Herma 400 User manual

Operating instructions

Label applicator HERMA 400

HERMA GmbH · Geschäftsbereich Maschinen · 70791 Filderstadt · Germany

US

Geräteschild /

type label

PREFACE OPERATING INSTRUCTIONS HERMA 400

2/154 3.28 US (130519)

Preface

Read and understand all parts of these operating instructions before unpacking,

installing or operating on the applicator.

They contain important instructions for ensuring your personal safety. These

operating instructions must have been read and understood by all persons carrying

out work on this applicator in any production phase.

Especially important are sections 2, „General information“, where you can find information on all

types of safety messages and their meaning, and section 3, „Safety“, which gives you details on

your personal safety and the responsibility of the various users of this Product.

Inform yourself about the applicable accident prevention regulations at the location and the

general safety regulations.

Keep these instructions and all accompanying documents (the „documentation“) , for example

the wiring diagram, in a safe location for future reference.

These operating instructions are an integral part of the machine. They must be made available at

the place of operation throughout the entire service life of the applicator.

Failure to do so could result in serious injury or death or property damage.

Please note that You as an operator of the machine bear the risk and the liability in the following

cases:

>non-complinace with these instructions

>unintended use

>the use of untrained personnel

>connection to any unapproved electrical system

>the use of unapproved replacement parts

>the repair and replacement of the Product(s) or any part thereto due to normal wear and tear,

vandalism, accidents, negligence, or otherwise without any fault of the manufacturer

>repairs, alterations or adjustments to the Product(s) performed or originated by the Purchaser or

any third party without manufacturerer's prior written consent

>unsuitable raw or working materials

>unreasonable use

>misuse

>abuse

>accident

>alteration

>lack of maintainance

>use after the Product is significantly worn

>and other similar cases

Operating instructions HERMA 400 APPLICABILITY

b

3.28 US (130519) 3/154

Applicability

These operating instructions apply to the following system:

Label applicator: Type HERMA 400 (the „Product“)

Year of construction: Specified on the type label (also on the cover sheet)

Manufacturer: HERMA GmbH

Geschäftsbereich Maschinen

70791 Filderstadt, Germany

Telephone: +49 (0)711 / 7702 0

Fax: +49 (0)711 / 7702 700

www.herma.com

Technical service: Tel.: +49 (0)711 7702 551 / +49 (0)711 7702 777

Fax: +49 (0)711 7702 786

service-machines@herma.com

https://machines.herma.com

Issue date: May 13, 2019

Version: 3.28 US (130519)

The documentation must be passed on to the new owner if the machine is sold.

Find an overview of the HERMA 400 applicator and its function in chapter 1 on page 12.

Copyright

© Copyright 2019, HERMA GmbH.

The information included in these operating instructions and/or in all of the sections, sub-sections and

chapters of them is the intellectual property of the manufacturer and is subject to domestic and

international copyright law and other laws for protecting intellectual property.

The information provided here is used to operate, maintain and correct faults for the units described

here.

Except for internal use no part of this documentation may be reproduced or processed, copied, or

distributed with the help of electronic systems in any form without prior written permission of

HERMA GmbH.

COPYRIGHT OPERATING INSTRUCTIONS HERMA 400

4/154 3.28 US (130519)

