herdstar MicroZone MPS100 Guide

Installation Manual

10/31/2014

0-10V Automatic Lamp & Mat Heating Control

Installation & Operation

Installation Manual

2

1400 Madison Ave, Suite 504 Mankato, MN 56001

PH: 507-344-8005 FAX: 507-344-8009

www.herdstar.com

Table of Contents

Installation Overview....................................................................................................................3

Mounting and Wiring....................................................................................................................3

Conduit and Connections.............................................................................................................3

Module Installation.......................................................................................................................4

Wiring/Setup ................................................................................................................................4

Wiring Multiple MPM100 Power Modulators into a System..........................................................4

Wiring MPM100 Power Modulator ...............................................................................................6

Wiring Instructions .......................................................................................................................7

Specifications...............................................................................................................................8

Service.........................................................................................................................................9

MicroZone is a trademark of HerdStar LLC.

Copyright © 2014 HerdStar LLC. All rights reserved.

Printed in the USA

Installation Manual

3

Installation Overview

This section covers the mounting and wiring of the MicroZone system. Anyone responsible for

programming and operating the MicroZone should also read the MicroZone Operations Manual.

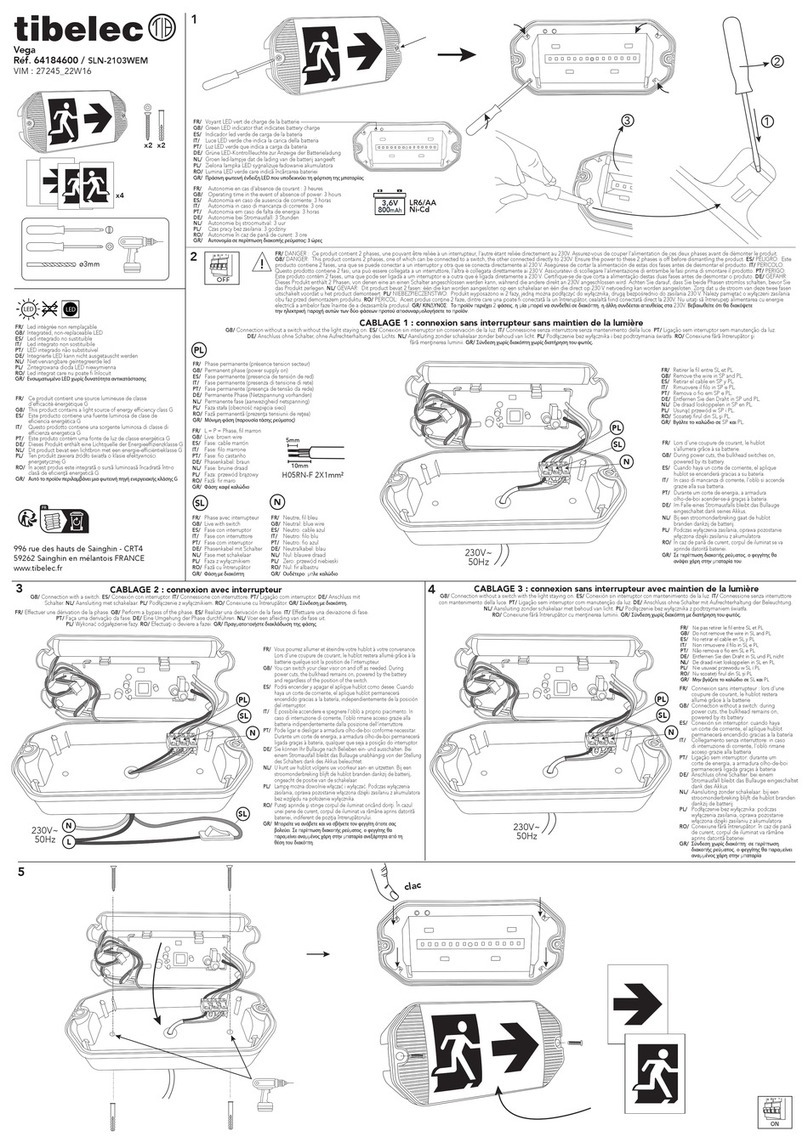

There are two symbols commonly used throughout this section:

This symbol means the text describes steps that involve going near terminals with

potentially deadly voltage. Always shut off power to all MicroZone modules and all

attached devices before opening the cover.

