Herida Healthcare Argyll II HH/P09 User manual

1 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

Herida II

NB: Please ensure this document is fully read & understood

by the Clinician / Carer / Service Engineer prior to use.

User & Full Service Manual

Pressure Relieving / Alternating Air Mattress & Pump

Pump Model: HH/P09 Mattress Model: HH/T04

2 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

3 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

CONTENTS

SAFETY………………………………………………………4

INTRODUCTION………………………………………….…5

Product Description

Application

Contra indications

Working Principle

OPERATION………………………..………………………..6

Static Mode

Alternating Mode

Profiled Bed –Clinical Considerations

Installation

Safety Instructions

Pump Operation

Mattress & Pump Characteristics

MAINTENANCE……………………………………………..10

Cleaning

Maintenance & Repair

Storage

Transportation

Other Considerations

Parts & Accessories

Mattress

P09 Pump

ROUTINE CHECKS………………………….……………..13

Mattress

P09 Pump

WARNINGS & SYMBOLS………………………………....15

TROUBLE SHOOTING……………………………………..16

COMPANY INFORMATION…………………………….….17

4 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

SAFETY

Before you connect the system pump to a mains socket, read carefully all the installation

instructions.

This system has been designed to comply with regulatory safety standards

including:

•EN 60601-1 / Class I Medical Device

For your own safety and the safety of the equipment always take the following

precautions:

•Keep the pump away from sources of liquids.

•Do not expose the system, especially the mattress, to naked flames, such as cigarettes etc.

•Do not store the system in direct sunlight.

•Do not use phenolic based cleaning solutions.

•Keep sharp objects away from the mattress.

•Ensure that the system is clean and dry prior to storage.

•Store the pump and mattress in the protective bags supplied.

•We recommend the use of cot sides on the bed while the system is in use and the patient is

positioned on top. Local policies regarding the use of cot sides should be taken into

account.

•Keep these instructions handy for reference.

WARNING

Electrical equipment may be hazardous if misused or damaged. Ensure the power is

isolated to the system before any repairs or maintenance is carried out & these should only

be carried out by suitably trained & authorised personnel.

For further advice please call Herida Healthcare on Freephone 0800 193 6030.

Parts and Accessories:

•Mattress (1PC) / Pump(1PC) /Air tube(1PC) / Mattress cover(1PC)

5 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

INTRODUCTION

Product Description

The Argyll II is a high end, specialised dynamic mattress replacement system with a digital pump,

targeted towards the assistive treatment for patients who have existing and potentially severe

pressure damage. This system is designed for those patients considered to be at very high risk of

pressure ulcer development and has a deep cell, consisting of two layers (8-inch / 20cm depth).

NB: A 10-inch / 25.5 cm cell is also available. The bottom layer remains inflated at all times to

increase stability and reduce bottoming in the event of a power failure. The top layer inflates and

deflates during the alternating cycle. The specially designed top cells operate in a ten-minute

alternating pattern with a 1 ½ minute pressure equaling of cells between each cycle. This process

provides direct pressure relief and patient stability throughout the whole dynamic process. The

multi-stretch, vapour permeable cover comprises of a high-level coating of polyurethane, which

makes it easy to clean whilst complying with strict infection control procedures. The prompt and

rapid cell deflation between cycles physically ventilates, thus allowing immediate pressure relief

between cell changeover, rather than awaiting deflation under patient weight as is often the case.

Application

This product is to be used for those patients who have existing tissue damage or pressure ulcers.

It can also be used as a high-risk preventative item.

Contraindications

Patients with severe spinal injuries / fractures should not be using this product.

Do not attach the mattress to the fixed part of the bed frame. It should be secured to the moving /

working parts to ensure the bed can be profiled as required.

This product forms part of a holistic care package and should only be used by trained personnel.

For training or further advice contact Herida Healthcare on Freephone +44 800 193 6030.

Working Principle

The dynamic mattress system consists of a dynamic air pump and an alternating air mattress. The

air mattress has three distinct airway chambers:

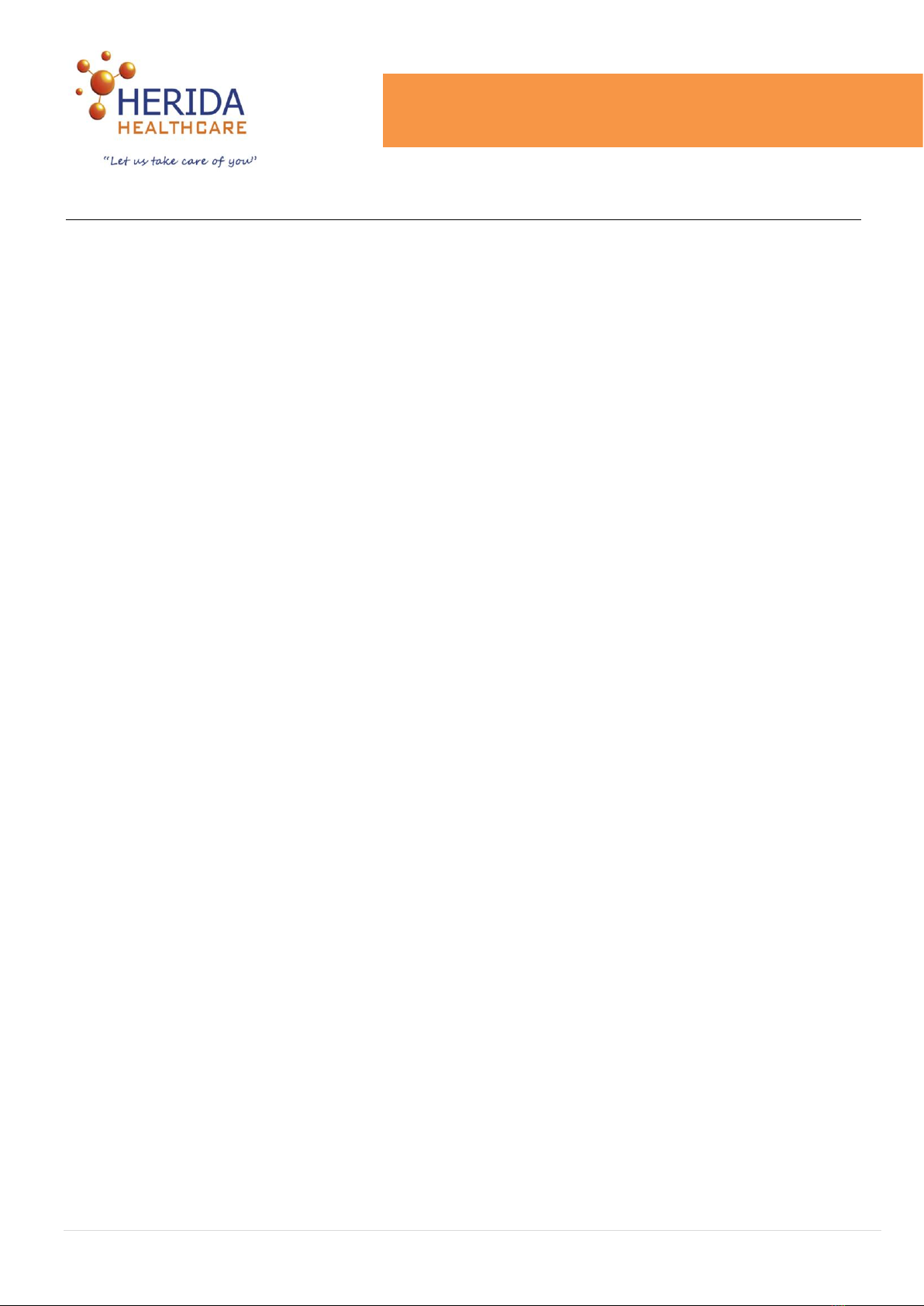

1. Bottom Layer/Pillow Chambers –The bottom layer of cells remain static throughout to

ensure stability and prevent bottoming whilst the pillow tubes 1,2 and 3 remain inflated to

avoid head movement / sickness to the user.

2. Group A Chambers –Air tubes 4,6,8,10,12,14,16 & 18.

3. Group B Chambers –Air tubes 5,7,9,11,13,15 & 17.

A and B chambers alternate inflating and deflating by using the pump. This air alternating,

mattress system enhances the blood circulation to treat and prevent pressure ulcers, when part of

a holistic care package. Initialisation can take up to 50 minutes to achieve & it is recommended

that a Rapid Inflator is used where possible, in order to reduce the inflation time to seconds.

6 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

OPERATION

Static Mode

When the pump is adjusted to the static mode, air chambers A & B are both fully inflated until

52mmHg / 180 Kg is achieved. This mode is used for clinical procedures or patient transfer.

Alternating Mode

When started, both chambers A & B are initially inflated to 52mmHg / 180 Kg. Group A chambers

deflate for 5 minutes followed by both A & B inflating for 1.5 minutes. This is followed by Group B

chambers deflating for 5 minutes. This is one complete cycle.

