HERBORNER pumpentechnik UNIBAD-X User manual

A - UX40 GB

UNIBAD

Bath water circulating pump

Operating manual Model - X

- XC

- X-PM

J.H. Hoffmann GmbH & Co. KG | Littau 3-5 | DE-35745 Herborn

+49 (0) 27 72 / 933-0 | +49 (0) 27 72 / 933-100

Copyright

The transfer and duplication of this document and utilisation

and communication of its content is prohibited, unless ex-

plicitly stated otherwise. Non-compliance with this stipulation

will result in compensation for damages.

All rights reserved.

Translation

Deliveries to countries of the EEA require the operating

manual to be translated in accordance with the language

spoken in the respective country.

If any discrepancies should occur in the translated text,

reference should be made to the original operating manual

(German) for clarification or the manufacturer is to be con-

tacted.

Herborn, 29-12-2009 ....................................................................

Signature

(Management)

EC Declaration of Conformity

Herborner Pumpenfabrik

J.H. Hoffmann GmbH & Co. KG

Littau 3-5, 35745 Herborn, Germany

Ms J. Weygand is authorised to create the technical documentation.

Herborner Pumpenfabrik

J.H. Hoffmann GmbH & Co. KG

J. Weygand

Littau 3-5, 35745 Herborn, Germany

We hereby declare that the

Bath water circulating pump

UNIBAD/ -XC/ -PM

complies with all pertinent provisions of the EC Machinery Directive 2006/42/EC.

The machine also complies with all pertinent provisions of the following EC directives:

- Directive 2004/108/EC, Appendices I and II

J.H. Hoffmann GmbH & Co. KG | Littau 3-5 | DE-35745 Herborn

+49 (0) 27 72 / 933-0 | +49 (0) 27 72 / 933-100

Table of contents

5

Table of contents

1 General information.................................... 6

1.1 Intended use ................................................. 6

1.2 Exploded view............................................... 7

1.3 Wear parts..................................................... 8

1.4 Technical specifications................................. 8

1.4.1 Model designation......................................... 8

1.4.2 Impellers........................................................ 9

1.4.3 Installation..................................................... 9

1.4.4 Shaft sealing ................................................. 9

1.4.5 Drive.............................................................. 9

1.4.6 Dimensions, weight, performance data....... 10

1.4.7 General data ............................................... 10

2 Safety ......................................................... 12

2.1 Notes / explanations.................................... 12

2.1.1 Machine identification.................................. 12

2.2 Integrated safety systems (optional) ........... 13

2.3 Connections on the pump ........................... 13

2.4 Safety measures ......................................... 14

2.5 Obligations of the operator.......................... 14

3 General hazard warnings ......................... 15

3.1 Dangers....................................................... 15

3.2 Danger zones on the pump......................... 15

3.3 Assembly, operation and maintenance

personnel .................................................... 15

3.4 Installation of replacement parts and wear

parts ............................................................ 15

3.5 Shut off procedures..................................... 16

4 Transport.................................................... 17

4.1 Scope of delivery......................................... 17

4.2 Transport and packaging ............................ 17

4.2.1 Delivery (including spare parts and re-

placement parts) ........................................... 17

4.2.2 Intermediate storage ................................... 17

4.3 Transport to the site of installation (by the

customer) .................................................... 17

4.3.1 Transport with a forklift truck ....................... 17

4.3.2 Transport with a crane ................................ 18

5 Installation / fitting .................................... 19

5.1 Installation................................................... 19

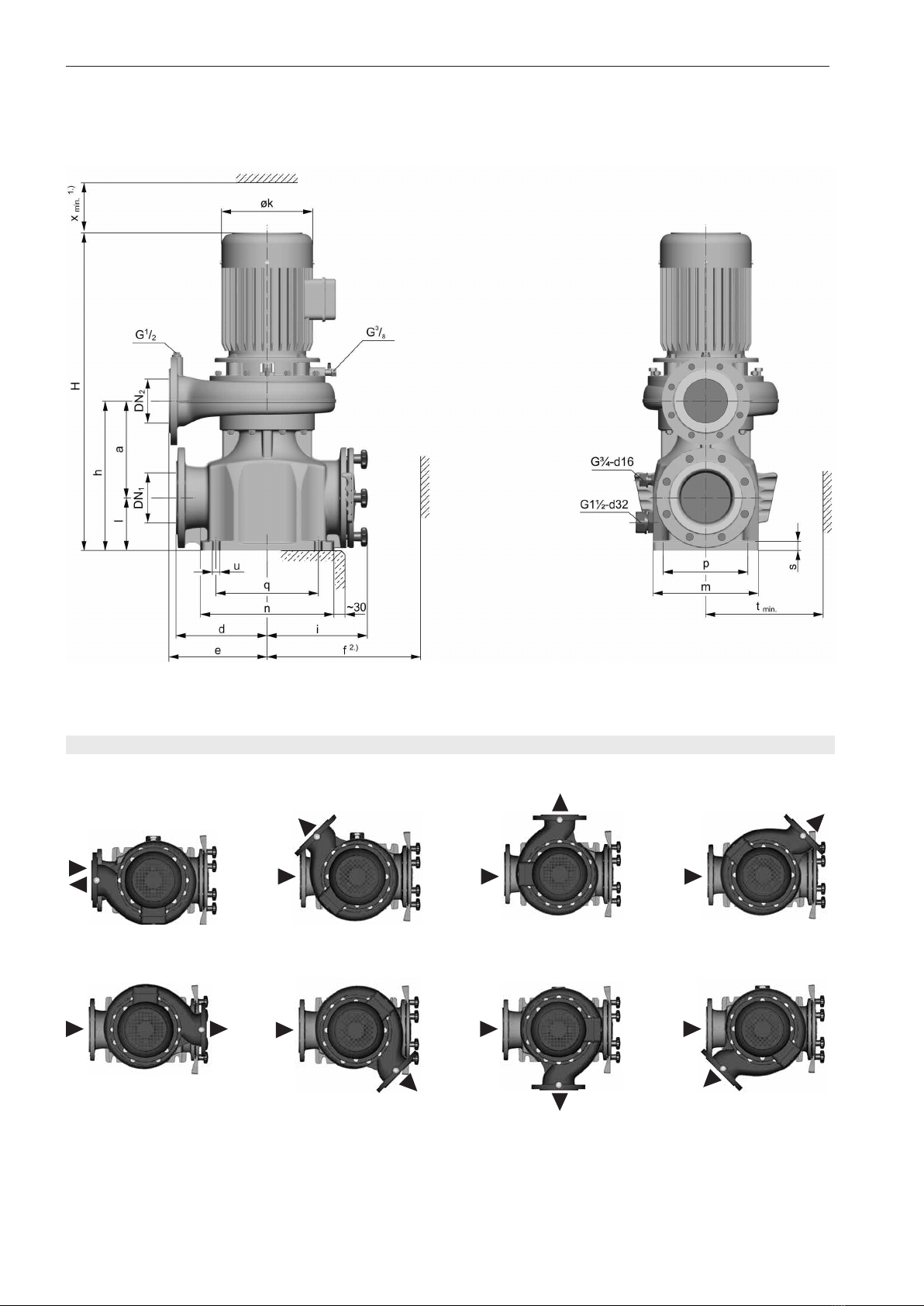

5.2 Dimensions ................................................. 20

5.2.1 Dimensions of X/X-PM model ..................... 20

5.2.2 Dimensions of XC model............................. 23

5.3 Technical specifications............................... 25

5.4 Electrical connection ................................... 26

5.5 Motor protection .......................................... 26

5.6 Direction of rotation check........................... 26

5.6.1 Change of direction of rotation.................... 27

5.7 Motor connection diagrams......................... 27

5.7.1 PTC thermistor connection.......................... 28

5.8 Frequency converter operation ................... 28

5.9 ETS X4........................................................ 28

5.10 Laying the pipes.......................................... 28

5.11 Soiling monitor of the filter strainer.............. 29

5.12 Frost protection ........................................... 29

6 Commissioning ......................................... 30

6.1 Mounting the screw connection................... 31

6.2 Adjusting the soiling monitor ....................... 31

6.3 Operating modes and connecting frequen-

cy................................................................. 31

6.4 Starting up................................................... 32

7 Maintenance / cleaning............................. 33

7.1 Maintenance................................................ 33

7.2 Maintenance instructions for prolonged

periods of inactivity...................................... 34

7.3 Bearing lubrication ...................................... 34

7.3.1 Relubrication unit ........................................ 34

7.3.2 Greasing intervals ....................................... 35

7.4 Seals ........................................................... 35

7.5 Cleaning...................................................... 36

7.6 Cleaning the filter strainer ........................... 36

7.7 Tightening torques for nuts and bolts.......... 37

7.8 Disposal ...................................................... 37

8 Disturbance / cause / trouble shooting... 38

9 Disassembly / assembly........................... 40

9.1 Disassembly................................................ 40

9.2 Assembly..................................................... 42

Table of figures

Figure 1a Exploded view (X/X-PM model) .................... 7

Figure 1b Exploded view (XC model)............................ 7

Figure 2 Name plate.................................................. 13

Figure 3 Connections on the pump ........................... 13

Figure 4 Transport with a crane ................................ 18

Figure 5a Dimensions (X/X-PM model)....................... 20

Figure 5b Dimensions (XC model) .............................. 23

Figure 6 Venting label................................................ 30

Figure 7 Screw connection label ............................... 31

Figure 8 Assembly of screw connection.................... 31

Figure 9 Screw connection with sealing cover .......... 31

Figure 10 Screw connection for pipeline ..................... 31

Figure 11 Dry running label......................................... 34

Figure 12 Relubrication label....................................... 35

Figure 13 Cleaning of filter strainer with sealing lip..... 36

Figure 14 Star handle label ......................................... 37

General information

6

Danger!

Pumping flammable or explosive liq-

uids is perilous.

Do not pump flammable or explosive

liquids.

Caution!

Pumping any liquid which chemically

attacks the pump material or contains

abrasive ingredients can destroy the

pump.

Use bronze or stainless steel as the

pump material for these media.

The media used for the intended operation of the pump

and the associated dangers are the responsibility of the

operator.

Important!

Intended use also extends to observing the operating and

maintenance conditions prescribed by the manufacturer.

1 General information

1.1 Intended use

The swimming pool water circulation pump UNIBAD with inte-

grated hair and fibre filter for dirt separation is the centrepiece

of modern circulation systems for the delivery and filtering of

swimming pool water, fresh water, brine, sea water, service

water, and other liquids contaminated by coarse materials.

It is used in indoor, outdoor, and adventure swimming baths,

water parks, and ice sports, recreation, and hotel facilities for

water slides, attractions, water treatment systems, fountains,

heat recovery systems, and industrial facilities.

Model UNIBAD

Bath water circulating pump

Model UNIBAD-XC

Energy-saving bath water circulating pump with water-

cooled motor (the loss heat of the motor is used to heat the

medium)

Type UNIBAD-PM

Energy-saving bathwater circulation pump in version with

PM motor (permanent-magnet motor) with extremely high

efficiencies

Each pump is solely intended for the purpose previously

specified. Any other application or applications extending

beyond the stated purpose or alterations made to the pump

without prior written agreement with the manufacturer is

not permitted. The manufacturer is not liable for damages

resulting from unintended use. The responsibility is solely

that of the user.

Notice!

Lack of safety equipment can damage the pump.

The pumping station must conform to the respective direc-

tives and all safety equipment must be installed and fully

operational.

Only then should the pump be operated.

General information

7

006

940

704

433

171

1.)

502

2.)

