MAINTENANCE

At point of service the following aspects must be maintained to ensure that manufacturer’s

warranty remains intact. These can be done in a non-alphabetic way, if all areas are covered:

•Ensure the pump unit and mattress / cells are fully decontaminated prior to service and are

cleaned in accordance with the schedule provided.

•Electrical safety checks / Pat Test –To be conducted annually or time of service. Please

make sure the kettle lead and plug fuse is compliant at 3amp only.

•Filters must be changed at point of return / before patient handover / new client and at time

of service.

•Rear pump fuse must be inspected and replaced if faulty –0.5A only.

•Pump casing must be opened and vacuumed internally, if any dust or particles are evident.

Never use any water / fluid internally to clean.

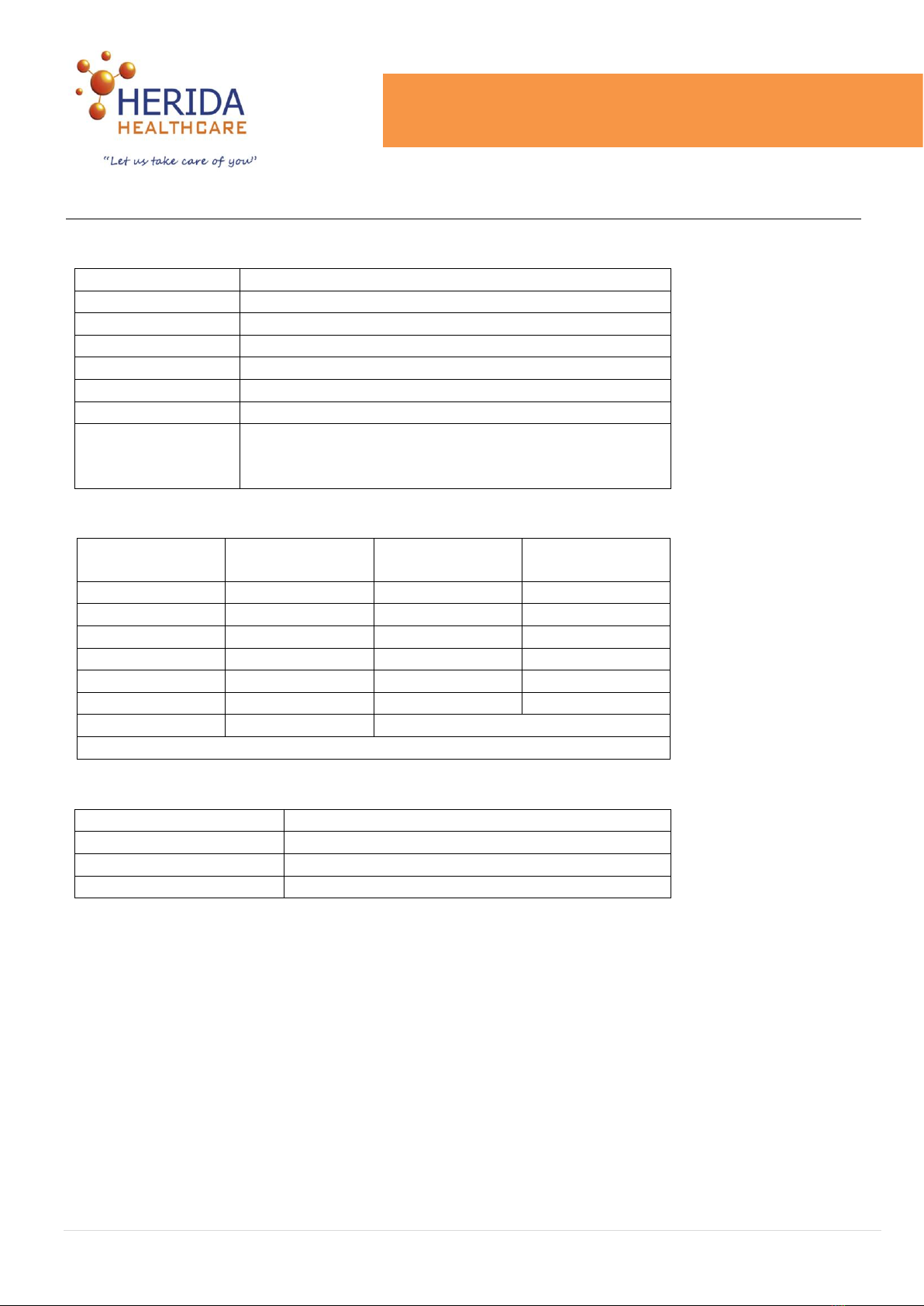

•Pump must achieve pressure within 20% tolerances as per page 9 of this manual –via

calibrated sphygomometer and cell attachments. Kits available to purchase via

manufacturer. Ensure that a rapid inflator is used at time of service to ensure that service

and installation time is reduced to minutes.

•Pump low pressure function is evident at 6mmHG or lower for 15-20 minutes or more.

•Cells are to be fully inflated and tested for leakage. This should be done via a pressurised

system, soak test over at least 3 cycles or under weights to replicate patient in situ.

•The tubing and connectors that run down the side of the mattress, must be clear of kinks /

debris or must not be snapped in any way. These should be running freely with air

distribution to each cell and have no leakage or deterioration of surface. A spring is situated

at the head section of the mattress tubing at to avoid kink in the critical area.

•The none return valve holding the 3 head cells must be functioning correctly. This is evident

via 3 solid static head cells / none alternating during cycle.

•A functional “soak test”, ensuring that the tactile panel / pump and mattress operates fully in

synergy. This is done by attaching and inflating the mattress to full pressure and then

increasing / decreasing both weight and other panel / button functions.

•CPR is to be checked functionally and deflated after all soak tests are completed.

•Mattress Cover and cells are to be inspected for puncture, tear, rip or excessive odour post

cleaning and replaced accordingly if defective.

•Calibration setting as required. See page 12 for further details.

Storage

Good ventilation will be required when storing the product & it should always be kept dry & away

from direct sunlight. Temperature should be maintained in the region of 22°C ± 3°C when in use.

Avoid repeat exposure to extreme temperatures.