Helm PTM LOADGARD Series User manual

1

HELM INSTRUMENT CO., INC.

PTM - LOADGARD

Series

USER MANUAL

Revision 6.5

Jan 24, 2019

i

LIMITED WARRANTY

Helm Instrument Co., Inc. (”HELM”) hereby warrants that the instruments and sensors

(collectively the ”Product”) manufactured by it and sold to customer, are free from defects

in material and/or workmanship under normal use subject to the following conditions. This

warranty shall not apply to any Product which has been subjected to improper installation,

misuse, negligence, accident, alteration, where service has been performed by other than

an authorized Helm serviceman, or where the serial number has been defaced or altered.

This warranty shall extend for the one (1) year period from date of shipment from our

factory or authorized dealer, provided that the product is returned, freight prepaid, to Helm

within the one (1) year warranty period within specific written authorization to perform

repairs. Helm’s obligations and the exclusive remedy of customer under this warranty are

limited to repairing or replacing any defective Product at no additional charge and returning

Product to customer freight paid. Repair parts and replacement Products shall be

furnished on an exchange basis and shall be either new or reconditioned. All replaced

parts and Products shall become the property of Helm.

EXCEPT AS SPECIFICALLY STATED HEREIN, HELM MAKES NO WARRANTIES

EXPRESSED OF IMPLIED, OF THIS PRODUCT INCLUDING BUT NO LIMITED TO

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

OR AS TO THE QUALITY, UTILITY OR PERFORMANCE, ALL QF WHICH ARE

HEREBY EXPRESSLY EXCLUDED. IN NO EVENT SHALL THE LIABILITY OF HELM

EXCEED THE PURCHASE PRICE OF THIS PRODUCT. NOR SHALL HELM BE LIABLE

FOR ANY DAMAGES WHATSOEVER, INCLUDING BUT NOT LIMITED TO SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL CHARGES, EXPENSE OR DAMAGES,

ARISING OUT OF THE USE OR INABILITY TO USE THIS PRODUCT OR FOR ANY

CLAIM BY ANY OTHER PARTY.

Should you have any questions concerning this Warranty, you may contact Helm by

writing or calling:

HELM INSTRUMENT COMPANY, INC.

CUSTOMER SERVICE

361 WEST DUSSEL DRIVE

MAUMEE, OHIO 43537

(419) 893-4356

PTM LOADGARD Series Operators Manual

ii

EXPLANATION OF SYMBOLS

~ Alternating Current

Earth (ground) TERMINAL

On (Supply)

Off (Supply)

Caution, risk of electric shock

Caution (refer to accompanying documents)

1

EXPLANATION OF SYMBOLS ................................................................................................................................. ii

Introduction................................................................................................................................................................. 5

ABOUT PTM LOADGARD SERIES ........................................................................................................................... 5

Benefit ........................................................................................................................................................................ 5

PTM (Peak Tonnage Module) .................................................................................................................................... 5

Main Features ............................................................................................................................................................ 6

OPERATING MODES ................................................................................................................................... 6

LOOK WINDOW TIME (ms) - Only applicable to none Resolver Model ..................................................... 6

SAMPLING (also referred to as “Learning” or “Trending” cycles) ................................................................ 6

ALARMS ....................................................................................................................................................... 6

Other Features ........................................................................................................................................................... 7

TOUCH SCREEN INTERFACE ................................................................................................................................. 8

MAIN MENU ............................................................................................................................................................... 8

PRESS MONITOR ..................................................................................................................................................... 9

Tonnage Display Screen ............................................................................................................................................ 9

MAIN PEAK LOAD SCREEN FOR VARIATY PTM MODELS ...................................................................... 9

CURRENT JOB DISPLAY .......................................................................................................................... 12

ALARM INDICATOR & HISTORY .............................................................................................................. 12

ALARM HISTORY ....................................................................................................................................... 12

TOTAL PEAK DISAPLY FOR FRAME ....................................................................................................... 12

PEAK TONNAGE DISPLAY FOR FRAME (Ch1 – 4) ................................................................................. 12

TREND LED ................................................................................................................................................ 13

ALARM INDICATOR LED FOR FRAME CHANNEL .................................................................................. 13

PEAK DISPLAY FOR IN-DIE & ALARM INDICATOR (In-Die Screen Only) .............................................. 13

VIEWING CURRENT ALARM SETTINGS (In-Die Screen Only) ............................................................... 14

ALARM RESET ........................................................................................................................................... 14

ALARM SETUP ........................................................................................................................................... 14

