Somark LABSTAMP User manual

USER GUIDE

Labstamp 2.05

SOMARK Innovations, Inc.

San Diego, CA

USA

www.SomarkInnovations.com/Labstamp-support

Email: support@somarkinnovations.com

Phone: 1-800-430-1243/+1-619-591-8687

2 Overview | Labstamp User Guide | PN: 1202.D

Copyright Information

© 2018 Copyright SOMARK

TM

Innovations, Inc.

All rights reserved. Somark, Labstamp and TriCell are trademarks of Somark Innovations Inc.

Safety Information

Always follow basic safety precautions when using this product to reduce risk of injury from

fire or electric shock.

1. Please read and understand all the instructions included in the documentation that comes with the

Labstamp™ System.

2. Observe all warnings and follow all instructions provided with the product.

3. The suitability of tattooing any particular mouse using the Labstamp System is based upon tail size,

specifically tail girth. The range of acceptable tail girths is determined by the Labstamp Tail Gauge.

Determining the correct Restraint Cartridge and Needle Cartridge combination as prescribed by the Tail

Gauge, enables tattooing mice from weanling to adult. Using the Labstamp System on mice smaller or

larger than the Tail Gauge indicates may result in poor tattoo quality, cause harm to the animal, and/or

damage to the Needle Cartridge.

4. Anesthesia is not required for tattooing mice. Defer to your Ethics Committee or Animal Welfare Officer

for any animal welfare concerns.

5. The Labstamp System was designed and tested for use on mice. The Labstamp System was neither

designed for nor tested on rats.

6. This product does not have a CE, CB or UL marking applied at this time, because compliance with

safety and/or emissions requirements have not yet been verified.

7. Use only the power supply provided or approved by SOMARK Innovations. Using a power supply not

provided by SOMARK Innovations could damage the Applicator Machine and void the warranty.

8. Use only a grounded electrical outlet when connecting this product to a power source. If you do not know

whether the outlet is grounded, check with a qualified technician.

9. Before cleaning this product, unplug it from wall outlets.

10. Do not install or use this product near water, when you are wet, or if the product is wet.

11. Handle Needle Cartridges with care and discard used Needle Cartridges into a sharps container. In the

unlikely event that you accidentally stick yourself with a needle, be familiar with your site policy for any

treatment and/or reporting the incident to your employer. If used and handled properly, Needle

Cartridges are safe and designed to last for up to 50 tattoos.

3 Overview | Labstamp User Guide | PN: 1202.D

Table of Contents

Section 1 Overview .................................................................................................................... 4

Section 2 Labstamp Components .............................................................................................. 5

Section 3 Procedure .................................................................................................................. 7

3.1. PREPARING WORKSPACE ..................................................................................................... 7

3.2. RESTRAINING THE MOUSE .................................................................................................... 7

3.3. DETERMINING THE CORRECT RESTRAINT AND NEEDLE CARTRIDGE COMBINATION ........ 8

3.4. INSTALL THE NEEDLE CARTRIDGE ....................................................................................... 9

3.5. CHANGING THE NEEDLE CARTRIDGE ................................................................................... 9

3.6. APPLYING TAIL OIL .............................................................................................................. 10

3.7. INSERTING THE INK SLIDE .................................................................................................. 10

3.8. PLACING THE TAIL COVER .................................................................................................. 11

3.9. LOADING THE RESTRAINT CARTRIDGE INTO THE APPLICATOR MACHINE ........................ 12

3.10. SELECTING THE ID METHOD / ENTERING THE ID ............................................................... 13

3.11. APPLY THE TATTOO ............................................................................................................ 14

Section 4 Cleaning & Maintenance .......................................................................................... 15

4.1. AS NEEDED ............................................................................... Error! Bookmark not defined.

4.2. AFTER EACH TATTOO.......................................................................................................... 15

4.3. AFTER EVERY 50 TATTOOS ................................................................................................. 15

4.4. AT THE COMPLETION OF THE SESSION ............................................................................. 15

Section 5 System Messages .................................................................................................... 16

Section 6 Troubleshooting ...................................................................................................... 17

Section 7 Applicator Machine Specifications .......................................................................... 20

4 Overview | Labstamp User Guide | PN: 1202.D

Section 1 Overview

This document describes the procedure for using the Labstamp System to create automated tail tattoos for

mouse identification. The Labstamp System is a significant breakthrough for researchers and scientists for

ensuring accuracy of animal research. The Labstamp System features unsurpassed technology that

automatically applies the most consistent, readable and durable ID to research mice. Its advanced design

overcomes issues associated with traditional visual identification methods. By applying automated tattoos to

mice from weanling to adult, the Labstamp System is setting a new standard to protect the integrity of critical

research with many advantages to the facility, operator and the animal.

IMPORTANT

The Labstamp System was designed and validated for mice. The System was neither designed nor validated for

rats. The System was designed to accommodate a specific range of mouse tail diameters (girth) as is generally

found in mice from weanling to adult. Accommodating such a wide range of tail girth is achieved by using a

combination of red (labelled SMALL) or blue (labelled LARGE) Restraint Cartridge, and yellow (shorter) or green

(longer) Needle Cartridge. For each animal, there is only one Restraint Cartridge and Needle Cartridge

combination that will produce an optimal tattoo (i.e. one that is legible and permanent). The Labstamp Tail

Gauge must be used for guidance in selecting the correct Restraint Cartridge and Needle Cartridge

combination.

Note: Tail size, and not animal age or weight, dictates the correct and singular combination of Restraint

Cartridge and Needle Cartridge that the user must use.

Using the Labstamp System on mice outside of the tail size range will result in light or incomplete tattoos on

undersized animals, and it may cause harm to the animal or damage to the Needle Cartridge on oversized mice.

Anesthesia is not required for using the Labstamp System. However, please defer to your Ethics Committee,

Animal Welfare Officer, attending veterinarian and/or veterinary services for any animal welfare concerns.

