Page 2

Selecting a mounting location:

The most common choice for a mounting area would be a trunk or

similar compartment. However, due to the wide variety of vehicles onto

which the UPS158A could be installed, this is not always possible. The

following guidelines will help the installer select an acceptable

alternative:

• The UPS158A should be mounted on a metal surface to aid

heat dissipation. Be sure that this surface is not one that

either generates or is exposed to excessive heat during

normal operation of the vehicle.

• Do not select a location where the unit will be exposed to

potential damage from any unsecured or loose equipment in

the vehicle.

• Be sure the area selected will not allow the unit to be exposed

to water.

• When routing the wires, it is important to choose a path that

will keep these wires away from excessive heat and from any

vehicle equipment that could compromise the integrity of the

wires (ex. trunk lids, door jams, etc.).

WARNING! The Strobe Light Power Supply is a high

voltage device. Do not touch or remove tube assembly in

strobe light head assemblies while in operation. Wait 10

minutes after disconnecting the unit from its power source

before starting work on the power supply or system.

WARNING! As it will be necessary to drill holes into the

mounting surface, the installer MUST be sure that no

vehicle components or other vital parts could be damaged

by the drilling process. Check both sides of the mounting

surface before drilling begins.

1. Position the UPS158A in its proposed mounting location to ensure

that it fits properly. With the unit in place, insert an awl or other

suitable tool into the mounting screw area of the power supply and

scribe the areas that are to be drilled.

2. Remove the unit from its mounting area and, using a drill bit sized

for a #10 sheet metal screw, drill a hole in each of the areas

scribed in the previous step.

3. Return the unit to its mounting location and using the supplied #10

sheet metal screws, mount the power supply onto its mounting

surface.

Wiring:

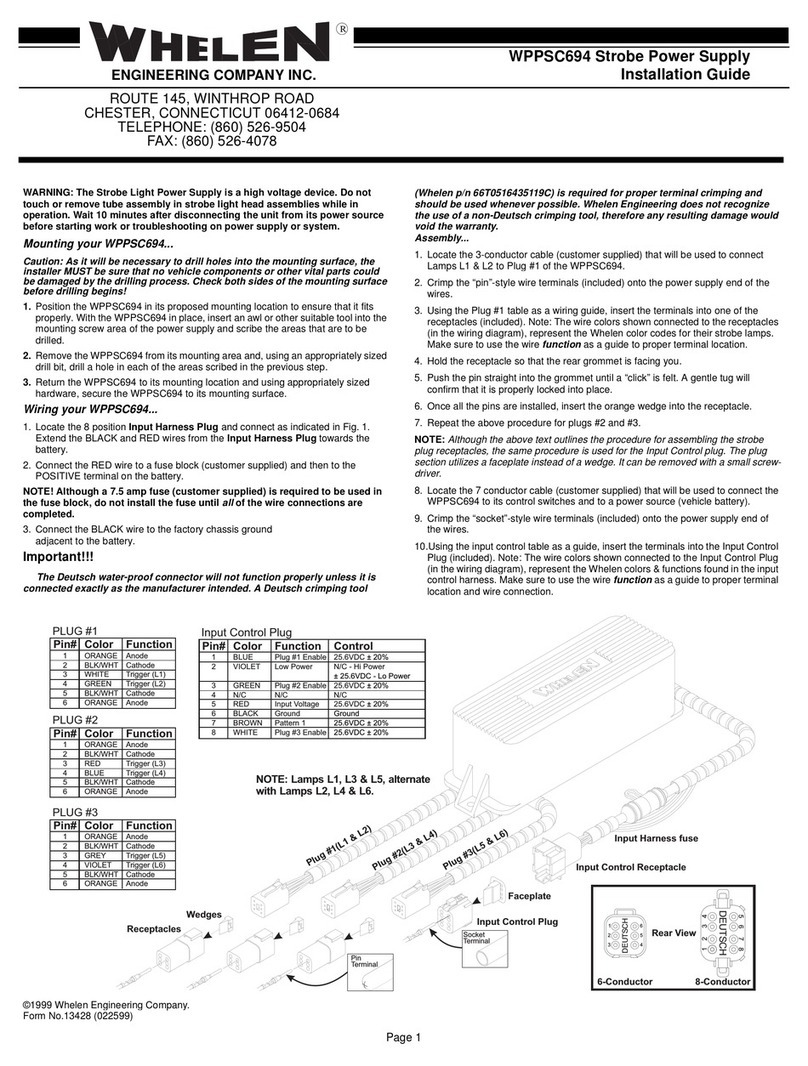

1. Locate the two, 3 position Power Connectors included and plug

them into their respective ports (fig. 1). Splice the two RED wires

together and extend to the the vehicle battery (see Wire Gage

chart on the last page for wire size guidelines).

WARNING! All customer supplied wires that connect to the

positive terminal of the battery must be sized to supply at

least 125% of the maximum operating current and FUSED

at the battery to carry that load. DO NOT USE CIRCUIT

BREAKERS WITH THIS PRODUCT!

2. Connect the extended wire to a fuse block (customer supplied)

and then to the POSITIVE terminal on the battery.

Note: Although a 30 amp fuse (customer supplied) is

required to be used in the fuse block, do not install the fuse

until all of the wire connections are completed.

3. Splice the two BLACK wires together and extend to the vehicle

battery. Connect the extended wire (same gage as determined for

the RED wire) to the factory chassis ground typically adjacent to

the battery.

4. Refer to Fig. 2 for wiring information for the Control Connectors

and for the Pattern Selection Connectors.

5. As shown in Fig. 2, there is a provision in the Power Connectors

for a wire (VIOLET) to activate Hi Power/Low Power strobe

operation. If this feature is desired, locate the VIOLET wires

included with your power supply and, with the Power Connectors

disconnected from the power supply, insert the pinned end of the

VIOLET wires into position 3 of each of the Power Connectors.

Refer to Fig. 2 for wiring information.

Scan-Lock™ Operation...

To cycle forward through the patterns, apply +12VDC to the WHT/VIO

wire for less than 1 second and release to cycle forward. Apply +12VDC

for more than 1 second and release to cycle backward.

To set a pattern as default, allow it to run for more than 5 seconds. The

lightheads will now display this pattern when active.

To reset to the Factory Default pattern: Turn off power. While

applying +12VDC to the WHT/VIO wire, turn power back on.

Available Scan-Lock™ Patterns (in order) -

1) CometFlash® 6) ModuFlash™

2) TripleFlash™ 7) MicroBurst II™

3) DoubleFlash 8) MicroBurst III™

4) RapidRate™ 9) LongBurst™

5) ActionFlash™ 10) ActionScan™

Sync Operation...

NOTE! Synchronized power supplies should be configured to

flash the same pattern.

If desired, the user may Sync the “A” and “B” outlets by connecting the

GREY wires together (see wiring diagram).

When synchronized, all strobes connected to outlets 1A, 3A, 1B & 3B

will alternate with all strobes connected to outlets 2A, 4A, 2B & 4B.

Hi/Lo Operation...

The type of switch used to activate Hi/Lo operation is dependant on

how the operator wishes the Hi/Lo feature to function:

Latching Mode:

By applying +voltage to the Violet wire for less than 1 sec., the power

supply is “latched” into low power operation. The unit must be turned off

and then back on to restore normal, Hi power operation. A momentary

switch is desired for this style.

Level Mode:

Applying +voltage to the Violet wire for more than 1 sec. holds the

power supply in low power mode until that voltage is removed. A toggle

switch is desired for this style.