www.herma.com

https://machines.herma.com

Operating instructions HERMA 400 TABLE OF CONTENTS

3.28 US (130519) 5/154

Table of Contents

1 Overview of the applicator 11

2 General information 15

2.1 Handling of the documentation 15

2.2 Explanation of symbols 15

2.2.1 Signal words 15

2.2.2 General designations 16

3Safety17

3.1 Important Safety Information 17

3.1.1 Signal word definitions 17

3.1.2 Mandatory signs 18

3.2 Personal protective equipment 18

3.3 Symbols on the applicator 19

3.4 Proper use of the applicator 20

3.5 Responsibility of the operator 21

3.6 Personnel 22

4 Applicator description 23

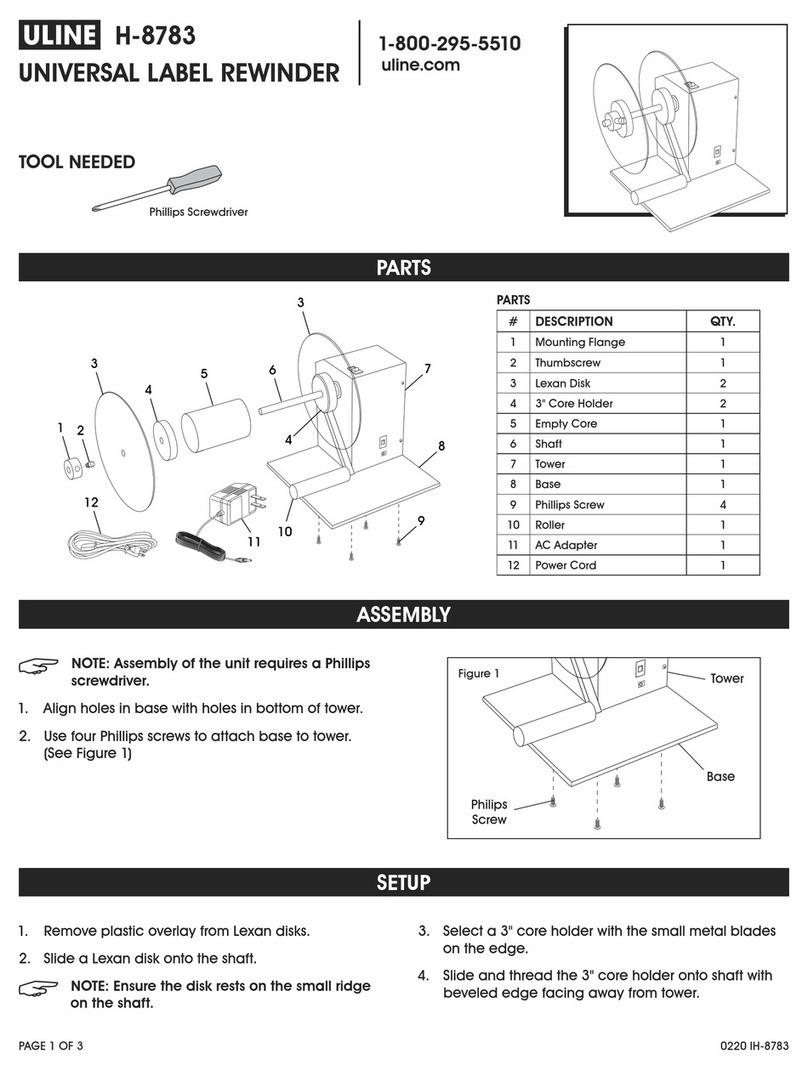

4.1 Sub-assemblies 23

4.1.1 Standard unwinder 24

4.1.2 Motorized unwinder – Slim line version 28

4.1.3 Motorized loop-type unwinder – Slim line version 34

4.1.4 Label web brake 39

4.1.5 Label sensor FS03 41

Work mode (normal mode) 41

Setting mode 42

4.1.6 Label sensor optoelectronic 46

4.1.7 Dispensing sytems 48

Rigid/Straight dispensing plates 48

Dispensing plate, 15° angular 49

Pivot beak / Application unit 50

Moving beak 51

4.1.8 Transfer systems 52

Telescope 52

Transverse transfer system 53

4.1.9 Drive/Transport roller 57

4.1.10 Standard rewinder 58

4.1.11 Motorized rewinder – Slim line version 64

5TechnicalData73

5.1 Dimensions / weight (configuration examples) 75

5.2 Inputs / outputs (X10) (option, standard signals) 76

5.3 Inputs / outputs (X19) (option, extended signals) 77

6 Transport, installation, storage and

TABLE OF CONTENTS Operating instructions HERMA 400

6/154 3.28 US (130519)