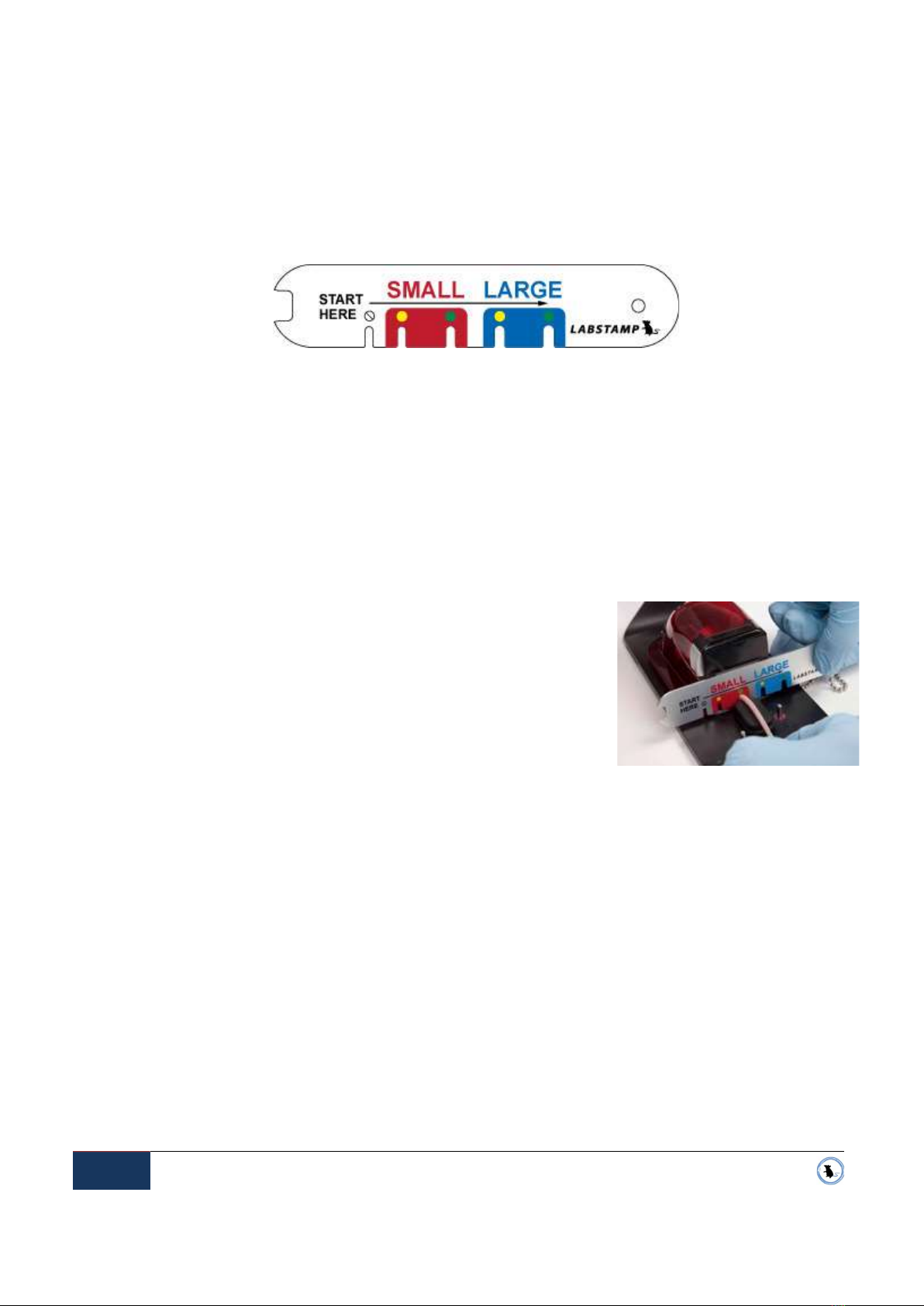

Figure 1-1 Labstamp System

5 Labstamp Components | Labstamp User Guide | PN: 1202.D

Section 2 Labstamp Components

LABSTAMP SYSTEM:

1 Applicator Machine

2 Restraint Cartridges (SMALL and LARGE)

3 Tail Gauge

4 Needle Cartridges (Yellow and Green)

5 UV Thumb Light

6 Ink Slides (Black or UV Green, in foil

pouches)

7 Tail Oil

RESTRAINT CARTRIDGE COMPONENTS

1 TriCell Ink slide

2 Tail Cover

3 Red Dome

4 Tail Gripper buttons

5 Tail Grippers

6 V-Groove Tail Guide

7 Tail Bed

8 Tail Cover Alignment Posts

9 Restraint Cartridge Platform

(labelled SMALL or LARGE)

