Henkel LOCTITE EQ VA20 User manual

1

EQ VA20 Volumetric Valve

2084141

Operating Manual

2

Table of Contents

1Please Observe The Following ............................................................................................. 3

1.1Emphasized Sections ..................................................................................................... 3

1.2For Your Safety .............................................................................................................. 3

1.3Unpacking and Inspection .............................................................................................. 4

1.4Items supplied ................................................................................................................ 4

1.5Features ......................................................................................................................... 4

1.6Usage ............................................................................................................................. 4

2Description ............................................................................................................................ 5

3Specifications ........................................................................................................................ 5

4Installation ............................................................................................................................. 6

5Operation .............................................................................................................................. 7

6Application Hints ................................................................................................................... 7

7Troubleshooting .................................................................................................................... 8

8Care and Maintenance .......................................................................................................... 9

9Accessories and Spare Parts .............................................................................................. 11

10Diagrams ............................................................................................................................. 12

11Warranty .............................................................................................................................. 1 5

3

1 Please Observe The Following

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that protect the operator or

other persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not

damaged.

Notice:

A notice gives recommendations for better handling of the unit during operation or

adjustment as well as for service activities.

1.2 For Your Safety

For safe and successful operation of the unit, read these instructions completely. If

the instructions are not observed, the manufacturer can assume no responsibility.

Do not expose the connecting plastic lines to heat, oil, or sharp edges.

Make sure the Unit stands stable and secure.

Use only original equipment replacement parts.

Always disconnect the power supply before servicing the unit.

Always disconnect the pneumatic supply before servicing the unit.

Observe general safety regulations for the handling of chemicals such as Loctite®

adhesives and sealants. Observe the manufacturer’s instructions as stated in the Safety

Data Sheet.

While under warranty, the unit may be repaired only by an authorized Loctite

service representative.

4

1.3 Unpacking and Inspection

Carefully unpack the Loctite® EQ VA20 Volumetric Valve and examine the items

contained in the carton. Inspect the unit for any damage that might have occurred in

transit. If such damage has occurred, notify the carrier immediately. Claims for damage

must be made by the consignee to the carrier and should be reported to the

manufacturer.

1.4 Items supplied

Loctite EQ VA20 Volumetric Valve 2084141

Equipment Manual

PTFE lined tubing, 6.4mm OD, 2 meters long

Air Line 4mm OD, blue, 2 meters

Air Line 4mm OD, yellow, 2 meters

Needle Sample Kit

1.5 Features

Volumetric displacement

Dosing range, 1.5 – 12 microliters

Cycle rate, 180/minute

Patent Pending priming system

Innovative Rod and Seal design

Slim design

Fluid inlet fitting – barbed stainless steel

Field Repairable

1.6 Usage

The Loctite EQ VA20 Volumetric Valve is a positive displacement metering valve

which dispenses a precise drop of adhesive with each cycle. Positive

displacement is not influenced by variations in pressure, time, temperature or

adhesive viscosity therefore making it a better choice for drop applications. The

Loctite EQ VA20 Volumetric Valve is specifically design to dispense low to

medium viscosity Loctite Light Cure Adhesives.

5

2 Description

The Loctite® EQ VA20 Volumetric Valve is a positive displacement metering valve which

dispenses a precise volumetric drop of adhesive with each cycle. The EQ VA20 is

designed with a flooded chamber and a single check valve that allows for quick priming

and minimizes the need for re-priming. The priming system utilizes a patent pending

check valve design which improves the speed and reliability of priming. The innovative

displacement rod and seal of the VA20 design provide long dispensing life before rebuild

is needed. The Loctite® EQ VA20 is specifically design to dispense drops of Loctite

Light Cure Adhesives with precise dosing in the range of 1.5 to 12 microliters.

The Loctite® EQ VA20 Volumetric Valve has a diameter of 19mm [0.748”] and an overall

length of 15.3 cm [6.0”]. This compact dispense valve is stackable at 19mm centers.

The fluid body is made of 316 stainless steel and the actuator is anodized aluminum.

The actuator is a double acting cylinder with a hardened rod and a Delrin® piston for

long life. The Loctite® EQ VA20 Volumetric Valve is capable of dispense rates up to 3

cycles a second.