920

400.1

101

702

001

005.2

320.2

423

819

113

230

554

412.2

903

400.2

002

003

004

802

320.1

005.1

412.1

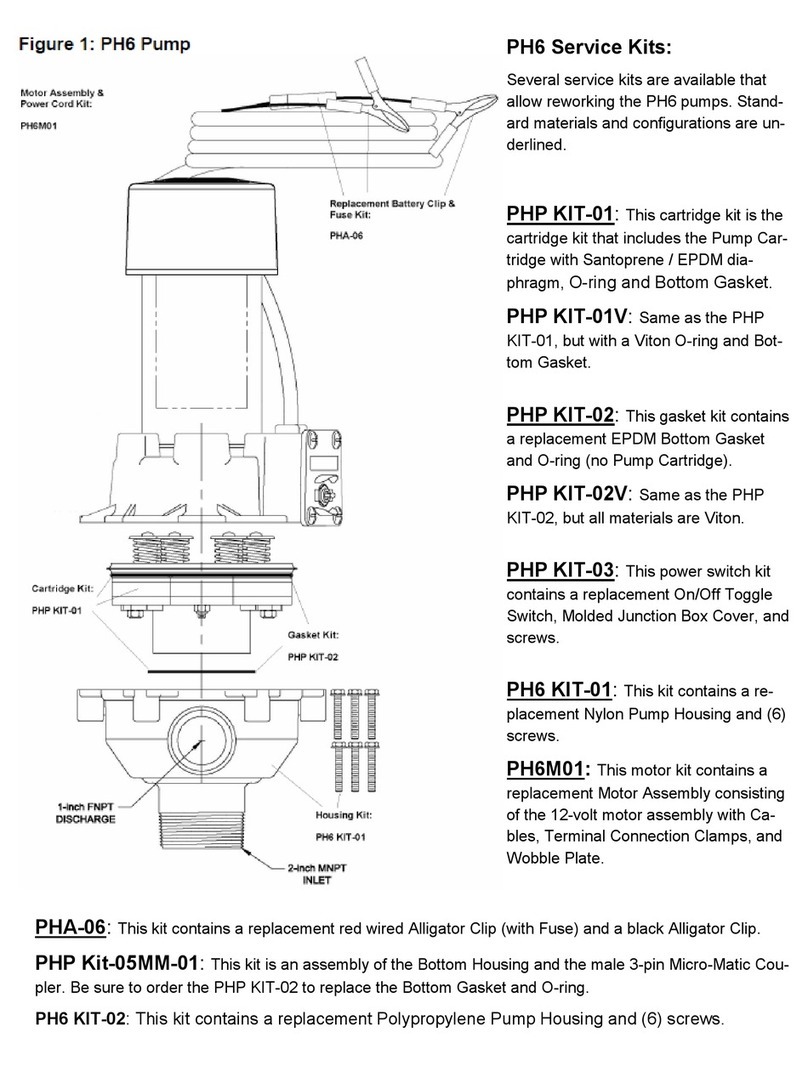

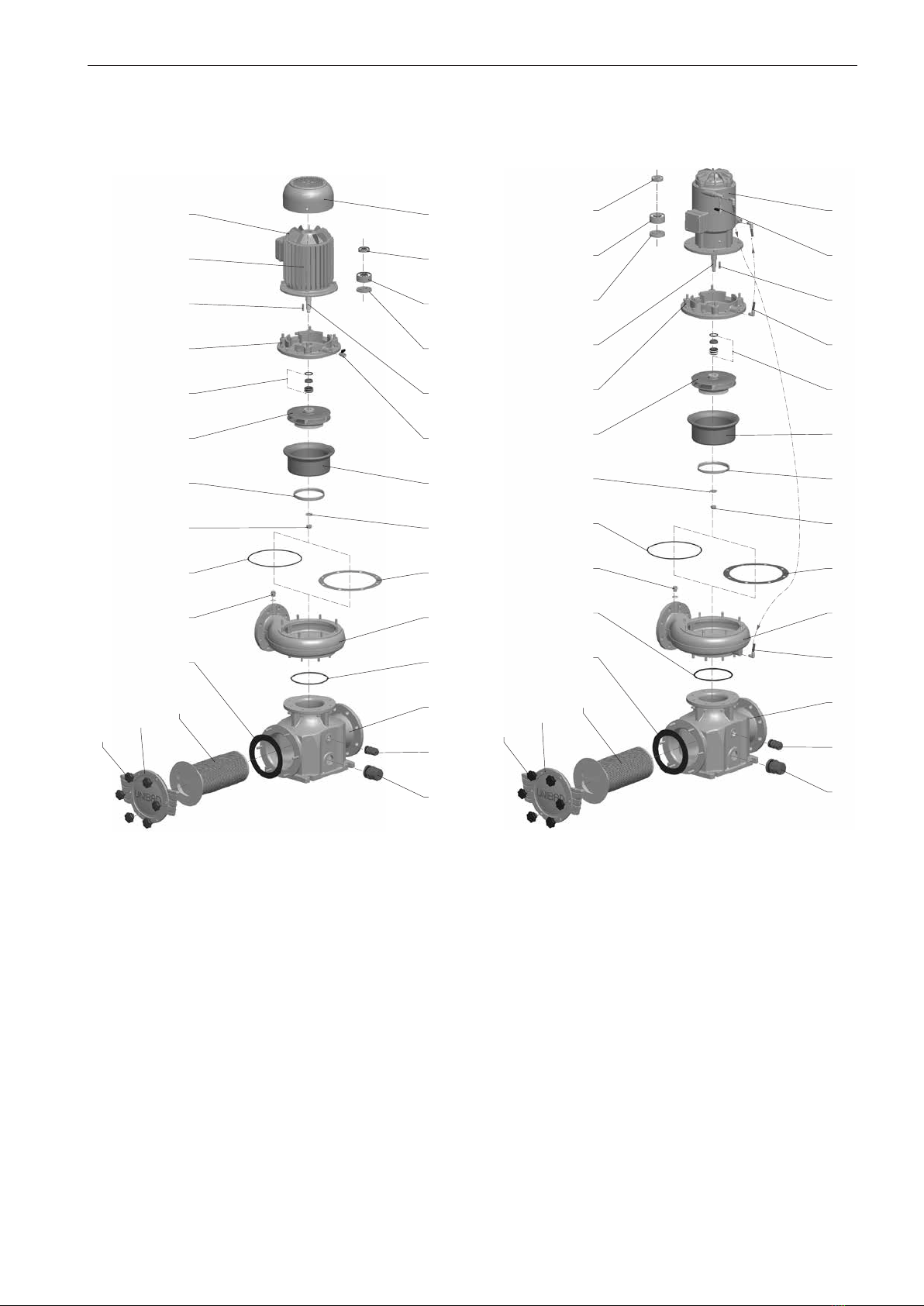

1.2 Exploded view

Model X/X-PM

Figure 1a Exploded view (X/X-PM model)

Model XC

Figure 1b Exploded view (XC model)

1.)

Only exists in case of design with screw propeller.

2.)

Only exists in case of design with closed multi vane impeller in material design W3, but not for 200-250/... and 200-270/....

320.

1

320.

2

423

819

006

171 1.

)

554

400.

1

101

412.

1

001

005.

2

802

940

113

433

230

502 2.)

920

412.2

903

002

003

004

832

831

005.

1

400.2

General information

8

Individual components

001 Filter casing

002 Filter strainer

003 Filter cover

004 Star handle

005.1 Screwed connection

005.2 Screwed connection

006 Ball valve

101 Pump casing

113 Intermediate casing

171

1)

Guiding ring

230 Impeller

320.1 Anti-friction bearing (non drive side)

320.2 Anti-friction bearing (drive side)

400.1 Gasket

400.2

3)

Gasket

412.1 O-ring

412.2 O-ring

423 Labyrinth ring

433 Mechanical seal

502

2)

Casing wear ring

554 Washer

702 Return pipe

704 Cooling water pipe

802 Block motor

819 Motor shaft

831 Fan

832 Fan hood

903 Screwed plug

920 Nut

940 Key

1.3 Wear parts

The specifications relating to the selection of wear parts are

based on the demand for a two-year operation in accordance

with DIN 24296.

Wear parts Number of pumps

(if available) 1 2 3 4 5 6-7 8-9 10-...

