Henry Tools 52RA Guide

The henry Tool Co., ManufaCTured by henry Tools

498 so. belvoir blvd., souTh euClid, oh 44121 u.s.a.

Ph: (216) 291-1011 or (800) 826-5257 ● Fax: (216) 291-5949 or (800) 303-2800

Email: da[email protected] ● WEbsitE: WWW.hEnrytools.com

General Safety and Maintenance Manual

Model

Number

Exhaust

Direction

Throttle

Type

Rated

Speed

Power

Output

Case

Material Weight Overall

Lenght

Body

Diameter

Working Air

Consump-

tion

Spindle Length & Thread

52 RA SIDE SAFETY

LEVER

4000-

8000

R.P.M.

2.0 H.P

1500 W

Alumi-

num

8.0 Lb/

.3.6 Kg

15 inch

381 mm

3.0 Inch

76.2 mm

40 cfm

(18.9 L/s)

T1-5/8-11 x 0.9 inch

(23mm)

T2-5/8-11 x 1.1 inch

(28mm)

CAPACITY

7 Inch (180 mm) or 9 Inch (230 mm) Type 27 Wheels

MODELS

52 RA

Henrytools 52RA right angle grinder

featuring a 2 HP motor

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 119 Revised 06/25/12

For additional product information visit our website.