3 Specifications

Dimensions (L x OD) 15.3 cm [6.0”] long X 19 mm [0.748”] OD

Total weight: lbs. (Kg) 0.13Kg

Viscosity Range: 1 to 10000cP

Operating Air Pressure: 4 to 7 bar [60 -100 Psi]

Operating Product Pressure: 2 to 5 bar [30 to 70 Psi]

Wetted Components: 316 Stainless Steel, TiN

Fluid Inlet Thread #10-32

Threaded Hole-Mounting M4 x 0.7mm

6

4 Installation

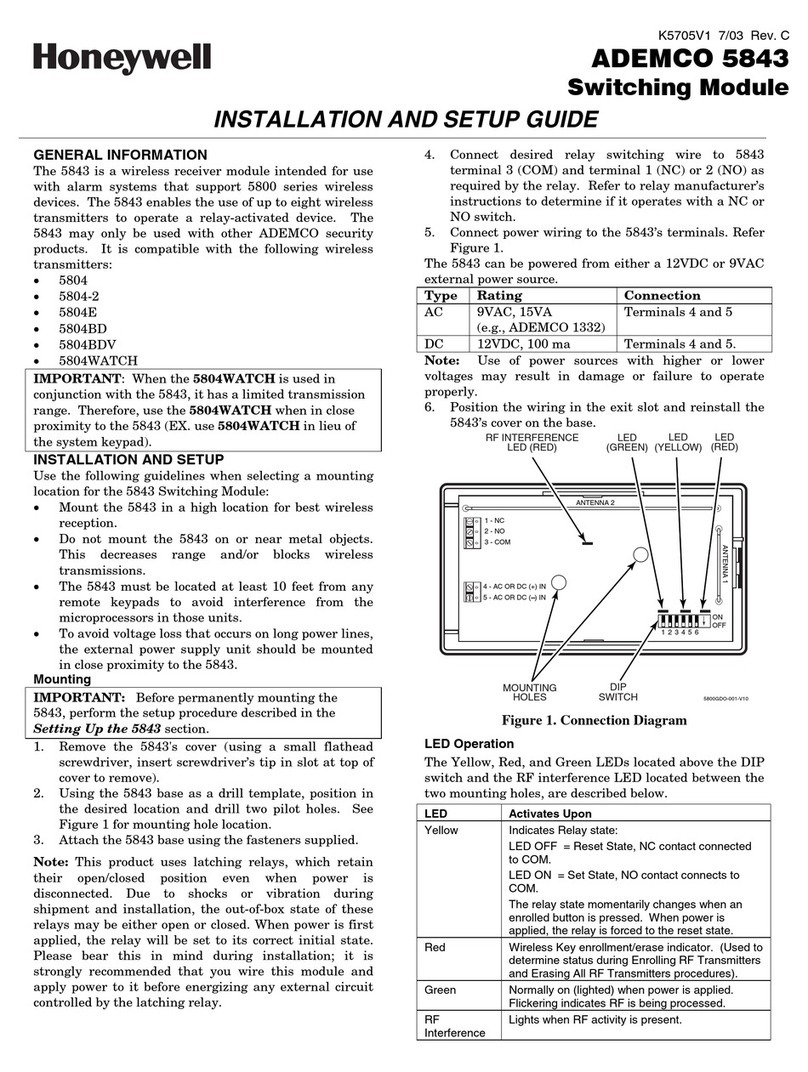

The Loctite® EQ VA20 Volumetric Valve requires a four way pneumatic solenoid valve

to actuate the cylinder section. The pneumatic valve must be operated with clean dry air

at 4 to 7 bars of pressure. The 4-way pneumatic solenoid valve has a normally open port

and a normally closed port. Use the supplied 4 mm OD tubing to connect the air ports to

the EQ VA20 Volumetric Valve.

The adhesive is supplied from a pressure reservoir to the barbed fitting located on the

fluid body of the Loctite® EQ VA20 Volumetric Valve. Use the supplied 6.4 mm OD

tubing, insert the tube over the barbed fitting, than insert the flange locking sleeve over

the tube. Secure the tubing to the reservoir with a compression fitting which allows the

tubing to pass through the fitting into the adhesive container.

Supply clean, dry, regulated air to the reservoir and set the pressure at 2 bar [30 psi].

The reservoir pressure setting is to insure adhesive product will flow into the Loctite EQ

VA20 Volumetric Valve at a rate which allow the EQ VA20 to operate at 180 cycle per

minute.