Impeller 1 1 1 1 2 2 2 20 %

Mechanical seal set 1 1 1 2 2 2 3 25 %

Anti-friction bearing set 1 1 1 2 2 2 3 25 %

Labyrinth ring 1 1 1 2 2 2 3 25 %

Casing wear ring 1 2 2 2 3 3 4 50 %

Seal set 2 4 6 8 8 9 12 150 %

1.4 Technical specifications

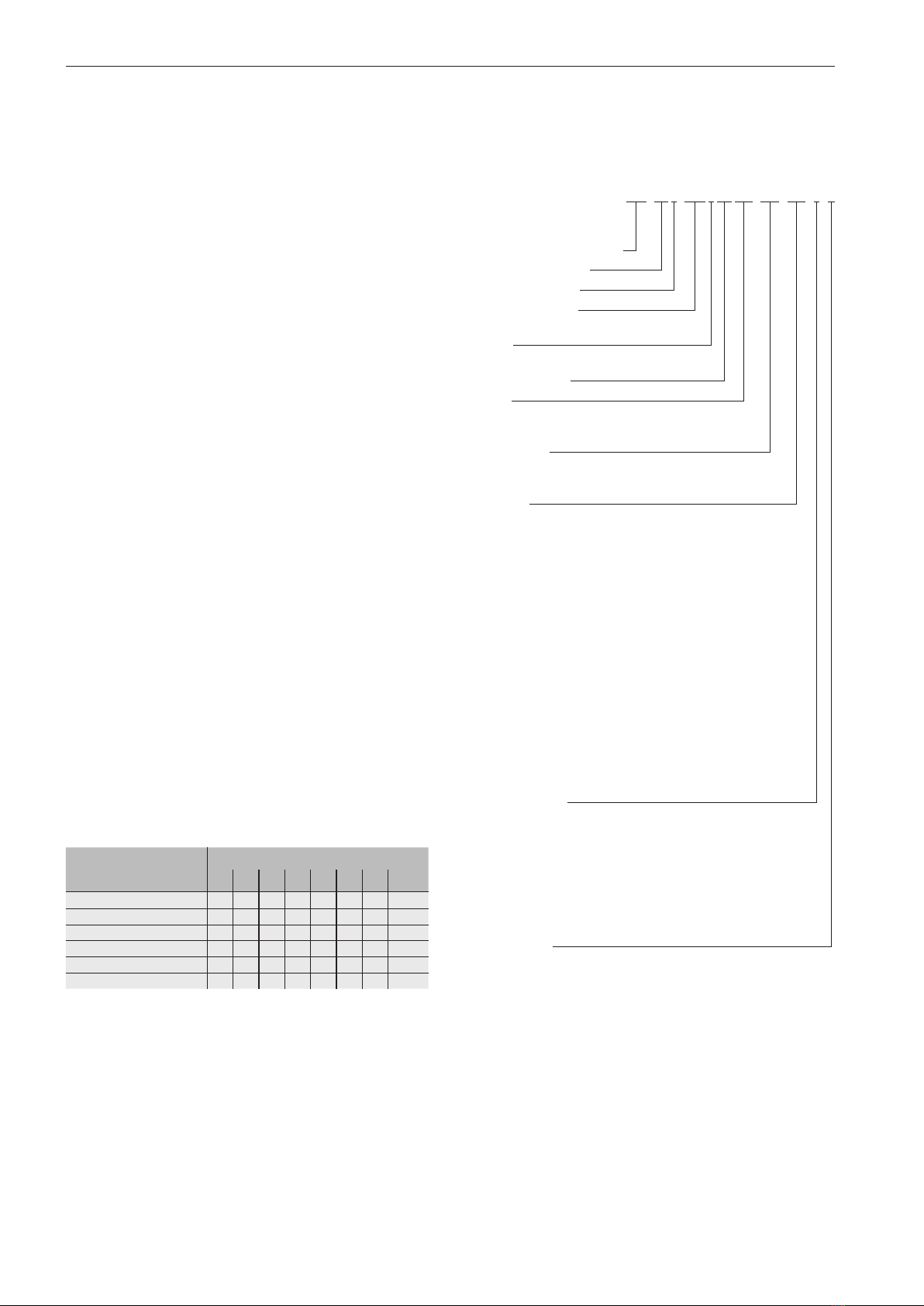

1.4.1 Model designation

Example:

150-270/0304SPXC-PM-W2-V-S

Nominal diameter of

pressure ange DN [mm]

Design dimensions

Hydraulic version

Motor rating [kW]

E.g.: 030 = 3.0 kW

Speed

4 = 1500 (60 Hz: 1800) min

-1

Impeller version

Model

X = standard

XC = Cooling jacket version

Motor model

= standard

PM = Permanent magnet motor

Materials

W0 = mixed materials

W1 = all castings manufactured from

EN-GJL-250

W2 = all castings apart from the impeller

manufactured from EN-GJL-250, impeller

manufactured from CuAl10Fe5Ni5-C

W3 = all castings apart from the impeller

manufactured from CuSn10-C, impeller

manufactured from CuAl10Fe5Ni5-C

W4 = all castings manufactured from 1.4408

W5 = all castings manufactured from

EN-GJS-400-15

W6 = all castings manufactured from 1.4439

W9 = Impeller manufactured from

CuAl10Fe5Ni5-C, intermediate casing

manufactured from CuSn10-C, pump

casing manufactured from EN-GJL-250

with epoxy resin hot powder coating

Flange position

V = front

VL = centred between the front and left

L = left

HL = centred between the rear and left

H = rear

HR = centred between the rear and right

R = right

VR = centred between the front and right

Construction

= standard

S = special construction

1)

Only exists in case of design with screw propeller.

2)

Only exists in case of design with closed multi vane impeller in material design W3, but not for 200-250/... and 200-270/...

3)

Only exists for filter strainer without sealing lip.

General information

9

1.4.2 Impellers

Open and closed multi vane impellers and

screw propellers (SP) for clean to slightly

soiled pumped media are used.

Large contaminant particles are removed by

the integrated hair and fibre filter.

1.4.3 Installation

The pumps are delivered in vertical installation:

Vertical installation of the pump

It is not permitted to install the pump with the

"motor facing downwards" for operational

safety reasons.

1.4.4 Shaft sealing

The shaft sealing on the pump side is effected in all models

via a maintenance-free mechanical seal, which is independ-

ent of the direction of rotation and made from wear-resistant

silicon carbide (SiC).

All motors are equipped with a special seal for splash-proof-

ing on the pump side.

Caution!

Dry running the pump will destroy the

mechanical seal!

Ensure there is adequate cooling and

lubrication for the sliding surfaces.

An existing ETS X4 permits monitoring of the mechanical

seal to protect it from dry running.

1.4.5 Drive

A three-phase motor with squirrel-cage drives the pump. The

motor is cooled by the dissipation of heat from the cooling

fins to the ambient air.

The motor in UNIBAD-XC pumps is also equipped with a

jacket. The pumped medium cools this and absorbs the

motor heat.

In the case of pumps of the type UNIBAD-PM, a synchronous

motor with permanent excitation for operating the frequency

converter drives the pump. Observe the operating instruc-

tions included in delivery!

Important!

Observe the limit temperatures specified in section 1.4.7

'General data'.

