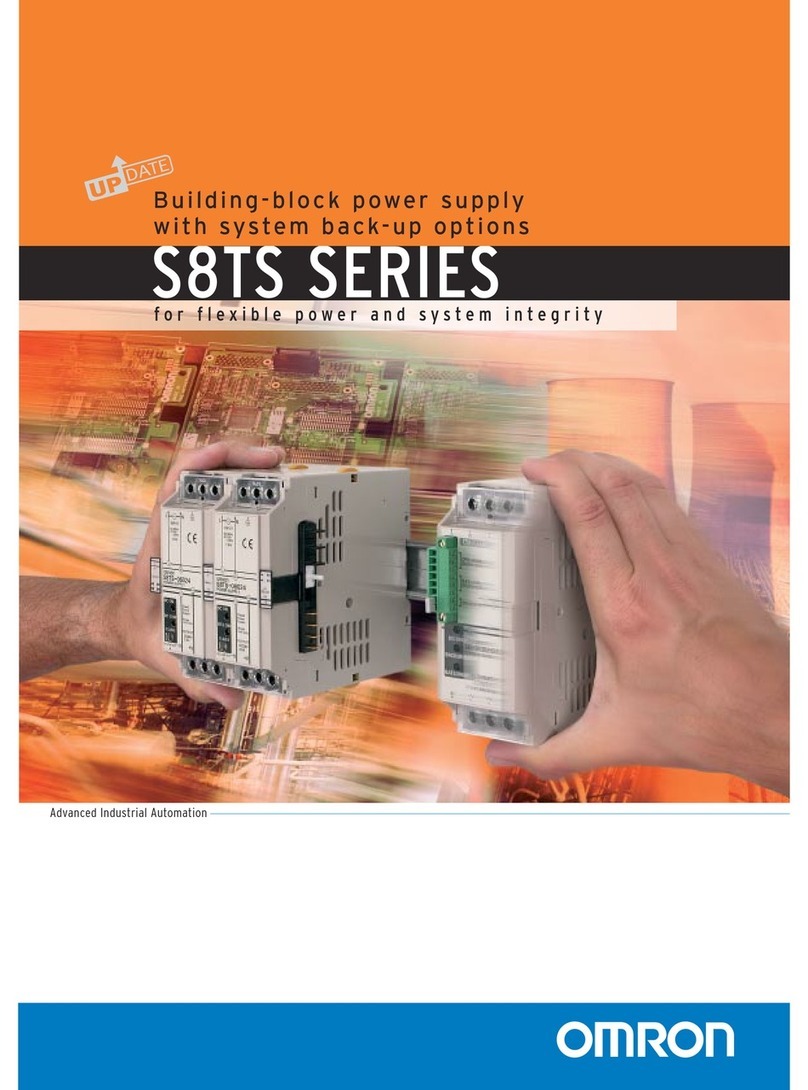

3. Block Diagram

Input current

detector

Input voltage

detector

OTP

Rectifier

Filter

OVP

Control circuit

OCP

Switching circuit

Inrush current

limiting circuit

Boosted

voltage

detector

Control circuit

Rectifier

Output filter

Switching Frequency

PFHC Circuit (fixed) : 100kHz

DC/DC Converter Circuit (fixed) : 180kHz (primary), 360kHz (secondary)

4. Sequence Time Chart

Input Line

ON

OVP

Acitivate

Input Line

Cut-off

Input Line

ON

OCP

Release

OCP

Activate

Input Line

Cut-off

Input Line

ON

OTP

Circuit

Activate

Input Line

Cut-off

Input Line

ON

Note : This product has no remote ON/OFF function.

V* voltage level: Refer to Application Notes “6-6.Power ON Signal (ENA Terminal)” section.