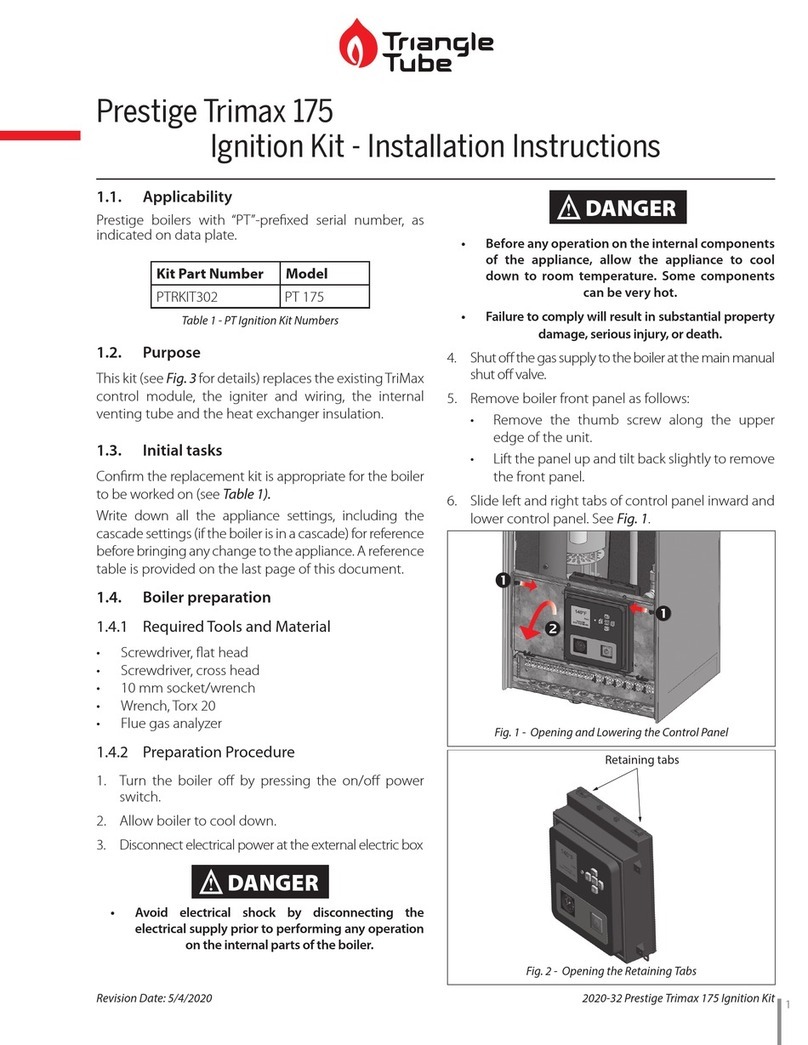

Loctite EQ VA20 Volumetric Valve – Annotated Drawing

7

5 Operation

The Loctite EQ VA20 Volumetric Valve Air is ready to dispense - control lines are

installed, pressure reservoir is loaded with adhesive and a feed line is attached to the

fluid body. The pneumatic pressure to the controller is set at 4 bars and the reservoir

pressure is set at 2 bars. The system is now ready to set- up for drop dispensing:

1. A dispense tip is inserted onto the Luer Check Valve and secured with the Tip Retainer

Nut.

2. The drop size is determined by the length of the stroke which the displacement rod

travels into the displacement chamber. The drop decreases as the stroke is shorten.

The stroke is set by loosening the clamping screws and rotating the stroke adjuster

clockwise to decrease the stroke. The maximum stroke is approximately 9.5 mm [0.374

inch] and the minimum stroke is approximately 1 mm [0.039 inch].

3. To prime the Loctite EQ VA20 Volumetric Valve rotate the Luer Check Valve

counterclockwise 2 1/4 rotations. When a steady flow of adhesive is observed rotate the

Luer Check Valve clockwise and tighten.

4. The Loctite EQ VA20 Volumetric Valve is ready to dispense. Set actuation rate at greater

than or equal to 0.166 seconds.

5. Cycle the Loctite EQ VA20 Volumetric Valve 5 -10 times than measure drop size. Adjust

stroke to suit.

6 Application Hints

The Loctite® EQ VA20 is specifically design to dispense drops of Loctite Light Cure

Adhesive. This adhesive cures in the presents of light. Caution should be used to protect

the dispense tip from ambient light.