This symbol means the text has extra importance since it is describing the importance

of a feature or explaining a step to which you should pay close attention to avoid

problems.

Mounting and Wiring

Mount the MicroZone MC110A control module indoors where the temperature remains between 0

degrees Fahrenheit (- 17 degree Celsius) and 105 degrees Fahrenheit (40 degrees Celsius).

Place the controller away from motors and relays/contactors that switch high current.

Do not install it in the same room where the animals live since the air tends to be corrosive to

electronic circuits. A separate room or control office is a preferred location.

Use the mounting holes on the enclosures for mounting the modules. Before you drill holes into

the enclosure, mark their locations and make sure that you do not drill into circuit boards and

cables.

Unless absolutely necessary, do not remove the circuit boards. They are static-sensitive

and should always be handled with appropriate grounding and electrostatic precautions.

Always remove power from the MicroZone modules and controlled devices before

removing any MicroZone module covers or servicing any heating device.

Conduit and Connections

To avoid electrical shorts or damage due to moisture, you should

never run conduit openings through the top of the box. Conduit

and hubs should be corrosion-resistant plastic or fiberglass. Use

only liquid-tight strain-relief connectors to bring wires into the

box.

Installation Manual

4

Module Installation

For trouble-free operation, follow these simple installation guidelines:

Electrical wiring used to connect the MicroZone modules must meet all state and local

regulatory requirements. Wire rated for 600 volts (minimum) is recommended.

Standard electrical conduit or raceways can be used to route wiring for the MicroZone

modules.

Do not install the modules in the same room where the animals live. A separate room or

hallway is a preferred location.

Do not install the modules where they will be subjected to harsh chemicals.

When fastening the covers to the units, be sure to only compress gaskets to ½ their original

size. This will result in a better seal to repel any moisture or dirt that may get into the units

and prevent normal operation.

