Henkel Loctite 97135 User manual

97135/97136 Membrandosierventil 2.0/3.0

97135/97136 Diaphragm Valve 2.0/3.0

2158 6/2158 8

Operating Manual

Bedienungsanleitung

2

1x 1x 2x

1x 1x

1x

1x 1x 1x

2x 4x 2x

alternative

97106

97125 97809 97124

97108 97631

97008/97009

97152 97153

1

ESC

Num

0

9

6

-

8

Start

3

P

45

2

7

A

B

97153

+

97003/9700497006

97102

R

START CONT

bar

psi

97006

97152

ESC Start

A

B

97204

97118/97119 97115

97112/97116

97113/97114

97121 97135/9713697130 98009/98013

97111

97131

97664/97676

3

Contents

English

................................

................................

................................

...................

4

-

2

1

Deutsch

................................

................................

................................

.................

2

2

-

3

9

4

Contents

1

Please observe the

following

................................

................................

........................

5

1.1

Emphasized Sections .................................................................................................. 5

1.2

Items Supplied ............................................................................................................. 6

1.3

For Your Safety............................................................................................................ 6

1.4

Field of Application (Intended Usage) .......................................................................... 7

2

Description

................................

................................

................................

...................

8

2.1

Theory of Operation ..................................................................................................... 8

2.2

Operating Elements and Connections.......................................................................... 9

3

Technical Data

................................

................................

................................

.............

9

4

Installation

................................

................................

................................

..................

10

4.1

Connecting to the Product Reservoir.......................................................................... 11

4.2

Connecting to the Controller....................................................................................... 12

5

Dispensing

................................

................................

................................

.................

13

5.1

Priming the Diaphragm Valve..................................................................................... 13

5.2

Adjusting the Dispensed Quantity .............................................................................. 13

5.3

Shutdown................................................................................................................... 13

5.4

Returning to Operation............................................................................................... 13

5.5

Upgrading the Feedline/Fitting ................................................................................... 14

6

Care, Cleaning and Maintenance

................................

................................

...............

15

6.1

Cleaning .................................................................................................................... 15

6.2

Maintenance .............................................................................................................. 15

6.2.1

Disassembly .............................................................................................................. 16

6.2.2

Assembly ................................................................................................................... 17

7

Troubleshooting

................................

................................

................................

.........

18

8

Annex

................................

................................

................................

........................

19

8.1

Accessories and Spare Parts..................................................................................... 19

8.2

Declaration for Incorporation...................................................................................... 21

5

1

Please Observe the Following

For safe and successful operation of the unit, read these instructions completely. The

manufacturer cannot be held responsible for damage or injury of any kind because of

misuse or improper application or because of failure to observe safety instructions or

warnings.

Be sure to retain this manual for future reference.

Refer to the technical data sheet of the assigned adhesive under the address

www.loctite.com or request the technical data sheet and the safety data sheet (acc. to

the EC Directive 91/155/EC) for the LOCTITE product used at

Henkel Ag & Co. KGaA

+49 89 92 68 11 67 for English version of data sheets;

089-92 68 11 22 for German version of data sheets.

Follow unconditionally the INSTRUCTIONS of these data sheets!

1.1

Emphasized Sections

WARNING!

Warning is the signal word used to indicate a potentially hazardous situation which, if not

avoided, could result in death or severe injury.

CAUTION!

Caution is the signal word used to indicate a potentially hazardous situation which, if not

avoided, could result in moderate or minor injury.

Note!

Gives recommendations for better handling of the unit during operation or adjustment as

well as for service activities.

The numbers printed in bold in the text refer to the corresponding position numbers in the

illustration on page

9

.

•The point emphasizes an instruction

step.

Instruction steps in the illustrations are

indicated with arrows.

