Herma 400 User manual

Translation of the original operating

instructions

HERMA 400

HERMA GmbH · Geschäftsbereich Maschinen · Plochinger Str. 48 · D-73779 Deizisau · Germany

EN

Hier und in

Kapitel 10

Geräteschild

aufkleben!

PREFACE Translation of the original operating instructions HERMA 400

2/130 3.26 EN (200416)

Preface

These operating instructions are to help you to safely set up your applicator and operate it troublefree.

You should read all of these instructions before starting the applicator in order to get well acquainted

with it.

If you have any queries or suggestions regarding your applicator or this manual please contact us.

Your questions, suggestions and comments are always welcome.

HERMA GmbH, Labelling Machines Division

www.herma.com

www.herma-components.com

Explanation of signs

DANGER

Indicates a hazardous situation which,if not avoided, will result in

death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, may result

in death or serious injury.

CAUTION

Indicates a hazardous situation which,if not avoided, will result in

minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, will result in physical

damage at your applicator.

Indicates information you should take notice of.

Note

Except for internal use, including integration in the customer‘s documentation, no part of this

documentation may be reproduced or processed, copied, or distributed with the help of electronic

systems in any form without prior written permission of HERMA GmbH.

Version 3.26 EN (200416)

2016 © Copyright HERMA GmbH

Translation of the original operating instructions HERMA 400 CONVENTIONS

b

3.26 EN (200416) 3/130

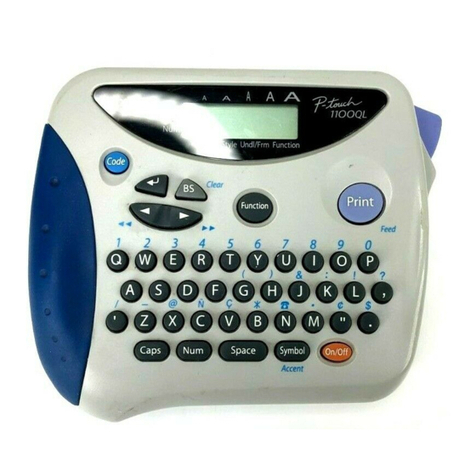

Conventions

Switch-on key

Manual feed key

Function key

LED (on)

LED (blinks)

LED (off)

Minus key

Plus key

Enter key

Elements of the HERMA 400 control are designated and depicted in these instructions as follows:

Find further explanation on these elements in section 5.1.1.

Notes: A few of the illustrations used in this manual are examples and may differ sightly from the

configuration of your applicator.

Furthermore, note that the HERMA400 applicator is available in both left and right-hand

versions and that some illustrations may only show one of these versions.

CONVENTIONS Translation of the original operating instructions HERMA 400

4/130 3.26 EN (200416)