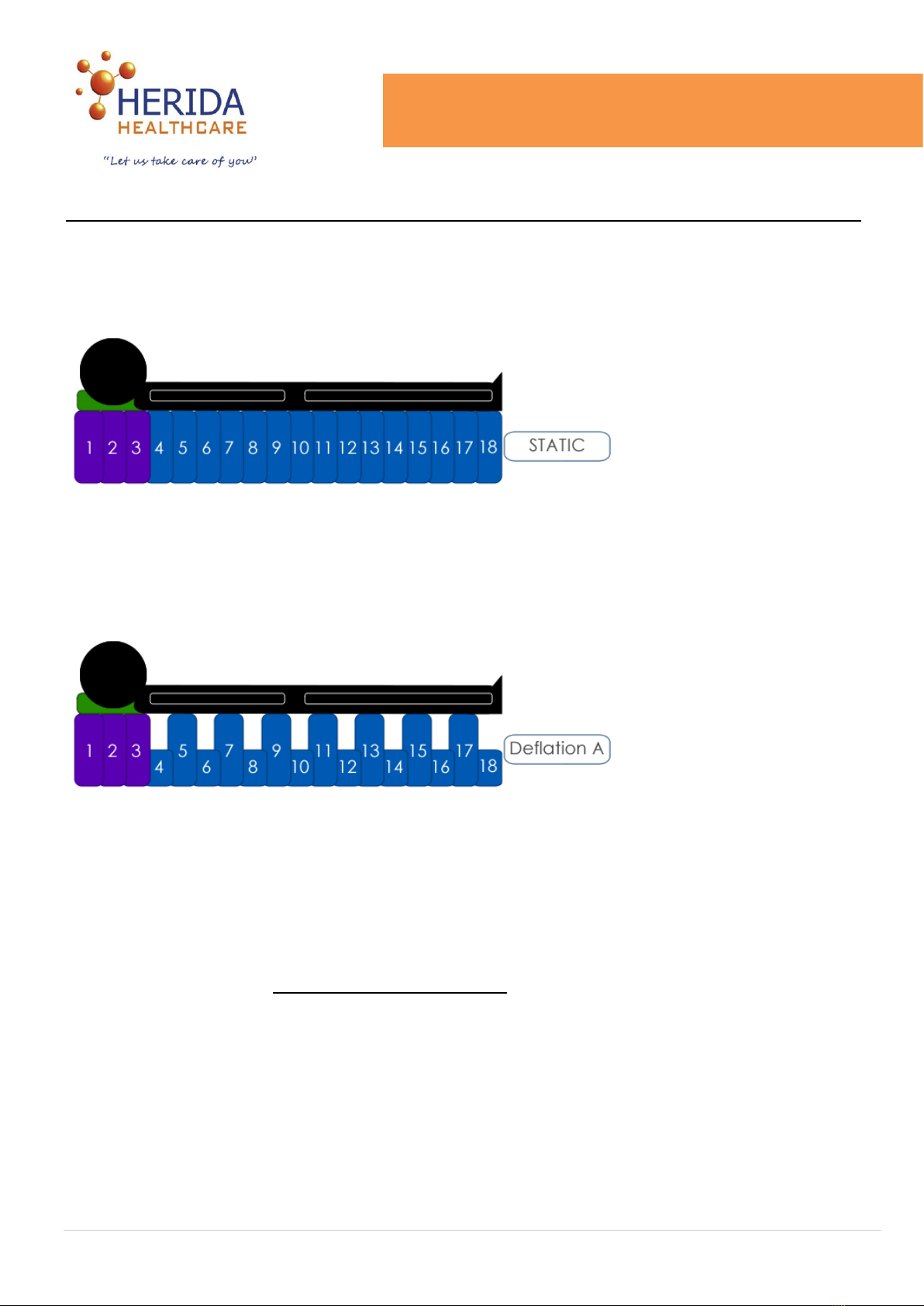

Profiled Bed - Clinical Considerations

If the bed is in the profiled position, ensure that the pump pressure is increased accordingly to

appropriately accommodate (*see below). Unless the clinical condition dictates, it is not advised to

adjust the bed profile beyond 45°. The Argyll II™will continue to operate beyond this but may

cause increased pressure points on the patient. A fist or hand test to ensure patient clearance

under the sacral area is a best practice guide (see image 1DA and diagram of profiled mattress

2DA or visit our website (www.heridahealthcare.co.uk) under “Education” tab section and select

Dynamic Best Practice from the drop-down menu). If you are dealing with heavier or more complex

patients that require a deeper cell mattress, then please contact your provider or seek assistance

via Herida Healthcare Customer Services on UK Freephone number 0800 193 6030. The clinician

must select the correct mattress type at prescription point / patients individual circumstances.

7 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

OPERATION

Image 1DA

(NB: use hand to check ensure appropriate clearance when profiled as below. Add more pressure

on the pump if required in order to achieve this. NB: Weight setting is a guide only and cell

pressure must also be taken into consideration for individual patients). Clinical judgement must

always overrule user guidance.

Image 2DA

Installation

1. Remove all packaging & place the pump either at the end of the bed on its hooks or on a

flat surface.

2. Ensure that there are no sharp or hard objects on the bed before unfolding the mattress &

laying out flat. The air inlet should be located at the feet side of the bed.