OPERATING MODE ................................................................................................................................... 14

COPYING SAMPLE TO TARGET .............................................................................................................. 15

VIEW PEAK HISTORY ............................................................................................................................... 15

Peak History & SPC(Statistical Process Control) Charts ......................................................................................... 16

ZOOMED MODE ......................................................................................................................................... 16

CHANNEL SELECT BUTTONS .................................................................................................................. 16

CONFIG ...................................................................................................................................................... 16

CHANGE GRAPH RESOLUTION .............................................................................................................. 17

SCROLL ...................................................................................................................................................... 17

UNZOOM .................................................................................................................................................... 17

GRID ........................................................................................................................................................... 17

BOLD........................................................................................................................................................... 17

LEGEND ..................................................................................................................................................... 17

SPC ............................................................................................................................................................. 17

Current Alarm Setting ............................................................................................................................................... 18

Group Select ............................................................................................................................................... 19

HIGH CAPACITY ........................................................................................................................................ 19

LOW CAPACITY ......................................................................................................................................... 19

TARGET ...................................................................................................................................................... 19

+ TOL .......................................................................................................................................................... 19

- TOL ........................................................................................................................................................... 19

EXPAND FACTOR ...................................................................................................................................... 19

DELTA TRACK EX (no longer applicable) .................................................................................................. 20

LEARNING CYCLE ..................................................................................................................................... 20

ADAPTIVE LEARNING ENABLE/DISABLE ............................................................................................... 21

PTM LOADGARD Series Operators Manual

2

ALARM WINDOW (Degreee or ms) ............................................................................................................ 21

(LOOK) WINDOW TIME (ms) - Only applicable to some of none Resolver Model .................................... 22

ENABLING EDIT ......................................................................................................................................... 22

DOWNLOAD ............................................................................................................................................... 22

JOB RECIPE ............................................................................................................................................... 23

SAVING TO RECIPE DATABASE .............................................................................................................. 23

MAIN MENU ................................................................................................................................................ 23

Press Curve Alarm ................................................................................................................................................... 24

PTM Loadgard Press Curve Setup Procedure ........................................................................................................ 24

JOB ............................................................................................................................................................. 26

PEAK ........................................................................................................................................................... 26

HIGH CAP ................................................................................................................................................... 26

LOW CAP .................................................................................................................................................... 26

TARGET ...................................................................................................................................................... 26

SAMPLE ...................................................................................................................................................... 26

HIGH TOL ................................................................................................................................................... 26

LOW TOL .................................................................................................................................................... 26

WAVE VIEWING WINDOW ........................................................................................................................ 27

READ TONNAGE AT ANGLE .................................................................................................................... 28

ZOOM IN ..................................................................................................................................................... 29

RESET ZOOM ............................................................................................................................................ 29

TREND TYPE ............................................................................................................................................. 29

TREND ........................................................................................................................................................ 29

GRID ........................................................................................................................................................... 30

BOLD........................................................................................................................................................... 30

LEGEND ..................................................................................................................................................... 30

CHANNEL SELECT .................................................................................................................................... 30

OVERLAY ................................................................................................................................................... 30

Overlay Screens ....................................................................................................................................................... 30

SIGNATURE OVERLAY SCREEN ............................................................................................................. 31

SIGNATURE OVERLAY SCREEN ............................................................................................................. 31

PEAK BARS SCREEN ................................................................................................................................ 31

RECIPE MANAGER ................................................................................................................................................. 32

Recipe Main Screen ................................................................................................................................................. 32

JOB SUMMARY DISPLAY.......................................................................................................................... 32

NAVIGATION BAR ...................................................................................................................................... 32

EDIT ON ...................................................................................................................................................... 32

REMOVE ..................................................................................................................................................... 33

EDIT ............................................................................................................................................................ 33

ADD ............................................................................................................................................................. 33

COPY .......................................................................................................................................................... 33

DOWNLOAD ............................................................................................................................................... 33

MAIN MENU ................................................................................................................................................ 33

Job Setup Screen ..................................................................................................................................................... 34

JOB NAME .................................................................................................................................................. 34

HIGH CAPACITY ........................................................................................................................................ 34

LOW CAPACITY ......................................................................................................................................... 34

TARGET ...................................................................................................................................................... 34

+ TOL .......................................................................................................................................................... 35

- TOL ........................................................................................................................................................... 35

EXPAND FACTOR ...................................................................................................................................... 35

LEARNING CYCLE ..................................................................................................................................... 35

ADAPTIVE LEARNING ENABLE/DISABLE ............................................................................................... 35