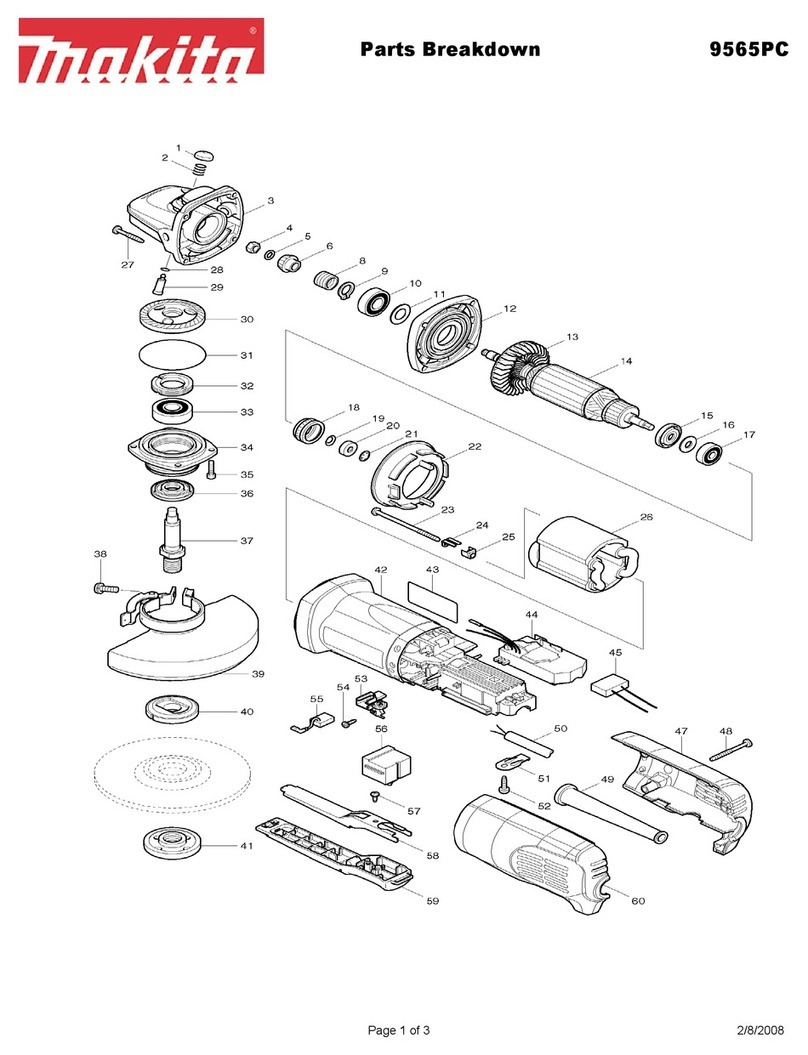

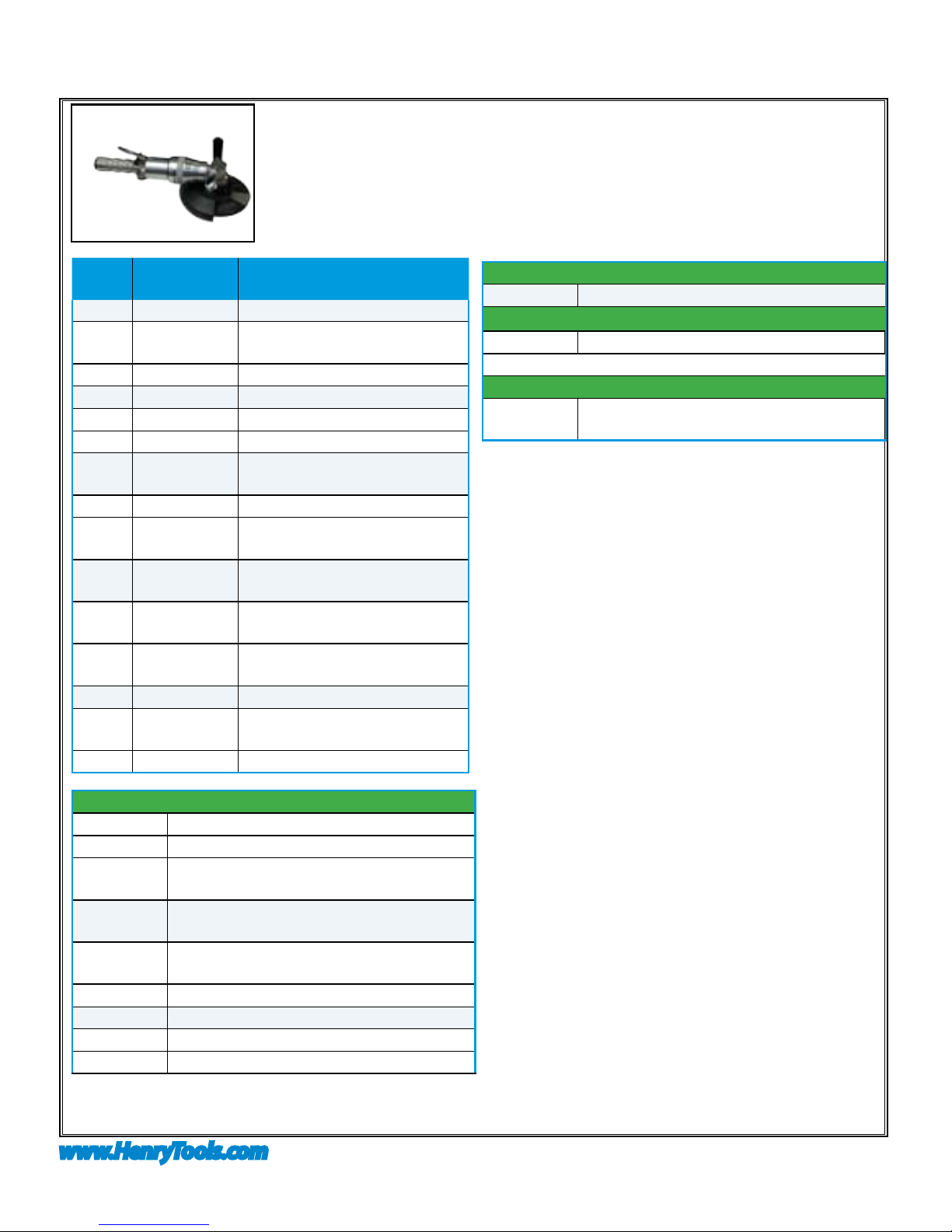

ITEM

NO. PART NO. DESCRIPTION

1 NRA-1 RIGHT ANGLE HEAD (52RA

Model)

2 NRA-24 LOCK BUTTON (52RA Model)

3 NRA-22 SPRING (52RA Model)

4 NRA-20 LOCK HOUSING (52RA Model)

5 NRA-21 LOCK PIN (52RA Model)

6 AA-NRA-20 ASSEMBLY COMPLETE

7 591164 CAP SCREW (Model 52RA)

8 NRA-9 BEARING (52RA Model)

ITEM

NO. PART NO. DESCRIPTION

9 NRA-15 SPACER (Model 52RA)

10 NRA-10 GEAR SET (sold as set) (Model

52RA)

11 NRA-43 KEY (Model 52RA)

12 NRA-16 BEARING (52RA Model)

13 NRA17A SPINDLE 5/8-11 X 0.9 (52RA

Model)

14 594030 O-RING (Model 52RA)

15 NRA-13 SPACER SHIELD (52RA Model)

16 NRA-14 SNAP RING (52RA Model)

17 500-25-G FITTING (52RA Model)

18 NRA-40 DEAD HANDLE (52RA Model)

MODELS

52 RA

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 120 Revised 06/25/12

For additional product information visit our website.