connection 79

6.1 Transporting the applicator 79

6.2 Installing the applicator 79

6.3 Storing the applicator 82

6.4 Electrical connection 83

6.4.1 Connections 84

6.5 Inserting the label web (web paths) 86

6.5.1 Right-hand applicator with standard dispensing plate 86

6.5.2 Left-hand applicator with standard dispensing plate 86

6.5.3 Right-hand applicator with pivot beak 87

6.5.4 Left-hand applicator with pivot beak 87

6.5.5 Right-hand applicator with dispensing plate with spring-loaded roller, 75° angular 88

6.5.6 Left-hand applicator with dispensing plate with spring-loaded roller, 75° angular 88

6.5.7 Winder system, left-hand applicator 89

6.5.8 Winder system, right-hand applicator 90

6.5.9 Winder system, loop-type unwinder 91

7Puttingintooperation93

8 Putting out of operation 95

8.1 End-of-life disposal 95

9 Operation (via the HERMA 400 control) 97

9.1 Design (keypad and display) 98

9.2 Function diagram 100

9.3 End of reel and diminishing reel (internal) 101

9.4 Overview display structure HERMA 400 102

9.5 The display’s Quick Menu 103

9.5.1 Format selection (Quick Menu parameter, optional) 103

9.5.2 Start delay applicator (Quick Menu parameter) 104

9.5.3 Stop delay label (Quick Menu parameter) 104

9.5.4 Speed difference between applicator and application roller (029) 104

9.5.5 Speed of the applicator (Quick Menu parameter) 105

9.5.6 Speed of the product (Quick Menu parameter, optional) 105

9.5.7 Conveyor speed 152 (036) 105

9.5.8 Product speed transverse transfer system (037) 105

9.6 Potentiometers 106

9.7 The display’s configuration menu 106

9.8 Menu 100 Basic data 107

9.8.1 115 Master enc. transfer 107

9.8.2 116 Master enc. transfer Label pos. difference 107

9.8.3 120 Master encoder Pulses / revolution 107

9.8.4 121 Master encoder Distance / revolution 107

9.8.5 122 Master encoder Start compensation 107

9.8.6 123 Master encoder Stop compensation 108

9.8.7 124 Master encoder Mini loop on/off 108

9.8.8 125 Master encoder Mini loop start delay 108

9.8.9 126 Master encoder Mini loop size 108

9.8.10 127 Master encoder rollfed Cutter distance 108

9.8.11 128 Master encoder rollfed Difference StSt cont. 108

Operating instructions HERMA 400 TABLE OF CONTENTS

3.28 US (130519) 7/154

9.8.12 140 Start signal 108

9.8.13 141 Start signal Mark field 1 109

9.8.14 142 Start signal Mark field 2 109

9.8.15 143 Start signal Mark field 3 109

9.8.16 144 Start inhibit Start inhibit distance 109

9.8.17 160 Multi labelling 109

9.8.18 161 Multi labelling Number of labels 109

9.8.19 180 Stop signal 110

9.8.20 181 Stop signal Mark field 1 110

9.8.21 182 Stop signal Mark field 2 110

9.8.22 183 Stop signal Mark field 3 110

9.8.23 184 Stop inhibit Stop inhibit distance 110

9.8.24 185 Hole inhibit Hole inhibit distance 110

9.8.25 186 Label tolerance 110

9.8.26 187 Stop sensor Label position 111

9.8.27 188 Stop at missing label 111

9.8.28 189 Stop sensor: NoLabel 111

9.8.29 190 Printer on/off 111

9.8.30 192 Printer Every nth label 111

9.8.31 194 Printer Start delay 111

9.8.32 195 Printer Print time 112

9.8.33 195 Printer Printing length 112

9.9 Menu 200 Transfer data 113

9.9.1 201 Application type 113

9.9.2 210 Pivot beak on/off 114

9.9.3 211 Pivot beak Type 114

9.9.4 212 Pivot beak Start delay 114

9.9.5 213 Pivot beak Activation time 114

9.9.6 214 Pivot beak Stop delay 114

9.9.7 217 Roller unit start delay 115

9.9.8 218 Roller unit stop delay 115

9.9.9 225 Dispensing unit Label start delay 116

9.9.10 226 Dispensing unit Work pos. reached 116

9.9.11 227 Dispensing unit Work pos. return del. 116

9.9.12 229 Dispensing unit Home pos. reached 116

9.9.13 235 Transfer unit After blow 116

9.9.14 236 Transfer unit Work pos. reached 116

9.9.15 237 Transfer unit Work pos. return del. 116

9.9.16 238 Transfer unit Blow 116

9.9.17 239 Transfer unit Home pos. reached 116

9.9.18 260 Prism control system 117

9.9.19 261 Outfeed jam Running time 117

9.9.20 262 AUTOMATIC Slow-down time 117

9.9.21 263 Prism Start delay 117

9.9.22 264 Prism Stop delay 117

9.9.23 265 Start detection Start delay 117

9.9.24 266 Start detection Start monitoring 117

9.9.25 267 Auxiliary control system 118

9.9.26 268: Auxiliary Start delay 118

9.9.27 269: Auxiliary Stop delay 118

9.9.28 280 Label check on / off 119

TABLE OF CONTENTS Operating instructions HERMA 400

8/154 3.28 US (130519)