10 Handle

Figure 2-1 Labstamp System

Figure 2-2 Restraint Cartridge Components

6 Labstamp Components | Labstamp User Guide | PN: 1202.D

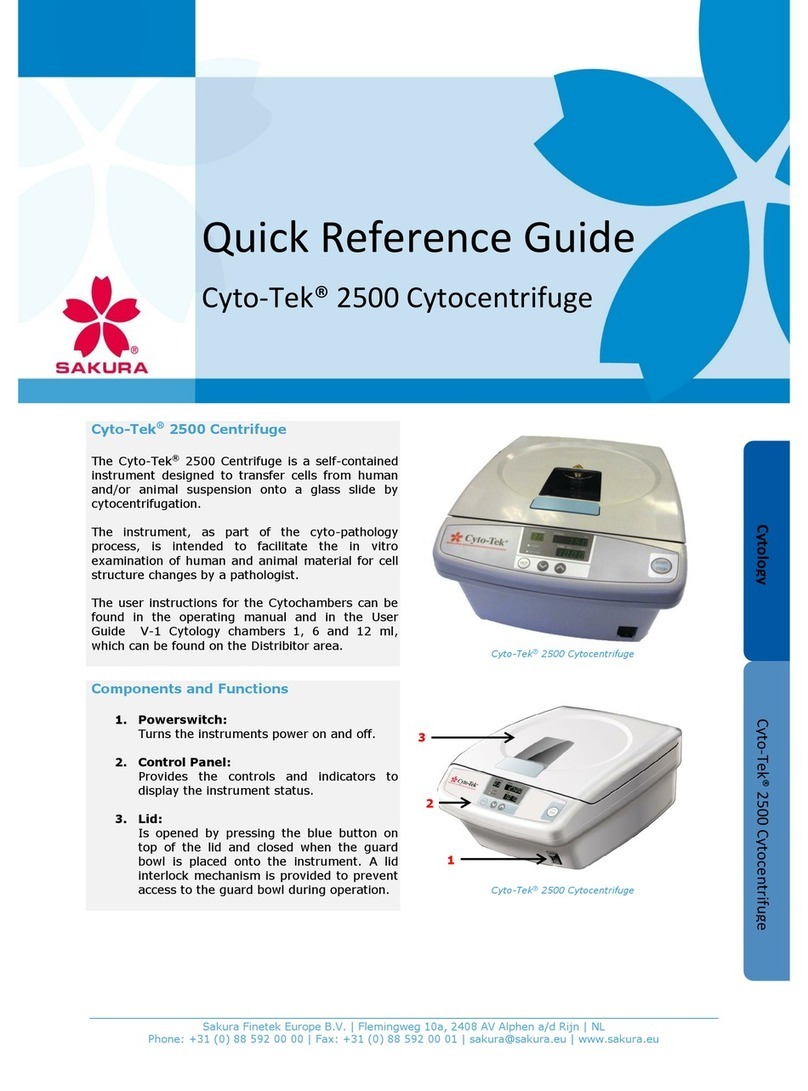

CONTROL PANEL

APPLICATOR MACHINE

1 Tattoo head door

2 Control Panel (see Control Panel, below)

3 Power Switch

4 Power Plug

5 USB Port (optional)

1 Restraint Cartridge Status light

Red solid light -The Restraint Cartridge is

inserted but not fully seated in place for

tattooing.

Red flashing light -Tattooing is in progress.

Do not remove Restraint Cartridge until

tattooing is complete and the status light has

returned to green.

Green light - The Restraint Cartridge has been

inserted correctly. You are ready to start a

tattoo or remove the Restraint Cartridge.

Light off - No Restraint Cartridge has been

detected.

2 Auto increment button

Turns the Auto Increment mode ON. The

Auto Increment button light will remain on

while the machine is in this mode.

3 Change Needle button

Opens the tattoo-head door and extends the

tattoo-head and installed Needle Cartridge out

of the Applicator Machine. May also be used

to retract the tattoo-head after installing a new

Needle Cartridge.

4 Start button

Begins the tattooing process. Retracts the

tattoo-head and Needle Cartridge into the

Applicator Machine.

5 LCD display screen

Provides user instruction. See System

Messages on page 16.

6 Stop button

Aborts Applicator Machine operations.

7 Alpha key

Changes keypad to A-Z. Press once to turn on

mode for single character. Press and hold to

lock-in the alpha mode.

8 Backspace button

“Backspace.” Erases the last character

entered.

Figure 2-3 Applicator Machine

Figure 2-4 Control Panel

7 Procedure | Labstamp User Guide | PN: 1202.D

Section 3 Procedure

3.1. PREPARING WORKSPACE

3.1.1 Set-up the tattooing area with the supplied Applicator

Machine, Restraint Cartridge(s), Tail Gauge, Ink Slides

(keep in foil pouch until ready to tattoo), Needle

Cartridge(s), and Tail Oil. See Figure 3-1 Labstamp

System

3.1.2 Obtain a small dish, cotton tipped applicators, and gauze.

3.1.3 Plug the SOMARK provided power supply into the Applicator

Machine, and plug the power supply into a power outlet. Using

the power switch located on the rear of the machine, turn on

the Applicator Machine. See Figure 3-2 Power Switch.

3.1.4 When ready to tattoo, open the foil pouch containing the Ink

Slides.

Note: Once opened, Ink Slides must be used

or re-sealed within twenty-four (24) hours.

3.1.5 Pour a small amount of Tail Oil into the dish.

3.2. RESTRAINING THE MOUSE

3.2.1 Make an initial selection of the Restraint Cartridge

(SMALL or LARGE) based upon whether mice are young

or adult. See Figure 3-3 Restraint Cartridges

3.2.2 Remove the Red Dome and Tail Cover from the Restraint Cartridge. (Remove the Tail Cover by

lifting it straight-up off of the Restraint Cartridge platform.) Pick-up a mouse by the tail and place

it on the Restraint Cartridge platform with the head facing toward the handle.

Figure 3-1 Labstamp System

Figure 3-2 Power Switch

Figure 3-3 Restraint Cartridges

8 Procedure | Labstamp User Guide | PN: 1202.D

Figure 3-4 Restraining a mouse

3.2.3 With one hand still holding the mouse by the tail, use your forefinger and thumb on your other

hand to pick up the Red Dome. Depress the tail gripper buttons on either side of the dome to

spread open the tail grippers. See Figure 3-4 Restraining a

mouse.

3.2.4 Lower the Red Dome over the mouse keeping the

tail gripper buttons pressed open. Set the Red Dome in place

on the Restraint Cartridge platform until the magnet guides

are engaged.

3.2.5 With the tail gripper buttons still pressed open, pull the

mouse gently against the back wall of the Red Dome.

Release the tail gripper buttons to secure the mouse. You may now release the mouse tail.

9 Procedure | Labstamp User Guide | PN: 1202.D

3.3. DETERMINING THE CORRECT RESTRAINT AND NEEDLE CARTRIDGE COMBINATION

IMPORTANT: The Labstamp Tail Gauge is used to determine the appropriate Restraint

Cartridge and Needle Cartridge combination that is to be used for each mouse. The proper

use of this tool will ensure that the best quality and most durable tattoo is produced.

Relying on the age or weight of a mouse to determine the appropriate Restraint Cartridge or

Needle Cartridge will not result in a quality tattoo.

The Tail Gauge is comprised of 5 slots of increasing widths. See Figure 3-5 Tail Gauge.

Two of the 5 slots fall within a red coloured zone, and two fall within a blue coloured zone.

These coloured zones correspond to the SMALL and LARGE Restraint Cartridges, respectively.

Above each of the 4 slots on the Tail Gauge is a yellow or green coloured dot. These coloured

dots correspond to the yellow and green coloured Needle Cartridges used in the Applicator

Machine.

The 5th slot on the far left of the Tail Gauge has the international circle-slash symbol above it.

It identifies mice that are too small to be used in the Labstamp System at this time.

3.3.1 To measure the tail, position the mouse tail across the

v-groove of the rubber tail bed. If necessary, gently hold the

tail in place. See Figure 3-6 Positioning the Tail Gauge.

3.3.2 Hold the Tail Gauge as close as practical to the tail grippers,

i.e. where the tail exits the red dome,

NOTE: Ensure the Tail Gauge is held vertically and square with

respect to the tail.