When several instruction steps are

indicated in an illustration, the shading of

the arrow has the following meaning:

Black arrow = 1st step

Grey arrow = 2nd step

White arrow = 3rd step

6

1

Please Observe the Following

1.2

Items Supplied

1 Diaphragm Valve 97135, Order No. 215846 or

1 Diaphragm Valve 97136, Order No. 215848

1 Product Feedline 1/4 inch

1 Needle Variety Kit Type No.97262;

1 Operating Manual

Note!

As a result of technical development, the illustrations and descriptions in this operating

manual can deviate in detail from the actual unit delivered.

1.3

For Your Safety

WARNING!

If chemical products are not properly handled, damage to health can result!

Observe general safety regulations for the handling of chemicals!

Observe the manufacturer’s instructions as stated in the Material Safety Data Sheet

(MSDS)!

Always wear safety glasses when operating with pressurized air!

Use only original substitute and spare parts.

7

1

Please Observe the Following

1.4

Field of Application (Intended Usage)

The Diaphragm Valves 97135/97136 are suitable for the exact application of LOCTITE

®

products. They show no suck back.

The Diaphragm Valve 97135 is equipped with an internal product bore of ∅2 mm. It is

used for anaerobic products up to a viscosity of 2,500 mPas.

The Diaphragm Valve 97136 is equipped with a internal product bore of ∅3 mm. It is

used for anaerobic thixotropic products up to a viscosity of 5,000 mPas.

For each product and corresponding application of the dispense valves, various

dispensing needle types and sizes are available:

–Conical dispensing needles of polyethylene for viscous products and large dispensed

quantities.

–Stainless steel needles for thin fluids and UV curing products.

–Flexible dispensing needles of polyethylene.

For high flow rates the diaphragm valve can be upgraded from feedline 1/4” to 3/8” by

the feedline upgrade kit, type no. 97220.

The diaphragm valve is used as a stationary applicator unit. It is mounted directly at the

dispensing position. The free end of the product feedline is connected to the product

reservoir.

As product reservoirs, 0.5 l and 2 l tanks are available.

A control unit of the LOCTITE

®

equipment line provides the control of the diaphragm

valve.

8

2

Description

2.1

Theory of Operation

The LOCTITE

®

product is transported through a product feedline to the diaphragm valve

by the dispensing pressure in the product reservoir.

At the shut off valve assembly PTFE material is used for the area in contact with the

adhesive to prevent curing of adhesive in this part of the diaphragm valve.

The opening of the diaphragm valve takes place by pressuring an internal single acting

cylinder. In the inactive position, the diaphragm valve is closed by spring force. A piston

pushing against a diaphragm, which seals off the product bore in the valve, achieves

sealing in idle position.

The floating mounted diaphragm enables easy repair and service.

As a result the diaphragm valve is not suitable for moisture sensitive product like CA`s.

The amount of product dispensed is controlled by:

–The amount of pressure in the reservoir.

–The length of time the shut off valve remains open.

–The dispensing needle.

The more precise and constant the amount of Loctite

®

product the longer has to be the

dispensing time and

lower the dispensing pressure.

