Hellma Analytics 3in1 FLOW-THROUGH CUVETTE User manual

Table of contents

Popular Laboratory Equipment manuals by other brands

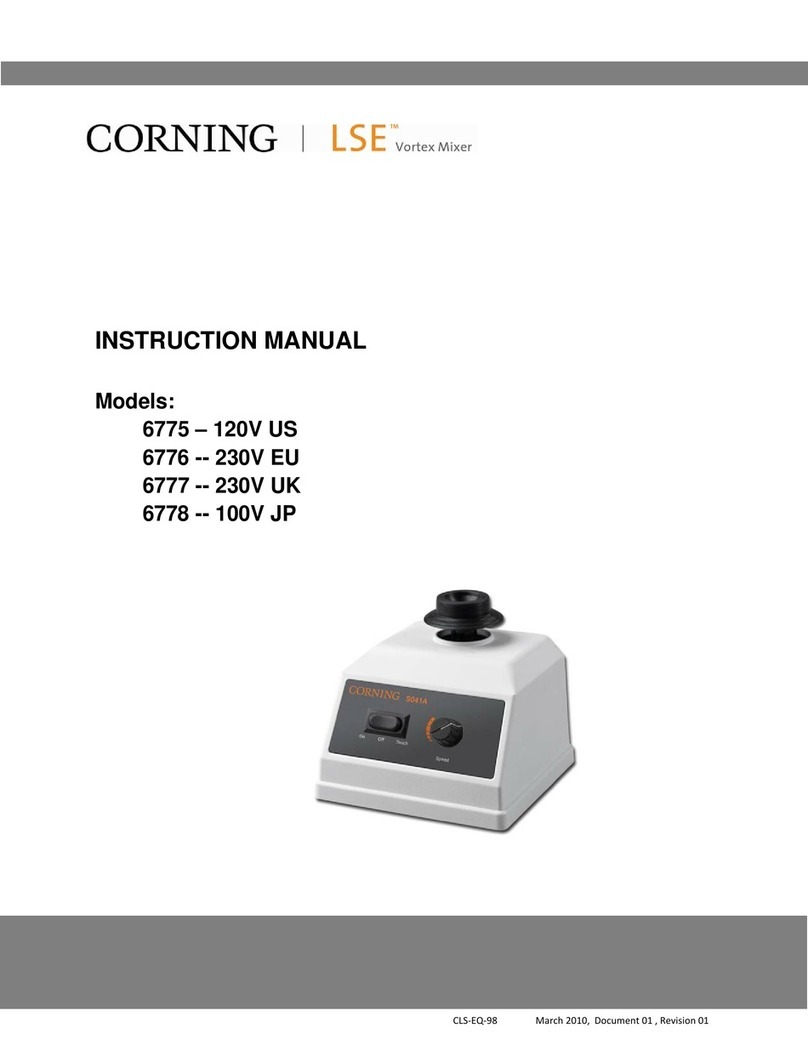

CORNING

CORNING LSE 6775 - 120V US instruction manual

Omni International

Omni International GLH 850 user manual

diagenode

diagenode Bioruptor Standard user guide

Thermo Hybaid

Thermo Hybaid PX2 User instruction manual

Bibby Sterilin

Bibby Sterilin Techne TECAL 700XS Operator's manual

Somark

Somark LABSTAMP user guide

Thermo Scientific

Thermo Scientific ProPac SCX-20 product manual

Agilent Technologies

Agilent Technologies BioCel 1200 user guide

bg edelstahl

bg edelstahl euroMAT basic operating manual

BANDELIN

BANDELIN SONOREX CNp 28-2 operating instructions

NanoEnTek

NanoEnTek JuLi Stage user manual

Thermo Scientific

Thermo Scientific RC 12BP Plus instruction manual

INTELLICYT

INTELLICYT iQue Screener PLUS Hardware manual

Elektro-Automatik

Elektro-Automatik PS 8000 E 3U Series operating guide

Labconco

Labconco Purifier Logic+ 30132 Technical Manual and Specifications

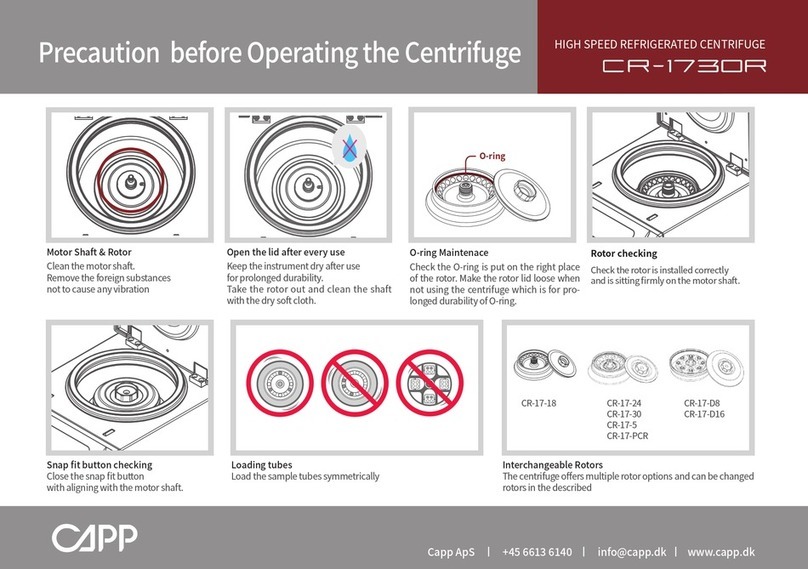

CAPP

CAPP CR-1730R quick guide

Agilent Technologies

Agilent Technologies 8890 Operation manual

Troxler

Troxler ICO 4740 Manual of Operation and Instruction