3.3.3 Measure from the largest slot on the right, to the smallest slot

on the left, until you find the appropriate fit.

3.3.4. The appropriate slot on the Tail Gauge should drop under its own weight over the tail. A

snug fit is permissible but do not force the gauge over the tail. See Figure 3-6 Positioning the

Tail Gauge.

3.3.5. Once the slot that best fits the mouse tail is determined, identify the correct Restraint Cartridge

size and Needle Cartridge colour that corresponds to that slot.

In some cases, you may need to change the mouse to the other Restraint Cartridge than what

you first selected to measure the tail.

NOTE: Any time that a mouse is placed or repositioned, either on the same Restraint Cartridge or

on a different Restraint Cartridge, it is important to use the Tail Gauge to confirm the appropriate

combination of Restraint Cartridge and Needle Cartridge is being used.

IMPORTANT: If the tail is too large for any of the slots, the animal is too large to be tattooed.

Figure 3-5 Tail Gauge

Figure 3-6 Positioning the Tail Gauge

10 Procedure | Labstamp User Guide | PN: 1202.D

3.4. INSTALL THE NEEDLE CARTRIDGE

IMPORTANT: Needle Cartridges can be used for a maximum of 50 IDs. After 50 IDs, the

needle tips become blunt and are not as effective at producing a quality tattoo. Also,

please always handle Needle Cartridges with care. Never put your fingers inside the

Applicator Machine.

NOTE: If the needle has not been properly installed, it may fall off the tattoo head inside of the machine.

If this happens, the needle may interfere with the operation of the Applicator. Do not install another

needle or attempt to operate the Labstamp System. Contact SOMARK for further assistance.

If you are changing a previously installed Needle Cartridge, proceed to Section 3.5 CHANGING THE

NEEDLE CARTRIDGE

3.4.1 Press the CHANGE NEEDLE button on the front panel of the

Applicator Machine. The tattoo head door will open, and the

tattoo head will emerge from inside the Applicator Machine.

See Figure 3-7 Change Needle Button

NOTE: If this is the first time the Applicator Machine is being used,

the tattoo head will already be in the Change Needle

position with the tattoo head protruding out of the

Applicator Machine.

3.4.2 With the needle pointing downward, install the Needle

Cartridge by lining up the clip arms of the Needle Cartridge

with the slots in the tattoo head. Gently push in until the clip

arms snap into place. See Figure 3-8 Install Needle Cartridge.

3.4.3 Press the CHANGE NEEDLE or START button on the front panel of the Applicator Machine to

retract the tattoo head. Ensure the small tattoo head door closes.

3.4.4 Once the Needle Cartridge is installed, proceed to section 3.6 - APPLYING TAIL OIL

3.5. CHANGING THE NEEDLE CARTRIDGE

IMPORTANT: Needle Cartridges can be used for a maximum of 50 IDs. After 50 IDs,

the needle tips become blunt and are not as effective at producing a quality tattoo.

Please always handle Needle Cartridges with care. Never put your fingers inside the

Applicator Machine.

3.5.1 Press the CHANGE NEEDLE button on the front panel of the

Applicator Machine. See Figure 3-7 Change Needle Button.

The tattoo head and used Needle Cartridge will emerge from

inside the Applicator Machine.

Figure 3-7 Change Needle Button

Figure 3-8 Install Needle Cartridge

11 Procedure | Labstamp User Guide | PN: 1202.D

Figure

3-11 Ink Slide Pouch

3.5.2 Using the forked-end of the Tail Gauge, push it onto the mid-section of the Needle Cartridge.

The tangs of the fork will depress the clip arms to release the Needle Cartridge from the tattoo

head. See Figure 3-9 Tail Gauge Fork-End.

3.5.3 Withdraw the Tail Gauge. The used Needle Cartridge will be retained between the fork tangs.

3.5.4 Install the replacement Needle Cartridge by holding it between your thumb and forefinger, lining-

up the clip arms of the Needle Cartridge with the vertical slots on the tattoo head, and then

gently pushing-in on the body of the Needle Cartridge until the clip arms snap into place. See

Figure 3-8 Install Needle Cartridge.

3.5.5 Press the CHANGE NEEDLE or START button on the front panel of the Applicator Machine to

retract the tattoo head. See Figure 3-7 Change Needle Button. Ensure the small tattoo head

door closes.

3.5.6 Discard used Needle Cartridges into an approved sharps container.

3.5.7 Install the replacement Needle Cartridge as described in Section 3.4- INSTALL THE NEEDLE

CARTRIDGE.