The exact motor data can be found on the name plate.

Caution!

Incorrect warming will damage the

three-phase motor.

Maintain the voltage tolerance of ±

10 % according to DIN EN 60034-1.

Motor data for model X/XC

Design IM B5

Motor connection Manufacturer-specific

Protection type IP 55

Speed 1500 (1800) min

-1

Frequency 50 (60) Hz

Connection ≤ 2.2 kW 230 5/ 400 3(460 3) V

Connection ≥ 3.0 kW 400 5/ 690 3(460 5) V

Insulation class VDE 0530 F

General information

10

Ambient temperature range for:

lower limit temperature: - 5 °C

upper limit temperature: + 40 °C

Density and viscosity of the pumped medium:

Density: max. 1000 kg/m3

Kinematic viscosity: max. 1 mm2/s (1 cST)

Customised solutions may differ from this standard data.

Power correction:

Reduce the power according to the specifications of the mo-

tor manufacturer if motors are used at ambient temperatures

> 40 °C or at altitudes > 1000 m above sea level.

A differing density or viscosity alters the hydraulic perform-

ance of the pump. Observe the motor performance with

these media.

Sound pressure level:

The sound pressure level dB(A) of the pump during cavita-

tion-free operation lies within the range of Qoptimal below the

limit values specified in EC Machinery Directive 2006/42/

EC.

Model X

50/60 Hz

P2 [kW] 1500/1800 min

-1

1.1/1.3 55/59

1.5/1.8 55/59

2.2/2.6 59/63

3.0/3.6 59/63

4.0/4.8 59/63

5.5/6.6 63/67

7.5/9.0 63/67

11.0/13.2 65/69

15.0/18.0 65/69

18.5/22.2 65/69

22.0/26.4 67/71

30.0/36.0 68/72

37.0/44.4 70/74

45.0/54.0 70/74

55.0/66.0 71/75

Motor data for model X-PM

Design IM B5

Motor connection Manufacturer-specific

Protection type IP 55

Speed 1500 min

-1

Connection 3 300 - 400 V

Insulation class VDE 0530 F

Customised solutions may differ from this standard data.

1.4.6 Dimensions, weight, performance data

The measurements, installation dimensions and weight de-

tails can be found in section 5.2 'Dimensions'. The instruction

documents and the name plate data specify the performance

and connection data of the respective pump type.

The performance verification of the pumps is performed ac-

cording to DIN EN ISO 9906 (Rotodynamic pumps - Hydraulic

performance acceptance tests), Class 2.

1.4.7 General data

Media temperature range for:

lower limit temperature: - 5 °C

upper limit temperature: + 60 °C

Caution!

In type UNIBAD-XC pumps, pumped

media < 15°C and > 40°C damage

the motor.

Connect another cooling circuit to the

motor.

General information

11

Model XC

50/60 Hz

P2 [kW] 1500/1800 min

-1

1.5/1.8 49/53

2.2/2.6 49/53

3.0/3.6 49/53

4.0/4.8 49/53

5.5/6.6 49/53

7.5/9.0 49/53

11.0/13.2 50/54

15.0/18.0 50/54

18.5/22.2 52/56

22.0/26.4 52/56

30.0/36.0 52/56

Model X-PM

P2 [kW] 1500 min

-1

1.1 52

1.5 55

2.2 55

3.0 55

4.0 56

5.5 61

7.5 63

11.0 63

15.0 65

18.5 65

22.0 67

30.0 67

37.0 70

45.0 70

55.0 71

Safety

12

The following signal words represent

Danger!

This indicates an imminent danger. If it is

not avoided it will result in death or the most

severe of injuries.

Warning!

This indicates a potentially dangerous situa-

tion. If it is not avoided it can result in death

or the most severe of injuries.

Caution!

This indicates a potentially dangerous situa-

tion. If it is not avoided it can result in slight

or minor injuries or damage to property.

Notice!

This indicates a potentially hazardous situa-

tion. If it is not avoided the product or items

in its vicinity may be damaged.

Important!

This indicates application tips and other

particularly useful information. It is not a

signal word for a dangerous or hazardous

situation.

2.1.1 Machine identification

The information contained in this operating manual is only

applicable to the pump that is indicated on the title page.

Stick the supplied name plate of the pump into the operating

manual or on the control panel. This will ensure the relevant

data is available at any time.