3

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

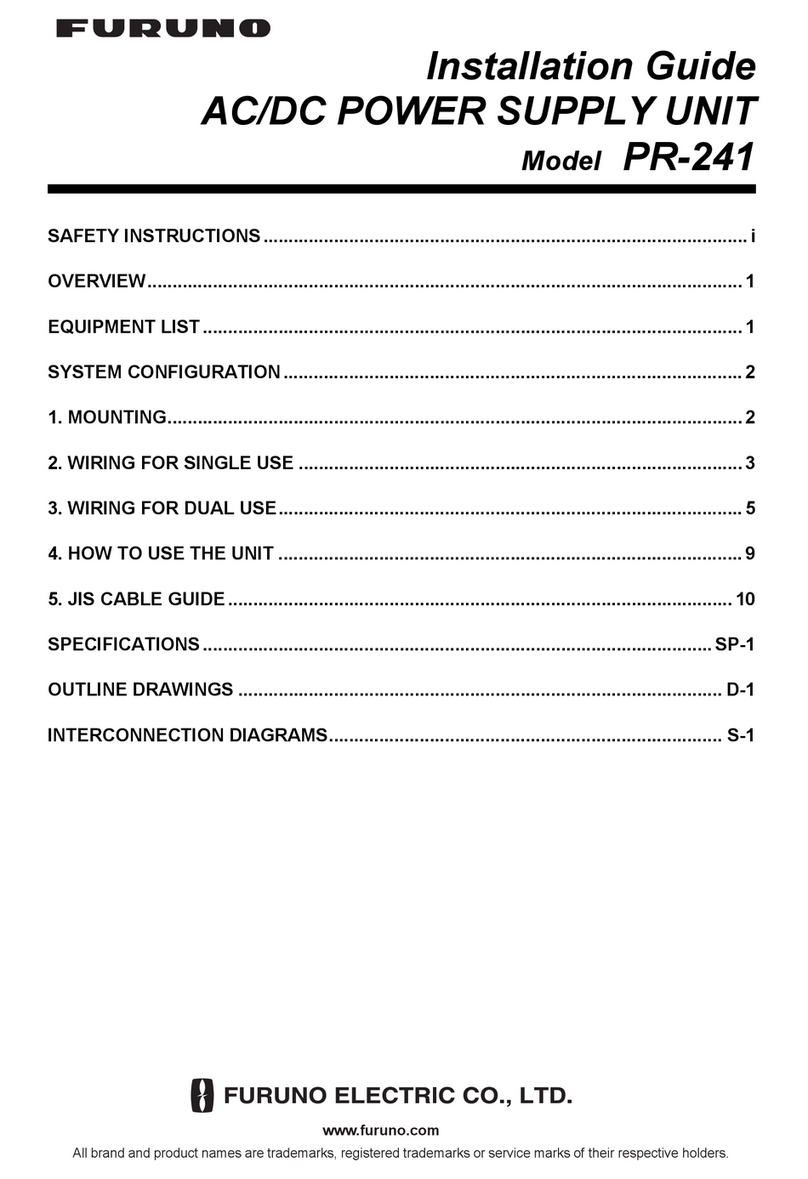

5. Terminal connecting method

In order to use the PFE700SA Series, this module must be connected with external components according

to Fig.5-1.

Pay attention to the each wiring. If it is connected to wrong terminal, the power supply will be damaged.

PFE700SA Series employs conduction cooling method. Use heat sink and fan to dissipate heat.

For selection of heat sink and heat sink dissipation method, refer to the Power Module Application Note.

Fig.5-1 Basic connection

4

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

F1 : External Input Fuse

PFE700SA Series has no internal fuse. Use external fuse to acquire each Safety Standard and to further

improve safety. PFE700SA Series acquired safety standard certification using 15A, 250V, Fast-Blow

external fuse. Further, Fast-Blow type fuse must be used per one module. Also, in-rush surge current flows

during line throw-in. Be sure to check I2t rating of external switch and external fuse.

Recommended External Fuse:15A , 250V

Note) Select fuse based on rated voltage, rated current and surge current capability.

(1) Voltage Ratings

100VAC line : AC125V

200VAC line : AC250V

(2) Current Ratings

Rated current is determined by the maximum input current based on operating conditions and can be

calculated by the following formula.

(Arms)

PFηVin

Pout

(max)Iin ´´

= (Formula 5-1)

Iin (max) : Maximum Input Current

Pout : Maximum Output Power

Vin : Minimum Input Voltage

η : Efficiency

PF : Power Factor

For Efficiency and Power Factor values, refer to separate document “PFE700SA Evaluation Data”.

C1, C4, C5 : 1uF (Film Capacitor)

Ripple current flows through this capacitor. When selecting capacitor, be sure to check the allowable

maximum ripple current rating of this capacitor. Verify the actual ripple current flowing through this

capacitor by doing actual measurement.

Connect C5 as close as possible towards the input terminals AC(N) and AC(L) of this power module.