9

2

Description

2.2

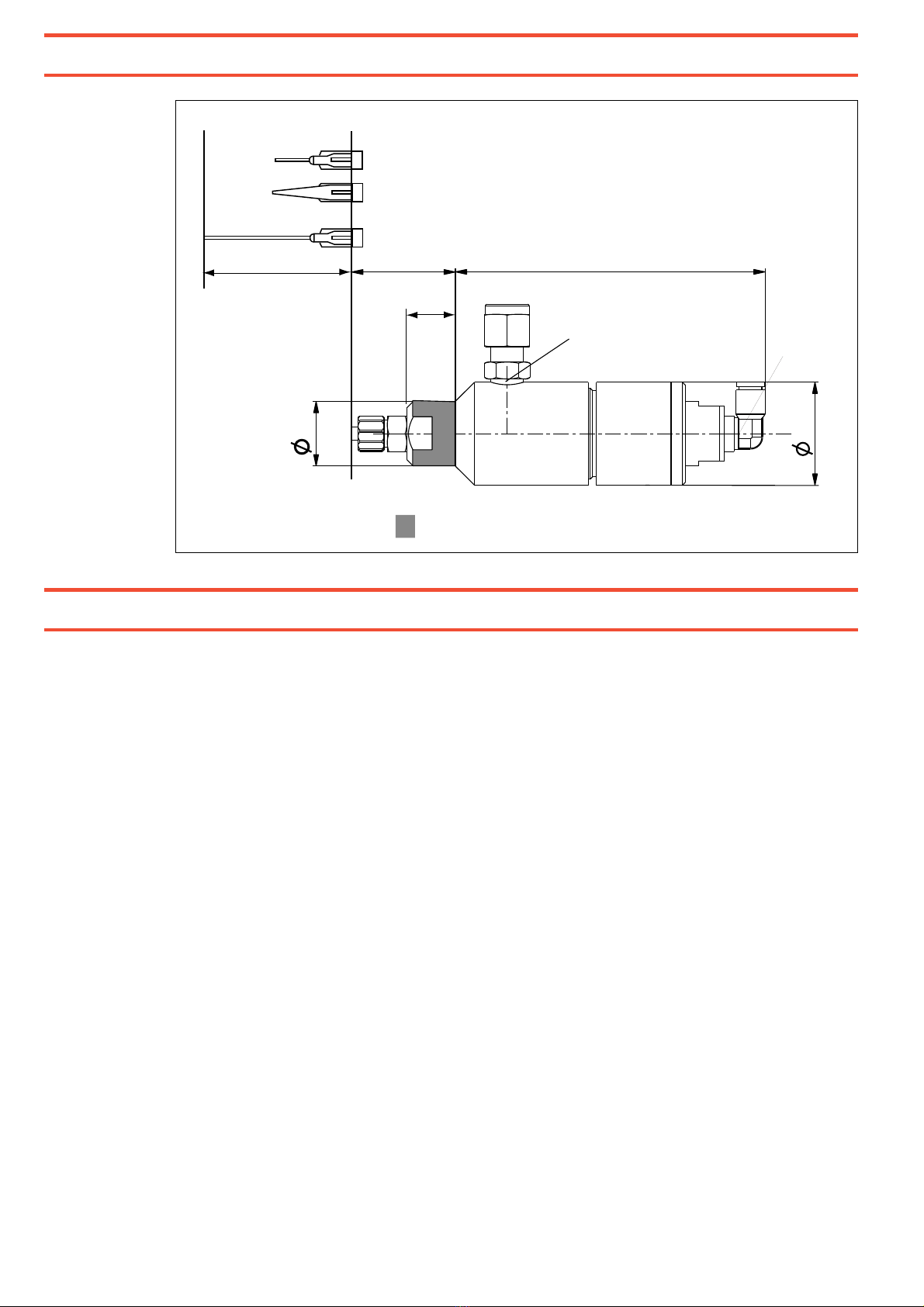

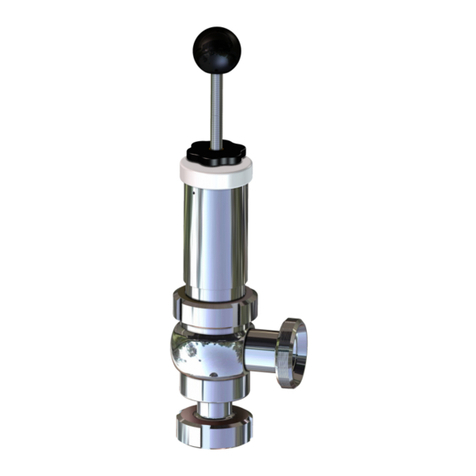

Operating Elements and Connections

1

Pressure hose connection

2

Actuator assembly

3

Diaphragm

4

Shut off valve assembly

5

Product feedline connection

6

Luer Lock

A

dapter

7

8

Luer Lock Connector

Coupling (not shown) to pick up the

dispensing needle when using the valve

in connection with a rotor spray

Z4218/4220.

