Herma LP Morgan Dipper User manual

LP Morgan

user manual

dipper

www.lpmorgan.com.au | www.herma.com.au

www.lpmorgan.com.au | www.herma.com.au

LP Morgan Dipper User’s Manual

Notes, Notices and Cautions

NOTE: A note indicates important information that helps you make better use of your Dipper.

NOTICE: A notice indicates either potential damage to ceiling or projector and tells you how to

avoid the problem.

CAUTION: A caution indicates a potential for property damage, personal injury or death.

Information in this document is subject to change without notice.

© 2002-2006 Herma Technologies. All rights reserved.

Reproduction in any manner whatsoever without permission of Herma Technologies is strictly forbidden.

Trademarks used in this text: Herma, the Herma Logo, Dipper, LP Morgan and LP Morgan logo are

registered trademarks of Herma Technologies.

Other trademarks and trade names may be used in this document to refer to either the entities claiming the

marks and names or their product. Herma Technologies disclaims interest in trademarks and trade names

other than its own.

January 2007 Version 2.3

Maintenance &

Troubleshooting

Troubleshooting/FAQ 25

Appendix

Accessories 26

Warranty Information 27

Important information

Precaution 6

To the owner 7

Unpacking 8

Part Names and Dimensions 10

Installation

Mechanical Installation 14

Ceiling opening 15

Ceiling Space 16

Ceiling type - Suspended ceiling 18

Ceiling type - Trussed ceiling 19

Electrical Installation 20

Wiring Diagram 21

Projector Installation 22

Cable Management 25

Table of contents

6 | installation instructions

Important

information

Precautions

ATTENTION: Please read all of these instructions before you operate your

Dipper for the first time. Save these instructions for further reference.

For your own protection and prolonged operation of your Dipper, be sure to read

the following precautions carefully before use.

On Safety

Check that the operating voltage of

your unit is identical with the voltage

of your local power supply. If voltage

adaptation is required, consult with

qualified an electrician.

Should liquid or solid objects fall into

the unit, unplug and have it checked by

qualified personnel before operating it

further.

To disconnect the cord, pull it out by the

plug. Never pull the cord itself.

The power supply should be near the

unit and easily accessible.

The unit is not disconnected from

the AC power source as long as it is

connected to the wall outlet, even if the

unit has been turned off.

Do not place your hand or other objects

near the trapdoor during operation.

The Skyhook Projector Mount must be

used for installation with the Dipper.

On Cleaning

To keep the unit looking new and clean

a dust cover is supplied. If cleaning is

necessary use a soft cloth and mild

detergent solution. Never use strong

solvents, such as thinners, benzene, or

abrasive cleaners.

Never operate the Dipper while the projector is still powered!

installation instructions | 7

Important

information

To the owner

Congratulations on purchasing an LP Morgan Dipper. This innovative

projector mounting system is a novel and secure way to mount your projector

out of sight when not in use, giving you maximum enjoyment and a truly

cinematic experience.

Please take a moment to review this manual, as it will ensure you many years

of trouble-free service from your new Dipper.

8 | installation instructions

Important

information

Unpacking the Dipper

When unpacking the Dipper, please handle all parts with care.

Do not destroy the inner box when unpacking, as it is the dustcover for

this unit!

T

h

e

F

a

c

e

P

l

a

t

e

o

n

t

h

i

s

p

r

o

j

e

c

t

o

r

m

o

u

n

t

h

a

s

b

e

e

n

t

r

e

a

t

e

d

o

n

l

y

w

i

t

h

a

w

a

t

e

r

-

b

a

s

e

d

u

n

d

e

r

c

o

a

t

f

o

r

y

o

u

r

c

o

n

v

e

n

i

e

n

c

e

.