Recommended Voltage Rating : 250VAC

L1, L2 : 6mH

Add common mode choke coil as EMI/EMS countermeasure. When using multiple modules, connect coil to

each module.

Note) Depending on the input filter used, noise might increase or power module might malfunction due to

filter resonance.

C2, C3 : 4700pF(Ceramic Capacitor)

Add ceramic capacitor as EMI/EMS countermeasure. Be sure to consider leakage current of your equipment

when adding this capacitor.

High withstand voltage are applied across this capacitor depending on the application. Select capacitor with

high withstand voltage rating.

5

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

R1 : 470kΩ

Connect bleeder resistor across AC(L) and AC(N) terminals.

C6, C7 : 1000pF(Ceramic Capacitor)

Add ceramic capacitor as EMI/EMS countermeasure. Be sure to consider leakage current of your equipment

when adding this capacitor.

High withstand voltage are applied across these capacitor during withstand voltage test depending on the

application. Select capacitors with high withstand voltage rating.

Connect C6 as close as possible to AC(N) terminal, C7 as close as possible to AC(L) terminal.

C8, C9 : 1uF(Film Capacitor)

Ripple current flows through this capacitor. When selecting capacitor, be sure to check the allowable

maximum ripple current rating of this capacitor. Verify the actual ripple current flowing through this

capacitor by doing actual measurement.

Connect C8 as close as possible to R terminal and -BC terminal, C9 as close as possible to +BC terminal

and -BC terminal.

Recommended Voltage Rating : 450VDC

Note) Select Capacitor with more than 3A (rms) rating.

C10, C11 : 390uF(Electrolytic Capacitor)

Refer to “Selection Method of External Bulk Capacitor for Boost Voltage” below. Allowable external

capacitance at nominal capacitance value is shown below.

Recommended Voltage Rating : 450VDC

Recommended Total Capacitance : 390uF‐1200uF

Note) 1. Do not connect capacitors with more than the above capacitance value as this would result into

power module damage.

2. When using module below -20℃ ambient temperature, AC ripple of boost voltage, output ripple

voltage might be affected by ESR characteristics of the bulk capacitors. Therefore, be sure to

verify characteristics by actual evaluation.

C12, C13 : 0.033uF

Connect ceramic or film capacitor as EMI/EMS countermeasure and to reduce spike noise.

High withstand voltage is applied across this capacitor during withstand voltage test depending on the

application.

Connect C12 as close as possible to +V terminal, C13 as close as possible to -V terminal.

C14 : 1000pF(Ceramic Capacitor)

Add ceramic capacitor as EMI/EMS countermeasure.

High withstand voltage are applied across this capacitor during withstand voltage test depending on the

application. Select capacitors with high withstand voltage rating.

Connect C14 as close as possible to -BC terminal.

6

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

C15: 220uF(Electrolytic Capacitor)

To reduce output ripple noise voltage, connect electrolytic capacitors across +V and -V.

Connect C15 as close as possible to the +V and -V output terminals of this power module.

Recommended Voltage Rating : 100VDC

C16: 2.2uF(Ceramic Capacitor)

Connect chip ceramic capacitor at 50mm from the output terminals +V and -V of the power module to

reduce output spike noise.

Also, note that output spike voltage may vary depending on the wiring pattern of the printed circuit board.

C17 : 220uF(Electrolytic Capacitor)

Connect C17 at 50mm from the output terminals +V and -V of the power module to stabilize operation.

Note that the output ripple and line turn off characteristics of the power module might be affected by the

ESR and ESL of the electrolytic capacitor.

Also, note that output ripple voltage may vary depending on the wiring pattern of the printed circuit board.

Sudden change in output voltage due to sudden load change or sudden input voltage change can be reduced

by increasing external output capacitance value.

Recommended Voltage Rating : 100VDC

Note) 1. Use low-impedance electrolytic capacitors with excellent temperature characteristics.

(Nichicon PM Series or equivalent)

2. For module operation at ambient temperature -20℃ or less, output ripple voltage might be

affected by ESR characteristics of the electrolytic capacitors. Increase the capacitance values

shown below.

C15,C17: 100V 220uF × 2 parallel (Ambient Temperature ≦ -20℃)

3. Take note of the maximum allowable ripple current of the electrolytic capacitor used. Especially,

for sudden load current changes, verify actual ripple current and make sure that allowable

maximum ripple current is not be exceeded.