3. Use the Rapid Inflator (if available) to inflate the mattress before connecting the air tubes to

the pump. The tubes should be connected securely in place without any signs of leakage. If

a Rapid Inflator is not available, the mattress will take approximately 50 minutes to inflate.

NB: The pump will not operate dynamically until the inflation setting is reached.

4. Connect the pump to the socket & switch on.

5. Adjust the mode & pressure by the users condition & weight to suit.

6. In order for the alarm to activate, the system must be switched on & powered up for at least

5 minutes. This should give the internal battery on the PCB sufficient time to charge.

8 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

OPERATION

Safety Instructions

1. Ensure that there are no sharp objects, fire or abrasive materials in the vicinity. If the

mattress is damaged. Remove the patient & transfer to an alternative mode of pressure

relief.

2. If there is an issue with the pump, remove the patient & transfer to another mode of

pressure relief.

Pump Operation

Power: Power On / Off

Soft / Firm: Pressure adjustment. Each single push adjusts ±5KG. Longer push adjusts ±5KG

rapidly.

Static: All tubes will inflate up to 52mmHg / 180 Kg. No alternating takes place & the digital display

will show “- - -“. The pump will revert back to the previous alternating cycle after 30 minutes.

Pressure Monitor: The light is illuminated when pressure is normal & extinguished when pressure

is abnormal. The light will continuously flash during the alternating cycle change-over.

Mute: When pushed, the audible alarm is silenced.

Lock/Unlock/Malfunction:

•Push the key for 2-3 seconds to lock / unlock the panel.

•The light will continuously flash on the following occasions: when the mattress has not yet

reached pressure during alternating cycles; the mattress probably has an air leak or the

pressure has dropped lower than 6mmHg.

•When the panel is unlocked, it will automatically lock itself after a period of time.

•The lock / unlock facility will be unavailable if the system cannot reach pressure.

Alarm Activation: In order for the alarm to activate, the system must be switched on & powered

up for at least 5 minutes. This should give the internal battery on the PCB sufficient time to charge.

9 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

OPERATION

Air Leakage / Low Pressure Alarm

•After working for 50 minutes and the pressure is lower than 15mmHg, the pump will alarm

indicating an initialisation failure.

•During normal operation, when the pressure is lower than 6mmHg for 6 minutes, the pump

will alarm indicating possible air leakage from the mattress.

•Pushing the mute key will silence the pump alarm.

•If the alarm sounds consistently and all attempts to remedy have failed, seek engineer

assistance to rectify.

Power Off Alarm

The alarm will sound if power is lost to the pump.

Pump Characteristics

Power

AC220V / AC110V

Pressure Range

10 –52 mmHg

Internal Fuse

F0.5A 250V

Plug Fuse

3A

Frequency

50Hz / 60 Hz

Power

8W

Noise

≤45dB

Alternating Time

1 complete cycle is 11 ½ minutes which is 2 x 5

minute periods of alternative cell inflation with a

change over time of 1 ½ minutes.

Pump Pressures

Mattress Characteristics

Model

Argyll II™/ ARG-121-2

Layers

2 including the static inflated base cells.

CPR

1

Max Loading Weight

180 Kg

Weight (Kg)

Pressure

(mmHg)

Weight (Kg)

Pressure

(mmHg)