www.herma.com

www.herma-components.com

Translation of the original operating instructions HERMA 400 TABLE OF CONTENTS

3.26 EN (200416) 5/130

Table of Contents

1Safety11

1.1 Important Safety Precautions 11

1.2 General safety information 12

2 Transport, installation and connection 13

2.1 Transporting the applicator 13

2.2 Installing the machine 13

2.3 Electrical connection 14

2.3.1 Connections 15

3 Area of application 17

3.1 Intended use of the machine 17

3.2 Adhesive labels 17

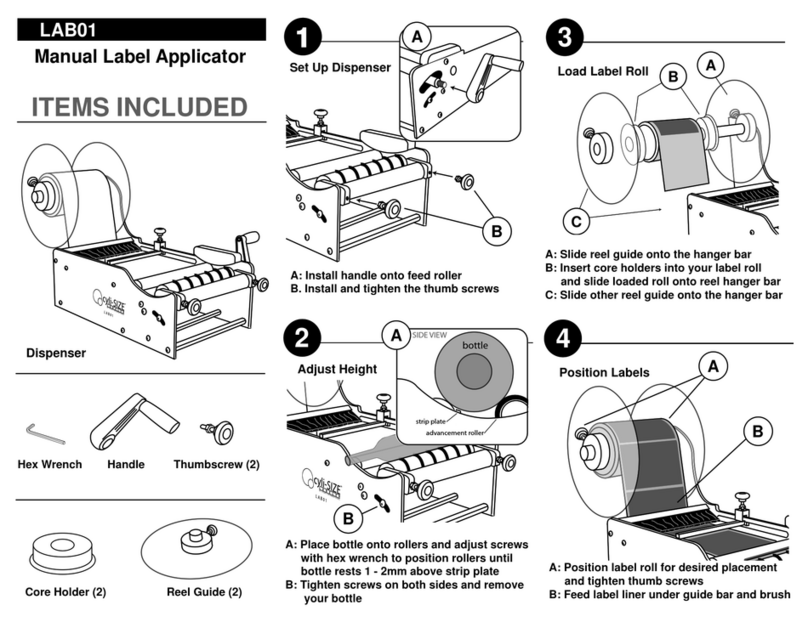

4 Inserting the label web 19

4.1 Label web insertion schemes 19

4.1.1 Right-hand applicator with standard dispensing plate 19

4.1.2 Left-hand applicator with standard dispensing plate 19

4.1.3 Right-hand applicator with pivot beak 20

4.1.4 Left-hand applicator with pivot beak 20

4.1.4.1 Detailed illustrations 20

4.1.5 Right-hand applicator with dispensing plate with spring-loaded roller, 75° angular 21

4.1.6 Left-hand applicator with dispensing plate with spring-loaded roller, 75° angular 21

4.1.7 Winder system, left-hand applicator 22

4.1.8 Winder system, right-hand applicator 23

4.1.9 Winder system, loop-type unwinder 24

5 Commissioning and operation 25

5.1 Operation / Settings via the HERMA 400 control 26

5.1.1 Design 27

5.1.1.1 Key pad 27

5.1.1.2 Display 29

5.1.2 Function diagram 29

5.1.3 End of reel and diminishing reel (internal) 30

5.2 Overview display structure HERMA 400 31

5.3 The display’s Quick Menu 32

5.3.1 Format selection (Quick Menu parameter, optional) 32

5.3.2 Start delay applicator (Quick Menu parameter) 33

5.3.3 Stop delay label (Quick Menu parameter) 33

5.3.4 Speed of the applicator (Quick Menu parameter) 34

5.3.5 Speed of the product (Quick Menu parameter, optional) 34

5.4 Potentiometers 34

5.5 The display’s configuration menu 35

5.5.1 Calling up 35

5.5.2 Design 35

TABLE OF CONTENTS Translation of the original operating instructions HERMA 400

6/130 3.26 EN (200416)