Wiring/Setup

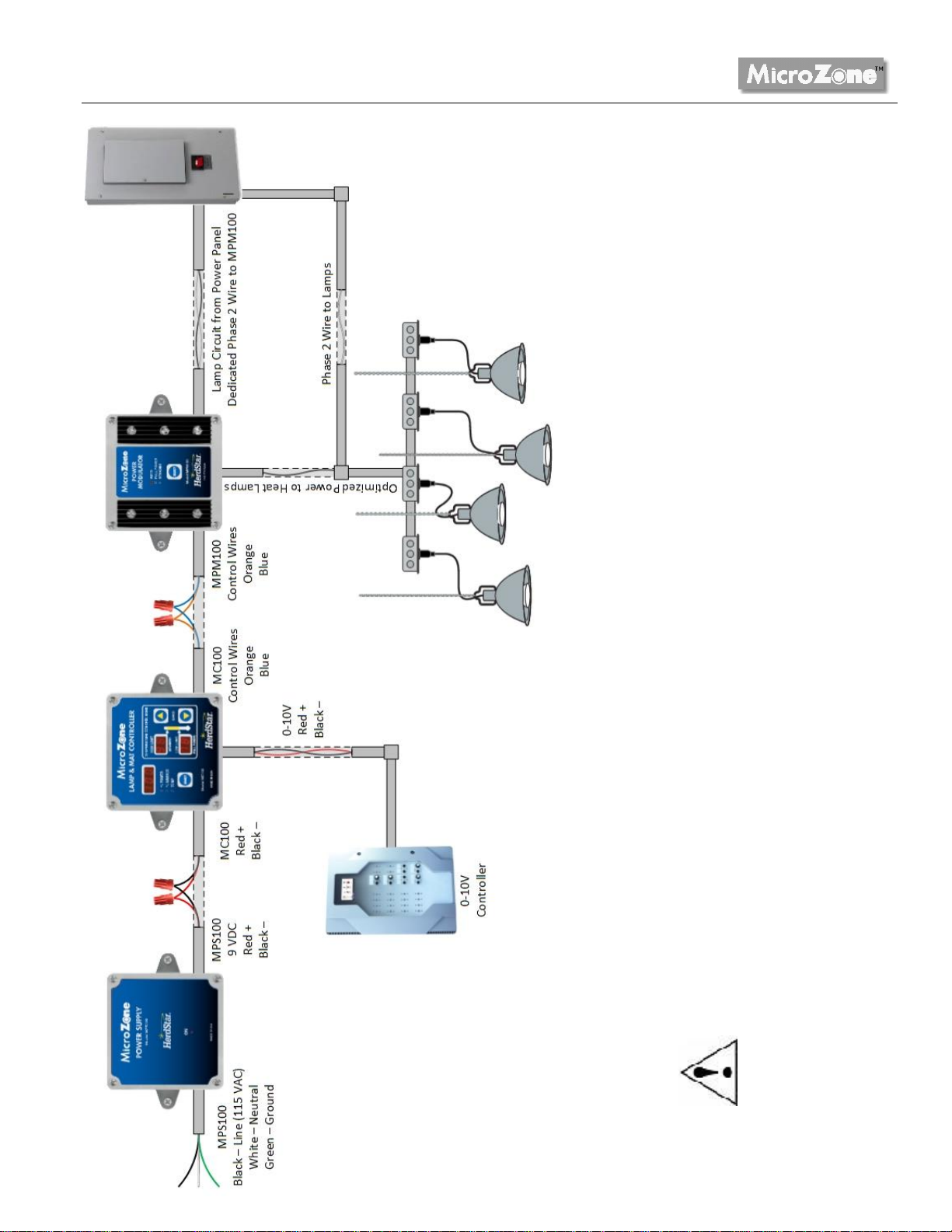

Below is a simplified diagram to show how the MicroZone units interconnect for a 120V

installation. A wiring diagram for 240V installation is on the next page. A qualified electrician can

easily wire the system with standard (600V-rated) wire.

Installation Manual

5

NOTE: To ensure proper operation of your MicroZone system, a dedicated Phase 2 wire must be run to the

Modulators (MPM100’s). This will prevent load current on the Phase 2 wire from interfering with proper

operation of the MPM100 modulator.

(For 120V operation, Phase 1 is the 120V hot line and Phase 2 is the neutral line.)