8

7 Troubleshooting

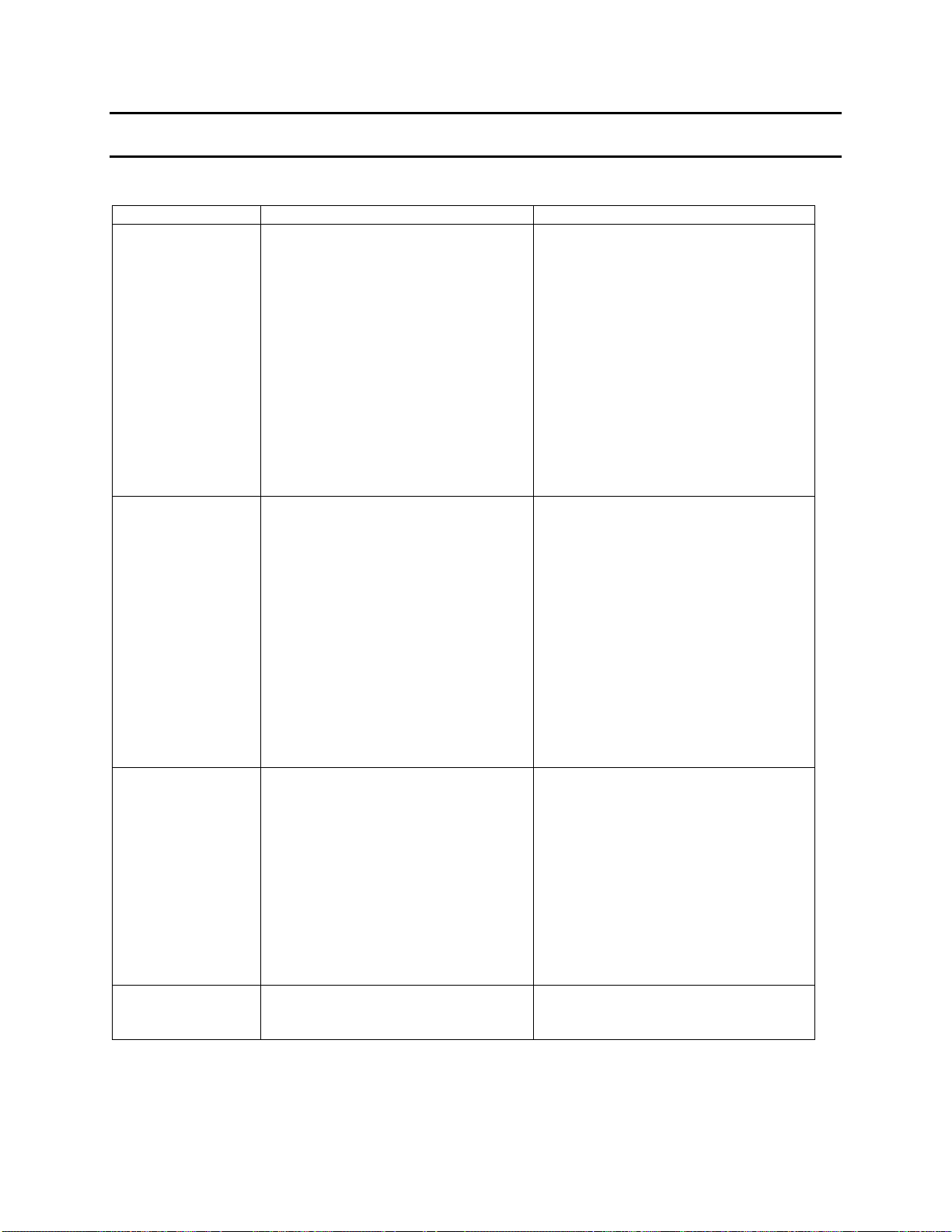

Problem Possible Cause Correction

No liquid flow If pneumatic valve operating

pressure is to low, the valve

will not shift.

The reservoir pressure may

not be high enough

Displacement rod may be in

forward position

The dispense tip may be

clogged.

Increase air pressure to 60

psi (4 bars) minimum

Increase pressure

Insure that the normally open

airport is energized

Replace tip

Fluid drools after

the volumetric

valve is cycled,

eventually

stopping.

This is caused by air coming

from the reservoir into the

fluid body and pumped out

into the lure check valve.

The air will expand after the

check valve closes, causing

product to extrude out the

dispense tip until the air

reaches atmospheric

pressure.

Prime the Loctite EQ VA20

Volumetric Valve by rotating

the Luer Check Valve

counterclockwise 2 1/4

rotations. When a steady flow

of adhesive is observed rotate

the Luer Check Valve

clockwise and tighten.

Liquid drips at a

steady rate after

the valve closes.

A steady drip can be caused

by excessive reservoir

pressure.

The Luer Check Valve is not

closing fully due to particle

build up on the ball and seat.

Check reservoir pressure to

ensure it is not above 70 psi

(4.8 bar)

Remove the luer check valve

body, inspect sealing surfaces

and ball surface. Clean or

replace ball if contaminated

with particulate.

Liquid flows out of

the drain hole

Fluid leaking out of the drain

hole indicates a seal failure.

Replace seal in accordance

with maintenance instructions

9

8 Care and Maintenance

The Loctite EQ VA20 Volumetric Valve is designed to provide continuous dispensing

service without any special maintenance. The Loctite EQ VA20 Volumetric Valve is a

robust design that will delivery over a million cycles with minimal maintenance. Adhesives

and/or small particles may build up on the sealing surfaces within the Luer Check Valve.

Luer Check Valve Disassembly and Surface Cleaning

1. Vent air pressure from product reservoir.

2. Use Equipment Flushing Solvent (item #12121) or Isopropyl Alcohol (IPA) to clean

parts.

3. Remove luer check valve and submerge parts in cleaning solvent.

4. Use a cotton tip applicator and cleaning solvent to clean the Displacement

Chamber surface.

5. Remove luer check valve body, spring and ball seat from cleaning solvent and

insure that parts are clean. Allow solvent to dry off.