ALARM WINDOW (ms) ............................................................................................................................... 36

(LOOK) WINDOW TIME (ms) - Only applicable to none Resolver Model .................................................. 36

PTM LOADGARD Series Operators Manual

3

PASTE......................................................................................................................................................... 36

CANCEL ...................................................................................................................................................... 36

SAVE ........................................................................................................................................................... 36

PASSWORD CHANGE ............................................................................................................................................ 37

MASTER PASSWORD ............................................................................................................................... 37

ADMINISTRATOR PASSWORD ................................................................................................................ 37

OPERATOR PASSWORD .......................................................................................................................... 37

INITIAL PASSWORD .................................................................................................................................. 37

ADTSERVER SETUP SCREEN .............................................................................................................................. 38

Monitor Screen ......................................................................................................................................................... 38

OPERATING STATUS INDICATOR ........................................................................................................... 38

OPERATING MODE INDICATOR .............................................................................................................. 38

Sensor Calibration Screen ....................................................................................................................................... 39

System Setup Screen .............................................................................................................................................. 40

WINDOW TIME (ms) - Only applicable to none Resolver Model ............................................................... 40

PEAK WINDOW (Enable/Disable) - Only applicable to none Resolver Model ........................................... 40

SCALE SET ................................................................................................................................................ 40

TREND ALARM .......................................................................................................................................... 40

System Setup Screen for PTM-5600P/6700P ............................................................................................ 41

SCALE SET ................................................................................................................................................ 41

System Setup Screen for PTM-4500TSM/6700TSM/6700i-TSM ............................................................................ 42

TREND WARNING OUTPUT LEVEL ......................................................................................................... 42

SAVE ........................................................................................................................................................... 42

CANCEL ...................................................................................................................................................... 42

LOOK WINDOWS ....................................................................................................................................... 42

PTM LOADGARD ADC SETUP for TSM model .................................................................................................... 43

•

Go To ADC Manager .......................................................................................................................... 43

•

ADC Manager Setup ........................................................................................................................... 43

•

ADC RS232 CABLE CONNECTION .................................................................................................. 45

GETTING READY FOR CALIBRATION .................................................................................................................. 46

SYSTEM SPECIFICATIONS ................................................................................................................................... 49

BYPASS & REMOTE ALARM RESET .................................................................................................................... 50

OPTION FOR PTM-4500TSM Model ...................................................................................................................... 50

To Enable the BYPASS OPTION ............................................................................................................................ 50

APPENDIX A ( PTM-4500L2 ) - 4Ch Frame with 2 Linear Transducer ................................................................. 53

APPENDIX B ( PTM-2300L ) – 2Ch Frame/Indie with 1 Linear Transducer Input ................................................ 54

APPENDIX C ( PTM-6700i ) – 6Ch In-Die Applcation ........................................................................................... 55

APPENDIX D ( PTM-5600F ) – 3Ch In-die + 2Ch Frame application .................................................................... 56

APPENDIX E ( PTM-6700TSM ) 4Ch Frame + 2Ch Indea with Resolver Input ................................................... 57

APPENDIX F ( PTM-4400i ) 4Ch In-die application ............................................................................................... 58

APPENDIX G ( PTM-4500TSM )- 4Ch Frame with Resolver Input ...................................................................... 59

PTM LOADGARD Series Operators Manual

4

APPENDIX H ( PTM-4500TSM-ASA )- 4Ch Frame + Auto Shutheight Adjust w/ Resolver Input ........................ 60

APPENDIX I ( PTM-5600P) - 5Ch Piezo Sensor Input .......................................................................................... 61

APPENDIX J ( PTM-4500) - 4Ch Frame with CAM input ...................................................................................... 62

APPENDIX K ( PTM-4500-ADC) - 4Ch Frame with Automatic Die Change Option .............................................. 63

APPENDIX L LINE SUPERVISOR WITH RLG CONENCTION ........................................................................... 64

APPENDIX M ( PTM-6100-SS) - 4Ch Frame, 1Ch In-Die, 1Ch Laser Sensor ....................................................... 65

APPENDIX N ( PTM-6700i-TSM) - 6Ch In-Die With Trend Warning Output .......................................................... 66

APPENDIX O PTM LOADGARD DIMEMSION (Standard Mount) ......................................................................... 67

APPENDIX P PTM LOADGARD DIMEMSION (FLANGE MOUNT)....................................................................... 68

