Henry Tools 45 Series Guide

The henry Tool Co., ManufaCTured by henry Tools

498 so. belvoir blvd., souTh euClid, oh 44121 u.s.a.

Ph: (216) 291-1011 or (800) 826-5257 ● Fax: (216) 291-5949 or (800) 303-2800

Email: da[email protected] ● WEbsitE: WWW.hEnrytools.com

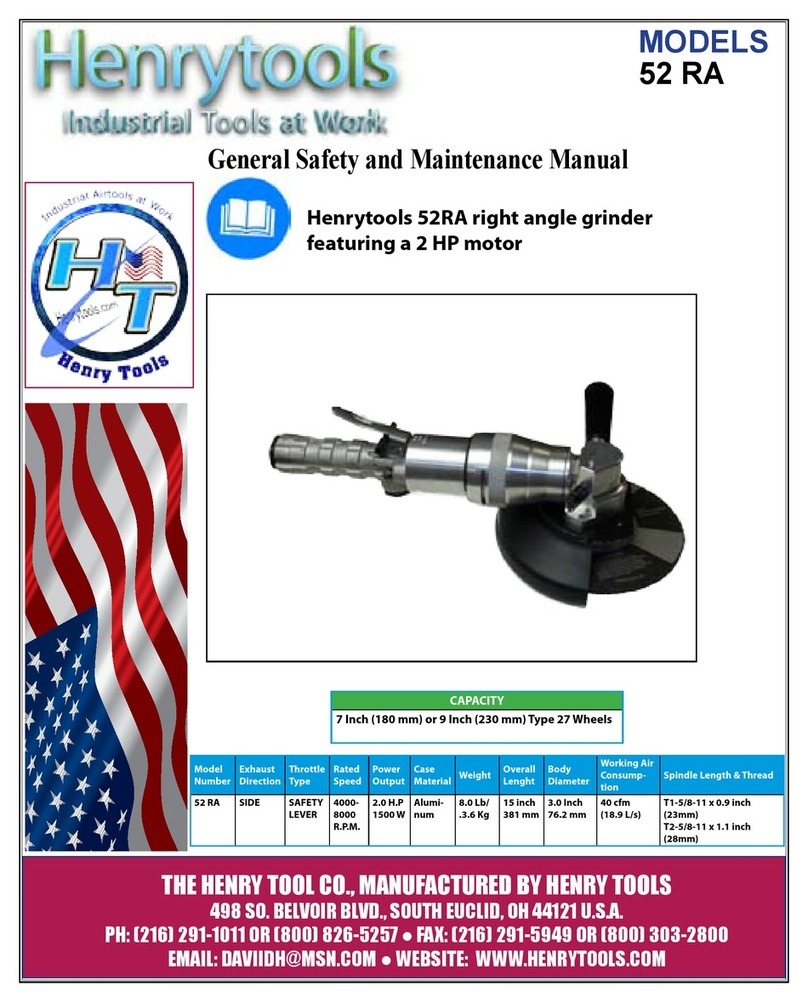

General Safety and Maintenance Manual

Original Style

Tools Pre-Year 2009

Model

Number

Exhaust

Direction

Throttle

Type

Speed Power

Output

Case

Material

Weight Length Diam-

eter

Air

Consumption

Spindle

Thread

Aluminum Steel

45RA

Side

(L) Lever

or

(K) Safety

Lever

12000

to 14000

R.P.M

(13500rpm

is standard)

0.9 H.P.

(675 W)

Steel

or

Alumi-

num

2 1/2 lbs

1.1kg

3.5 Lbs

(1.6

Kg)

8

5/16”-

211mm

1 3/4”

4.4cm

25 CFM

(11.8 L/S)

3/8-24 x

0.98 Inch

45RAZ 5/8-11 x

0.98 Inch

45RAS 3/8-24 x

0.98 Inch

45RAC

1/4 Inch

Built-In

Collet

Original Style

Tools Pre-Year 2009

MODELS

45 RA

45 RAC

45 RAZ

45 RAS

45 RA SERIES PNEUMATIC RIGHT ANGLE GRINDER

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 77 Revised 03/05/12

For additional product information visit our website.