6. Remove ball from solvent and inspect. Insure that the surface of the ball is clean

and free of all containments. If there are particles imbedded into the surface of the

ball, replace ball.

10

7. Reassembly luer check valve

a. Insert ball seat into spring

b. Place spring and ball seat into luer check valve body.

c. Place ball into the ball seat

8. The Loctite EQ VA20 Volumetric Valve is ready to dispense.

Dispense Valves Flushing & Cleaning Procedure

If the dispensing system (reservoir, dispense valve, etc.) will not be used for one or more

weeks, it is recommended that the feed line and dispense valve be flushed clean with the proper

solvent. This procedure will describe the process.

1. Turn off the reservoir pressure and verify that pressure has been exhausted from

the reservoir.

2. Remove the reservoir lid and remove the adhesive container.

3. Replace it with a container of Equipment Flushing Solvent (item # 12121).

4. Replace the reservoir lid and tighten all wing nuts so the lid is secure.

5. Adjust the air pressure regulator to 5 psi.

6. Place a beaker or similar container under the dispense valve.

7. Rotate the Luer Check Valve counterclockwise 2 ¼ rotations and allow the

Equipment Flushing Solvent to flow into the container.

8. Note: this may take a few moments (or minutes) depending upon the viscosity of

the adhesive in the feed line.

9. While the solvent is flowing, be sure to cycle the volumetric valve in order to

simulate an “agitation” effect.

10. Continue this process of opening and closing the valve every 5 seconds for a

total of two (2) minutes or until the solvent is clear.

11. Once you are satisfied that all adhesive has been removed from the feed line and

dispense valve, shut off the air and remove the flushing solvent.

12. Re-install the reservoir lid and adjust the pressure regulator to approx. 70 % of its

maximum value.

13. Allow air to continually flow out of the dispense valve.

11

14. CAUTION: the vapors from the flushing solvent will be emitted and should be

directed into a paper towel or similar cloth. If an exhaust hood or fume filtration

system is available, it should be used.

15. Continue to dispense air for approx. 1 minute or until all solvent has been

removed from the feed lines.

16. While the air is being forced thru the feed lines, lightly tap the feed line leading

from the reservoir to the dispense valve.

17. Once you are confident that all of the remaining solvent has been purged from

the feed line and valve, the process is complete.

18. Rotate the Luer Check Valve clockwise until tight.

NOTE: the operator must wear Safety glasses and proper gloves while this procedure is being

performed.

9Accessories and Spare Parts

Optional Accessories and System Components (sold separately):

Dispensing From a Reservoir

Loctite® Dual Channel Integrated Semi-Automatic Control Dispenser: PN 1390321 &

1390322

Loctite® Bond-A-Matic 3000 Reservoirs, 0 to 100 psi : PN 982723, 982724, 982727

Dispensing From a Syringe

Loctite® Precision Air Regulator: PN 98099 (IDH# 855974)

Elbow fitting, 1/8” NPT male x male luer : PN 98095 (IDH# 698608)