3

Technical Data

Pneumatic supply Min. 5 bar (73 PSI), max. 7 bar (100 PSI)

Quality

If required quality is not achieved, install a

LOCTITE filter regulator Type no. 97120

Filtered 10 µm, oil-free, non-condensing

Accessory Order Code No. 88649

Pneumatic hose size, control air connection

External Dia. 4 mm ;

Internal Dia. 2.5 mm

Product Feedline Standard: 1/4 inch,

optional: Feedline Upgrade Kit 3/8 inch,

Type 97220, Accessory Order Code No.

135561

Dispensing pressure range of the valve: 0.5 bar (7 PSI) - 4 bar (60 PSI)

Weight 0,300 kg

+0.05

- 0.10

1

2

3

4

5

6

7

10

3

Technical Data

4

Installation

– Keep the pressure hose as short as possible. Short switch-on and switch-off times for

the diaphragm valve are within reach.

– Keep product feedlines as short as possible. The shorter the feedline the smaller the

specific resistance and the lower the dispensing pressure can be.

– Avoid kinking of feedlines and pressure hoses.

– Typically, the pressure hose and product feedline should not be longer than 2 m.

– Do not use inflexible hoses and feedlines, so that unnecessary loads on the fittings will

be avoided.

– Keep all fittings tight.

–

No direct sunlight; no UV light!