Original Style

Tools Pre-Year 2009

PART NO. DESCRIPTION

400-G-11 FRONT BEARING

400-G-17 Alum Side Exhaust Sleeve

400-G-17-S Steel Side Exhaust Sleeve

400-G-4-GL Aluminum Backhead

400-G-4-GLS Steel Backhead

400-G-26 THROTTLE LEVER

400-G-34 SPRING

400-G-38 COLLET NUT

400-G-42 3/8-24 FLANGE (2”-3” WHEELS)

400-G-47 3/8-24 JAM NUT

400-2G CYLINDER WITH PIN INSTALLED

400-5 ROTOR

400-6 ROTOR BLADE (5 are required)

400-7 FRONT ENDPLATE

400-10 KEY

400-44 ROLL PIN

400-51 0-RING

402-126 SAFETY LEVER

402-127 SAFETY LEVER PIN

402-128 LOCKOUT LEVER

402-129 SAFETY LEVER SPRING

402-134 MUFFLER

404-1 ANGLE HEAD

404-2 BEARING CAP

PART NO. DESCRIPTION

404-3 UPPER OUTPUT SPINDLE BEARING

404-4 KEY

404-6 WAVY WASHERS(2 required)

404-7 LOWER SPINDLE BEARING

404-9 REAR MOTOR BEARING

404-14 SPINDLE

404-19 REAR ENDPLATE

404-20 MOTOR SPACER

404-38 BEARING COVER

404-39 SNAP RING

404-40 DEAD HANDLE

404-41 MOTOR CASE ALUMINUM

404-44 DEAD HANDLE OFFSET

405-5-625 5/8-11 X .980 OUTPUT SPINDLE

405-10 GEAR SET

405-15 GEAR SPACER SLEEVE

405-17 3/8-24 X .980 OUTPUT SPINDLE

540607 COLLET OUTPUT SPINDLE

405-17-5/8” 5/8-11 X .980 OUTPUT SPINDLE

500-G-44 3/8 ID FLANGE ( for 4”-5” WHEELS)

700-34 5/8-11 JAM NUT

700-37 THROTTLE LEVER PIN

1100-680 5/8 I.D. FLANGE

1100-682 “(6”” OR SMALLER WHEELS)

3/8 I.D. FLANGE”

591028 SCREW

591040 STAR WASHER

591048 BRACKET BOLT

591106 SET SCREW (SPECIFY SPEED)

592016 SNAP RING

594016 0-RING

832636 GASKET

841553 3/8 NPT TO 1/4 NPT BUSHING

844302 0-RING

869311 THROTTLE VALVE CAP

834782 THROTTLE VALVE-INCLUDES 844302

4503 3” TYPE 27 GUARD

4504 4” TYPE 27 GUARD

4505 5” TYPE 27 GUARD

490-3 PIN SPANNER

102-SPWR WRENCH FOR SANDING PAD NUT

1100-044 7/16” WRENCH

1100-050 1/2” WRENCH

MODELS

45 RA

45 RAC

45 RAZ

45 RAS

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 78 Revised 03/05/12

For additional product information visit our website.

Original Style

Tools Pre-Year

2009

PART NO. DESCRIPTION

1100-056 9/16” WRENCH

1100-063 5/8” WRENCH

1100-068 11/16” WRENCH

1100-075 3/4” WRENCH

1100-094 15/16” WRENCH

300-16 1/8” COLLET ADAPTER

400-78 3/8-24 TO 5/8-11 ADAPTER

405-24 BACKING PLATE FOR 490-KR

490-K 3/8-24 X .980 TYPE 27 ADAPTER

A S S Y.