9.9.29 284 Label check aft. feed 119

9.9.30 285 Lab. check aft. transf. 119

9.9.31 286 Label check start delay 119

9.10 Menu 400 Format 120

9.10.1 410 Format load 120

9.10.2 420 Format save 120

9.10.3 422 Format save Enter name 120

9.10.4 430 Format delete 120

9.11 Menu 500 Batch 121

9.11.1 510 Batch size 121

9.12 Menu 900 System 122

9.12.1 910 Rotate display drehen 122

9.12.2 912 Sprache / Language 122

9.12.3 915 Ready screen 122

9.12.4 940 Alarm message after missing labels 123

9.12.5 941 Alarm message after end of reel 123

9.12.6 942 Alarm message after undefined web move 123

9.12.7 943 Alarm message after start sequ. too close 123

9.12.8 944 Monitoring quality 123

9.12.9 947 Unwinder disc 124

9.12.10 948 Diminishing reel diameter 124

9.12.11 980 Bluetooth 124

9.12.12 990 Bus adress (RS485) 124

9.12.13 992 Display add. output 124

9.12.14 997 Serial no. applic. 124

9.12.15 950 Unwinder oper. modes 125

9.12.16 951 Unwinder output 125

9.12.17 952 Loop unwinder 126

9.12.18 953 Loop unwinder output 127

9.12.19 954 Unwinder Mode 128

9.12.20 955 Rewinder Mode 128

9.12.21 956 Loop unwinder Mode 128

9.12.22 957 Rewinder output 128

9.12.23 958 Unwinder protection 1 129

9.12.24 959 Unwinder protection 2 129

9.12.25 990 Bus adress (RS485) 129

9.12.26 992 Display add. output 130

10 Cleaning, maintenance, service 131

10.1 Maintenance schedule 132

11 Troubleshooting 133

11.1 Indication of malfunctions 133

11.2 List of malfunctions (indicated via display) 134

11.2.1 SM106 Missing label at dispensing beak 134

11.2.2 SM107 End of label web 134

11.2.3 SM108 Dispensing unit does not reach home position 134

11.2.4 SM109 Dispensing unit does not leave home position 134

11.2.5 SM110 Dispensing unit does not reach work position 134

11.2.6 SM111 Dispensing unit does not leave work position 134

11.2.7 SM113 Transfer unit does not reach home position 134

Operating instructions HERMA 400 TABLE OF CONTENTS

3.28 US (130519) 9/154

11.2.8 SM114 Transfer unit does not leave home position 135

11.2.9 SM115 Transfer unit does not reach work position 135

11.2.10 SM116 Transfer unit does not leave work position 135

11.2.11 SM119 Label check Error after label feed 135

11.2.12 SM120 Label check Error after label transfer 135

11.2.13 SM130 Error control prism air pressure low 135

11.2.14 SM134 Printer fault 135

11.2.15 SM141 Undefined movement of label web 135

11.2.16 SM148 Missing label series fault (web break?) 136

11.2.17 SM153 Multi labelling Start sequence too close 136

11.2.18 SM154 Batch finished! 136

11.2.19 SM162 Start delay too low or vMax was exceeded 136

11.2.20 SM163 Start sequence too close 136

11.2.21 SM164 Start signal Sensor mark not detected 136

11.2.22 SM165 Roller unit Communication error 136

11.2.23 SM166 Applicator Communication error 136

11.2.24 SM167 Roller unit Error 137

11.2.25 SM168 CAN connection Disconnect! 137

11.2.26 SM169 Firmware update required! 137

11.2.27 SM180 Printer not finished 137

11.2.28 SM181 Chip changed! 137

11.2.29 SM185 Firmware update Winder required 137

11.2.30 SM186 Label sensor Check signals 137