APPENDIX P-1 PTM LOADGARD PANEL PC CONNECTIONS LAYOUT ........................................................... 69

APPENDIX Q (PTM-884TSM-SS) 4Ch Frame, 4Ch In-Die Sensors...................................................................... 70

APPENDIX R (PTM-844TSM-SS) Connection Drawing ......................................................................................... 71

APPENDIX R (PTM-844TSM-SS) Connection Drawing ......................................................................................... 71

APPENDIX S (PTM-1248TSM-SS) 4Ch Frame, 8Ch In-Die Sensors .................................................................... 72

APPENDIX S (PTM-1248TSM-SS) 4Ch Frame, 8Ch In-Die Sensors .................................................................... 72

APPENDIX T (PTM-1248TSM-SS) Connection Drawing ....................................................................................... 73

APPENDIX U RLG Line Supervisor Connection .................................................................................................... 74

APPENDIX V PTM-102L Connections .................................................................................................................... 75

APPENDIX W PTM-4500TSM New I/O Board Connections .................................................................................. 76

APPENDIX X PTM-6600TSM for Doule Action Connections ................................................................................ 77

APPENDIX Y PTM-8800TSM for Doule Action Connections ................................................................................. 78

APPENDIX Z PTM-2300D-TSM with Diverter Output ............................................................................................ 79

APPENDIX A1 PRofinet Add-On Kit Connection .................................................................................................... 80

APPENDIX B1 PTM-2300-TSM-RD (Remote Display) ......................................................................................... 82

APPENDIX C1 PTM-2100-SS Laser Sensor Input with Cutter Control ................................................................ 83

PTM LOADGARD Series Operators Manual

5

INTRODUCTION

HELM INSTRUMENT CO., INC. manufactures a complete line of load monitoring control systems

for use on metal stamping, forging, compaction and assembly presses; cold forming, cold heading,

injection molding and die cast machines. Standard or custom transducers and load cells are

available for in-die monitoring and transfer or progressive tooling. At HELM, quality is inherent not

only in the design of our products but in the attitudes of our employees as well. We're working

together to give you the best. After all, that's what our business is all about - providing innovative

instrumentation to help make your manufacturing process more productive and your operation

more effective.

ABOUT PTM LOADGARD SERIES

PTM LOADGARD series is one of the most advanced load monitoring systems Helm can offer.

Sophisticated features such as smart sampling, adaptive learning, SPC(Statistical Process Control)

Charts, etc. help monitoring the operation of your machine and protect them from faulty operation.

BENEFIT

• Press Protection – protect press components, including dies, from costly damage

• Parts Quality Control – ensure parts are being made (stamped) as specified

Variations in the mechanical press and the part making process have the costly potential of press

damage, waste of material, and downtime. The PTM LOADGARD uses force monitoring for both

press protection and parts quality control. If an excessive force that could potentially damage the

press machine or a variation in force occurs during the part making process are detected, the PTM

LOADGARD triggers an “alarm” and stops the press. This allows the press operator to correct the

potential problem ahead.

PTM (PEAK TONNAGE MODULE)

• PTM is a single channel strain gage sensor input module to process the signal of the strain

gage to analog output.

• PTM provides Auto-Zero® feature (patented by Helm Instrument Co., Inc.). The Auto-Zero®

feature automatically keeps the zero balance of the load signal between every load cycles to

compensate the tonnage variation affected by any environmental conditions changes such as

temperature.

PTM LOADGARD Series Operators Manual

6

MAIN FEATURES

OPERATING MODES

PTM LOADGARD Series has three function modes controlled by an operator.

• Setup Mode – Used for system setup, Job setup or new job download.

Capacity alarms are active. Trend Alarms are active if the Trend Alarm in

Setup option is enabled from Server Setup screen. Target value is used

for monitoring the Trend alarm conditions as a reference point.

• Learn Mode – Learns new sample value.

Capacity alarms are active. Trend alarms are active if the Trend Alarm in

Setup option is enabled from Server Setup screen. Target value is used

for monitoring the Trend alarm conditions as a reference point.

• Monitor Mode – Adaptive learning can be active in this mode.

Capacity alarms are active. Trend alarms are active. Sample value is

used for monitoring the Trend alarm conditions as a reference point.

LOOK WINDOW TIME (ms) - Only applicable to none Resolver Model

PTM LOADGARD monitors tonnages between the “critical” time of the press stroke called the look

window. 224 points (tonnage readings) per channel are recorded during the look window time from

the look window start trigger point. These points are displayed as a “wave” or “signature” in the

Signature Analysis screen.