490-KR 3/8-24 X .580 TYPE 27 ADAPTER

A S S Y.

490-1 BACKING PLATE FOR 490-K

490-2 NUT FOR 490-K & 490-KR

1100-660 3/8-24 TO 5/8 I.D. TYPE 27 ADAPTER

A S S Y.

1100-661 3/8-24 TO 5/8 I.D. BACKING PLATE

1100-662 3/8-24 TO 5/8 I.D. ADAPTER NUT

1100-664 3/8-24 TO 7/8 I.D. BACKING PLATE

1100-666 3/8-24 TO 7/8 I.D. ADAPTER NUT

1100-668 3/8-24 TO 7/8 I.D. TYPE 27 ADAPTER

A S S Y.

1100-692 5/8-11 TO 7/8 I.D. TYPE 27 ADAPTER

A S S Y.

1100-694 5/8-11 TO 7/8 I.D. BACKING PLATE

1100-696 5/8-11 TO 7/8 I.D. ADAPTER NUT

849259 5/8-11 SANDING PAD NUT

849259-A 3/8-24 SANDING PAD NUT

889271 5/8-11 4” SANDING PAD (MAX

12000 RPM)

889271-A 3/8-24 4” SANDING PAD (MAX

12000 RPM)

849848 5/8-11 5” SANDING PAD (MAX

10000 RPM)

849848-A 3/8-24 5” SANDING PAD (MAX

10000 RPM)

849913 5/8-11 7” SANDING PAD (MAX 8500

RPM)

849914 5/8-11 9” SANDING PAD (MAX 6500

RPM)

REPAIR KITS

510076 REPAIR KIT INCLUDES ALL BEAR-

ING, ROTOR BLADES, SNAP RINGS.

(WITH GEARS)

510078 REPAIR KIT INCLUDES ALL BEAR-

ING, ROTOR BLADES, SNAP RINGS.

(WITHOUT GEARS)

MODELS

45 RA

45 RAC

45 RAZ

45 RAS

PART NO. DESCRIPTION

ASSEMBLIES

402-26 SAFTETY LEVER ASSEMBLY

GRINDER SAFETY

ALWAYS COMPLY WITH:

1. General Industry Safety & Health Regulations, Part 1910, OSHA 2206, available from:

Sup’t of Documents; Government Printing Ofce; Washington DC 20402

2. Safety Code for Portable Air Tools, ANSI B186.1 available from: American National

Standards Institute, Inc.; 1430 Broadway; New York, NY 10018

3. State and Local regulations.

4. Portions of the above codes and regulations are listed below for quick reference.

THESE EXCERPTS ARE NOT INTENDED TO BE ALL INCLUSIVE - STUDY AND COMPLY WITH

ALL REGULATIONS!

1. Always turn off the air supply and disconnect the air supply hose before installing,

removing or adjusting any accessory on this tool, or before performing any maintenance on

this tool.

2. After mounting a wheel or other abrasive accessory, the Grinder shall be run in a

protected enclosure, at gradually increasing speed, for at least 60 seconds. When starting

work with a cold wheel, apply it gradually to the workpiece until it becomes warm. Do not

continue to use a grinder if:

• The speed rating of the accessory is less than the speed of the grinder

• If tool vibrates repair immediately.

• You sense changes in tool speed or an unusual increase in noise that would indicate

tool is running at excessive speed.

• You notice excessive end play in spindle

• You hear any unusual sound from grinder

RETURN THE TOOL TO THE TOOL CRIB FOR SERVICE IMMEDIATELY.

3. Make certain no one is in front of or in line with the wheel or other abrasive accessory.

Be aware that it may fail at this time if it is defective, improperly mounted or the wrong

size and speed. Stop immediately if considerable vibration or other defects are detected.

Shut off the air supply and determine the cause.

4. OPERATOR PROTECTIVE EQUIPMENT - Wear goggles or face shield at all times

tool is in operation. Other protective clothing shall be worn, if necessary. SEE REGULA-

TIONS.