5.5.3 Menu 100 Basic data 35

5.5.3.1 120 Master encoder Pulses / revolution 35

5.5.3.2 121 Master encoder Distance / revolution 36

5.5.3.3 122 Master encoder Start compensation 36

5.5.3.4 123 Master encoder Stop compensation 36

5.5.3.5 124 Master encoder Mini loop on/off 36

5.5.3.6 125 Master encoder Mini loop start delay 36

5.5.3.7 126 Master encoder Mini loop size 36

5.5.3.8 115 Master enc. transfer 36

5.5.3.9 116 Master enc. transfer Label pos. difference 37

5.5.3.10 140 Start signal 37

5.5.3.11 141 Start signal Mark field 1 37

5.5.3.12 142 Start signal Mark field 2 37

5.5.3.13 143 Start signal Mark field 3 37

5.5.3.14 144 Start inhibit Start inhibit distance 37

5.5.3.15 160 Multi labelling 37

5.5.3.16 161 Multi labelling Number of labels 38

5.5.3.17 180 Stop signal 38

5.5.3.18 181 Stop signal Mark field 1 38

5.5.3.19 182 Stop signal Mark field 2 38

5.5.3.20 183 Stop signal Mark field 3 38

5.5.3.21 184 Stop inhibit Stop inhibit distance 38

5.5.3.22 185 Hole inhibit Hole inhibit distance 38

5.5.3.23 187 Stop sensor Label position 39

5.5.3.24 188 Stop at missing label 39

5.5.3.25 189 Stop sensor: NoLabel 39

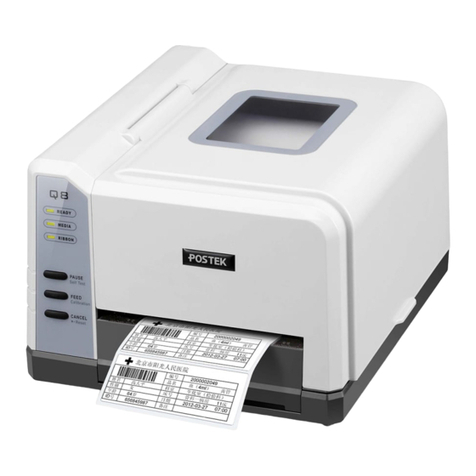

5.5.3.26 190 Printer on/off 39

5.5.3.27 192 Printer Every nth label 39

5.5.3.28 194 Printer Start delay 39

5.5.3.29 195 Printer Print time 39

5.5.3.30 195 Printer Printing length 40

5.5.4 Menu 200 Transfer data 41

5.5.4.1 201 Application type 41

5.5.4.2 210 Pivot beak on/off 42

5.5.4.3 211 Pivot beak Type 42

5.5.4.4 212 Pivot beak Start delay 42

5.5.4.5 213 Pivot beak Activation time 42

5.5.4.6 214 Pivot beak Stop delay 42

5.5.4.7 215 Roller unit start delay 43

5.5.4.8 216 Roller unit stop delay 43

5.5.4.9 225 Dispensing unit Label start delay 44

5.5.4.10 226 Dispensing unit Work pos. reached 44

5.5.4.11 227 Dispensing unit Work pos. return del. 44

5.5.4.12 229 Dispensing unit Home pos. reached 44

5.5.4.13 236 Transfer unit Work pos. reached 44

5.5.4.14 237 Transfer unit Work pos. return del. 44

5.5.4.15 238 Transfer unit Blow 44

5.5.4.16 239 Transfer unit Home pos. reached 44

5.5.4.17 239 Transfer unit After blow 44

5.5.4.18 260 Prism control system 45

5.5.4.19 261 Outfeed jam Running time 45

5.5.4.20 262 AUTOMATIC Slow-down time 45

5.5.4.21 263 Prism Start delay 45

5.5.4.22 264 Prism Stop delay 45