11.2.31 SM187 Quality control Series fault 137

11.2.32 SM188 Quality control Stop delay change 137

11.2.33 SM189 Quality control label length wrong 137

11.2.34 SM190 Quality control label length wrong 138

11.2.35 SM193 Label size wrong Manual feed 138

11.2.36 SM198 CAN communikation Response time 138

11.2.37 SM199 CAN communication no CAN module detected 138

11.2.38 SM804 Unwinder failure Unwinder protec. Active 138

11.2.39 SM805 Unwinder failure TEACH process 138

11.2.40 SM808 Unwinder failure Too slow 138

11.2.41 SM809 Unwinder failure Circuit voltage too low 138

11.2.42 SM810 Unwinder failure Overload 138

11.2.43 SM811 Unwinder failure Temperature too high 138

11.2.44 SM812 Unwinder failure End of reel 138

11.2.45 SM813 Unwinder failure Diameter determination 138

11.2.46 SM814 Unwinder failure Power stage 139

11.2.47 SM825 Loop unwinder failure TEACH process 139

11.2.48 SM827 Loop unwinder failure 139

11.2.49 SM828 Loop unwinder failure Too slow 139

11.2.50 SM829 Loop unwinder failure Circuit voltage too low 139

11.2.51 SM830 Loop unwinder failure Overload 139

11.2.52 SM831 Loop unwinder failure Temperature too high 139

11.2.53 SM832 Loop unwinder failure End of reel 139

11.2.54 SM834 Loop unwinder failure Power stage 139

11.2.55 SM845 Winder failure TEACH process 139

11.2.56 SM848 Winder failure Torn tape / too slow 139

11.2.57 SM849 Winder failure Circuit voltage too low 140

11.2.58 SM850 Winder failure Overload 140

TABLE OF CONTENTS Operating instructions HERMA 400

10/154 3.28 US (130519)

11.2.59 SM851 Winder failure Temperature too high 140

11.2.60 SM854 Rewinder failure Power stage 140

11.2.61 SM865 Loop filler failure 140

11.2.62 SM910 Drive failure Low voltage 140

11.2.63 SM911 Drive failure High voltage 140

11.2.64 SM912 Drive failure High temperature 140

11.2.65 SM913 Drive failure Overload (period) 140

11.2.66 SM914 Drive failure 140

11.2.67 SM916 Drive failure 140

11.2.68 SM917 Drive failure Powerfail 141

11.2.69 SM918 Drive failure 141

11.2.70 SM919 Drive failure Low voltage (peak) 141

11.2.71 SM920 Drive failure Overload (peak) 141

11.2.72 SM921 Drive failure 142

11.2.73 SM922 Drive failure 142

11.2.74 SM923 Drive failure 142

11.2.75 SM924 Drive failure Overload 142

11.2.76 SM925 CAN communication disturbed 142

11.2.77 SM926 Drive failure: Overload (vMax exceeded!) 142

11.2.78 SM999 Drive mode was changed! f-button = restart 143

11.3 Malfunction table (LED indication) 144

11.3.1 Remedy of malfunctions 145

11.4 Error blink codes with PLC connection 145

11.5 Other malfunctions 146

11.6 Replace the drive unit 148

11.6.1 Remove the drive unit 148

11.6.2 Ship the drive unit 150

11.6.3 Mount the drive unit 150

11.7 Technical Service 150

12 Spare parts 151

A1 Index 153

3.28 US (130519) 11/154

1Overviewoftheapplicator

On the following pages you can see what your applicator is made up of, can learn

>which sub-assemblies the applicator comprises,

>how we name different items,

>what the functions of the applicator are – and which functions are not intended –,

>where there are hazard points,

>how to avoid hazardous actions,

>and more.