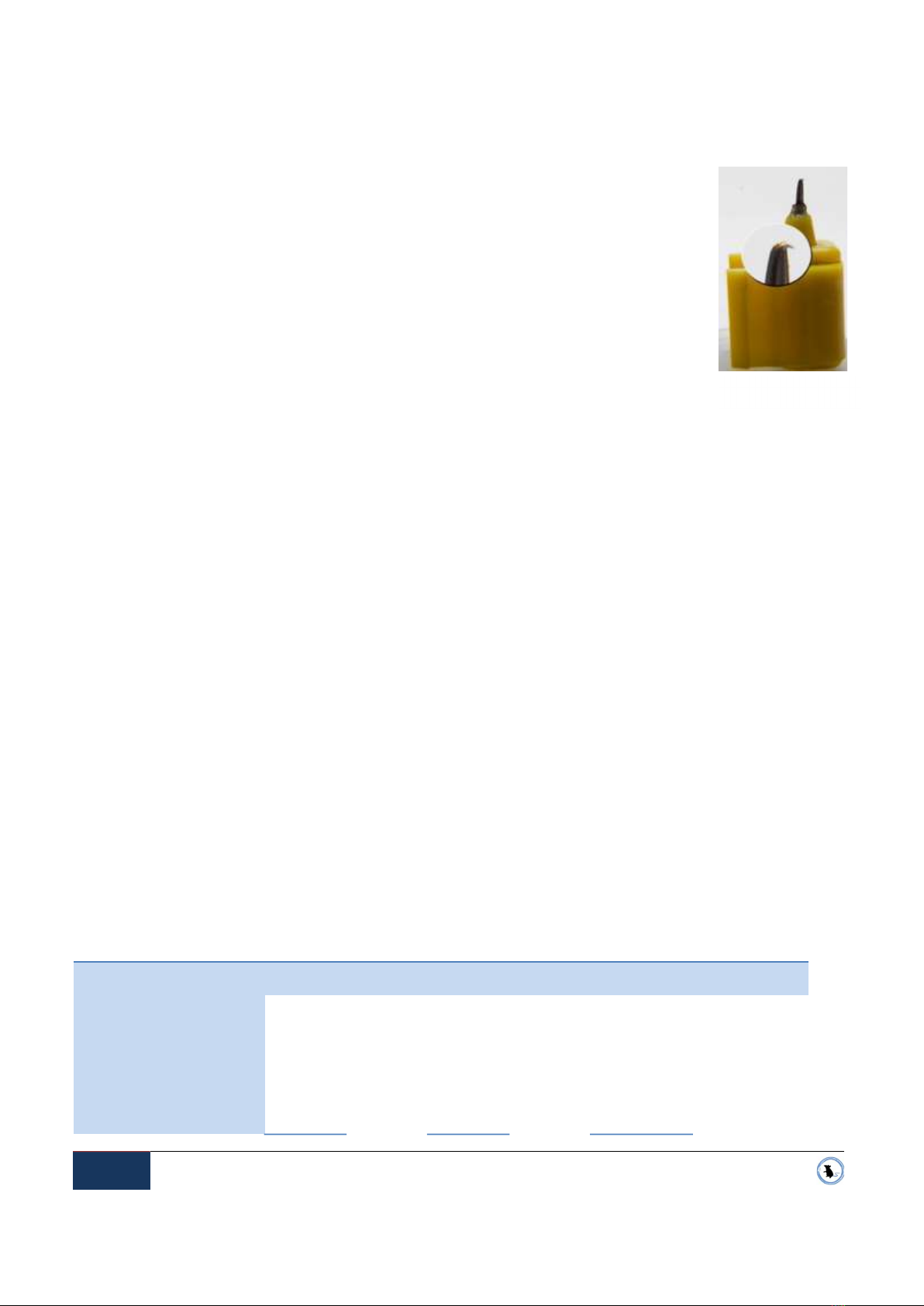

3.6. APPLYING TAIL OIL

IMPORTANT: Prior to tattooing, the mouse tail should be

coated with a layer of Tail Oil. The Tail Oil serves to condition

the skin, enhance needle penetration, and enable excess tattoo

ink to be removed more readily after the tattoo process.

3.6.1 Saturate a cotton-tipped applicator with Tail Oil.

3.6.2 While gently holding the tail, liberally apply a layer of Tail Oil

on the top and sides of the tail that lies across the v-groove of the rubber tail bed. See Figure

3-10 Apply Tail Oil.

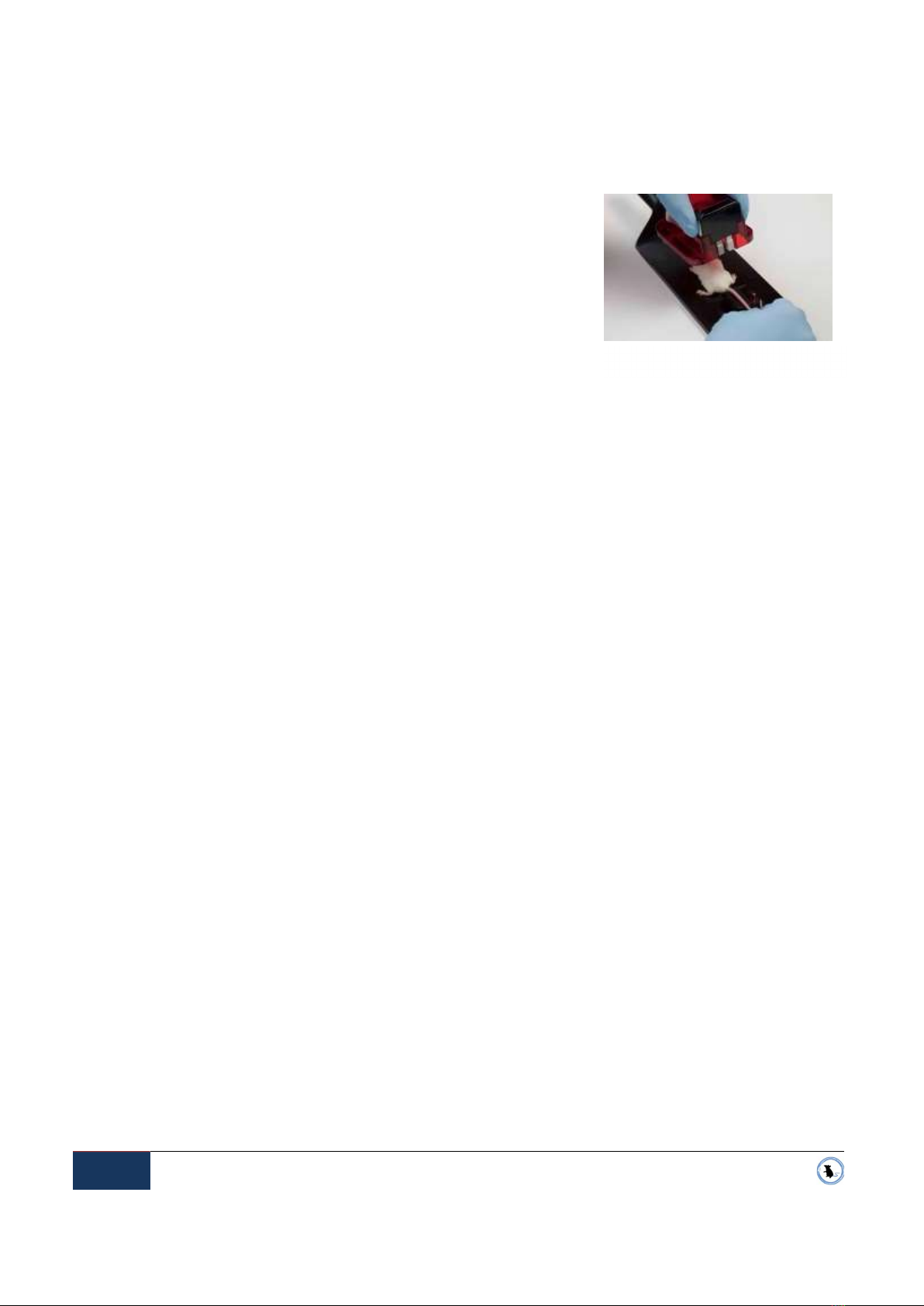

3.7. INSERTING THE INK SLIDE

NOTE: The Ink Slides are single-use only and will need to be replaced after

each ID. Once opened, the package of slides must be used within twenty-

four (24) hours or re-sealed otherwise the Ink Slides will dry-out and result in

light or incomplete tattoos when used.