2 Safety

2.1 Notes / explanations

The following symbols represent

Warning of a hazardous area

Warning of hand injuries

Warning of dangerous electrical voltage

Warning of explosive atmospheres

Warning of a biohazard

Warning of hot surfaces

Prohibited for people with pacemakers

Command to wear protective gloves

Command to refer to the operating instruc-

tions

General information

Safety

13

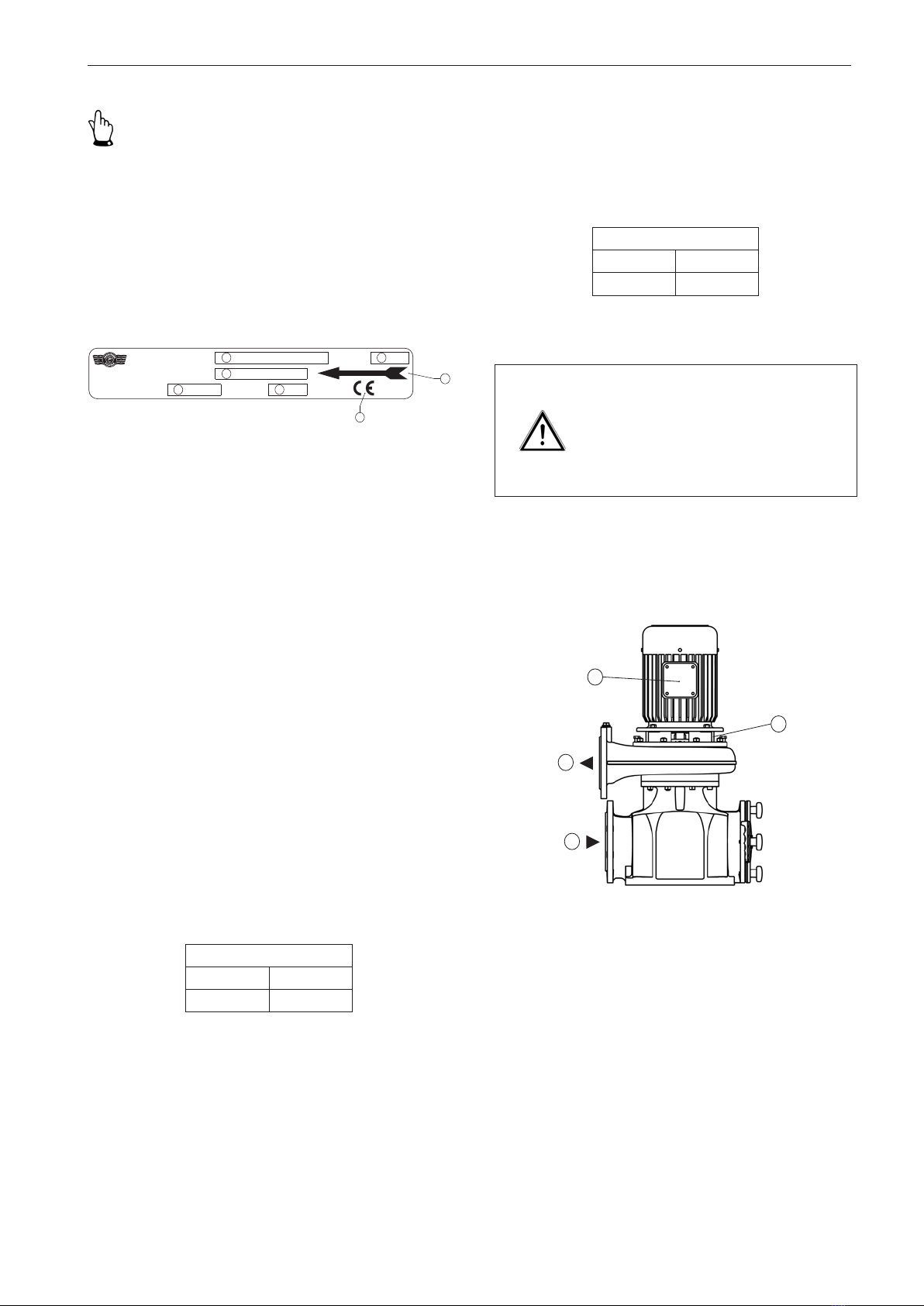

Figure 2 Name plate

Key to figure 2

1. Model designation

2. Year of manufacture/ month

3. Order No.

4. Nominal flow rate [m3/h]

5. Nominal head [m]

6. CE symbol

7. Observe the direction of rotation!

2.2 Integrated safety systems (optional)

Check the integrated safety devices in regular inspection

intervals j= annually.

The inspection methods applied here are:

S= Visual inspection, F= Functional check.

Winding protection

If the pump is also equipped with thermal winding protec-

tion with direct temperature monitoring, this switches off the

pump's motor if it starts to get too hot.

Inspection

Interval Method

j S, F

Important!

When making any inquiries and ordering spare parts

please make sure you specify the pump type and the order

number.

Also observe the name plate on the motor.

The name plate is attached to the fan hood or the motor

housing (UNIBAD-XC).

ETS X4

An existing ETS X4 (electronic dry running protection system)

that uses a vibrating fork sensor prevents the dry running

of the slide ring seal. This protects the functionability of the

pump.

Inspection

Interval Method

j S, F

Caution!

Incorrect warming will damage the

three-phase motor.

Do not decommission safety equipment

or change its mode of operation.

2.3 Connections on the pump

Figure 3 Connections on the pump

The following connections are available on the pump:

1. Inlet connecting flange

2. Outlet connecting flange

3. Electric connection (terminal box)

4. Venting

1.

2.

3.

4.

Auftrag-Nr.

Q

Bj./ Mon.

m

m/h

3

1

3

45

2

6

UNIBAD

Pumpe

Herborner Pumpenfabrik

J.H. Hoffmann GmbH&Co. KG

Littau3-5, DE-35745 Herborn

7

Safety

14

2.4 Safety measures

This operating manual is part of the machine and, as such,

must always be made available to operating personnel.

Please make sure that

- you observe the safety precautions it contains,

- you retain this operating manual for future use,

- you adhere to the frequency of inspections and control

measures.

The work described in this operating manual is specified in

such a way that enables

- a trained person to understand and im-

plement instructions associated with the

section 'Commissioning',

- a specialist to understand and implement

instructions associated with the sections

'Transport', 'Installation / fitting', 'Mainte-

nance / cleaning' and 'Disturbance / cause

/ trouble shooting'.

Important!

A trained person is understood to be a person who

- has been instructed by a specialist about the tasks they

are assigned and the possible dangers associated with

improper conduct,

- has received practical training, if necessary, and

- has been informed about the necessary protective equip-

ment and precautions.

Important!

According to EN 60204-1 a person is understood to be a

specialist if they

- are able to use their professional training, knowledge and

experience as well as knowledge of the relevant standards

to assess the work they have been assigned and

- are also able to identify any potential dangers.

2.5 Obligations of the operator

The operator is obligated to:

- instruct his/her operating and maintenance personnel with

regard to the pump's safety equipment and

- monitor compliance with the safety measures.

Important!

In the European Economic Area observe and comply with

- the national realisation of the framework directive (89/391/

EEC) with regard to the implementation of measures for

improving the protection of health and safety of workers

at work,

- as well as the associated specific directives and the direc-

tive (89/655/EEC), in particular, concerning the minimum

requirements for the protection of health and safety of

workers when using equipment at work and

- the occupational safety regulations.

The operator has to obtain the local operating licences and

observe the associated conditions.

In addition he/she also has to comply with the local statutory

provisions for

- the safety of personnel (accident preven-

tion regulations)

- the safety of operating equipment (protec-

tive equipment and maintenance)

- product disposal (waste management

law)

- material disposal (waste management

law)

- cleaning (cleaning agents and their dis-

posal)

- and the relevant environmental con-

straints.

Connections:

Observe the local regulations (e.g. for electrical connection)

for fitting, installation and commissioning.

General hazard warnings

15

3 General hazard warnings

3.1 Dangers

Warning!

Maintenance and repair work can

cause hand injuries.

Observe all of the safety precautions.

Observe the safety systems and safety precautions that are

described in this manual. The pump is operated by the control

elements or by the superordinate system. Keep the access

area free from any clutter while operating the pump in order

to ensure unrestricted access at all times.

3.2 Danger zones on the pump

A radius of approximately 1 m around the pump is designated

a danger zone for maintenance and cleaning work. The

control elements form the only operating area.

Caution!

Material escaping from the pump can

cause injuries.

Install or secure the pump in such

a way that the direction of pumping

is away from areas personnel may

frequent.

3.3 Assembly, operation and maintenance person-

nel

Assembly, operation and maintenance personnel are re-

sponsible for the transportation, fitting, installation, operation,

cleaning and reparation of the pump.

1. Only trained and authorised persons may

install and operate the pump.

2. Clearly define and observe the respon-

sibilities for operating the pump.

3. Observe the shut off procedures speci-

fied in the operating manual for all work

processes (operation, maintenance,

repair, etc.).

4. The operator should not impair the safety

of the pump.

5. The operator has to ensure that only au-

thorised persons work with the pump.

6. The user must notify the operator im-

mediately of any alterations to the pump

which affect the safety measures.

7. The operator may only actuate the pump

if it is in a perfect condition.