OVERVIEW OPERATING INSTRUCTIONS HERMA 400

12/154 3.28 US (130519)

Overview

Sub-assemblies (see picture):

1. Unwinding the label web (with the help of the „unwinder“; shown here: standard unwinder;

alternatively used: motorized version)

2. Tightening the label web (with the help of the „web brake“)

3. Sensing the individual labels on the web (with the help of the „label sensor“; shown here: model

FS03; alternatively used: optoelectronic sensor, for example, and others)

4. Dispensing the labels off the web (with the help of the „dispensing beak“, or „dispensing plate“)

(shown here: rigid dispensing plate; alternatively used: pivot beak, for example, and others)

5. Rewinding the backing paper after dispensing the labels (with the help of the „rewinder“, or

„backing paper take-up unit“; shown here: standard rewinder; alternatively used: motorized

version)

6. Motor and integrated applicator control (called „drive unit“)

7. Housing

The applicator shown above is a configuration example and may differ from the version delivered to

you. You will find information on different sub-assemblies in section 4.1 as of page 23.

1

5

2

7

6

3

4

Operating instructions HERMA 400 OVERVIEW

b

3.28 US (130519) 13/154

Warning symbols on the applicator

These symbols / hazard notification labels are used on the applicator:

Risk due to missing hazard notification labels.

Verify that all hazard notification labels shown on the overview picture

are in place.

lf hazard notification labels are not present, this could lead to injuries.

Contact your HERMA representative before energizing your machine

Find information on safety messages in chapter 2 as of page 15.

Find comprehensive general information on safety in chapter 3 as of page 17.

1Label roll

2Label roll core

3Label

4Backing paper

3+4 Label web

1

2

3

4

Risk of electric shock. 110-240 Volts

may be present.

Disconnect all sources of supply and

wait for five minutes before opening

the rear cover or touching the

connector pins!

If components are worked while the

applicator is not disconnected from

mains on this could cause

electrocution.

In this specially designated area, work

must be performed only by trained

electricians. Unauthorized persons

are not permitted to open the

designated area.

Risk of being drawn in.

Do not reach into the area where the

feed roller draws in the web when

machine is on!

This could lead to serious injuries.

DANGER

WARNING

WARNING

OVERVIEW OPERATING INSTRUCTIONS HERMA 400

14/154 3.28 US (130519)

www.herma.com

https://machines.herma.com

3.28 US (130519) 15/154

2Generalinformation

2.1 Handling of the documentation

The operating instructions must be available to all personnel working on the machine at all times.

The operating company must ensure that personnel who operate or maintain the system have read

andunderstood all safety instructions, precautionary measures, prohibited behaviour and comments

contained in these operating instructions.

2.2 Explanation of symbols

Warnings in these operating instructions are indicated by a warning symbol ( ) and/or signal words.

The signal words describe the extent of the danger. See the following section.

Follow the instructions precisely and act cautiously to prevent accidents, personal injury, damage to

property and life-threatening dangers.

2.2.1 Signal words

Danger: Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

Warning: Indicates a hazardous situation which, if not avoided, could result in death or serious

injury.

Caution: Indicates a hazardous situation which, if not avoided, could result in minor or moderate

injury.

Furthermore this word is used:

Notice: Indicates a situation which, if not avoided, could result in physical damage at your

applicator.

2

General information Operating instructions HERMA 400

16/154 3.28 US (130519)

2.2.2 General designations

Elements of the HERMA 400 control are designated and depicted in these instructions as follows:

Switch-on key

Manual feed key

Function key

LED (on)

LED (blinks)

LED (off)

Minus key

Plus key

Enter key

Find further explanation on these elements in section 9.1.

The HERMA 400 applicator is configured and offered as different model types.

The applicator type will be indicated in the basic display image with a corresponding letter, provided,

parameter „915 Ready screen“ is set to 00. See page 122.

Find here an overview of these models / letters and the corresponding symbols used in this manual:

Symbol / Abbreviation Type name

Vario

Vario M

Premium

Premium Plus Serial

Econ

Idea

Notes: A few of the illustrations used in this manual are examples and may differ sightly from the

configuration of your applicator.

Furthermore, note that the HERMA 400 applicator is available in both left-hand and right-

hand versions and that some illustrations may only show one of these versions.

3.28 US (130519) 17/154

3Safety

Risk of disregarding or neglecting possible dangerous situations or

actions.

Read and understand all the safety notes described in the following

sections as well as the safety messages found in the rest of these

operating instructions

Failure to do so could result in serious injury or death and/or property

damage.