For connection other than recommended capacitance, be sure to verify characteristics by actual evaluation.

7

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

●Selection Method of External Bulk Capacitor for Boost Voltage

Boost voltage bulk capacitor is determined by boost voltage ripple voltage, ripple current and hold-up time.

Select capacitor value such that boost voltage ripple voltage does not exceed 15Vp-p.

Note) When ambient temperature is -20℃ or less, ripple voltage of boost voltage might increase due to

ESR characteristics. Therefore, verify above characteristics by actual evaluation.

For output hold-up time, refer to separate document “PFE700SA Evaluation Data" and use appropriate

capacitor up to 1200uF maximum. It is recommended that verification should be done through actual

evaluation.

For allowable ripple current value, refer to Fig.5-2 and select a capacitor with higher ripple current rating.

0

500

1000

1500

2000

2500

0 100 200 300 400 500 600 700

Ripple Current (mA rms)

Output Power (W)

100VAC

200VAC

Fig. 5-2 Allowable ripple current value

The recommended boost voltage bulk capacitance value range is 390uF-1200uF.

When using with reduced the bulk capacitance value, it is necessary to reduce output power as shown in

Fig. 5-3.

Fig. 5-3 shows recommended value at 25℃ Base-plate Temperature (Tbp). Temperature variance might

have some effect on the characteristics. Therefore, verify characteristics by performing actual evaluation.

Refer to “Fig. 7-1 Base-plate Measuring Point”.

Note that reducing the bulk capacitance affects output hold-up time, dynamic line response and dynamic

load response characteristics. It is recommended that verification should be done through actual

evaluation.

0

100

200

300

400

500

600

700

300 600 900 1200

Output Power (W)

Bulk Cap. (uF)

390

Tbp:25℃

Fig. 5-3 Output Power v.s. Boost Voltage Bulk Capacitance

8

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

TFR1 : 10Ω - 100Ω

By connecting thermal fuse resistor across R and +BC terminals as shown in Fig. 5-1, in-rush current

during line throw-in can be suppressed. Failures due to in-rush current such as melting of external fuse,

welding of relay or switch connecting joints or shutdown of No-Fuse Breakers (NFB) can occur.

Therefore, be sure to connect this external thermal fuse resistor of 10Ω or more.

The allowable resistance value is limited by the external bulk capacitance value of shown in fig.5-4.

Note that power supply will not operate if this external resistor is not connected.

●Selection Method of External Resistor

(1) Calculating Resistance Value for External TFR1

Resistance can be calculated by the formula below.

)(

Irush

Vin

RΩ = (Formula 5-2)

R : Resistance Value for External TFR1

Vin : Input Voltage converted to DC value = Input Voltage (rms) x 2

Irush : Input surge current value

(2) Required Surge Current Rating

Sufficient surge current withstand capability is required for external TFR1.

Required Surge Current Rating can be selected by I2t. (Current squared multiplied by time)

)sA(

R

2

VinCo

tI 2

2

2

´

´

= (Formula 5-3)

I2t : Current-squared multiplied by time

Co : Boost Voltage Bulk Capacitance

Vin : Input Voltage converted to DC value = Input Voltage (rms) x 2

R : Resistance Value for External TFR1

(3) Resistance limitation Value for External TFR1

External TFR1 is limited as shown in drawing below.

Drawing below shows resistor value at 25℃ Base-plate Temperature. Input Surge current might vary

due to temperature. Therefore, verify characteristics by performing actual evaluation.

10

40

70

100

300 600 900 1200

Resistance Value[Ω]

Bulk Cap[uF]

390

Tbp:25℃

Fig.5-4 Resistance Value v.s. Boost Voltage Bulk Capacitance

9

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

6. Explanation of Functions and Precautions

6-1. Input Voltage

Input voltage range is single phase 85-265VAC(47-63Hz). Take care not to apply input voltage which is

out specified range nor should a DC input voltage be applied as this would result into power supply

damage.

For cases where conformance to various safeties required, described as 100-240VAC (50-60Hz)

6-2. Inrush Current

Input surge current changes with the thermal fuse resistor (TFR1) value and external boost voltage bulk

capacitance value (C10, C11).

It is recommended that verification should be done through actual evaluation.