Installation Manual

6

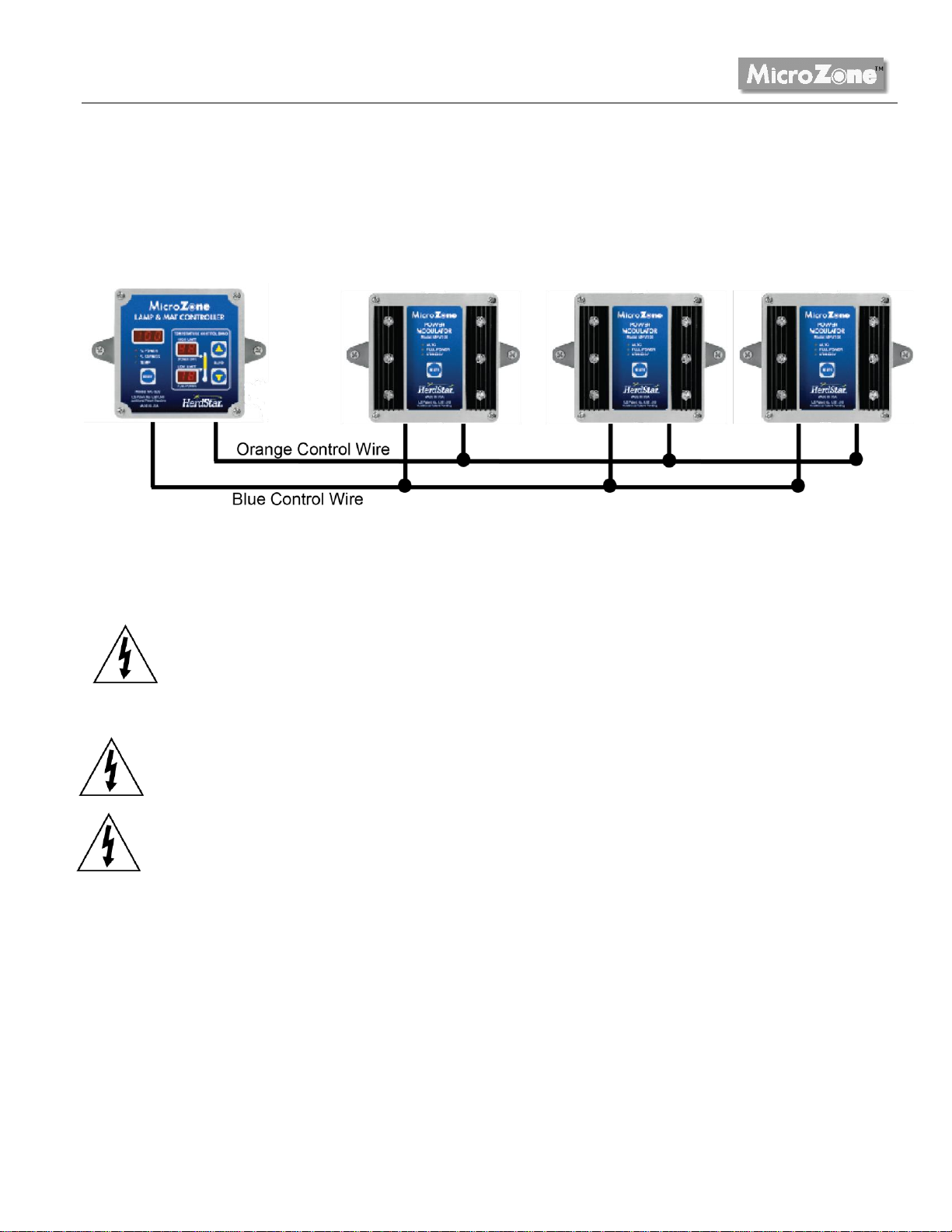

Wiring Multiple MPM100 Power Modulators into a System

When wiring multiple MPM100 modules to a MC110A control unit, connect the orange and blue

control wires together in parallel, as shown in the diagram below. You can connect up to twelve

power modulators to a single MC110A control unit. Each power modulator will have its own

heating device circuit wiring.

Wiring MPM100 Power Modulator

Ensure power is removed from the power distribution panel before wiring in the heating

device feed circuit.

Ensure the power modulator (MPM100) and heating device supply circuits are properly grounded.

Always remove power from the MicroZone modules and controlled devices before

removing any MicroZone module covers.

Note that line voltages are still present when STANDBY is selected on units wired

for 240V operation.

Installation Manual

7

Wiring Instructions

MPS100 Power Supply

The power supply (MPS100) requires an input of 115 volts AC, 50/60 Hz. Using 14-16

gauge wires connect AC power to the BLACK (LINE), WHITE (NEUTRAL), and GREEN

(GROUND) power supply wires.

MC110A Control Unit

Matching wire color, connect the power supply RED +9VDC and BLACK -9VDC wires to

the MC110A control module’s RED and BLACK 9-12 VDC input wires.

Matching wire color, connect the MC110A control module’s ORANGE and BLUE control

wires to the MPM100 power module’s ORANGE and BLUE control wires. See the Wiring

Multiple MPM100 Power Modulators into a system section above for more information

MPM100 Power Modulator

Connect the MPM100’s (BLACK) wire to the power panel Phase 1.

Connect the MPM100’s (WHITE) wire to Phase 2 of the power panel with a dedicated wire.

Connect a wire from Phase 2 of the power panel to Line 2 of the heating devices.

Connect the MPM100’s LOAD (RED) wire to the L1 line of the heating devices.

NOTE: To ensure proper operation of your MicroZone system, a dedicated wire must be run

from the load center Phase 2 to the WHITE wire of the MPM100 modulators. This will prevent

lamp load current on Phase 2 from interfering with proper operation of the MPM100 modulator.

(For 120V operation, Phase 1 is the 120V hot line and Phase 2 is the neutral line.)

Installation Manual

8

System Setup / Operation

Initial System Configuration

New MicroZone installations require a one-time system configuration procedure before use. In this mode

you can change whether the unit is connected a heat lamp or a heat mat.

Changing System Configuration / Displaying Software Revision

1. On the MC110A Controller, press and hold the SELECT key for

approximately 8 seconds (“H L” will be displayed above the SELECT key).

2. Press the UP or DOWN buttons to select between “HL” for heat lamps

and “HP” for heating pad (mats).

Troubleshooting

Common problems include incorrect wiring, tripped circuit breakers, burned out heat lamps or mats,

damaged power cords, etc. Internal diagnostics of the unit can detect other problems as follows:

Flashing “888” displayed –The MC110A needs to be returned to the factory for repair.

Flashing AUTO indicator –Communications between the Controller MC110A and the Modulator

have failed. The communications wiring may have been damaged or become disconnected.