30

10

110

26

40

12

120

28

50

14

130

30

60

16

140

32

70

18

150

34

80

20

160

40

90

22

170

46

100

24

180

52

This is subject to a tolerance of ±20%

10 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

MAINTENANCE

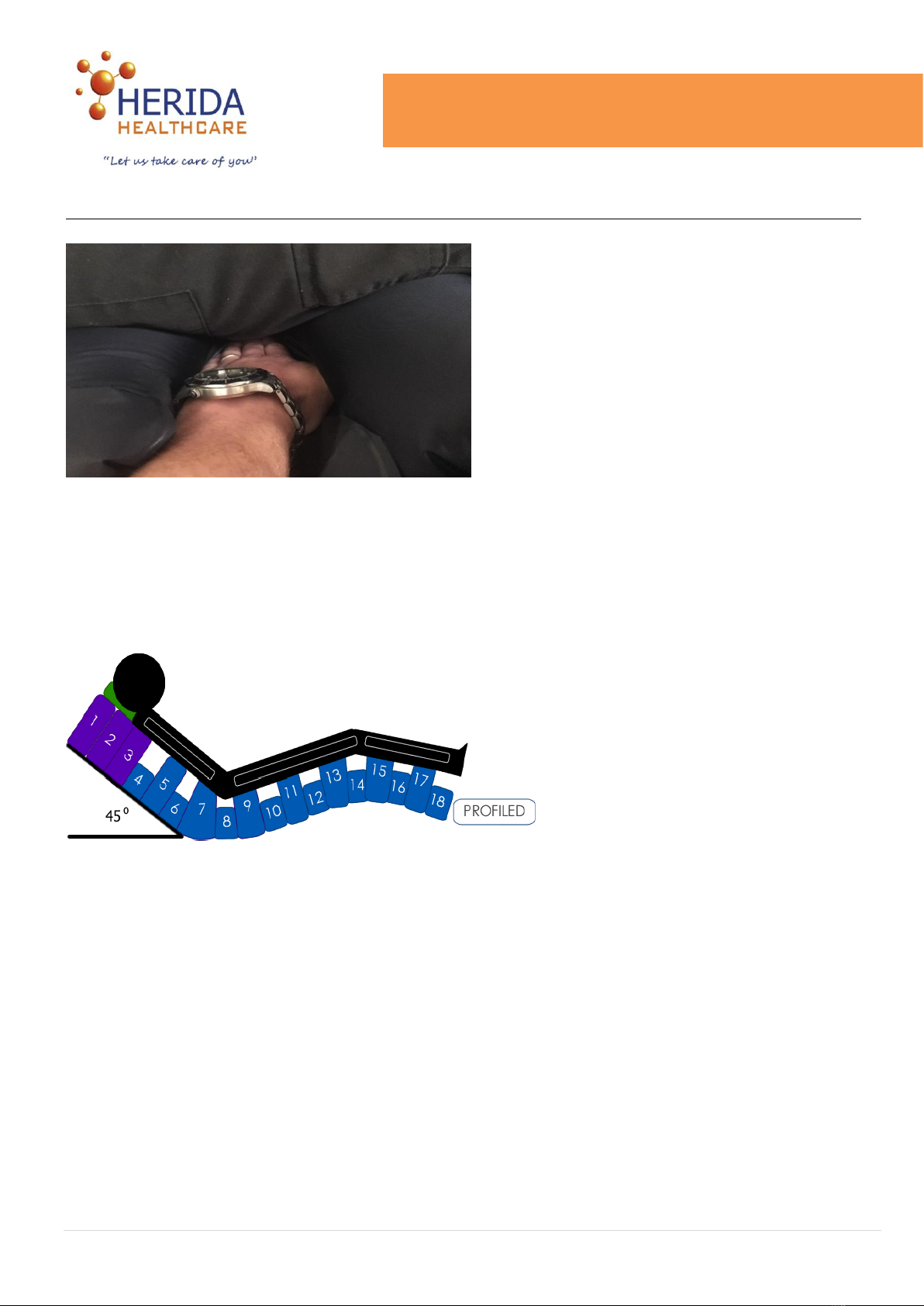

Cleaning

Regular cleaning of the mattress is required as per the below instructions. Failure to follow these

instructions may result in a void warranty situation.

Maintenance & Repair

Maintenance & repair work should only be carried out by an appointed engineer who have been

trained by Herida Healthcare Ltd. and only original manufacturers parts should be used. Failure to

follow the instructions could result in a void warranty situation.

Service Interval & Instructions

This product must be serviced annually as a minimum (or as suggested upon patient return) to

ensure ongoing safe, trouble free usage. The service must be conducted by a Herida trained /

competent individual that has demonstrable training records. This training must be reviewed

regularly. Only Herida Healthcare spare parts can be used to ensure warranty and safe use is

achieved throughout.

11 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

MAINTENANCE - 12 months or as suggested upon patient return

At point of service the following aspects must be maintained to ensure that manufacturer’s

warranty remains intact. These can be done in a non-alphabetic way, if all areas are covered:

•Ensure the pump unit and mattress / cells are fully decontaminated prior to service and are

cleaned in accordance with the schedule provided.

•Electrical safety checks / Pat Test –To be conducted annually or time of service. Please

make sure the kettle lead and plug fuse is compliant at 3amp only.

•Filters must be changed at point of return / before patient handover / new client and at time

of service.

•Rear pump fuse must be inspected and replaced if faulty –0.5A only.

•Pump casing must be opened and vacuumed internally, if any dust or particles are evident.

Never use any water / fluid internally to clean.

•Pump must achieve pressure within 20% tolerances as per page 9 of this manual –via

calibrated sphygomometer and cell attachments. Kits available to purchase via

manufacturer. Ensure that a rapid inflator is used at time of service to ensure that service

and installation time is reduced to minutes.

•Pump low pressure function is evident at 6mmHG or lower for 15-20 minutes or more.

•Cells are to be fully inflated and tested for leakage. This should be done via a pressurised

system, soak test over at least 3 cycles or under weights to replicate patient in situ.

•The tubing and connectors that run down the side of the mattress, must be clear of kinks /

debris or must not be snapped in any way. These should be running freely with air

distribution to each cell and have no leakage or deterioration of surface. A spring is situated

at the head section of the mattress tubing at to avoid kink in the critical area.