SAMPLING (also referred to as “Learning” or “Trending” cycles)

Samples for pre-determined number of press strokes, defined as sample counts in Alarm Setup

screen.

When the sampling is completed, PTM LOADGARD takes an average peak tonnage and / or

tonnage signature per channel (while sampling), and stores as a Sample peak value and/or Sample

Signature per channel and uses it as a reference point for Trend / Tracking Alarm conditions.

• Sample – Sample is the value learned automatically from Learn mode or Monitor mode by

adaptive learn feature. The Sample value is used to calculate the Trend and Tracking

Alarm condition in Monitor mode.

• Target – When you create a new job, Target values need to be entered manually. These

values can be copied from the Sample values when Leaning process is completed for the

job. The Target can be used during Setup or Learn mode to monitor the Trend Alarm

conditions before new Sample values are available or just can be used as visual reference

for each Job.

ALARMS

In normal operation, the Alarm relay is closed for fail safe. When the tonnage alarm(s) condition

is detected, the system opens the TOP STOP relay

• High/Low Capacity – Normally set at machine capacity. This provides the protection for

the Machine. This alarm is active in all modes.

• High/Low Trend – creates high and low tolerance for peak load based on Target or

Sample tonnage. The tolerance values are the allowable tonnage deviation above and

below Sample or Target tonnage. This provides the means to maintain the quality of the

part making. Trend alarms are available in all modes. There is an option to disable the

Trend alarm during Setup or Learn mode.

PTM LOADGARD Series Operators Manual

7

• High/Low Tacking – creates high and low tolerance bands around the sample tonnage

signature for monitoring the alarm condition through out the stroke. Tracking alarm is only

available in Monitor mode

• Press Curve (only available for Resolver based model) – Since a press may have

different force capacities at different angles, the press manufacture may provide a

“through the stroke press-curve and motion curve” set of data points. This alarm is valid

in both setup and Monitor mode.

OTHER FEATURES

• Signature Analysis – Displays the forming force signature for each channel. You can

zoom, read the tonnage value at angle, overlay multiple channels, view multiple peak

tonnage value in bar graph, and more to help you analyzing the force signature.

• Alarm History – You can view last 500 alarm messages with time stamped.

• Peaks History – You can view a peak tonnage history graph of last 10000 strokes.

• SPC (Statistical Process Control) – You can view statistical charts of peak tonnage

variation from selected peak history. Avail SPC charts are Individual & Moving Range,

*Average & Range, *Median & Range, *Average & Std. Deviation, and Histogram

• Jobs Recipe – You create alarm settings per job base and store to Job Recipe for later

quick download to setup the system.

• Adaptive learning – While the system is in Monitor mode, you can enable an Adaptive

Learning option to continuously learn new sample tonnage while monitoring. This will allow

the system to adapt any small gradual variances of the tonnage through time when requires

• Multi-Level Password Protection – you can restrict certain functions or screens of the

system from being accessed by unauthorized personnel or prevent from unauthorized

changes of the system settings. Different level of passwords gives more secure and

effective protection for the system.

PTM LOADGARD Series Operators Manual

8

TOUCH SCREEN INTERFACE

MAIN MENU

Main menu allows you to access different area of the system. The PTM LOADGARD™

features a touch screen display for easy navigation and operation of the system. Click or

touch on the button you wish to access.

PRESS MONITOR – This is where you can monitor the peak tonnage values, tonnage

signatures, change Alarms setting, view Alarm Messages, SPC and more.

RECIPE MANAGER – You can create a new job, edit or delete existing jobs, and download a

job settings to the system.

PASSWORD EDIT – set or change the passwords.

ADTSERVER – helps to diagnose the system status for the trouble shooting purposes. Initial

and system setup is done here.

SHUTDOWN – prepares the system to be powered down safely. This is protected by

operator password. Use “4356123” as password to exit out to Windows Desktop screen

without shutting down the system.

Warning: We recommend to use SHUTDOWN button before powering down the system.

Improper shutting down of the system may cause an abnormal system operation.

PTM LOADGARD Series Operators Manual

9

PRESS MONITOR

TONNAGE DISPLAY SCREEN

PRESS MONITOR provides the screens to view peak tonnage load, Tonnage signatures, ,peak

tonnage history, and SPC charts, You can change Alarm settings and view Alarm Messages as

well.

MAIN PEAK LOAD SCREEN FOR VARIATY PTM MODELS

This screen displays peak tonnage values, alarm settings, and alarm indicators for all channels.