The inrush current value indicated in the specification is measured under 25℃ using basic connection.

Inrush current increases after recovery from short interruptions.

Please be careful in the selection of an input switch, an external fuse, etc.

6-3. Over Voltage Protection (OVP)

This module is equipped with OVP function. OVP function operates within 60V-69.6V. When OVP triggers,

the output will be shut down.

When the OVP function activates, first cut off input line and verify that boost voltage has dropped down to 7V

or less. Then, recover output by recycling input line.

OVP value is fixed and cannot be set externally. Pay attention not to apply higher voltage externally to the

output terminal to avoid power supply damage.

6-4. Over Current Protection (OCP)

This module is equipped with OCP function. OCP function operates when the output current exceeds 105% of

maximum DC output current of specification.

Output will automatically recover when short circuit or overload condition is removed. OCP value is fixed and

cannot be adjusted externally.

Note that continuous short circuit or overload condition might result in power supply damage.

6-5. Over Temperature Protection (OTP)

This module is equipped with OTP function. This function will activate and shut down the output when ambient

temperature or internal temperature abnormally rises. OTP activates at following Base-plate temperature.

OTP operate temperature : 105℃ - 130℃

When OTP function operates, output can be recovered by cooling down the baseplate sufficiently and letting

the boost voltage drop down to 7V or less before recycling the input line.

6-6. Power ON Signal (ENA Terminal)

This signal is located at the secondary side (output side) and an open drain output.

Maximum sink current : 10mA

Maximum applied voltage : 75V

Return line for ENA terminal is the -V terminal.

When output voltage goes over 45V(TYP) at start up, Power ON Signal is “Low level”.

10

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

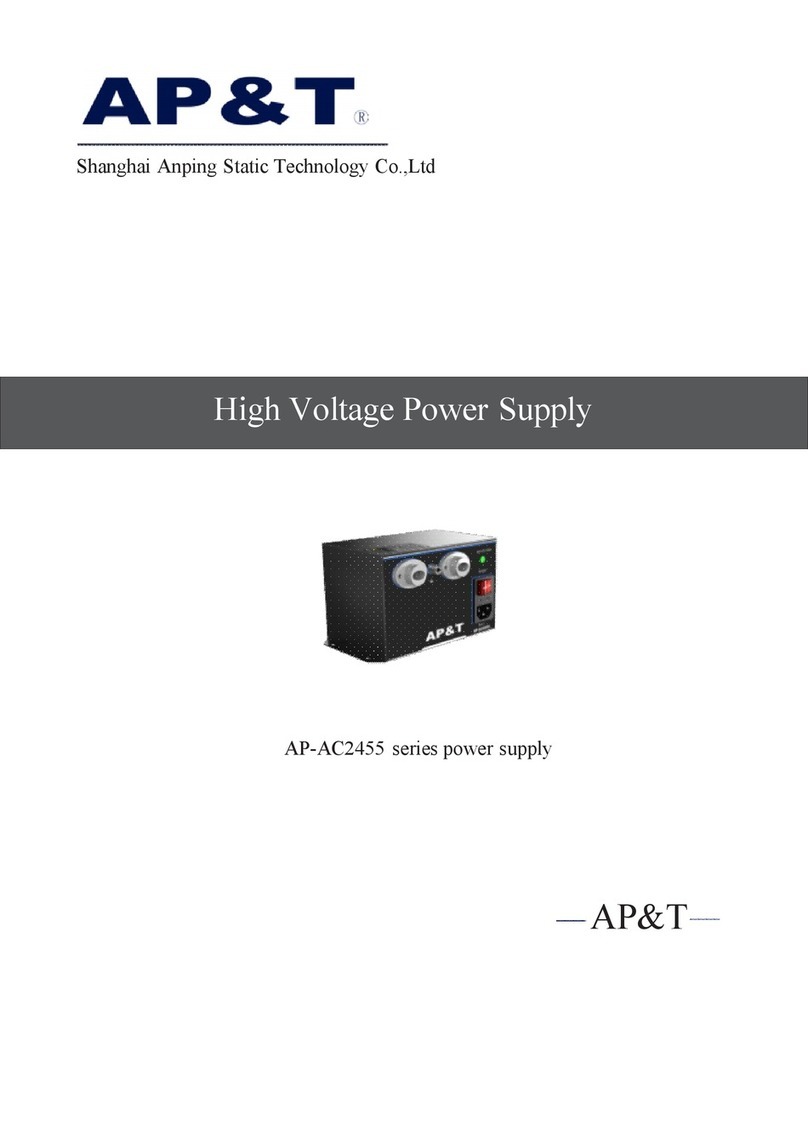

6-7. Maximum Ripple and Noise

This value is measured according to the description below in accordance with JEITA RC-9131B.