8. The operator has to provide the operat-

ing staff with the appropriate protective

equipment according to the statutory

requirements and the pumped medium.

3.4 Installation of replacement parts and wear parts

Replacement parts and accessories that are not supplied

by the manufacturer are unchecked and, as such, are not

approved. The installation and/or use of such products may

adversely affect the specified properties of your pump.

The manufacturer accepts no responsibility whatsoever for

any damage caused by the use of non-original parts and

accessories.

General hazard warnings

16

3.5 Shut off procedures

The following shut off procedure must be complied with

before conducting any maintenance, cleaning and/or repair

work (only by specialists).

Warning!

Electric current can result in death.

Disconnect the block motor (802) ac-

cording to the 5 safety rules.

When cleaning close any electrical

cabinets that are open to prevent dust

or water from entering.

The five safety rules are as follows:

1.Disconnect.

2.Secure against reactivation.

3.De-energise.

4.Earth and short-circuit.

5.Cover or shield any adjacent live parts.

Transport

17

Packaging for transportation by HGV

When the pump is transported by HGV it is packed and

secured on a transport pallet.

4.2.2 Intermediate storage

The freight packaging of the pump and the spare parts

are suitable for storage for a period of approximately 3

months.

Storage conditions

An enclosed and dry room with an ambient temperature of

5 - 40 °C.

4.3 Transport to the site of installation (by the cus-

tomer)

The pump should only be transported on a transport pallet by

specialist personnel in accordance with local conditions.

Warning!

An improperly secured pump can

cause severe injuries.

Make sure that lifting devices and stop

belts are adequate for the total weight

of the pump (see section 5.2 'Dimen-

sions').

If necessary, secure the pump during

transport using separate lifting acces-

sories.

Only set up the pump on a sufficiently

solid surface that is level in all direc-

tions.

4.3.1 Transport with a forklift truck

- The forklift must be designed to support

the weight of the pump.

- The driver must be authorised to operate

the forklift truck.

4 Transport

4.1 Scope of delivery

The detailed scope of delivery can be viewed in the order

confirmation.

4.2 Transport and packaging

The pumps are carefully checked and packed before being

shipped. However, damage developing during transport

cannot be excluded.

4.2.1 Delivery (including spare parts and replacement

parts)

Receiving inspection

Check the completeness of the order based on the delivery

note!

Damage

Check the delivery for signs of damage (visual inspection)!

Complaints

If the delivery has been damaged during transport:

- Contact the last shipping agent immedi-

ately!

- Keep the packaging (for possible review

by the shipping agent or for return ship-

ment)

Packaging for return shipment

If possible, use the original packaging and the original

packaging material.

If neither is available:

- Contact a packaging company with spe-

cialist staff if necessary.

Place the pump on a pallet (which must

be capable of supporting the weight).

- Please contact the manufacturer if you

have any queries with regard to packaging

and transport security.

Transport

18

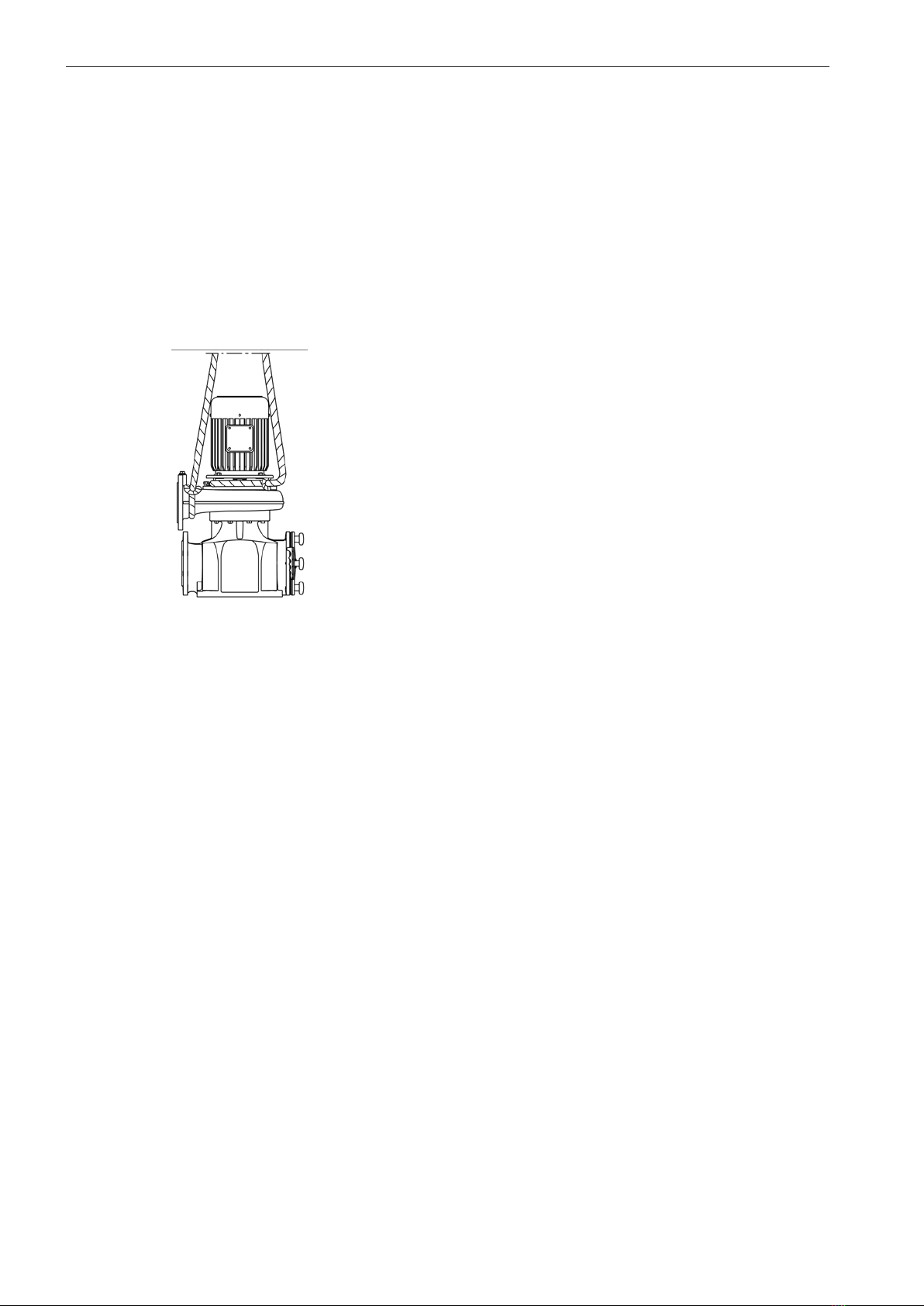

Figure 4 Transport with a crane

The measurements, installation dimensions and weight

details can be found in section 5.2 'Dimensions'.