Alarm Setting

Display

Trend LED

Alarm Indicators

LEDs

Peak Tonnage per Channel

Alarm Indicator & Alarm History

Total Peak Display

Main Tonnage screen from PTM-6700TSM

Main Tonnage screen from PTM-4500TSM

Display Select

Switches

PTM LOADGARD Series Operators Manual

10

Main Tonnage screen from PTM-4500L2

Main Tonnage screen from PTM-5600P

Main Tonnage screen from PTM-2300PG

Main Tonnage screen from PTM-6100A-SS

PTM LOADGARD Series Operators Manual

11

Main Tonnage screen from PTM-6600TSM-DA

Main Tonnage screen from PTM-8800TSM-DA

FOR DOUBLE ACTION PRESS MACHINES

PTM LOADGARD Series Operators Manual

12

CURRENT JOB DISPLAY

ALARM INDICATOR & HISTORY

ALARM HISTORY

Click on ALARM WARNING DISPLAY button to view ALARM HISTORY.

TOTAL PEAK DISAPLY FOR FRAME

PEAK TONNAGE DISPLAY FOR FRAME (Ch1 – 4)

This peak display shows the peak tonnage load of each channel within the look window from each

cycle of the press.

Shows current Job name. Job name can be edited from

RECIPE MANAGER screen

This ALARM INDICATOR button has two functions, It indicates

any alarms tonnage condition and lets you view alarm history.

When the machine is running within normal parameter, the

message on the button shows ALARM HISTORY. The message

ALARM with red color background indicates there is an alarm

condition(s). In this case, it will flash the message “Click Here for

Detail”. To view the detail message of the alarm, click on the

display to open ALARM HISTORY screen. You can click on this

display to view previous alarm messages at anytime.

You can view up to last 500 alarm

messages that have date and time

stamp. Use the scroll bar on the

right side of the list box or arrow

buttons on the bottom to scroll up

and down the history list. Use

Clear button to empty all

messages.

Note: you need administrator or

higher level of password to clear

the alarm history.

TOTAL displays the summation of the four corner peak tonnages .

This value is the actual peak tonnage load that the press is taking in each

cycle.

PTM LOADGARD Series Operators Manual

13

TREND LED

ALARM INDICATOR LED FOR FRAME CHANNEL

H TND (HIGH TREND ALARM)

When the peak tonnage of an individual channel reaches the high limit of the setting for Trend

Alarm, the black rectangle next to the description will turn red to indicate that a High Trend alarm

is triggered. Refer to ALARM SETUP SCREEN for details.

L TND (LOW TREND ALARM)

When the peak tonnage of an individual channel reaches the low limit of the setting for Trend

Alarm, the black rectangle next to the description will turn red to indicate that a Low Trend alarm

is triggered. Refer to ALARM SETUP SCREEN for details.

L CAP (LOW CAPACITY ALARM)

When the peak tonnage of an individual channel reaches the low limit of the setting for Capacity

alarm, the black rectangle next to the description will turn red to indicate that a Low Capacity alarm

is triggered. Refer to ALARM SETUP SCREEN for details.

PEAK DISPLAY FOR IN-DIE & ALARM INDICATOR (In-Die Screen Only)

When alarm(s) occurred, ALARM INDICATOR LED displays the cause of the

alarm.

H CAP (HIGH CAPACITY ALARM)

When the peak tonnage of an individual channel reaches the high limit of the

setting for Capacity alarm, the black rectangle next to the description will turn

red to indicate that High Capacity alarm is triggered. Refer to ALARM SETUP

SCREEN for details.

The vertical bar meter next to the peak display box is a Trend Display bar. It shows

the visual reference of a peak tonnage variation comparing to TARGET or

SAMPLE tonnage for Trend Alarm. The center green light indicates 0% variance

within the tolerance of the Trend Alarm. The green light, one above the center,

indicates 25% variance. Toward to the red light on the top, the yellow light shows

50% and 75%. Once the tonnage reaches 100% of the tolerance or beyond, all the

bars from the center to top light up and it indicates the High Trend Alarm condition.

This applies to Low Trend Alarm as well. Only difference is the negative

percentage (-25%, -50%, -75% and –100%) and opposite instead.

Gag Tool Input Indicator

Trend LED

High Capacity

Alarm Indicator

High Trend Alarm

Indicator

Low Trend Alarm

Indicator

Low Capacity

Alarm Indicator

Peak Display

PTM LOADGARD Series Operators Manual

14

VIEWING CURRENT ALARM SETTINGS (In-Die Screen Only)

ALARM RESET

ALARM SETUP

OPERATING MODE

Setup Mode – Used for system setup, Job setup or job download.