Clamping area

32 95

32

25.5

52

26.5

20

15

R1/8 R1/8

11

4

Installation

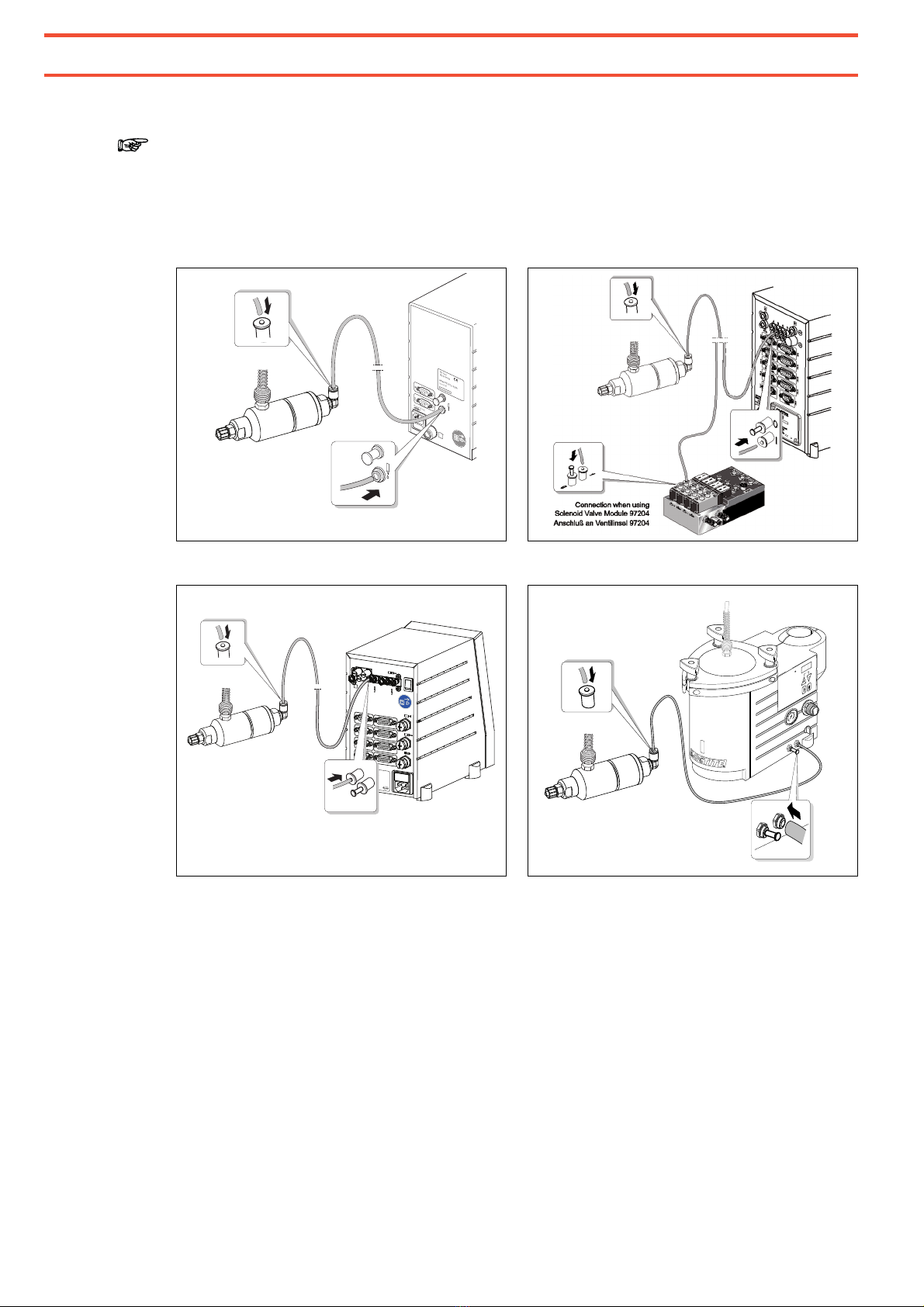

4.1

Connecting to the Product Reservoir

97106, 97108, 97127

0.5 ltr.: length 200 mm

2 ltr.: length 275 mm

12

4

Installation

4.2

Connecting to the Controller

Note!

When connecting to the coax-outlet (controller 97102 and 97103/97204) use Coax

Adapter, type no. 8900102! When connecting to the single port, use port Iand

close port O.

97102

971

5

3/97204

97152

97008/

97009

888

CONT

CONT

2

0

30

60 90

120

6

8

10

psi

bar

I

0

XS16

XS18

XS17

XS5 RS 232 XS8 I/O Port

XS3 Flow Monitor

XS2 Reservoir

XS1 Start

XS10 PLC Interface

XS12 Valves

XS11 DC Drive

HenkelAG & Co. KGaA

Standort München

Gutenbergstr.3

D-85748 Garching

100-240 VAC,50/60 Hz

Fuse: 2A T (time-lag)