5. Keep hands, loose clothing and long hair away from rotating end of tool.

6. Anticipate and be alert for sudden changes in motion during start up and operation of

any power tool.

7. Keep body stance balanced and rm. Do not overreach when operating this tool. High

reaction torques can occur at or below the recommended air pressure.

8. Tool accessories may continue to rotate briey after throttle is released.

9. Air powered tools can vibrate in use. Vibration, repetitive motions or uncomfortable

positions may be harmful to your hands and arms. Stop using any tool if discomfort, tin-

gling feeling or pain occurs. Seek medical advice before resuming use.

10. This tool is not designed for working in explosive atmospheres. Do not use this tool on

materials whose dust or fumes can cause a potentially explosive environment.

11. This tool is not insulated against electric shock.

12. Product Safety information - When Placing the Tool in Service

•NEVER MODIFY ANY PART OF THIS TOOL!!!! Always install, oper-

ate, inspect and maintain this product in accordance with all applicable standards and

regulations (local, state, country, federal, etc.).

• Always use clean, dry air at 90 psig (6.2 bar/620 kPa) maximum air pressure at the

inlet. Higher pressure may result in hazardous situations including excessive speed,

rupture, or incorrect output torque or force.

• Be sure all hoses and ttings are the correct size and are tightly secured.

• Install a properly sized Safety Air Fuse upstream of hose and use an anti-whip.

• Always turn off the air supply, bleed the air pressure and disconnect the air supply

hose before installing, removing or adjusting any accessory on this tool, or before per-

forming any maintenance on this tool or any accessory.

• Ensure that the grinding wheel or other abrasive accessory is correctly mounted and

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 79 Revised 03/05/12

For additional product information visit our website.

tightened before use.

• Always replace a damaged, bent or severely worn wheel guard.

Do not use a wheel guard that has been subjected to wheel failure.

• • Guard opening must face away from the operator. Bottom of

wheel must not project beyond guard.

•DO NOT MODIFY THE TOOL, SAFETY DEVICES, OR ACCES-

SORIES.

• Use accessories recommended by Henry tools.

• Do not use this tool if the actual free speed exceeds the rated rpm.

Check the free speed of the Grinder

before mounting a wheel, after all tool repairs, before each job and after

every 8 hours of use. Check speed with a calibrated tachometer, without

the abrasive product installed.

• Do not use any wheel or other abrasive accessory whose maximum

operating speed, as dened by its manufacturer, is less than the rated

speed of the Grinder.

• Inspect all grinding wheels for chips or cracks prior to mounting. Do

not use a wheel that is chipped, cracked or otherwise damaged.

• Inspect arbor, threads & clamping devices for damage & wear prior to

mounting wheel or other abrasive accessory.

• Do not use a grinding wheel that has been exposed to freezing tem-

peratures, extreme temperature changes, high humidity, solvents, water

or other liquids.

• Make certain grinding wheel or other abrasive accessory properly ts

the spindle. The wheel should not t too snugly or too loosely. Plain

hole wheels should have about .007” (0.17 mm) maximum diametral

clearance. Do not use reducing bushings to adapt a wheel to any arbor

unless such bushings are supplied by and recommended by the wheel

manufacturer.

• Always use the wheel anges furnished by the manufacturer and ap-

propriate for the wheel size and type.

Never use a makeshift ange or plain washer. Flanges should be in good

condition and free of nicks, burrs and sharp edges.

• Ensure that the thread type and size of the threaded abrasive product

exactly matches the thread type and size of the spindle.

• Prevent the spindle end from touching the bottom of the hole of cups,

cones or plugs with threaded holes, intended to be mounted on machine

spindles, by comparing dimensions and other relevant data for them.

• Do not use an unguarded grinder unless used for internal work and

only operated when the work offers protection.