ITEM

NO. PART NO. DESCRIPTION

19 NRA-8 BEARING (52RA Model)

20 NRA-7 FRONT END PLATE (52RA

Model)

21 NRB-5 ROTOR (Model 52RA)

22 N6 ROTOR BLADE (4 are Req’d)

23 N2 CYLINDER (Model 52RA)

24 400-44 PIN

25 NV-3 REAR END PLATE (Model

52RA)

26 NV-9 BEARING (52RA Model)

27 NGOV-63 6000RPM GOVERNOR (Model

52RA)

28 NGOV-64 8000RPM GOVERNOR (Model

52RA)

29 NRA-17 SPINDLE 5/8-11 X 1.1 (52RA

Model)

30 N70 GOVERNOR SEAT (Model

52RA)

31 HTA-130 MOTOR CASE (Model 52RA)

32 NRA-27A EXHAUST DEFLECTOR (Model

52RA)

33 594228 O-RING (Model 52RA)

ACCESSORIES

1100-150 1-1/2”WRENCH

849259 5/8-11 SANDING PAD NUT

889271 5/8-11 4” SANDING PAD (MAX 12000

RPM)

849848 5/8-11 5” SANDING PAD (MAX 10000

RPM)

849848-R 3/8-24 5” SANDING PAD (MAX 10000

RPM)

849850 5/8-11 6” SANDING PAD (MAX 8500 RPM)

849913 5/8-11 7” SANDING PAD (MAX 8500 RPM)

849914 5/8-11 9” SANDING PAD (MAX 6500 RPM)

849269 DEP. CENTER WHEEL ADP. KIT

ACCESSORIES

1100-150 1-1/2”WRENCH

ASSEMBLIES

AA-NRA-20 SPINDLE LOCK ASSY

REPAIR KITS

510260-A REPAIR KIT INCLUDES: ALL BEARINGS ,

ROTOR BLADES AND SNAP RINGS.

MODELS

52 RA

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 121 Revised 06/25/12

For additional product information visit our website.