Intermittent AUTO Indicator –The power modulator has detected a short circuit. When this

happens the power modulator will immediately turn off the output power, and after a 5 second

delay, slowly re-apply power. If the short circuit condition remains, the output power is turned off

and the cycle repeats until the condition is corrected. This feature protects the MicroZone modules

from a catastrophic failure. When infrared lamps are initially plugged in, or supply circuit

breaker turned on, the high surge current may cause this error code to be momentarily

displayed.

Resetting to Factory Default Settings

To restore your MicroZone to its factory default settings, turn off power to the MC110A controller. While

holding the SELECT key on the controller, reapply power to the system. The default settings will be

restored.

Installation Manual

9

Specifications

Operating Environment: 0° F to 105°, 10 to 95% RH (indoor use only)

MPS100 MicroZone Power Supply

Input Voltage: 120VAC, 0.1A, 50/60Hz

Output Supply: 200mA max output at 9 VDC

Output Capacity: Maximum of 5 MicroZone Controllers within 200 feet using 18AWG, two-

conductor wire.

MC110A MicroZone Controllers

Input Power: 9VDC

Temperature Specifications: +/- 2 degrees Fahrenheit at 30’

+/- 2.5 degrees Fahrenheit at 2000’ using 22AWG two-conductor cable

+/- 2.5 degrees Fahrenheit at 5000’ using 18AWG two-conductor cable

Communications Output Capacity: Maximum of 12 MPM MicroZone Power Modulators within 500

feet using 18AWG two-conductor wire.

MPM100 MicroZone Power Modulator

Input Power: 120/240VAC, 16A Maximum

Load Rating: 0-120VAC or 0-240VAC (2kW@120V or 4kw@240V Maximum)

Load Type: Resistive or Incandescent

Electrical protection: Short circuit, overload and voltage surge

Noise filter: FM radio filter

Enclosures: Weather tight (approximately 4” x 4” x 2”)

IMPORTANT:

Do not exceed the listed Load Rating and Operating Environment limits, or attempt to use the

MicroZone as an electronic speed control for electric motors.

Service

For assistance, make sure you have checked the parameters on the MicroZone. If you still need

assistance, contact:

1400 Madison Ave, Suite 504 Mankato, MN 56001

PH: 507-344-8005 FAX: 507-344-8009

www.herdstar.com

This manual suits for next models

2

Table of contents

Popular Lighting Equipment manuals by other brands

STERNO HOME

STERNO HOME GL33600 instructions

Welch Allyn

Welch Allyn LS200 Procedure Light owner's manual

Quasar Science

Quasar Science Rainbow 2 quick start guide

Photoflex

Photoflex LS2205 Assembling

Gama Sonic

Gama Sonic 20B50033 instruction manual

LUMENWERX

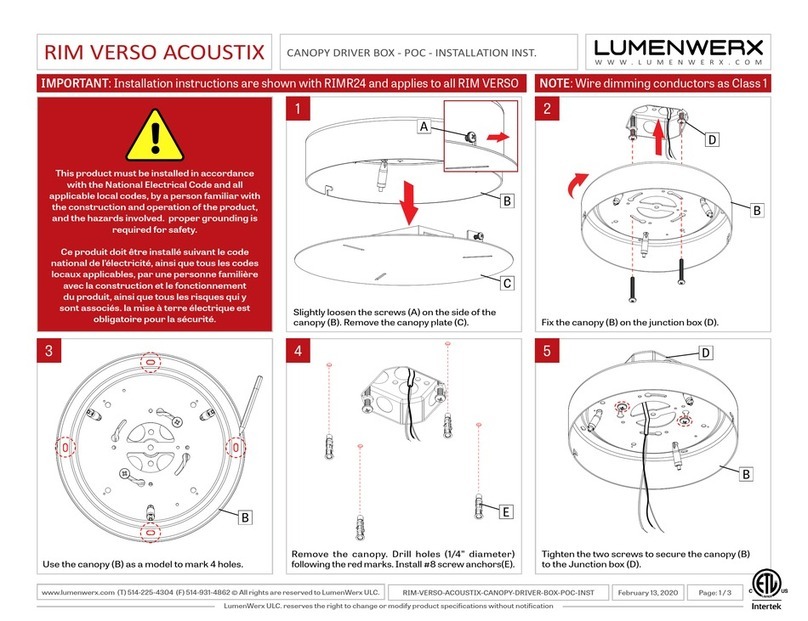

LUMENWERX RIM VERSO ACOUSTIX installation instructions