•The none return valve holding the 3 head cells must be functioning correctly. This is evident

via 3 solid static head cells / none alternating during cycle.

•A functional “soak test”, ensuring that the tactile panel / pump and mattress operates fully in

synergy. This is done by attaching and inflating the mattress to full pressure and then

increasing / decreasing both weight and other panel / button functions.

•The pump, if stored for a period of time, may require attaching to the mains electric for at

least 30 minutes prior to use. This is to ensure the battery is sufficiently charged, ensuring

the alarm function is fully functioning. Contact manufacture if a warranty item.

•Ensure the timer valve is rotating freely & a light application of grease should be applied if

required. The manufacturer recommends Molykote 111 compound lubricant.

•The key lock button is effective by release / addition, holding 3 seconds or more to activate.

•CPR is to be checked functionally and deflated after all soak tests are completed.

•Mattress Cover and cells are to be inspected for puncture, tear, rip or excessive odour post

cleaning and replaced accordingly if defective.

12 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

MAINTENANCE

Storage

Good ventilation will be required when storing the product & it should always be kept dry & away

from direct sunlight. Temperature should be maintained in the region of 22°C ± 3°C when in use.

Avoid repeat exposure to extreme temperatures.

Transportation

•Care should be taken when loading, unloading and during transportation & refrain

from placing heavy objects on top of the mattresses.

•Do not expos to direct sunshine for any period of time when loading and unloading &

ensure a cover is used to protect the mattress when raining or snowing.

•Do not open with a knife or sharp objects as this may damage the mattress cover.

•Always use the provided re-usable pump protector for all transportation methods. This plastic

sleeve will need to be cleaned prior to re-use for infection control purposes.

Calibration

•During service intervals or between patients, it is recommended to check pressure

tolerances (see the table on page 9) using a Herida Testing System. Calibration training

must be conducted & applied by a Herida trained technician.

Other Considerations

•Original internal fuse is F0.5A 250V. When replacing the fuse, ensure a similar type is

used and that the fuse is disposed of in the appropriate manner.

•During normal working, when the emergency deflation is needed, switch off the pump

and pull out the CPR toggle quickly.

•The mattress should be away from sharp objects to avoid any scratches or punctures.

•Put bed cover sheet or blanket over the mattress before use. No plastic or rubber

sheets should be used.

•Ensure that all the tubes remain flat & any twists / kinks are avoided.

•If any air leakage is found, check all the tube connectors and air tubes carefully to see if

any are loose or damaged.

•If any major problems or issues are found or the product is not working, stop

using immediately and ask the engineer / manufacturer / provider for assistance.

•Any discarded mattress or covers should be treated in accordance with local rules

and guidance in accordance with contaminated products.

•The pump is factory set to 80Kg and is a guide only. This can be adjusted depending

on the needs of the patient.

13 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

ROUTINE CHECKS

Mattress

•Remove top cover and inspect for signs of wear or any tears.

•Check zips are still operative & function as normal.

•Check integrity of all connectors including cells, tubing and CPR toggle.

•Ensure all cell fasteners are snapped to the mattress base and are not lose or faulty.

•Check that stitching which secures the straps to the base of the mattress is sound and no

fraying or damage has occurred.

Pump

•Check the outer casing of the pump unit for damage.

•Examine the mains supply lead of the pump unit for signs of wear or damage & replace if

necessary.

•Test power fail alarm system before use.