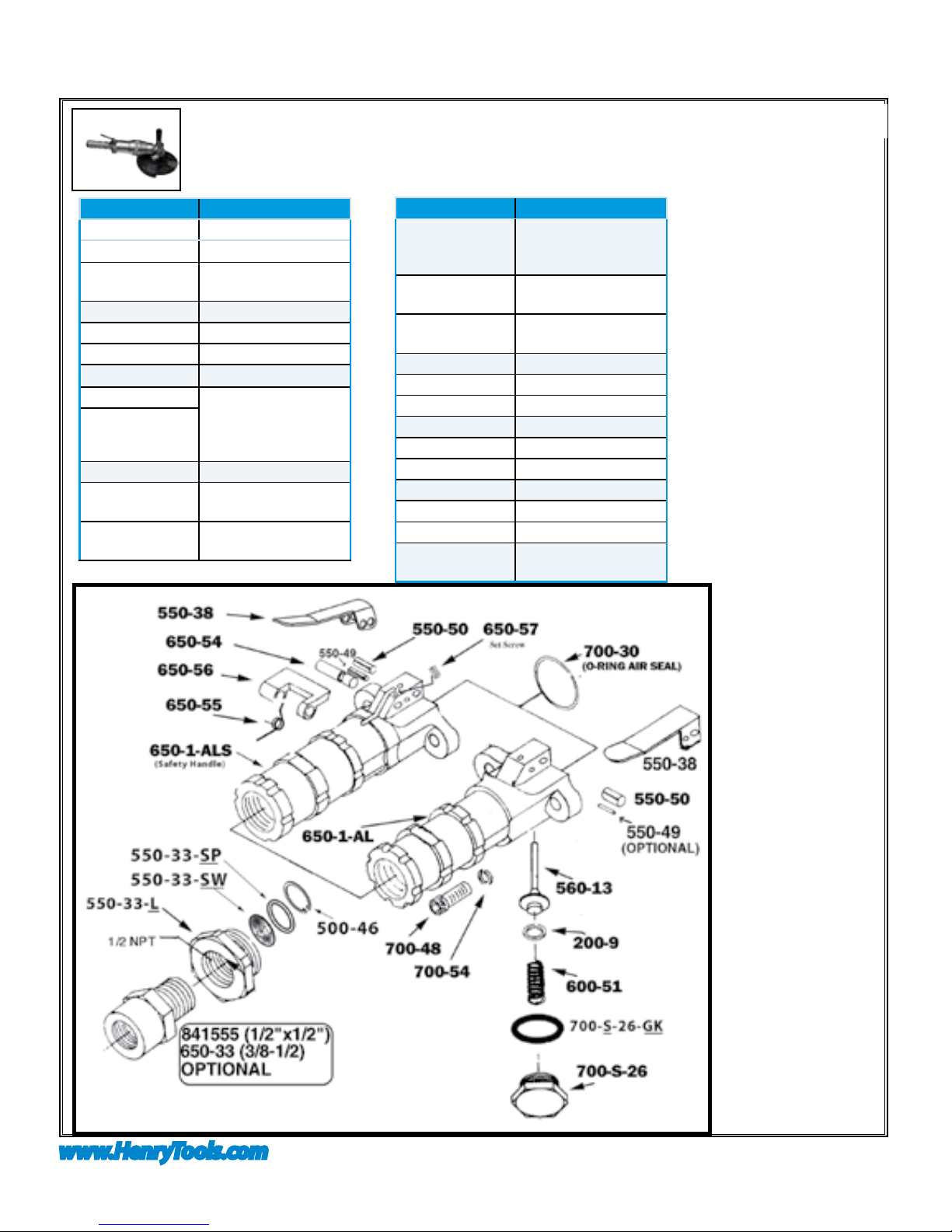

Part Number Description

200-9 O-Ring

500-46 Snap Ring

550-33-L Live Handle Adaptor

bushing

550-33-SW Screen Filter

550-33-SP Spacer

550-38 Lever

550-50 Lever Pin

560-13 Throttle Valve As-

sembly

with 200-9 O-ring

installed

600-51 Plunger Spring

650-1-AL Live Handle Body

(Non-Lockout type)

650-1-ALS Safety Lock Valve

Body(Bare)

Part Number Description

AA-650-1-AL Handle Assembly

(Complete)(Non-

lockout handle)

AA-650-1-ALS Safety Lock Handle

Assembly (Complete)

650-33 Screen

Bushing(1/2x3/8)

650-54 Safety Lock Pin

650-55 Safety Lock Spring

650-56 Safety Lock Lever

650-57 Set Screw

700-30 O-Ring

700-48 Cap Screw

700-54 Lock Washer

700-S-26 Plug

700-S-26-GK Gasket

841555 Screen Bushing

(1/2X1/2)

MODELS

52 RA

HENRY TOOLS, INC. Ph: (216) 291-1011 or (800) 826-5257

General Operators Instructions and Service Manual

www.HenryTools.com | Page 122 Revised 06/25/12

For additional product information visit our website.

Disassembly

1. Remove grinding wheels. Disconnect tool from

air supply. Remove spindle lock assembly (AA-

NRA-20).

2. Secure the tool in vise vertically with the angle

head (NRA-1) toward downward direction. Clamp

lightly onto dead handle boss on the side of angle

head. Using a wrench on ats of live handle,

unscrew motor housing from angle head. Remove

motor from case or angle head.

motor Disassembly

1. Place brass jaws on vice. Secure pinion gear

(NRA-10) in vise and remove governor (NGOV-XX).

Note: (Left-hand thread).

2. Clamp motor assembly into vise with output

pointed down. Clamp lightly onto the cylinder (N2)

and rear endplate (NV-3). Place a small punch into

the center of the motor spindle (NRB-5) where the

governor was removed. Tap lightly on end of punch

with a small hammer. This will drive the spindle

through the rear bearing (NV-9) (Be sure not to

damage threads on the rear of the spindle.) (DO

Not DROP spindle assembly when it becomes free.)

Remove everything from vise.

3. Remove rear bearing from rear endplate (NV-3)

with a suitable punch or screwdriver. Remove rotor

blades (N6) from rotor.

4. Place brass jaws on vise. Clamp front spindle as-

sembly in vise vertically with output in upward

direction. Clamp onto the large outside diameter

of the rotor. Remove pinion gear (NRA-10) with a

wrench. Remove assembly from vise.