3.7.1 Pull out one Ink Slide from the foil pouch. See Figure 3-11 Ink Slide

Pouch. Verify that ink is present in each of the three (3) ink

compartments. If any of the ink compartments are dried or damaged,

use a different ink slide.

Figure 3-9 Tail Gauge Fork-End

Figure 3-10 Apply Tail Oil

12 Procedure | Labstamp User Guide | PN: 1202.D

Figure 3-14 Aligning the tail

Figure 3-13 Tail Cover

3.7.2 Insert the Ink Slide into the slotted opening on the side of the Tail Cover. Ensure that the holes

of the Ink Slide line up with the holes in the Tail Cover. The Ink

Slide is properly installed when it will not push-in any further and

the alignment holes are aligned. See Figure 3-12 Ink Slide

Insertion.

3.8. PLACING THE TAIL COVER

3.8.1 Align the tail within the v-groove of the rubber tail bed. Hold

the tail gently to keep it in place, but do not attempt to stretch

the tail nor hold it taut. See Figure 3-14 Aligning the tail.

3.8.2 Align the Tail Cover with the colour-coordinated posts of the Restraint Cartridge platform - blue

aligns with blue, and red with red. See Figure 3-13 Tail Cover

3.8.3 Carefully lower the Tail Cover, with the Ink Slide inserted,

over the tail. Be sure to release any tension that you may

have applied to the tail while attempting to hold the tail in

place.

NOTE: The Tail Cover has magnets and alignment posts to ensure

that the Tail Cover snaps into proper position.

3.9. LOADING THE RESTRAINT CARTRIDGE INTO THE APPLICATOR MACHINE

3.9.1 With the mouse and Tail Cover in place, lift the Restraint Cartridge by the handle.

3.9.2 Gently insert the Restraint Cartridge into the docking port

on the front of the Applicator Machine. See Figure 3-15

Load Restraint Cartridge.

3.9.3 In the upper left corner of the Control Panel, check the

RESTRAINT CARTRIDGE STATUS light:

3.9.3.1 The Restraint Cartridge is properly installed when the

RESTRAINT CARTRIDGE STATUS light changes from

red to green.

3.9.4 You are ready to apply a tattoo.

Figure 3-12 Ink Slide Insertion

Figure 3-15 Load Restraint Cartridge

13 Procedure | Labstamp User Guide | PN: 1202.D

Figure 3-16 Entering the ID

3.10. SELECTING THE ID METHOD / ENTERING THE ID

There are two options for selecting the ID to be applied:

Manual entry

Auto increment.

3.10.1 Option 1: Manual Entry

3.10.1.1 Using the Applicator Machine keypad, enter the desired alpha/numeric

ID combination from 0-999 and/or A-Z. A space and plus/positive (+) or minus/negative

(-) are also available.

3.10.2 Option 2: Auto Increment

3.10.2.1 Press the AUTO INCREMENT button. The button light will illuminate.

3.10.2.2 Enter the first ID in your desired sequence. Beginning with the number that you

entered, the subsequent tattoos that are applied will increase according to the rules

below.

Auto increment sequence rules

Alpha/Numeric sequences will increase by 1 from 0-999 or A-Z. You may start with any alpha/numeric

character.

If the first ID is… the next ID will be … & the final ID will be …

9 _ _ 1 0 _ 9 9 9

_ _ 9 _ 1 0 9 9 9

A 9 _ B 0 _ Z 9 _

_ A 9 _ B 0 _ Z 9

A 0 9 A 1 0 Z 9 9

1 Z _ 2 A _ 0 Z _

_ 1 Z _ 2 A _ 0 Z

0 1 Z 0 2 A 9 9 Z

A 0 Z 1 B 0 9 Z 9

Z _ _ A A _ Z Z Z

_ _ Z _ A A Z Z Z

14 Procedure | Labstamp User Guide | PN: 1202.D

Figure 3-19 Tattoo Complete

3.11. APPLY THE TATTOO

3.11.1 Ensure that the ID has been selected and the RESTRAINT

CARTRIDGE STATUS light is green.

3.11.2 Press the START button to begin tattooing. See Figure 3-17

Start Button. The button will beep when it has been pressed,

and the Applicator Machine will begin to tattoo.

NOTE: When the machine begins to tattoo, the RESTRAINT CARTRIDGE STATUS light

will begin to flash red. Do not attempt to remove the Restraint Cartridge from the Applicator

Machine while the light is flashing red.

NOTE: While one animal is being tattooed, you can use a second Restraint Cartridge to

prepare the next animal for identification. However, for the comfort of the mouse, animals

should not be left for more than a couple of minutes with the tail grippers restraining the

mouse.

3.11.3 After tattooing is complete and the RESTRAINT CARTRIDGE

STATUS light returns to green, remove the Restraint

Cartridge by sliding it straight-back and out of the Applicator

Machine. See Figure 3-18

3.11.4 Remove the Tail Cover by lifting it straight-up off of the Restraint Cartridge platform.

3.11.5 While holding the tail gently, remove excess tattoo ink by wiping the newly tattooed tail with

either a cotton-tipped applicator or a piece of gauze saturated with Tail Oil.

3.11.6 To return the mouse to their cage, place the Restraint

Cartridge in the cage and depress the tail gripper buttons on

the red dome in order to release the mouse from the

Restraint Cartridge.

When finished, clean the Labstamp components as needed, and proceed

with the next mouse, See Cleaning & Maintenance below for detailed

instruction on cleaning the System.

IMPORTANT: If the Labstamp machine is to be moved or transported after the tattoo session has

been completed, it is advisable to park the machine tattoo head in the Needle Change position.

Simply press the CHANGE NEEDLE button on the front panel of the Applicator Machine. This will

lock the tattoo head in place and prevent compromising the critical alignment and calibration of the

machine. For questions, please contact SOMARK for further assistance.