5.5.4.23 265 Start detection Start delay 45

5.5.4.24 266 Start detection Start monitoring 45

5.5.4.25 267 Auxiliary control system 46

5.5.4.26 268: Auxiliary Start delay 46

5.5.4.27 269: Auxiliary Stop delay 46

Translation of the original operating instructions HERMA 400 TABLE OF CONTENTS

3.26 EN (200416) 7/130

5.5.4.28 280 Label check on / off 47

5.5.4.29 284 Label check aft. feed 47

5.5.4.30 285 Lab. check aft. transf. 47

5.5.4.31 286 Label check start delay 47

5.5.5 Menu 400 Format 48

5.5.5.1 410 Format load 48

5.5.5.2 420 Format save 48

5.5.5.3 422 Format save Enter name 48

5.5.5.4 430 Format delete 48

5.5.6 Menu 500 Batch 49

5.5.6.1 510 Batch size 49

5.5.7 Menu 900 System 50

5.5.7.1 910 Rotate display drehen 50

5.5.7.2 912 Sprache / Language 50

5.5.7.3 915 Ready screen 50

5.5.7.4 940 Alarm message after missing labels 51

5.5.7.5 941 Alarm message after end of reel 51

5.5.7.6 942 Alarm message after undefined web move 51

5.5.7.7 943 Alarm message after start sequ. too close 51

5.5.7.8 947 Unwinder disc 51

5.5.7.9 948 Diminishing reel diameter 51

5.5.7.10 980 Bluetooth 51

5.5.7.11 990 Bus adress (RS485) 52

5.5.7.12 992 Display add. output 52

5.5.7.13 997 Serial no. applic. 52

5.5.7.14 950 Unwinder oper. modes 52

5.5.7.15 951 Unwinder output 53

5.5.7.16 952 Loop unwinder 54

5.5.7.17 953 Loop unwinder output 54

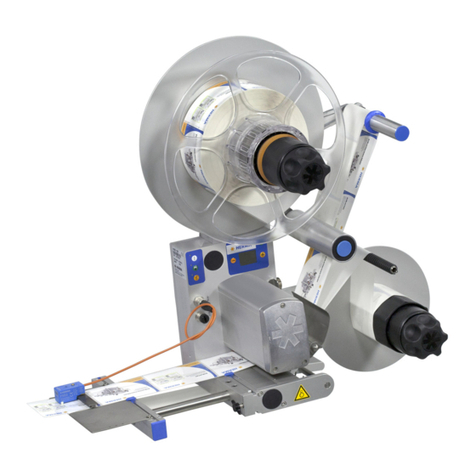

6 Overview and sub-assemblies 57

6.1 Overview 57

6.1.1 Function 57

6.2 Sub-assemblies 58

6.2.1 Standard unwinder 59

6.2.2 Motorized unwinder – Slim line version 63

6.2.3 Motorized loop-type unwinder – Slim line version 68

6.2.4 Label web brake 72

6.2.5 Label sensor FS03 74

6.2.5.1 Work mode (normal mode) 74

6.2.5.2 Setting mode 75

6.2.6 Label sensor optoelectronic 79

6.2.7 Dispensing sytems 81

6.2.7.1 Rigid/Straight dispensing plates 81

6.2.7.2 Dispensing plate, 15° angular 82

6.2.7.3 Pivot beak / Application unit 83

6.2.7.4 Moving beak 84

6.2.8 Transfer systems 85

6.2.8.1 Telescope 85

6.2.8.2 Transverse transfer system 86

6.2.9 Drive/Transport roller 89

6.2.10 Backing paper take-up unit standard 90

6.2.11 Motorized rewinder – Slim line version 95

7 Troubleshooting 103

7.1 Indication of malfunctions 103

TABLE OF CONTENTS Translation of the original operating instructions HERMA 400

8/130 3.26 EN (200416)