Stainless steel reducing adapter, 1/8” NPT female x #10-32 male: McMaster Carr

part# 2684K19 or similar

12

Recommended Spare Parts / Accessories

Loctite EQ VA20 Seal Kit IDH# 2084140

Valve Mounting Bracket Kit 985281

10 Diagrams

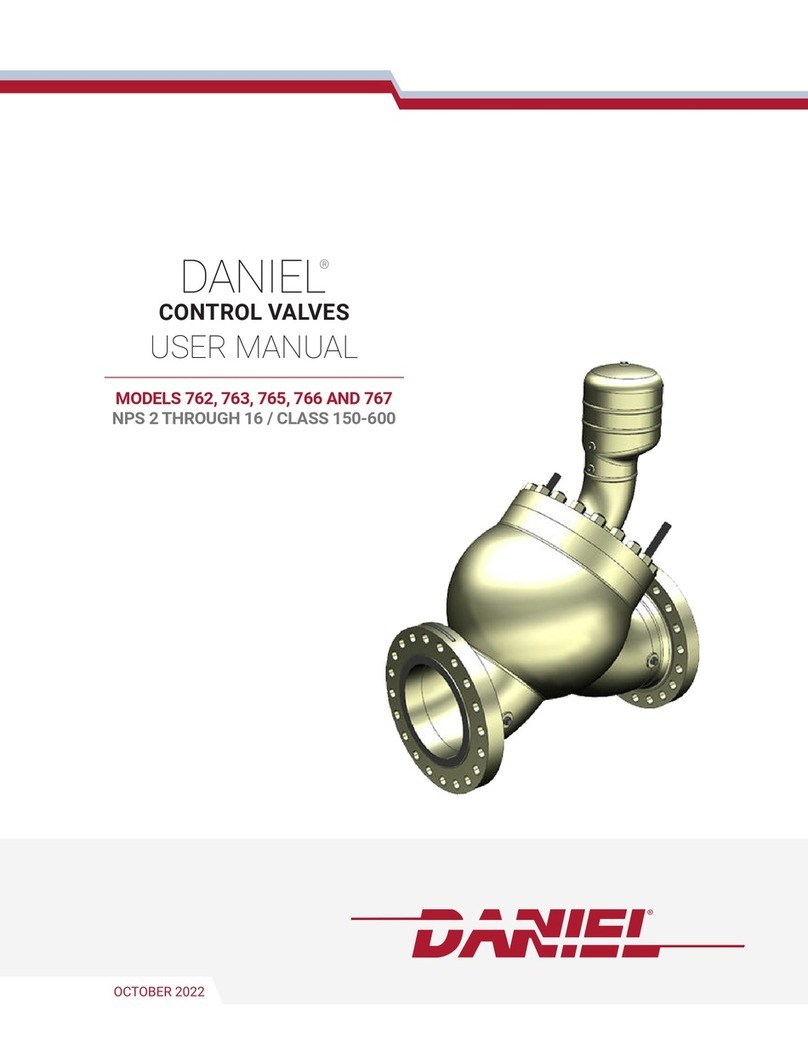

Loctite EQ VA 20 Volumetric Valve Fluid Body Sub- Assembly

13

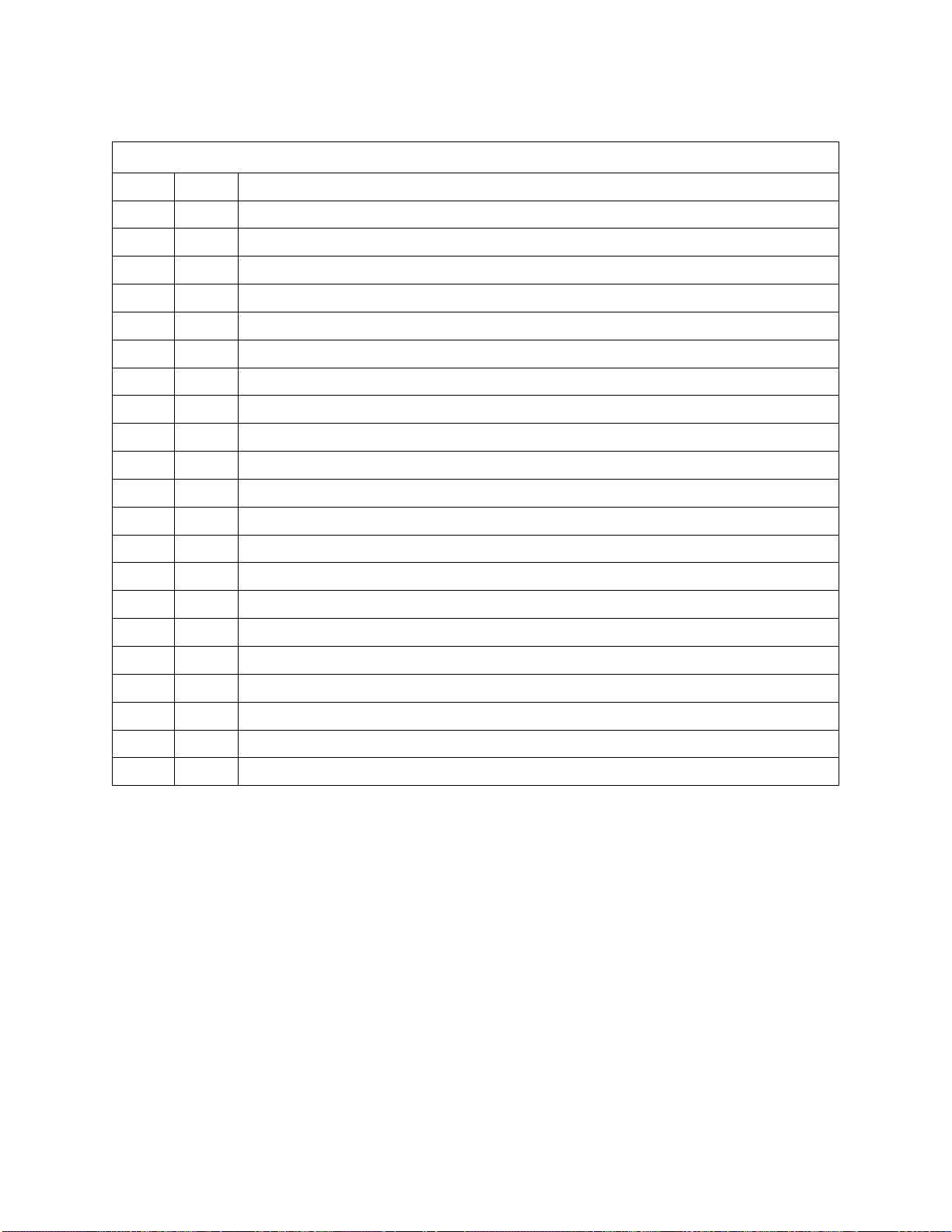

Parts List- Loctite EQ VA 20 Volumetric Valve Fluid Body Sub- Assembly

Item Qty Description

1 1 Fluid Body

2 2 O-ring AS568A-007

3 1 O-ring AS568A-012

4 1 Actuator Pin Fluid Seal

5 0.01ml Krytox RFE

6 1 Displacement Chamber

7 1 O-ring AS568A-006 Viton EPT

8 1 Internal Retaining Ring

9 1 Ball 0.125, PTFE

10 1 Ball Seat

11 1 Luer Check Valve

12 1 Tip Retainer Nut

13 1 Compression Spring

14 1 Barbed Fitting, Mem-Co. Fitting Inc.; PN B4-0-316-Viton

15 1 Flanged Locking Sleeve, Mem-Co. Fitting Inc.; PN S-14

16 1 Coupling

17 1 Seal

18 1 Bearing