Power Consumption: 100 W

Made in Germany

Place for Serial No. Sticker

I/0

P in

6-8 bar

0I 0I

AB

P out

0.1-7 bar

O

I

90–260VAC/47–63 Hz

2AM

XS1

XS1: Start

XS2: Reservoir

Henkel AG & Co. KGaA

cat.no.97102

XS2

0

1

1

0

13

5

Dispensing

5.1

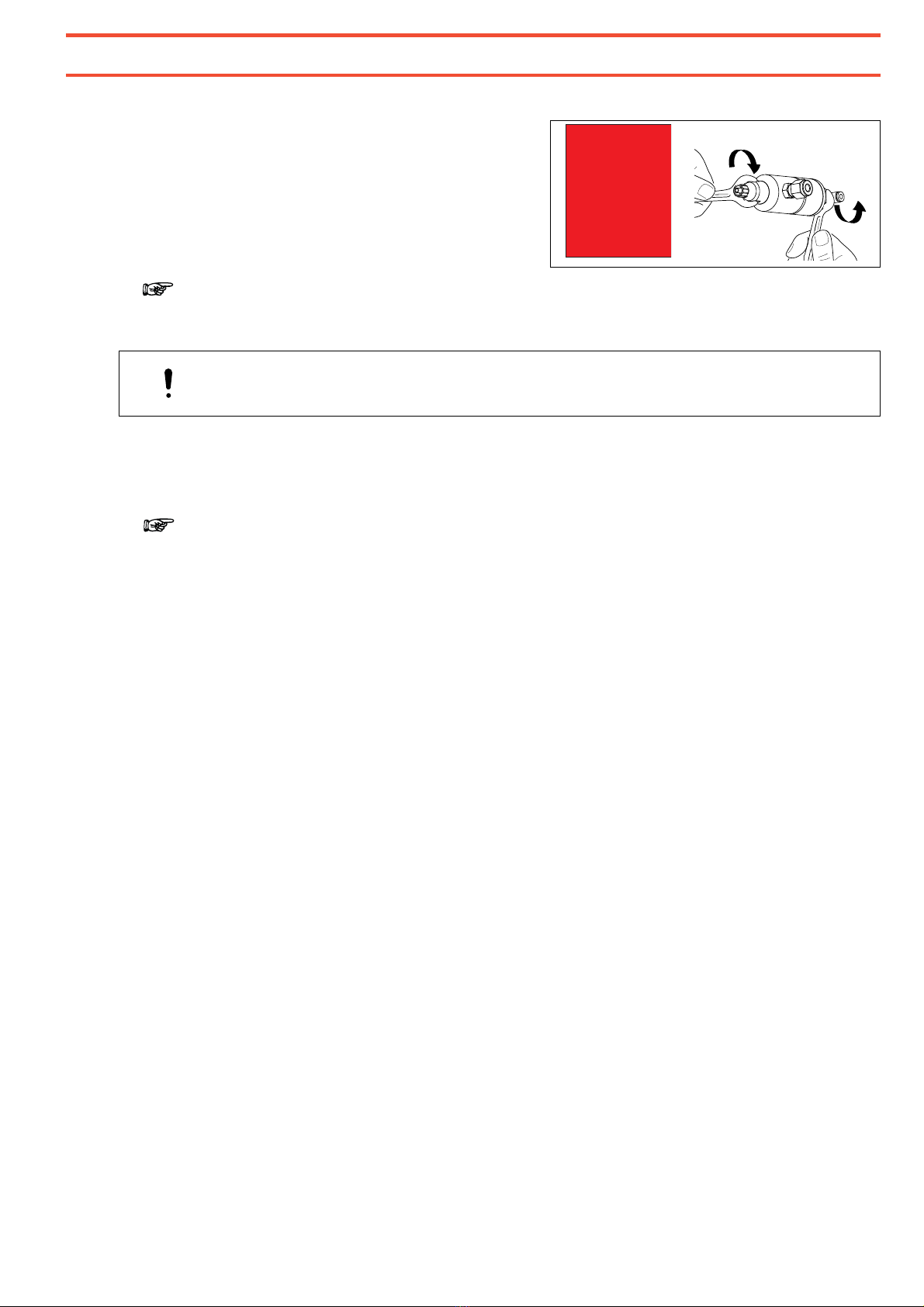

Priming the Diaphragm Valve

•Before initial operation:

Hand-tighten the valve actuator and

valve body by means of two combination

wrenches (wrench size 17 mm) in

accordance with the data of the sticker

(max.17 Nm). Only then it is guaranteed

that the valve is tight.

Note!

To avoid air bubbles during dispensing, the product feedline and the diaphragm valve

must be filled.

CAUTION!

Place a container under the diaphragm valve since the product will flow out!

•Perform the filling of the product feedline acc. to the operating manual of the used

Controller.

5.2

Adjusting the Dispensed Quantity

Note!

Adjust the dispensing quantity according to Chapter 5 of the operating manual of the

used controller.

5.3

Shutdown

To protect anaerobic products from curing, remove dispensing needle leaving Luer-Lock

adapter

6

exposed to air.

Shutdown for longer Periods.

•Remove product out of the reservoir.

•Purge the diaphragm valve with air until no product run out.

5.4

Returning to Operation

•Insert product bottle into the reservoir.

•Purge the diaphragm valve with air until product run out.

•Check the dispensing quantity acc. to Chapter 5 of the operating manual of the used

controller.