7.1.1 List of malfunctions (indicated via display) 104

7.1.1.1 SM106 Missing label at dispensing beak 104

7.1.1.2 SM107 End of label web 104

7.1.1.3 SM108 Dispensing unit does not reach home position 104

7.1.1.4 SM109 Dispensing unit does not leave home position 104

7.1.1.5 SM110 Dispensing unit does not reach work position 104

7.1.1.6 SM111 Dispensing unit does not leave work position 104

7.1.1.7 SM113 Transfer unit does not reach home position 104

7.1.1.8 SM114 Transfer unit does not leave home position 105

7.1.1.9 SM115 Transfer unit does not reach work position 105

7.1.1.10 SM116 Transfer unit does not leave work position 105

7.1.1.11 SM119 Label check Error after label feed 105

7.1.1.12 SM120 Label check Error after label transfer 105

7.1.1.13 SM134 Printer fault 105

7.1.1.14 SM141 Undefined movement of label web 105

7.1.1.15 SM148 Missing label series fault (web break?) 106

7.1.1.16 SM153 Multi labelling Start sequence too close 106

7.1.1.17 SM154 Batch finished! 106

7.1.1.18 SM162 Start delay too low or vMax was exceeded 106

7.1.1.19 SM163 Start sequence too close 106

7.1.1.20 SM164 Start signal Sensor mark not detected 106

7.1.1.21 SM165 Roller unit Communication error 106

7.1.1.22 SM166 Applicator Communication error 106

7.1.1.23 SM167 Roller unit Error 106

7.1.1.24 SM168 CAN connection Disconnect! 106

7.1.1.25 SM169 Firmware update required! 107

7.1.1.26 SM170 Bluetooth Initialization error! 107

7.1.1.27 SM171 Bluetooth H400 S/N required! 107

7.1.1.28 SM180 Printer not finished 107

7.1.1.29 SM181 Chip changed! 107

7.1.1.30 SM185 Firmware update Winder required 107

7.1.1.31 SM198 CAN communikation Response time 107

7.1.1.32 SM199 CAN communication no CAN module detected 107

7.1.1.33 SM805 Unwinder failure TEACH process 107

7.1.1.34 SM808 Unwinder failure Too slow 107

7.1.1.35 SM809 Unwinder failure Circuit voltage too low 107

7.1.1.36 SM810 Unwinder failure Overload 108

7.1.1.37 SM811 Unwinder failure Temperature too high 108

7.1.1.38 SM812 Unwinder failure End of reel 108

7.1.1.39 SM813 Unwinder failure Diameter determination 108

7.1.1.40 SM825 Loop unwinder failure TEACH process 108

7.1.1.41 SM828 Loop unwinder failure Too slow 108

7.1.1.42 SM829 Loop unwinder failure Circuit voltage too low 108

7.1.1.43 SM830 Loop unwinder failure Overload 108

7.1.1.44 SM831 Loop unwinder failure Temperature too high 108

7.1.1.45 SM832 Loop unwinder failure End of reel 108

7.1.1.46 SM845 Winder failure TEACH process 108

7.1.1.47 SM848 Winder failure Torn tape / too slow 108

7.1.1.48 SM849 Winder failure Circuit voltage too low 108

7.1.1.49 SM850 Winder failure Overload 109

7.1.1.50 SM851 Winder failure Temperature too high 109

7.1.1.51 SM865 Loop filler failure 109

7.1.1.52 SM910 Drive failure Low voltage 109

7.1.1.53 SM911 Drive failure High voltage 109

7.1.1.54 SM912 Drive failure High temperature 109

7.1.1.55 SM913 Drive failure Overload (period) 109

7.1.1.56 SM914 Drive failure 109

7.1.1.57 SM917 Drive failure Powerfail 109

7.1.1.58 SM918 Drive failure 109

Translation of the original operating instructions HERMA 400 TABLE OF CONTENTS

3.26 EN (200416) 9/130

7.1.1.59 SM919 Drive failure Low voltage (peak) 109

7.1.1.60 SM920 Drive failure Overload (peak) 109

7.1.1.61 SM921 Drive failure 110

7.1.1.62 SM922 Drive failure 110

7.1.1.63 SM923 Drive failure 110

7.1.1.64 SM924 Drive failure Overload 110

7.1.1.65 SM925 CAN communication disturbed 110

7.1.1.66 SM926 Drive failure: Overload (vMax exceeded!) 110

7.1.1.67 SM999 Drive mode was changed! f-button = restart 110

7.1.2 Malfunction table (LED indication) 111

7.1.2.1 Remedy of malfunctions 112

7.1.3 Error blink codes with PLC connection 112

7.2 Other malfunctions 113

7.3 Replace the drive unit 115

7.3.1 Remove the drive unit 115

7.3.2 Ship the drive unit 117

7.3.3 Mount the drive unit 117

7.4 Technical Service 117

8 Cleaning, maintenance, service 119

9 Technical Data 121

9.1 Inputs / outputs (X10) (option, standard signals) 123

9.2 Inputs / outputs (X19) (option, extended signals) 124

10 Declaration of Incorporation 125

11 Spare parts 127

A1 Index 129

TABLE OF CONTENTS Translation of the original operating instructions HERMA 400

10/130 3.26 EN (200416)

www.herma.com

www.herma-components.com

3.26 EN (200416) 11/130

1Safety

1.1 Important Safety Precautions

WARNING

❏The applicator may not be used in explosive atmospheres.

❏Mount the applicator appropriately upstream of the energy

input.

❏The applicator/machine must have a mains disconnection

device to cut off the mains supply in case of malfunction.

❏Switch off the mains supply before maintaining or cleaning

the machine. Reattach protective covers after this work is

complete.

❏The machine may only be operated, maintained and serviced

by trained personnel. Additional training must be provided.

❏Installation/removal may only be performed by trained

specialists when the applicator is disconnected from the

mains supply. Mount the applicator appropriately upstream

of the energy input and put the protective covers back on.

❏Switch off the mains supply before maintenance and cleaning

of the applicator. Mount the applicator appropriately

upstream of the energy input and put the protective covers

back on.

❏Do not put your hands into rotating parts during operation.

CAUTION

❏Remove the roll of labels when transporting the applicator.

❏During operation, there is a risk of being cut when the label

web is moving.

Warning symbols

Symbols used on the applicator:

Risk of being drawn in

Dangerous electrical voltage

1

SAFETY Translation of the original operating instructions HERMA 400

12/130 3.26 EN (200416)

1.2 General safety information

WARNING

❏Before commissioning, ensure that the protective equipment

is functioning properly.