19 1 Seal Gland

20 1 Seal Gland Front

21 1 O-ring AS568A-010, Viton

14

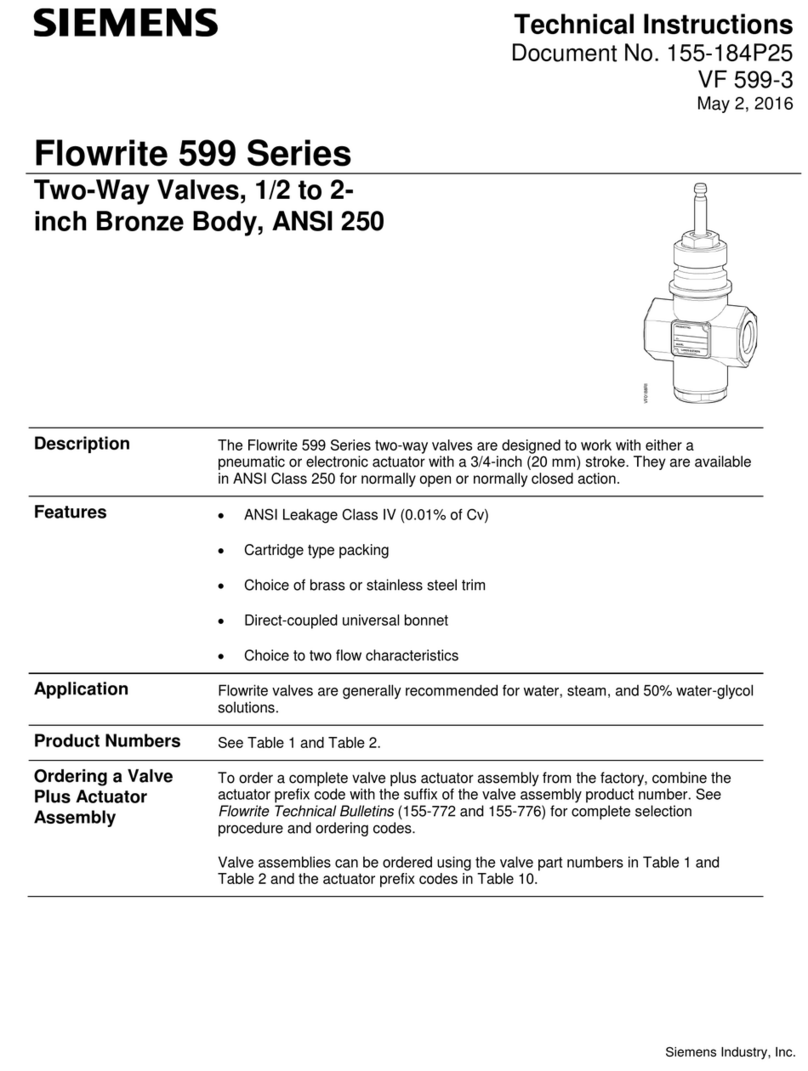

Loctite EQ VA 20 Volumetric Valve Cylinder Sub- Assembly

15

Parts List- Loctite EQ VA 20 Volumetric Valve Cylinder Sub- Assembly

Item Qty Description

1 1 EQ VA 20 Volumetric Valve Cylinder Housing

2 3 O-Ring MIL-P-25732-007, Buna -N

3 1 EQ VA 20 Volumetric Valve Air Port Insert

4 2 O-Ring #2-111 Buna N

5 2 External Retaining Ring, 4 mm shaft

6 1 EQ VA 20 Volumetric Valve Cylinder Piston

7 1 Shim

8 1 EQ VA 20 Volumetric Valve Stroke Hub

9 1 Internal Retaining Ring

10 2 Male Elbow, 4mm tube X M5

11 1 EQ VA 20 Volumetric Valve Stroke Adjuster

12 1 Pin and Rod Assembly

13 2 Socket Head Screw, M3 X 0.5 X 6mm

14 1 Set Screw, M4 X 0.7 X 10mm

15 1 Standoff, Female Threaded Hex M4 X 0.7 X 19mm

11 Warranty

Henkel expressly warrants that all products referred to in this Instruction Manual for (IDH #