Original Style

Tools Pre-Year

2009

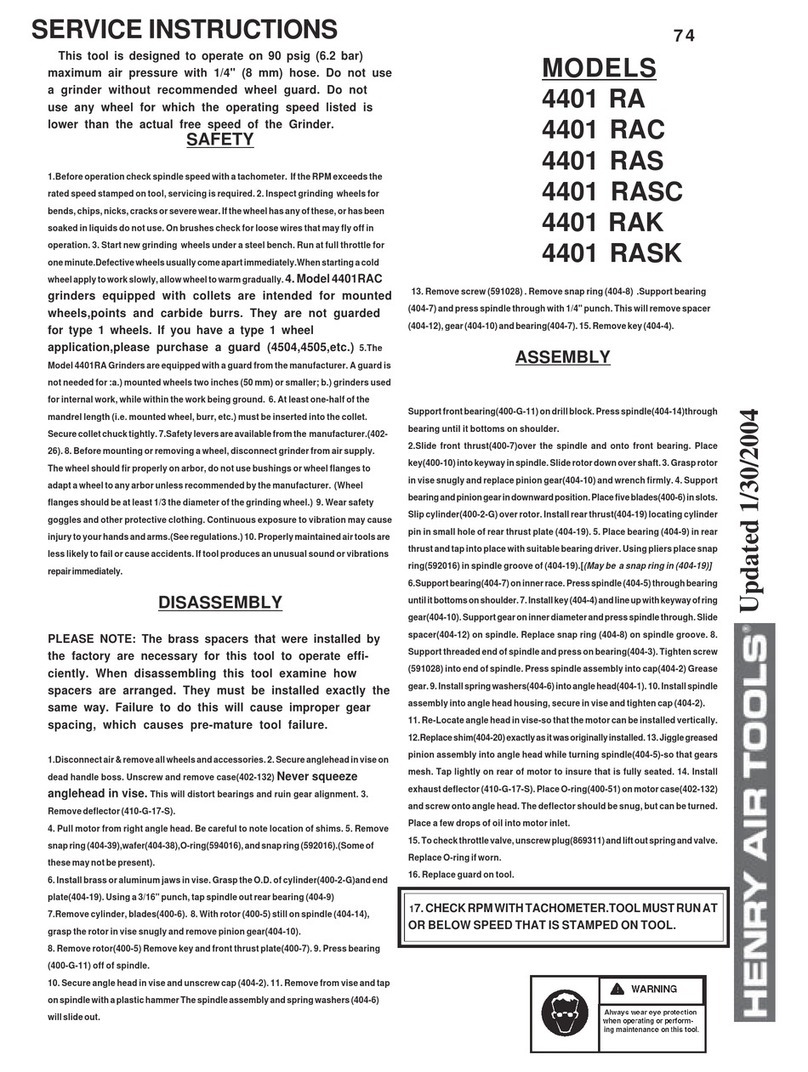

DISASSEMBLY

PLEASE NOTE: The brass spacers that were installed by the factory are

necessary for this tool to operate efciently. When disassembling this

tool examine how spacers are arranged. They must be installed exactly

the same way. Failure to do this will cause improper gear spacing, which

causes pre-mature tool failure.

1. Disconnect air & remove all wheels and accessories.

2. Remove dead handle (404-40). Secure anglehead vertically in vise

on dead handle boss. Never squeeze anglehead(404-1) in vise. This

will distort bearings and ruin gear alignment.

3. Unscrew backhead (400-G-4). Unscrew case (400-G-1).

4. Remove deector (400-G-17).

5. Pull motor from right angle head. Be careful to note location of

shims.

6. Remove snap ring (404-39),wafer(404-38),O-ring(594016), and

snap ring (592016).(Some of these parts may or maynot be present).

7. Install brass or aluminum jaws in vise. Grasp the O.D. of

cylinder(400-2-G) and end plate(404-19). Using a 3/16” punch, tap

spindle out rear bearing (404-9).