❏Check that the protective equipment is functioning properly

every time before starting work on the applicator.

❏If any protective equipment is not functioning properly,

replace it or repair it immediately.

❏The technical condition of the protective equipment must be

inspected at regular intervals by a qualified person, at least

once annually.

❏If you cannot ensure safe operation of the machine, you must

immediately shut down the machine and secure it against

future use.

❏The machine may be operated by trained staff only.

Additional training must be provided.

❏Distribute the operating instructions for safe operation.

❏Only use the machine to process suitable products.

❏Do not bypass any safety switches.

❏Note the cleaning methods described in these instructions.

❏Only use original replacement parts and accessories.

❏The machine may not be modified.

❏Keep the operating instructions in a safe place.

❏The operating instructions must be included when reselling

the machine.

The user is solely responsible for injuries or damage caused by improper use that is not in accordance

with the instructions in this manual.

Personal protective equipment

WARNING

❏Make sure to tie up long hair (if required, wear a hair net) and

avoid wide clothing.

3.26 EN (200416) 13/130

2Transport, installation and connection

2.1 Transporting the applicator

When you transport the applicator/the machine using a forklift/pallet truck, note the following

requirements:

WARNING

❏The means of transport must be approved for the weight of

the machine.

❏Note the safety regulations for transporting and lifting heavy

loads.

❏Guide the forks between the machine feet or the palette.

Be aware of the machine’s centre of gravity.

❏The forks must extend so they are sticking out on the other

side of the machine or the palette.

CAUTION

❏Remove the roll of labels when transporting the applicator.

2.2 Installing the machine

WARNING

❏The applicator may not be used in explosive atmospheres.

❏Only use the machine in dry areas.

❏Mount the applicator appropriately upstream of the energy

input.

❏Installation/removal may only be performed by trained

specialists when the applicator is disconnected from the

mains supply. Mount the applicator appropriately upstream of

the energy input and put the protective covers back on.

If you should notice damage due to transport when you unpack the machine inform your HERMA sales

office immediately.

2

TRANSPORT, INSTALLATION AND CONNECTION Translation of the original operating instructions HERMA 400

14/130 3.26 EN (200416)

Mount the applicator using the two mounting holes for round rods (2), Ø 30 mm, hole spacing: 182 mm.

Secure the mounting system appropriately on the rods, e.g. using a locking screw (3), a washer (4) or

the optional fine-adjustment device (5).

2.3 Electrical connection

WARNING

❏HERMA 400 applicators may only be operated on TN mains

networks.

❏Only connect the applicator to AC voltage, and check whether

your mains voltage complies with the voltage specification on

the nameplate.

❏Only connect the applicator to a properly installed, earthed

power socket or connect it appropriately in the control cabinet

of the relevant machine.

❏The applicator/machine must have a mains disconnection

device to cut off the mains supply in case of malfunction.

❏Work on electrical components may only be performed by

authorised specialists and in observance of the relevant

safety regulations.

❏Disconnect the applicator from the mains before working on

the parts of the electrical equipment.

❏When you disconnect the HERMA 400 applicator from the

mains, wait at least five minutes before opening the housing

or touching the connector pins. RESIDUAL VOLTAGES!

❏Mount the applicator appropriately upstream of the energy

input.

2

3

4

5

2

Translation of the original operating instructions HERMA 400 TRANSPORT, INSTALLATION AND CONNECTION

3.26 EN (200416) 15/130

2.3.1 Connections

The following connections are available at theHERMA 400 applicator (depending on the configuration):

X14 – Serial OUT

X16 – Labelling start

X19 – Inputs/Outputs (ext. signals)

X10 – Inputs/Outputs (stand. signals) /

signal column (optional)

X12 – Power supply

* X16 as special case, if X10/X19 occupied and separate start signal required .

Impossible with .

** X16 as start signal, if X10/X19 are free.

†Must be interrupted before effecting a program update or if initialized for the very first

time.

†† In the standard configuration as of applicator no. 206... pin 5 of the cable from X17 to X3

of the CAN-I/O board is plugged in (a). Furthermore a jumper from pin 7 to pin 8 is set on

X27 (b). Thus the signal „printer running“ / „printer error“ can be interrogated.