5. Press output end of spindle through front bearing

(NRA-8) with an arbor press. Remove front bearing

support (NRA-8).

the angle heaD Disassembly

1. Remove snap ring (NRA-14) using snap ring pliers.

Remove spacer (NRA-13) and o-ring (594030). Lift

output spindle assembly from angle head.

2. Place brass jaws on vise. Clamp rmly onto threads

of output assembly. Unscrew and remove screw

(591164) from end of spindle. Remove from vise.

3. Support the spindle assembly vertically on a suit-

able drill block supporting under the rear bearing

(NRA-9). Press spindle out of rear bearing.

4. Slide the gear spacer (NRA-15) off rear of spindle.

5. Support the spindle assembly vertically on a suit-

able drill block. Press spindle through ring gear

(NRA-10). Grasp key (NRA-43) and remove from

key slot.

6. Support the spindle assembly vertically on a suit-

able drill block. Press spindle through front bearing

(NRA-16).

assembly

1. Make sure all parts are clean.

THE MOTOR REASSEMBLY

1. Place the front endplate (NRA-7) over the rotor

(NRB-5). (The recessed side of the endplate faces

the output of the motor assembly.)

2. Support the assembly with the output end up on a

suitable drill block. Press the bearing (NRA-8) onto

the shaft and up to the rotor.

3. Place brass jaws onto vise. Clamp front spindle assembly in vise

vertically with output in upward direction. Clamp onto the large out-

side diameter of the rotor. Thread on and tighten the pinion gear

(NRA-10) with a wrench. Remove assembly from vise.

4. With brass jaws still in vise, clamp motor assembly into vise verti-

cally with output down. Clamp onto the sides of the pinion gear.

5. Place four blades (N6) into blade slots of rotor. Place the cylinder

(N2) over the spindle/rotor with the locating pin pointing away from

the pinion gear.

6. Place the rear endplate (NV-3) onto the end of the cylinder. (Align

the smaller hole of the endplate over the pin on the cylinder.)

7. Place the rear bearing (NV-9) over the governor stem of the spindle

and drive into place with a suitable bearing driver.

8. Prior to reassembly inspect governor for gouges, nicks or dents.

Thread on and tighten the governor with a wrench (LEFT hand

thread). Remove assembly from vise.

the angle heaD reassembly

1. Support the bearing (NRA-16) on a suitable drill block.

2. Press the spindle (NRA17{A}) through bearing until it bottoms on

shoulder.

3. Install the key (NRA-43) into the key slot of the spindle.

4. Place the ring gear (NRA-10) over the spindle and key. Align the

key with the keyway of ring gear.

5. Support the spindle assembly vertically on a suitable drill block with

output toward downward direction.

6. Press the ring gear over the key and up to front bearing. (Take care

not to damage the teeth of the gear.)

7. Slide spacer (NRA-15) onto spindle.

8. Support the spindle assembly vertically on a suitable drill block with

output toward downward direction.

9. Press the rear bearing (404-3) onto end of spindle.

10. With brass jaws in vise, secure spindle assembly into vise vertically

with output toward downward direction. Clamp onto the threads of

the angle spindle.

11. Screw in and tighten screw (591164) into end of spindle. Remove

from vise.

12. Grease gear teeth with a lithium soap based, NGLI grade 2 grease.

13. Slide the spindle assembly into right angle head (NRA-1).

14. Install o-ring (594030) and spacer (NRA-13) in front of angle head.

Install snap ring (NRA-14) into groove in angle head housing.

Final stage reassembly

1. Install o-ring (594228) onto motor housing (NRA-130). Lightly oil

o-ring. Install exhaust deector (NRA-27A) onto motor housing.

2. Assemble live handle. Bolt live handle onto motor housing with 4

screws (550-48) and lockwashers (550-54).

3. Secure angle head assembly in vise with motor opening toward

upward direction. Clamp lightly onto the dead handle boss.

4. Install motor assembly onto angle head. Jiggle assembly until gears

align. Turning the output spindle will aid gear mesh.

5. Slide motor housing over motor assembly and tighten onto threads

of right angle head, using ats on live handle.

6. Install spindle lock assembly (AA-NRA-20). Replace guard on tool.

7. Check RPM with a reliable tachometer. Tool must run at or below

speed stamped on tool.

8. NEVER MODIFY ANY PART OF THIS TOOL AND

ITS ACCESSORIES!!! Serious injury can result.

MODELS

52 RA

Other Henry Tools Grinder manuals