Capacity alarms and Press Curve alarm are available. Trend alarm is only available if enabled. The

tolerance band for Trend alarm is calculated by Target value + ( ±TOL x Expand Factor ) instead

Once the Alarm output relay is disengaged by an alarm condition(s), click on the

RESET button to clear all alarm indication and alarm relay output.

Operating mode can be switched by clicking one of the

CURRENT MODE buttons. While in LEARN mode, the

mode always changes to MONITOR mode

automatically after LEARN cycle is completed.

Click on one of the buttons to view current alarm setting values. The values will be

displayed in the Peak tonnage display boxes for 20 seconds and change back to

PEAK automatically.

The TOTAL PEAK display box shows the viewing mode currently selected.

PEAK Current peak tonnage value.

TARGET (TARG) Target tonnage value.

SAMPLE (SAMP) Sample tonnage value.

HIGH CAP (HCAP) High Capacity tonnage limit

+TOL (+TOL) High tolerance tonnage limit above the Sample or Target

value.

-TOL (-TOL) Low tolerance tonnage limit below Sample or Target

value

LOW CAP (LOW) Low capacity tonnage limit

EFACTOR (EFAC) Expanded Factor which is tolerance multiplier to

increase the tolerance band in Setup & Learn Mode

Click on ALARM SETUP button to bring up CURRENT ALARM SETTING screen

where you can set or change the current alarm settings and download the new

settings to the system to take effect. You can also stores any change you made in

this screen to Recipe database easily. Refer to CURRENT ALARM SETTING for

details.

PTM LOADGARD Series Operators Manual

15

of sample in Setup mode if enabled. You can enable or disable the Target Trend Alarm in Setup

mode from the ADT Server System Setup screen.

Learn Mode – In LEARN mode, system averages the peak values for each channel during the

predefined learning cycle. Once the learning cycle is completed, each average tonnage value is

stored as sample tonnage for each channel and the mode automatically switches to Monitor mode.

Capacity alarms and Press Curve are available. Trend alarm is only available during Learn mode

if enabled. The tolerance band for Trend alarms is calculated by Target value + ( ±TOL x Expand

Factor ). You can enable or disable the Target Trend Alarm from ADTServer System Setup screen.

Note: you can define the number of Learn Cycle and store it as a part of job recipe item in Job

Setup screen.

Monitor Mode – In Monitor mode, you have the option to enable or disable the Adaptive Learning

feature which is part of job recipe item. When the Adaptive Learning is active, the system

continuously re-learns sample values while monitoring for any alarm condition. You can change

the number of Adaptive Learning cycle by changing the Learning Cycle from Alarm Setup screen.

ADPT ON/OFF - This indicates whether Adaptive Learning feature is turned on or off.

Once the Adaptive Learn is active, you should see that the green LED on the mode select button

flashes.

COPYING SAMPLE TO TARGET

VIEW PEAK HISTORY

Use COPY button to replace the TARGET value with the SAMPLE value. It is

useful when you have to arbitrary set the Target value for a new job for the first

time. After the Learning procedure is completed for a new job, click on the COPY

button to update the Target values with the Sample values. When making a copy,

it prompts with a message to give you the option to update the new TARGET

values to the Recipe database for a current job.

Click this button to open PEAK TONNAGE HISTORY screen where you can view

a recorded peak tonnage graph up to previous 1000 hits in one screen. Also, you

can select the range of the peak history to display SPC (Statistical Processor

Control) charts. Refer PEAK HISTORY & SPC for details.

PTM LOADGARD Series Operators Manual

16

PEAK HISTORY & SPC(STATISTICAL PROCESS CONTROL) CHARTS

The Peak history records up to 40,000 previous peak values and archives up to last 50

data files, totaling stores last 2,000,000 stokes of peak data.

ZOOMED MODE

This indicates that the current history graph has been zoomed. To zoom the graph, point to the

area on the screen where you want to start zooming and drag the point down right to create a zoom

rectangle. Once the inside of the zoom rectangle covers the area where you want to zoom in,

release the point from the screen. You can repeat this to continue zooming within the area.

CHANNEL SELECT BUTTONS

Toggle the buttons to add or remove the peak graph of the channel from the history graph.

CONFIG

Channel Select

Buttons

Zoom Mode

Indicator

You can define how often the peak values need to be recorded into the

peak history. Set the Update Frequency value and click Save to take

effect the new setting.