In the basic connection shown in Fig. 5-1, additional connection shown in Fig. 6-1 is done for measurement.

Capacitor (Ceramic Capacitor : 2.2µF and Electrolytic Capacitor : 220uF) must be connected within 50mm

from the output terminals. Then, connect coaxial cable with JEITA attachment across the ceramic capacitor

electrodes. Use 100MHz bandwidth oscilloscope or equivalent.

Also, note that output ripple voltage and output spike noise may vary depending on the wiring pattern of the

printed circuit board.

In general, output ripple voltage and output spike noise can be reduced by increasing external capacitor value.

Fig.6-1 Output Ripple Voltage (including Spike Noise)

Measurement Method

6-8. Parallel Operation

Output current sharing through parallel operation is possible for PFE700SA Series by connecting the output

terminal.

For maximum output current at parallel operation, use within 85% of the rated output current.

In order to evenly split the load current, wiring impedance should be the same for each module from output

terminals up to the junction point of each power supply. Perform actual evaluation to ensure that output current

of each module does not exceed their own rated output current.

Also, maximum allowable modules in parallel are 5 pieces.

Consult us for details when using PFE700SA Series at parallel operation.

6-9. Series Operation

Series operation is possible for PFE700SA Series. Connections shown in Fig.6-2 and Fig.6-3 are possible.

Also, Maximum allowable modules in series are 3 pieces.

-V

+V

Load

+

-

+V

-V

+

-

Load

C17C15

C17'C15'

Fig.6-2 Series Operation Fig.6-3 Series Operation

(High Output Voltage Applications) (+/-Output Series Applications)

11

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

6-10. Isolation Resistance

Isolation resistance between Output – Base-plate is more than 100MΩ at 500VDC. For safety operation, voltage

setting of DC isolation tester must be done before the test. Ensure that the unit is fully discharged after the test.

Output – Base-plate : 100MΩ or more at 500VDC

Fig.6-4 Isolation Resistance Test Method

6-11. Withstand Voltage Test

This series is designed to withstand 2.5kVAC between input and base-plate, 3.0kVAC between input and output and

1.5kVDC between output and base-plate each for 1 minute.

When performing tests at Input – base-plate and Input – Output, do the withstand voltage test after setting current

limit value of the withstand voltage testing equipment to 20mA.

Be sure to apply DC voltage between Output - base-plate. Avoid applying AC voltage during this test because this

will damage the power supply.

The applied voltage must be gradually increased from zero to testing value and then gradually decreased for shut

down. When timer is used, the power supply may be damaged by high impulse voltage generated during timer switch

on and off.

Connect each terminal according to the circuit diagram shown below.

2.5kVAC 1 minute (20mA) 3kVAC 1 minute (20mA)

Fig.6-5 Fig.6-6

Input to Base-plate Withstand Voltage Test Method Input to Output Withstand Voltage Test Method

1.5kVDC 1 minute

Fig.6-7

Output to Base-plate Withstand Voltage Test Method

12

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

Withstand Voltage

Testing with External Application

The above Withstand Voltage Testing specification applies only to power module as stand-alone unit. Please take

note of the following points when Withstand Voltage Testing is performed with attached external application.

For connections shown in Fig. 5-1, when injecting 3kVAC between Input – Output, Voltage Divider Ratio between

Input – Base-plate and Output – Base-plate will be affected by capacitance value ratio connected between the Input

– Base-plate and Output – Base-plate.

When selecting external capacitor at the Input – Base-plate and Output – Base-plate, take care of the capacitance

value and voltage rating.

Capacitor of Input – Base-plate : (C2,C3,C6,C7,C14)

Capacitor of Output – Base-plate : (C12,C13)

7. Mounting Method

7-1. Mounting Method

These products can be used in any orientation but be sure to consider enough airflow to avoid heat

accumulation around the power supply. Consider surrounding components layout and set the PCB mounting

direction such that air can flow through the heat sink by forced or convection cooling.