ACHTUNG:

Vor Inbetriebnahme

Ventilober- und

Unterteil (SW 17 mm)

handfest nachziehen

(max 17 Nm).

NOTE:

Hand-tighten valve

top and bottom

(wrench opening

17 mm) prior to first

use (17 Nm max.).

14

5

Dispensing

5.5

Upgrading the Feedline/Fitting

Note!

For viscous products, a feed tube adapter with a 9.5 mm product feedline, type no.

97220, is available by ordering part no. 135561.

•Disconnect the feedline and unscrew the

fitting.

•Screw the new fitting into the shut off

valve 4.

15

6

Care, Cleaning and Maintenance

6.1

Cleaning

The diaphragm valves have to be cleaned if

- idle periods of the dispensing system exceed seven days, and/or

- a different type of product is to be dispensed and/or

-

valves are disassembled for replacement of spare parts.

Liquid residues may be removed with several solvent. Chlorinated hydrocarbons will

obtain optimum results; acetone would be the best alternative among nonCHC solvents.

WARNING!

If chemical products are not properly handled, damage to health can result.

Observe general safety regulations for the handling of chemicals!

If diaphragm valve is cleaned after prolonged idle periods or for a switch to a different

product, be sure to place new Loctite

®

product bottle into the tank, see operating manual

of the used reservoir.

Priming of the feedline, see operating manual of the used controller.

Setting of dispensing parameters, see operating manual of the used controller.

6.2

Maintenance

To ensure trouble-free operation of the diaphragm valves 97135/97136 we recommend

servicing at regular intervals.

•Every 6 months

Replace diaphragm

3

(Repair Kit),

type no. 97271, o

rder code no.

360444

.

Following is a description of diaphragm valve cleaning, disassembly and reassembly

procedures.

16

6

Care, Cleaning and Maintenance

6.2.1

Disassembly

•Disconnect feedline and pneumatic tube

and remove dispensing nozzle.

•Disassemble Diaphragm valve (2 open

end wrenches size 17).

•Carefully remove diaphragm 3from shut

off valve

4

.

Note!

Do not use metal tools! For example use

small wooden spatulas or toothpicks.

When the insert is damaged product can

get in contact with the housing and cures.

•Clean the ring groove.

17

6

Care, Cleaning and Maintenance

6.2.2

Assembly

•Slightly grease threads and neck of

actuator 2.

•Insert new diaphragm 3in shut off

valve 4.

•Screw actuator 2onto shut off valve 4

and tighten securely by hand, then by

using wrench size 17 turn max. 180° to

fix them correctly and get dispensing

valve tight in accordance with the data

of the sticker (max.17 Nm).

•Connect feedline and pneumatic tube and slip on dispensing nozzle.

ACHTUNG:

Vor Inbetriebnahme

Ventilober- und

Unterteil (SW 17 mm)

handfest nachziehen

(max 17 Nm).

NOTE:

Hand-tighten valve

top and bottom

(wrench opening

17 mm) prior to first

use (17 Nm max.).

18

7

Troubleshooting

Type of malfunction Possible causes Correction

No product or too little

product.

– Product feedline and/or pneumatic

hose not connected correctly or

kinked.

•Connect the product feedline correctly.

If kinked, replace it.

– Control pressure not adequate.

Control pressure must be between

5 and 7 bar.

•Check and adjust the control pressure.

– Curing in the product feedline or in

the dispensing needle.

– Curing in the diaphragm valve.

•Replace the product feedline and/or the

dispensing needle.

•Replace the shutoff valve 4and the

diaphragm 3.

– Controller incorrectly adjusted. •Check the controller setting (see

operating manual for the controller).

– Product reservoir not switched on,

depressurized or pressure is too

low.

•Check the reservoir (see operating

manual for the product reservoir).

Diaphragm valve does

not open.

– Actuator 2of the valve is

contaminated with product.

•Replace the actuator 2and the

diaphragm 3.

Dispensing operation is

irregular.