3.1 Important Safety Information

This section provides an overview of all of the important safety aspects for ensuring optimum

protection for personnel and safe and trouble-free operation.

Non-compliance with the guidelines and safety instructions listed in these instructions can lead to

serious danger.

3.1.1 Signal word definitions

DANGER

Indicates a hazardous situation which, if not avoided, will result in

death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result

in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result

in minor or moderate injury.

NOTICE

Indicates a situation which, if not avoided, could result in physical

damage at your applicator.

WARNING

3

Safety Operating instructions HERMA 400

18/154 3.28 US (130519)

3.1.2 Mandatory signs

Cut the applicator / the machine off mains.

Make sure to tie up long hair (if required, wear a hair net) and avoid wide

clothing.

Make sure to read these instructions before working on the applicator.

The signs shown here indicate that the operation must be performed without fail / the information is

mandatory to take notice of.

Furthermore, this non-safety-related symbol is used:

Indicates information you should take notice of.

3.2 Personal protective equipment

While performing work, personal protective equipment must be worn to minimize the risks to health.

There are rotating parts at the applicator. Make sure to tie up long hair (if

required, wear a hair net) and avoid wide clothing. Your hair or your

clothes could get entangled in the applicator and lead to serious injuries.

WARNING

3

Operating instructions HERMA 400 SAFETY

3.28 US (130519) 19/154

3.3 Symbols on the applicator

These symbols / hazard notification labels are used on the applicator.

Missing safety labels could lead to disregarding possible dangerous

situations. Ensure that all symbols and signs are in a condition that is easy

to read at all times. Replace any damaged signs or labels. Illegible signs

can lead to dangerous situations.

Risk of electric shock. 110-240 Volts

may be present.

Disconnect all sources of supply and

wait for five minutes before opening the

rear cover or touching the connector

pins!

If components are worked while the

applicator is not disconnected from

mains on this could cause electrocution.

In this specially designated area, work

must be performed only by trained

electricians. Unauthorized persons are

not permitted to open the designated

area.

Risk of being drawn in.

Do not reach into the area where the

feed roller draws in the web when

machine is on!

This could lead to serious injuries.

CAUTION

DANGER

WARNING

3

Safety Operating instructions HERMA 400

20/154 3.28 US (130519)

3.4 Proper use of the applicator

Risk due to using the applictor in a way that is not intended. Always use

the applicator only for its intended use, which is unwinding label rolls,

dispensing labels and rewindig the backing paper. Any use other than the

purpose described above, in particular using the system to wind any

materials other than rolls of labels, is considered unintended use and is

prohibited. Unintended use could lead to unforeseen action and lead to

serious injuries.

>Use the applicator as intended.

The HERMA 400 applicator is an electronically-controlled device that is used to apply different

adhesive labels to a wide variety of products.

The labeler dispenses from the backing paper one label after the other at the dispensing plate.

Transport of the label web is effected via a pair of rollers driven by a servo motor.

You can use the applicator to unwind label rolls, dispense labels from the backing paper and then roll

up the backing material.

The HERMA 400 applicator is to be used in industrial environment only. It must not be used in private

environment.

The applicator can be configured for different needs and applications. This is done, apart from using

different sub-assemblies (see section 4.1 as of page 23), by setting various parameters with the help

of the integrated control (see chapter 7as of page 93).

The manufacturer/distributor cannot be held liable for any damage or injuries which result from

improper use. ln such a case, the user assumes liability.

Keep the applicator in optimal working order.

Proper inspection and maintenance needs to be performed regularly as outlined in this manual. Any

disturbances or faults must be eliminated immediately.

>Follow all operating instructions.

The applicator must only be operated by trained personnel and in accordance with the operating

instructions outlined in this manual.

>Observe all safety requirements.

The applicator has been designed according to the latest technologies in mechanical and electrical

engineering and according to recognized safety rules. Nevertheless, the use of this system may imply

danger to life and limb of the user or a third party. Also, there is potential for damage to the applicator

and other assets. All safety rules outlined in the manual must be followed to minimize the risk of injury

or property damage.

WARNING

Other manuals for 400

1

Table of contents

Other Herma Label Maker manuals