4.3.2 Transport with a crane

- The crane must be able to support the full

weight of the pump.

- The operator must be authorised to oper-

ate the crane.

- Attach the pump to the crane using the

corresponding separate lifting accessories

(e.g. cross bar, stop belt, ropes, etc.) and

the respective attachment points.

Installation / fitting

19

5 Installation / fitting

5.1 Installation

Prepare the construction in accordance with the pump

dimensions.

Important!

Provide sufficient room for maintenance and repair proce-

dures!

Plan for sufficient room for opening the terminal box, for

the electrical connection, and for any existing frequency

converters.

The concrete foundation must

- have hardened,

- exhibit satisfactory rigidity (at least class

X0 according to DIN EN 206),

- have a horizontal and flat surface,

- be able to absorb vibrations, effects of

force and impacts and

- be dimensioned in such a way that the star

handles (004) on the filter cover (003) can

be turned by hand.

Only then should the pump be installed.

The connection flanges must be perfectly aligned and

screwed in such a way that prevents leakage. The seals

must be resistant to the pumped medium.

Caution!

Incorrect warming will damage the

three-phase motor.

Ensure there is an adequate supply of

cooling air during operation (except for

UNIBAD-XC models).

In order to prevent transferring vibrations to the building

and the pipeline system it is recommended to install pipe

compensators and vibration dampers.

Caution!

Injuries may be caused when installing

the pump.

Observe the safety regulations and

the generally recognised "codes of

practice".

Installation / fitting

20

Flange position

3)

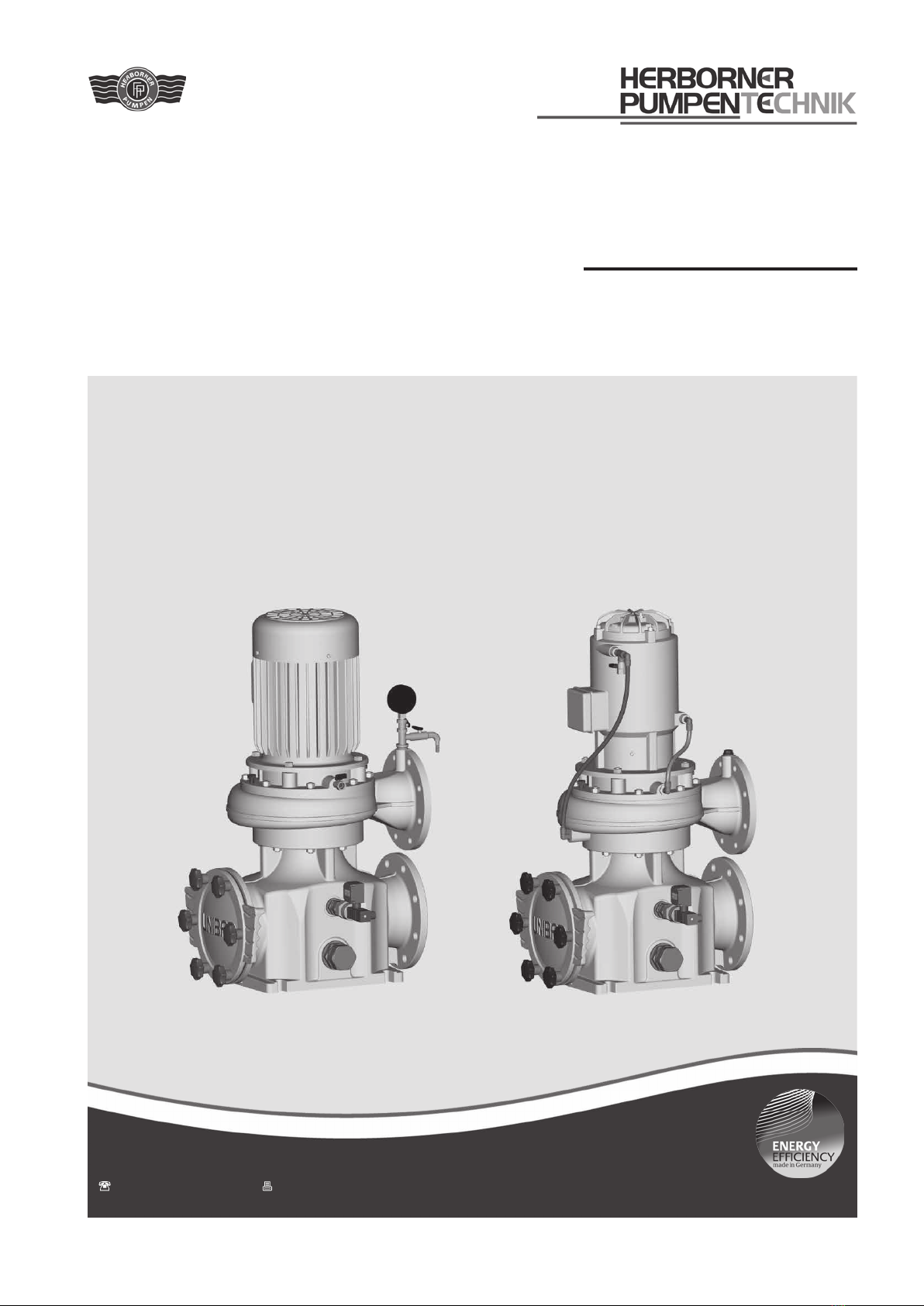

5.2 Dimensions

5.2.1 Dimensions of X/X-PM model

1.) When dismounting the motor ensure there is sufficient room for

the lifting device.

2.) Main controlling dimensions of filter strainer

Figure 5a Dimensions (X/X-PM model)

Figure V Figure L

Figure VR

Figure VL Figure HL

Figure H Figure HR Figure R

3.) The terminal box alignment may vary in the case of the design

with frequency converter.

Flange connection dimensions according to DIN 2501 PN 10

Dimensions with integrated frequency converter on request.

This manual suits for next models

2

Table of contents

Other HERBORNER pumpentechnik Water Pump manuals

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS SE2D3 Installation, operation and maintenance manual

GORMAN-RUPP

GORMAN-RUPP SM SERIES manual

Graco

Graco ChemSafe 307 Instructions - parts

Macnaught

Macnaught OKT583-1-001 instruction manual

Graco

Graco SaniForce Operation

Ribimex

Ribimex PRPVC1100CI/1 User and maintenance manual

WITA

WITA Delta Plus UE 70A-XX PWM TRANSLATION OF THE ORIGINAL INSTALLATION AND OPERATING INSTRUCTIONS

Makita

Makita DVP181ZK instruction manual

Sicce

Sicce Voyager 2 instruction manual

Grundfos

Grundfos ALPHA 26-99 Installation and operating instructions

SKF

SKF Lincoln OCL-M-G Series Assembly instructions

Jilong

Jilong JL29P423NG manual