Refer to the power module application note "Power module mounting method" for mounting method on PWB.

This product can operate at actual mounting condition when Base-plate temperature and ambient temperature

are maintained at below the 100℃. For details, refer to “Derating Curve Fig.7-3 and Fig.7-4”.

Temperature at worst case operating condition at the measuring point is shown in Fig.7-1 and Fig.7-2.

For Thermal Design details, refer to Application Notes “Thermal Design” section.

Fig.7-1 Base-plate Temperature Measuring Point Fig.7-2 Ambient Temperature Measuring Point

13

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

7-2. Output Derating

Operating temperature range is limited according to Fig.7-3 and Fig.7-4.

0

20

40

60

80

100

-40 -20 0 20 40 60 80 100

Load (%)

Baseplate and Ambient Temperature (℃)

85

85

Fig.7-3 Derating Curve

(Load v.s. Baseplate and Ambient Temperature)

0

20

40

60

80

100

80 100 120 140 160 180 200 220 240 260

Load (%)

Input voltage (VAC)

Tbp:less than 85℃

Tbp:100℃

265

70

85

85

Fig.7-4 Derating Curve

(Load v.s. Input voltage)

To further improve the reliability, it is recommended to use this power supply with Base-plate and ambient

temperature derating.

14

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

7-3. Notes on Designing PWB for Power Module Mounting

In order to satisfy withstand voltage specification, it is recommended to keep following distances for each

pattern wiring and mounting components distance of primary circuit (Input), secondary circuit (Output) and FG

(Base-plate).

Between primary circuit and FG ・・・・・ 5.0mm or more

Between secondary circuit and FG ・・・・ 2.0mm or more

To ensure conformance to various safety standards, creepage distance and clearance between the primary and

the secondary of the PWB for power module mounting shall be considered. From the power module cover

outline and terminals, keep creepage distance and clearance between the primary and the secondary.

In order to acquire safety standards for this power module, creepage distance and clearance between the primary

and the secondary is designed to be 7.5 mm. The pattern wiring prohibited area of the PWB is shown in Fig. 7-5,

and power module cover outline is shown in Fig. 7-6.

Creepage distance and clearance between the primary and the secondary of the PWB for power module

mounting varies depending on power module mounting condition, contact our customer support for details.

・・・ Pattern wiring prohibited area of the secondary circuit

・・・ Pattern wiring prohibited area of the primary circuit

・・・ Pattern wiring prohibited area of the primary and the secondary circuit

Fig.7-5 Pattern wiring prohibited area of PWB for power module mounting

(When the distance on the primary and the secondary is 7.5 mm)

Fig.7-6 Dimensions of the power supply cover

15

TDK-Lambda

PFE700SA Series

INSTRUCTION MANUAL

7-4. Recommended Soldering Condition

Recommended soldering temperature is as follows.

Soldering Dip :260℃, within 10 seconds

Preheat :130℃, within 60 seconds

7-5. Recommended washing Condition

After soldering, following washing condition is recommended.

For other washing conditions, consult our Customer Support Group.

(1) Recommended washing solution

・IPA(Isopropyl Alcohol)

(2) Washing method

In order to avoid penetration inside the power module, washing should be done with brush.

Then, dry up thoroughly after washing.

8. Before Concluding Power Module Damage

Verify following items before concluding power module damage.

(1) No output voltage

- Is specified input voltage applied?

- Is there no abnormality with the output load?

- Is the actual baseplate temperature within the specified operating temperature of this module?

(2) Output voltage is low

- Is specified input voltage applied?

- Is there no abnormality with the output load?

(3) Load regulation or line regulation is large

- Is specified input voltage applied?

- Are the input or output terminals firmly connected?

- Are the input and output wires too thin?

(4) Large output ripple

- Is the measurement done according to methods described in the Instruction Manual or is it an equivalent

method?

9. Warranty Period

Warranty period is 5 years.

For damages occurring at normal operation within this warranty period, repair is free of charge.

Following cases are not covered by warranty

(1) Improper usage like dropping products, applying shock and defects from operation exceeding

specification of the unit.

(2) Defects resulting from natural disaster (fire, flood etc.)

(3) Unauthorized modifications or repair by the buyers’ defects not cause by our company.

Table of contents

Other Helios Power Solutions Power Supply manuals