14 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

P09 3-Way Pump

15 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

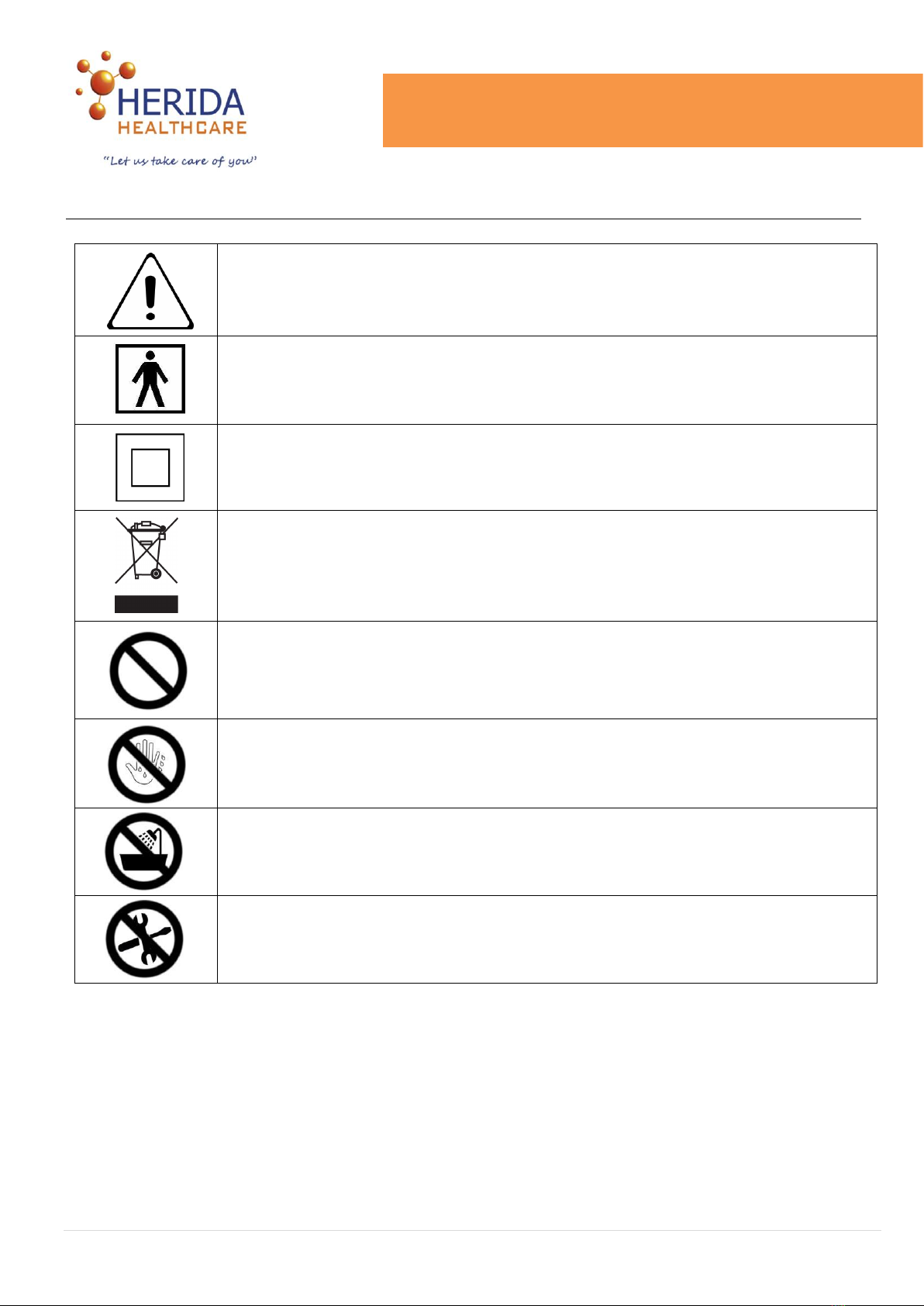

WARNINGS & SYMBOLS

Warning –Follow guidance at all times as per the instructions within the user

manual.

BF application symbol –Provides a higher degree of protection against

electric shock.

Class II electrical appliance –Double insulated.

Dispose of electrical equipment correctly (WEEE).

Do not use broken or damaged electrical plugs or cables as this may lead to

electric shocks.

Ensure hands are dry before handling all electrical items.

No exposure to water / splashing or it may cause electric shocks or fire.

Only authorised / qualified personnel should dis-assemble, repair or rebuild

this product.