– Actuator 2and shut off valve 4are

tightened too much.

•Back off actuator from shut off valve,

proceeding in small steps,

90° max (1/4 turn).

Dispensing sequence

too short despite long

time setting.

– Disassemble valve and push button

on controller to actuate the actuator:

> air escapes at the plunger.

•Replace the actuator 2and the

diaphragm 3.

19

8

Annex

8.1

Accessories and Spare Parts

Note!

Also see the illustration on page 9.

Pos. No.

Description Type No. Order Code No.

2 Actuator ........................................................................................

97254 338119

3 Repair Kit Diaphragm ....................................................................

97271 360444

4 Shut off Valve Ø 2 mm ..................................................................

97268 333180

4 Shut off Valve Ø 3 mm ..................................................................

97269 360443

– Dispense Needle, Polyethylene – Conical (PPC),

especially for viscous products and large dispensing quantities:

Dispense Needle PPC16GA (50 pcs/box), ID Size 1.19 mm, grey.

Dispense Needle PPC18GA (50 pcs/box), ID Size 0.84 mm,

green.............................................................................................

Dispense Needle PPC20GA (50 pcs/box), ID Size 0.58 mm, pink.

Dispense Needle PPC22GA (50 pcs/box), ID Size 0.41 mm, blue.

97221

97222

97223

97224

88660

88661

88662

88663

– Dispense Needle, Stainless Steel – Standard (SSS),

especially for low viscosity and UV curing products:

Dispense Needle SSS15GA (50 pcs/box), ID Size 1.35 mm,

amber............................................................................................

Dispense Needle SSS18GA (50 pcs/box), ID Size 0.84 mm,

green.............................................................................................

Dispense Needle SSS20GA (50 pcs/box), ID Size 0.58 mm, pink

Dispense Needle SSS25GA (50 pcs/box), ID Size 0.25 mm, red...

97225

97226

97227

97228

88664

88665

88666

88667

– Dispense Needle, Polyethylene – Flexible (PPF),

especially for fast curing products:

Dispense Needle PPF15GA (50 pcs/box), ID Size 1.24 mm,

amber............................................................................................

Dispense Needle PPF18GA (50 pcs/box), ID Size 0.81 mm,

green.............................................................................................

Dispense Needle PPF20GA (50 pcs/box), ID Size 0.48 mm, pink

Dispense Needle PPF25GA (50 pcs/box), ID Size 0.36 mm, red...

97229

97230

97231

97232

142640

142641

142642

142643

20

8

Annex

Pos. No.

Description Type No. Order Code No.

– Dispense Needle, Appryl (PPS),

especially for spot applications, not suitable for UV adhesives:

Dispense Needle PPS20GA (50 pcs./box), ID Size 0.6 mm,

nature ...........................................................................................

97290

397462

– Luer Lock Tip Caps ......................................................................

97248 218275

6 Luer Lock Adapter Kit....................................................................

97233 88672

– Feedline, PTFE, 1/4”.....................................................................

8953672 1257724

– Feedline Upgrade Kit 1/4“ to 3/8” ..................................................

97220 135561

– Repair Kit Sealing Adapter 2.0 (for 97135)....................................

8952235 529530

– Repair Kit Sealing Adapter 3.0 (for 97136)....................................

8952326 529531

– Coupling Product bore Ø 1,5 mm (97135).....................................

8950523 585000

– Coupling Product bore Ø 2,5 mm (97136).....................................

8950560 585001

This manual suits for next models

3

Table of contents

Languages:

Other Henkel Control Unit manuals

Popular Control Unit manuals by other brands

weed instrument

weed instrument EOTec 2000 installation instructions

Contrive

Contrive Quad manual

Meinberg

Meinberg IMS-PIO180 manual

Panasonic

Panasonic PAN9026 Developer's guide

Gemalto

Gemalto Cinterion BGS2-W miniPCIe Hardware interface description

KIESELMANN

KIESELMANN 6268 Translation of the original operating instruction