2084141 Loctite®EQ VA 20 Volumetric Valve) (hereafter called “Products”) shall be free from

defects in materials and workmanship. Liability for Henkel shall be limited, as its option, to

replacing those Products which are shown to be defective in either materials or workmanship or

to credit the purchaser the amount of the purchase price thereof (plus freight and insurance

charges paid therefor by the user). The purchaser’s sole and exclusive remedy for breach of

warranty shall be such replacement or credit.

A claim of defect in materials or workmanship in any Products shall be allowed only when it is

submitted in writing within one month after discovery of the defect or after the time the defect

should reasonably have been discovered and in any event, within (12) months after the delivery

of the Products to the purchaser. This warranty does not apply to perishable items.. No such

claim shall be allowed in respect of products which have been neglected or improperly stored,

16

transported, handled, installed, connected, operated, used or maintained. In the event of

unauthorized modification of the Products including, where products, parts or attachments for use

in connection with the Products are available from Henkel, the use of products, parts or

attachments which are not manufactured by Henkel, no claim shall be allowed.

No Products shall be returned to Henkel for any reason without prior written approval from

Henkel. Products shall be returned freight prepaid, in accordance with instructions from Henkel.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT WHICH HAS BEEN ALTERED,

MISUSED, NEGLECTED, OR DAMAGED BY ACCIDENT.

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN THIS SECTION, HENKEL MAKES

NO WARRANTY OF ANY KIND WHATSOEVER, EXPRESS OR IMPLIED, WITH RESPECT TO

THE PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND

OTHER WARRANTIES OF WHATEVER KIND (INCLUDING AGAINST PATENT OR

TRADEMARK INFRINGEMENT) ARE HEREBY DISCLAIMED BY HENKEL AND WAIVED BY

THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF LIABILITY FOR HENKEL TO THE

PURCHASER IN CONTRACT, IN TORT OR OTHERWISE IN THE EVENT OF DEFECTIVE

PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE FULLEST EXTENT POSSIBLE UNDER

APPLICABLE LAWS, HENKEL EXPRESSLY DISCLAIMS ANY LIABILITY WHATSOEVER FOR

ANY DAMAGES INCURRED DIRECTLY OR INDIRECTLY IN CONNECTION WITH THE SALE

OR USE OF, OR OTHERWISE IN CONNECTION WITH, THE PRODUCTS, INCLUDING,

WITHOUT LIMITATION, LOSS OF PROFITS AND SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, WHETHER CAUSED BY NEGLIGENCE FROM HENKEL OR OTHERWISE.

17

Henkel Corporation

One Henkel Way

Rocky Hill, CT 06067-3910

USA

Henkel Canada Corporation

2515 Meadowpine Boulevard

Mississauga, Ontario L5N 6C3

Canada

Henkel Corporation

Automotive/ Metals H.Q.

32100 Stephenson Hwy,

Madison Heights 48071

USA

Henkel Capital, S.A. de C.V.

Calzada de la Viga s/n Fracc.

Los Laureles

Loc. Tulpetlac, C.P. 55090

Ecatepac de Morelos, MEXICO

Henkel Singapore Pte Ltd

401, Commonwealth Drive

#03-01/02 Haw Par Technocentre

SINGAPORE 149598

Henkel (China) Company Ltd.

No. 928 Zhang Heng Road,

Zhangjiang, Hi-Tech Park, Pudong,

Shanghai, China 201203

Henkel Loctite Korea

8F, Mapo Tower, 418,

Mapo-dong, Mapo-gu,

Seoul, 121-734, KOREA

Henkel Japan Ltd.

27-7 Shin Isogo-cho, Isogo-ku

Yokohama, 235-0017

JAPAN

Henkel AG & Co. KGaA

Standort München

Gutenbergstraße 3

85748 Garching b. München

Deutchland

www.equipment.loctite.com

® and ™ designate trademarks of Henkel Corporation or its affiliates. ® = registered in the U.S. and elsewhere. ©

Henkel Corporation. All rights reserved. Data in this operation manual is subject to change without notice.

Manual P/N: 8904545, Rev A, Date: 07-27-2016

This manual suits for next models

1

Table of contents

Other Henkel Control Unit manuals