8. Remove cylinder, blades(400-6). 8. With rotor (400-5) still in

spindle (404-14), grasp the rotor in vise snugly and remove pinion

gear(405-10).

9. Remove rotor(400-5) Remove key and front thrust plate(400-7).

Press bearing (400-G-11) off of spindle.

10. Secure angle head in vise and unscrew cap (404-2).

11. Remove from vise and tap on spindle with a plastic hammer. The

spindle assembly and spring washers (404-6) will slide out.

12. Clamp ats of spindle(405-17) in vise.

MODELS

45 RA

45 RAC

45 RAZ

45 RAS

13. Using a 9/64” T-Handle hex wrench unscrew (591028) screw. Using a

plastic hammer tap on O.D. of bearing cap, until it is free of bearing(404-3).

Note positioN of shims.

14. Press bearing (404-3) off spindle. Support bearing (404-7) and

press spindle through with 1/4” punch. This will remove spacer (405-15),

gear(405-10) and bearing. Remove key (404-4).

ASSEMBLY

1. Support front bearing(400-G-11) on drill block. Press spindle (404-14)

through bearing until it bottoms on shoulder.

2. Slide front thrust(400-7)over the spindle and onto front bearing.

3. Place key(400-10) into keyway in spindle. Slide rotor down over shaft.

4. Grasp rotor in vise snugly and replace pinion gear(405-10) and wrench

rmly.

5. Support bearing and pinion gear in downward position. Place ve

blades(400-6) in slots. Slip cylinder(400-2-G) over rotor. Install rear

thrust(404-19) locating cylinder pin in small hole of rear thrust plate (404-

19).

6. Place bearing (404-9) in rear thrust and tap into place with a suitable

bearing driver. Using snap ring pliers, place snap ring(404-39) in end plate

groove.

7. Support bearing(404-7) on inner race. Press spindle (405-17) through

bearing until it bottoms on shoulder. Install key (404-4) and line up with

keyway of ring gear(405-10). Support gear on inner diameter and press

spindle through. Slide spacer(405-15) on spindle.

8. Support threaded end of spindle and press on bearing(404-3). Tighten

screw (591028) into end of spindle. Press spindle assembly into cap(404-2).

Grease gear.

9. Install spring washers(404-6) (rouNded side dowN) into angle head(404-

1).

10. Install spindle assembly into angle head housing, secure in vise and

tighten cap (404-2).

11. Re-Locate angle head in vise-so that the motor can be installed verti-

cally.

12. Replace shim(404-20) exactly as it was originally installed.

13. Jiggle greased pinion assembly into angle head while turning spindle

(405-17)-so that gears mesh. Tap lightly on rear of motor to insure that is

fully seated.

14. Install mufer (402-134) inside exhaust deector (400-G-17-S). Place

O-ring(400-51) on motor case(400-G-1), then slide case (400-G-1) over

motor assembly and screw onto anglehead(404-1). The deector (400-G-

17) should be snug, but can be turned. Place a few drops of oil into motor

inlet. Replace backhead assembly (400-G-4).

15. (optioNal step): To check throttle valve, unscrew plug(869311) and lift

out spring and valve. Replace O-ring if worn.

16. Replace guard on tool.

17. CHECK RPM WITH TACHOMETER.TOOL MUST RUN AT OR BELOW

SPEED THAT IS STAMPED ON TOOL.

This manual suits for next models

4

Table of contents

Other Henry Tools Grinder manuals

Popular Grinder manuals by other brands

Scheppach

Scheppach TIGER2000S Assembly and operating instructions

Metabo

Metabo WXLA 24-180 Quick Original instructions

Hitachi Koki

Hitachi Koki G 10SR2 Safety instructions and instruction manual

Clarke

Clarke CAT146 Operating & maintenance instructions

Arc-Zone

Arc-Zone Neutra LTG Operation manual

Makita

Makita 9553NB instruction manual