With motorized unwinders the signals for end of reel and diminishing reel can be detected at the same

time only if the unwinder is connected via CAN bus (X18). Detection of these web signals is effected

automatically.

If, however, external sensors for detecting end of reel (at X3) and diminishing reel (at X2) are to be

used at the same time for a motorized unwinder of the winder system at the CAN bus this plug of X17

must be removed from X3. The printer signal can then not be interrogated any longer.

Additionally the jumper from pin 7 to pin 8 on X27 must be removed since otherwise end of reel would

be indicated as a printer error.

X14 ()

/(X16 (special)*)

X16 (,,)/

X19 (,,,)**

X10 (,,,)

X12

X13 (all types)†

X11 (,,)

X18 (all types)†

Shownhere:left-handversion;

right-hand version is mirror-

inverted.

X13 – Serial IN

X11 – Master encoder

X18 – CAN extension

X17 – Transfer /

Printer ††

X15 – Label sensor

X17

X15

a

b

NOTICE

❏For the appropriate pin assignment of the connections, please

refer to the section 9or the separate wiring diagram 823299.

❏All plugs are secured with coupling rings. Do not tilt the

coupling rings when screwing it onto the socket because this

could damage the thread or render it unusable. Screw the

plugs in completely in order to ensure safe long-term contact.

2

TRANSPORT, INSTALLATION AND CONNECTION Translation of the original operating instructions HERMA 400

16/130 3.26 EN (200416)

See chapter 9 for the assignment of connectors X10 and X19 (if available).

3.26 EN (200416) 17/130

3Area of application

3.1 Intended use of the machine

WARNING

❏Any use other than the purpose described above, in

particularly using the system to wind any materials other

than rolls of labels, is considered unintended use and is

prohibited.

The HERMA 400 applicator is an electronically-controlled device that is to be used to apply different

adhesive labels to a wide variety of products.

You can use the applicator to unwind label rolls, dispense labels from the backing paper and then roll

up the backing material.

The applicator can be equipped with a printing unit if required. This allows the user to print labels with,

for example, lines of text, changing dates, bar codes and batch numbers.

3.2 Adhesive labels

Winding outside

1Label roll

2Label roll core

3Label

4Backing paper

3+4 Label web

Winding inside

1

2

3

4

1

2

3

4

3

AREA OF APPLICATION Translation of the original operating instructions HERMA 400

18/130 3.26 EN (200416)

www.herma.com

www.herma-components.com

3.26 EN (200416) 19/130

4Inserting the label web

4.1 Label web insertion schemes

The following schemes show how to insert the label web with the most common standard applicators.

A separate insertion scheme is provided for applicator configurations other than shown here . As the

case may be, this scheme may also be attached to the machine.

CAUTION

❏Before inserting the label web, ensure that the applicator/

machine is switched off.

4.1.1 Right-hand applicator with standard dispensing plate

4.1.2 Left-hand applicator with standard dispensing plate

OI

O = Außenwicklung / outside winding

I = Innenwicklung / inside winding

681297

681297

0 = Außenwicklung / outside winding

I = Innenwicklung / inside winding

O

I

O = Außenwicklung / outside winding

I = Innenwicklung / inside winding

681296

681296

0 = Außenwicklung / outside winding

I = Innenwicklung / inside winding

4

INSERTING THE LABEL WEB Translation of the original operating instructions HERMA 400

20/130 3.26 EN (200416)

4.1.3 Right-hand applicator with pivot beak

4.1.4 Left-hand applicator with pivot beak

4.1.4.1 Detailed illustrations

OI

O = Außenwicklung / outside winding

I = Innenwicklung / inside winding

681299

681299

0 = Außenwicklung / outside winding

I = Innenwicklung / inside winding

O

O = Außenwicklung / outside winding

I = Innenwicklung / inside winding

681298

I

681298

0 = Außenwicklung / outside winding

I = Innenwicklung / inside winding

Detail dispensing plate Detail pivot beak

Detail dispensing plate, 75° angular

Other manuals for 400

1

Table of contents

Other Herma Label Maker manuals