PTM LOADGARD Series Operators Manual

17

CHANGE GRAPH RESOLUTION

SCROLL

UNZOOM

GRID

BOLD

LEGEND

SPC

Click this toggle button to make the width of the peak graph line bold.

Click this button to show or hide the legend of the graphs displayed on the screen.

Click this button to reset the zoomed graph and return to original size.

You can change the number of viewable peak points on a graph by

choosing one of the options

100pt – to display 100 peak points at a time

500pt – to display 500 peak points at a time

1000pt – to display 1000 peak points at a time

Click this button to show or hide vertical and horizontal grid lines on Peak Graph

screen.

These buttons let you scroll left or right to view rest of the peak points outside

the graph. Click left arrow button to scroll left, right arrow button to scroll right.

Click this button to generate SPC charts within the peak data displayed on the history

graph. Use Zoom or Scroll to select the range of the peak history to generate SPC chart

you want to see.

If more than one channel is displayed in the history graph, SPC averages them to

generate the charts.

This manual suits for next models

21

Table of contents

Other Helm Control System manuals

Popular Control System manuals by other brands

Techsys

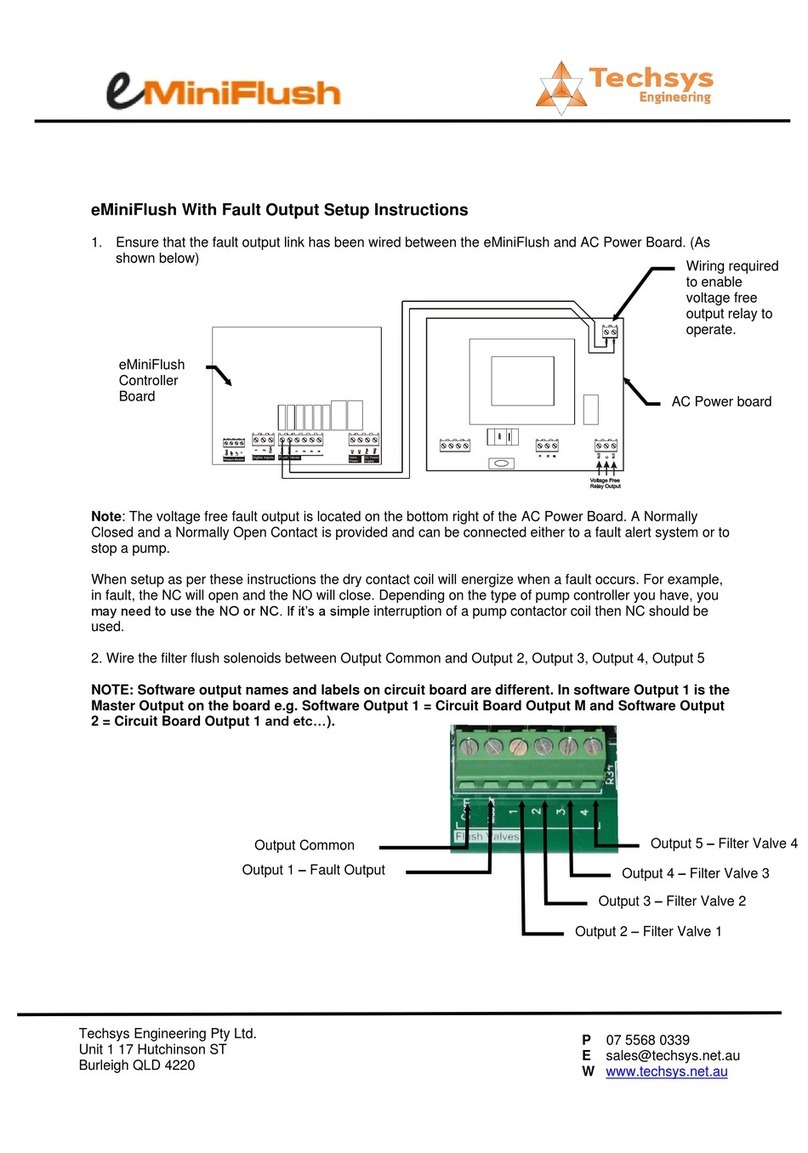

Techsys eMiniFlush Setup instructions

Balboa Water Group

Balboa Water Group BP600 Troubleshooting & Service Manual

SecureSpot

SecureSpot STATEMENT Installation & user guide

Rain Bird

Rain Bird ESPLXD-ET Installation, programming & operation guide

Inovance

Inovance NICE9000-V Series user guide

LEGRAND

LEGRAND Pass & Seymour Harmony De-Hummer installation instructions