16 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

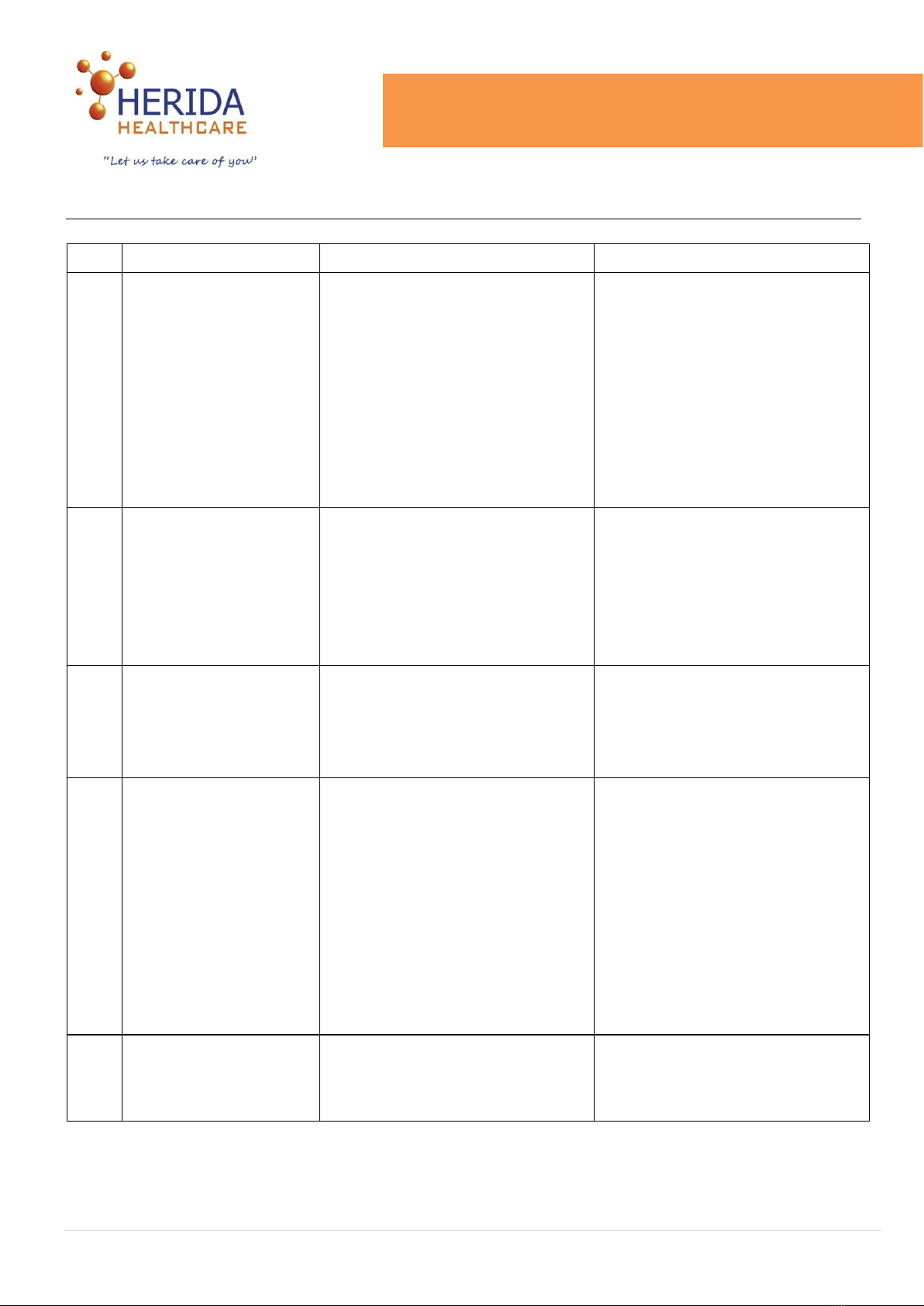

TROUBLE SHOOTING

No.

Issue

Possible Cause

Possible Resolution

1

No power

•The plug is not

properly connected.

•Power Cut.

•The fuse is broken.

•The machine / system

is broken.

•Make sure the power is

correctly connected and the

voltage is normal.

•Await re-connection of

power / look at generator.

•Check the fuse, replace if

broken.

•Call the local distributor for

repair or replacement.

2

Air mattress leakage /

Alarm Sounding

•The mattress is not

connected to the

pump correctly.

•Air tube is disconnected

or damaged.

•CPR not attached properly

•Check the tube connectors.

•Repair the air tubes or call

for replacement.

•Re-attach CPR plug

3

Mattress is too hard

or too soft

•The air pressure is not

adjusting to required

level.

•Adjust the pump pressure

according to the user

weight until suitable and

comfortable.

4

No full inflation

cycle after

initialisation

•Air hoses are loose or

not connect properly.

•CPR is loose or

not connected.

•Air pump has not enough

air pressure.

•Check all the air hoses and

connectors.

•Connect the CPR tightly.

•Adjust the pressure on

the pump. If it is showing

maximum pressure full

inflation has not been

achieved, the pump has a

problem. Ask for repair or

replacement.

5

Pump has

strong vibration

•The pump is not located on

a flat area or not hooked

properly on the bedframe.

•Place the pump on flat area

or hook it in a suitable

position on the bedframe.

17 | P a g e J A N U A R Y 2 0 2 0

Argyll II™User/Service Manual

COMPANY INFORMATION

Herida Healthcare Ltd.

Herida House

Unit 2, Leeds 27 Industrial Estate

Bruntcliffe Avenue, Morley

Leeds, LS27 0LL

Freephone: +44 800 193 6030

Company Number: 9918019

VAT Registration Number: 233587691

Disclaimer

Please be aware that all products should be disposed of in an environmentally friendly & infection

control manner in compliance with any local or national requirements. Contact Herida Healthcare

Ltd. for responsible WEEE disposal methods.

This manual suits for next models

1

Table of contents

Other Herida Healthcare Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Regency

Regency LWMS3015 Assembly instructions

Furniture of America

Furniture of America CM7751C Assembly instructions

Safavieh Furniture

Safavieh Furniture Estella CNS5731 manual

PLACES OF STYLE

PLACES OF STYLE Ovalfuss Assembly instruction

Trasman

Trasman 1138 Bo1 Assembly manual

Costway

Costway JV10856 manual