Figure 3-17 Start Button

Figure 3-18 Removing the Restraint

15 Cleaning & Maintenance | Labstamp User Guide | PN: 1202.D

Section 4 Cleaning & Maintenance

For best results and to preserve the life of your Labstamp System, please ensure the

following:

4.1. AT LEAST EVERY 10 TATTOOS

4.1.1 Clean the Needle Cartridge.

4.1.1.1 Press the “Change Needle” button. Wait for the tattoo head to

emerge. Gently wipe the needle tips with a cotton-tipped applicator

coated in tail oil, alcohol or other cleaning agent. Press the “Change

Needle” button to retract the tattoo head.

4.1.2 Inspect the Needle Cartridge to check for damaged or J-Hooked needles. See Figure 4-1

J-Hooked Needle

4.1.2.1 Press the “Change Needle” button. Wait for the tattoo head to emerge. Using the

forked-end of the Tail Gauge, push it onto the mid-section of the Needle Cartridge. The

tangs of the fork will depress the clip arms to release the Needle Cartridge from the

tattoo head. See Figure 3-9 Tail Gauge Fork-End

4.1.2.2 Inspect the Needle Cartridge to check for damaged or J-Hooked needles.

See Figure 4-1

J-Hooked Needle

4.2. AFTER EACH TATTOO

4.2.1 Replace the Ink Slide.

4.3. AFTER EVERY 50 TATTOOS

4.3.1 Replace the Needle Cartridge at least after every 50 tattoos.

4.4. AT THE COMPLETION OF THE SESSION

4.4.1 Wipe down the Applicator Machine, all Restraint Cartridge

components and Tail Gauge thoroughly according to your laboratory guidelines. Clean the

needle cartridge with a cotton-tipped applicator coated in tail oil, alcohol or other cleaning

agent.

Note: Do not spray into the Applicator Machine port in the front nor into the air vents to the rear of the System.

CLEANING METHODS

Acceptable cleaning methods for each Labstamp component are listed below:

ETO Irradiate Autoclave VHP Spray/wipe Chlorine

dioxide gas

Applicator machine •

• • •

Restraint cartridge • • • • •

Ink slide (single-use)

•

• • •

Needle • •

• • •

Figure 4-1

J-Hooked Needle

16 System Messages | Labstamp User Guide | PN: 1202.D

Tail oil • • • • • •

ETO= Ethylene oxide

VHP= Vaporized hydrogen peroxide

The Applicator Machine can fit inside an isolator with a 12” diameter transfer portal.

WARNINGS

The Applicator Machine has electrical components that can be damaged by autoclave processes.

The external surfaces of the machine can be cleaned with any sterilant or disinfectant solution.

Do not spray any liquid (including sterilant or disinfectant) directly into the docking port or air vents,

located on the back.

Section 5 System Messages

Message What it means

ENTER MOUSE ID

_ _ _

Appears in the Manual Entry option. In this option, a new ID

will need to be entered for each mouse.

ENTER FIRST ID Appears in the Auto Increment option. See rules on page 13.

TATTOOING IN PROGRESS The machine is tattooing a mouse. Do not remove the

Restraint Cartridge from the docking port until the

RESTRAINT CARTRIDGE STATUS light returns to green.

NEXT MOUSE ID _ _ _

PRESS START

In the Auto Increment option, the next number in the sequence

automatically appears. Press START to begin tattooing.

REPLACE NEEDLE 50 tattooed IDs have been applied. The needle must be

replaced. Will stay on until the new needle has been installed.

REMOVE RESTRAINT CARTRIDGE Usually appears after pushing the CHANGE NEEDLE button.

The Restraint Cartridge must be removed before changing the

Needle Cartridge.

PLEASE WAIT The tattoo head is either extending out of or retracting into the

machine. Wait until the tattoo head stops before attempting to

change the Needle Cartridge.

AUTO INCREMENT

MODE ON

The Auto Increment option has been turned on.

AUTO INCREMENT

MODE OFF

The Auto Increment option has been turned off.

17 Troubleshooting | Labstamp User Guide | PN: 1202.D

Section 6 Troubleshooting

ALERT MESSAGES

If you experience an alert message or problem with the Labstamp System:

Turn off the Applicator Machine. Wait 5 seconds. Then turn the Applicator Machine on. If this does not resolve

the issue, note the Labstamp alert message that appears on the LCD screen and the Applicator’s serial number

and contact SOMARK or your local support representative.

LIGHT OR INCOMPLETE TATTOOS

Check the Ink Slides before use by gently squeezing the ink portion to ensure liquid is present inside. In

addition, check the expiration date. Slides are intended for single use only. Re-using an ink slide is not

recommended.

Check the Needle Cartridge for damaged or J-hooked needles. Use an eye loupe or stereo microscope to

inspect the needles and verify if the needles are hooked or damaged.

Check to ensure that the appropriate Restraint Cartridge and Needle Cartridge were selected for the mouse

as prescribed by the Tail Gauge.

Check to ensure the tail was properly positioned in the Restraint Cartridge.

Check for any debris that may be present under the Tail Cover. Clear the debris and resume tattooing.

MISSING / IMPROPERLY INSTALLED NEEDLE

If the needle has not been properly installed, it may fall off the tattoo head inside of the machine. If this

happens, the needle may interfere with the operation of the Applicator. Do not install another needle or

attempt to operate the Labstamp System. Contact SOMARK for further assistance.

REMOVING A NEEDLE FROM INSIDE THE LABSTAMP APPLICATOR MACHINE

If a needle has dropped inside of the Applicator Machine, it must be removed before continuing to use the

Machine as the Needle may interfere with proper operation of the Machine. Resist the urge to shake or turn

upside-down the Labstamp Machine in an attempt to remove a fallen needle. Instead, please follow the

step-by-step instructions below for removing the Top Cover of the Machine and extracting the Needle. If

you have any questions or encounter difficulties in executing these instructions, please contact SOMARK for

further assistance.

6.1. REMOVING THE MACHINE TOP COVER

6.1.1. Turn ON the Machine power using the rocker switch located on the back of the Machine.

6.1.2. Press the Change Needle button to bring the tattoo head out of the door (i.e. the Needle Change

position).

6.1.3. Turn OFF the power and unplug the power cord from the back of the Machine.

6.1.4. Try looking inside the door to see if the loose needle is visible and readily accessible to be removed,

for example, using tweezers or forceps.

6.1.4.1. If so, remove the fallen needle and resume normal operation after installing an

appropriate new needle.

6.1.4.2. If not, disconnect the power supply cord from the Applicator Machine.

6.1.5. Remove the blue Top Cover of the Applicator Machine.

18 Troubleshooting | Labstamp User Guide | PN: 1202.D

6.1.5.1. Locate the four (4) deeply recessed socket head cap screws found on the bottom of the

Machine.

Note: These are not the four socket head cap screws used to secure the rubber feet to

the Machine bottom. DO NOT LOOSEN THESE.

6.1.5.2. Keeping the Machine upright, slide it forward until one end overhangs partially the

edge of the work table.

6.1.5.3. Using a 9/64” Allen hex key, remove completely two (2) of the four (4) deeply recessed

socket head cap screws.

Note: The screws have been semi-permanently secured using a locking adhesive. It

may require some torque to begin turning them.

6.1.5.4. Still keeping the Machine upright, rotate it 180 degrees and slide it forward until the

other end overhangs partially the edge of the work table.

6.1.5.5. Remove completely the two (2) remaining deeply recessed socket head cap screws.

6.1.5.6. With the four mounting screws removed, lift the blue Top Cover straight up using two

hands and set it carefully aside.

Caution: Take care to avoid dropping anything inside of the Machine while it is open.

6.2. REMOVING THE FALLEN NEEDLE

6.2.1. With the blue Top Cover removed, locate the fallen Needle and extract it.

Note: If the Needle is not immediately visible, look beneath the black Restraint Plate (i.e. the

plate where the Restraint Platform is inserted into the Machine.)

Caution: When reaching into the Machine, take care to avoid touching any of the electronics (i.e.

any part of the green printed circuit boards, wiring, and cables).

6.2.2. Inspect the extracted Needle for damage.

6.2.2.1. If it is the intent to re-use the extracted Needle, it must be inspected for damage. The

Needle tips are very delicate and one or more of the four Needle tips may have

become j-hooked. If so, discard the Needle.

6.3. REPLACING THE MACHINE TOP COVER

6.3.1. Using two hands, lower the blue Top Cover down onto the Machine.

6.3.1.1. While lowering, angle the Top Cover with the front edge of the cover slightly lower

than the rear in order to first engage the top lip of the angled Keypad Faceplate.

6.3.1.2. With the Top Cover engaging the Faceplate, lower the rear of the Top Cover until it

rests on the silver-coloured Backplate in back.

6.3.1.3. Release the Top Cover.

19 Troubleshooting | Labstamp User Guide | PN: 1202.D

6.3.2. Using a small thin screwdriver, insert it partially into one of the air vents of the Backplate where

the fan is installed.

6.3.3. Pull back lightly on the screwdriver until the Backplate is aligned with the groove on the

underside of the Top Cover.

Caution: Use only a very light force when pulling back on the screwdriver. The Backplate is fairly

loose at this point and will readily respond.

6.3.4. Finish lowering the Top Cover until its rear alignment groove fully seats onto the Backplate.

6.3.5. Remove the screwdriver.

6.3.6. Inspect the seating of the Top Cover onto the Machine.

6.3.6.1. Inspect to ensure that the front interface of the Top Cover is evenly seated across the

seam of the Faceplate, and that the rear groove of the Top Cover is fully engaged and

seated onto the Backplate.

6.3.6.2. Inspect to ensure that the rounded left and right seams of the Top Cover match-up and

are flush with the radius of the blue Bottom Cover.

6.3.6.3. If the Top Cover is misaligned, repeat steps 6.3.1 -6.3.6 until it is aligned properly.

6.3.7. Keeping the Machine upright, slide it forward until one end overhangs partially the edge of the

work table.

6.3.8. Using the 9/64” Allen hex key, install two (2) of the socket head cap screws from underneath the

Machine and tighten them until slightly snug.

6.3.9. Still keeping the Machine upright, rotate it 180 degrees and slide it forward until the other end

overhangs partially the edge of the work table.

6.3.10. Install the two (2) remaining socket head cap screws from underneath the Machine and tighten

them until slightly snug.

6.3.11. Re-inspect the seating of the Top Cover to the Machine, making sure that all interfacing seams

are still flush.

6.3.11.1. If the Top Cover is misaligned, repeat steps 6.3.1-6.3.11 until it is aligned properly.

6.3.12. Tighten the four (4) socket head cap screws until they are snug.

6.3.13. Caution: Do not overtighten the screws as they may crack the plastic Bottom Cover.

6.3.14. Plug the power cord back into the back of the Machine.

6.3.15. Turn ON the power using the rocker switch in the back of the Machine. The Machine is now

ready for use.

20 Applicator Machine Specifications | Labstamp User Guide | PN: 1202.D

Section 7 Applicator Machine Specifications

General

Model Labstamp 2.06

Dimensions 10.9” x 12.5” x 4” (27.7 x 31.8 x 10.2 cm)

Weight 9.5 lbs (4.3 kg)

DISPLAY

Type LCD

Screen size 2.5” x 0.6” (6.35 x 1.52 cm)

Resolution 80 x 16

ELECTRICAL

Power source 120V, 60Hz

Power consumption 1.5A (max)

Operating temperature 32°F to 122°F (0°C to 50°C)

ENVIRONMENTAL

Storage temperature -4°C to 122°C (-20°C to 50°C)

Operating relative humidity 90% max. (non-condensing)

Other manuals for LABSTAMP

1

Table of contents

Other Somark Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Nickel-Electro

Nickel-Electro Clifton NE1B Series manual

Tuttnauer

Tuttnauer LABSCI 11L CPVG Operation and maintenance manual

Fast Mover

Fast Mover FMT9000 instruction manual

Thermo Electron

Thermo Electron IEC CL40 Series user manual

Sakura

Sakura Cyto-Tek 2500 Quick reference guide

Biohit

Biohit PROLINE PLUS instruction manual

Thermo Scientific

Thermo Scientific STANDARD Series manual

LABTEC

LABTEC ECO static user manual

Velp Scientifica

Velp Scientifica ECO 16 instruction manual

Atie Medical Industries

Atie Medical Industries PS-140 user manual

Tuttnauer

Tuttnauer LABSCI 11LV ELV Operation and maintenance manual

VWR

VWR Bead Mill MAX quick start guide