T

h

i

s

w

i

l

l

e

n

a

b

l

e

y

o

u

t

o

p

a

i

n

t

i

t

t

o

m

a

t

c

h

y

o

u

r

c

e

i

l

i

n

g

.

installation instructions | 9

Important

information

12

7

34

56

1. Dipper Unit

2. Control Unit, Protective Enclosure

3. LP Morgan Skyhook Projector Mount System

(including mounting bolts and springs)

4. 24V Power Supply

5. Ceiling Face Plate

6. Ceiling Trim

7. Wall Switch and Architrave Mount

8. Cardboard Dustcover

9.Spring, Bolts Washers

8

9

10 | installation instructions

Important

information

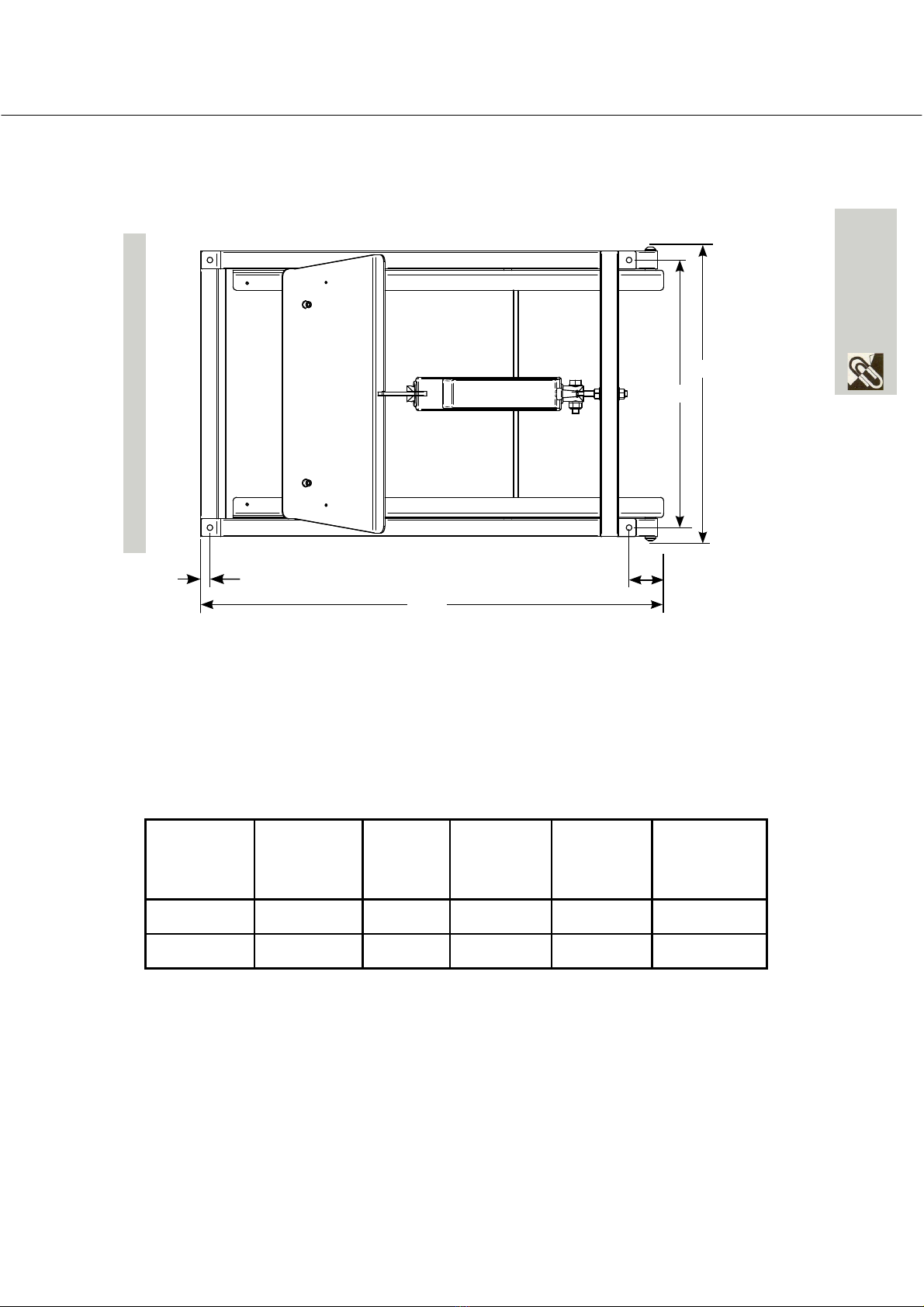

Part Names and Dimensions

Make consideration of the maintenance of the Dipper when installing it. Wherever

possible, allow access to the ceiling cavity other than through the Dipper’s hole

- so that you can access the projector if the power supply fails!

Side View

A3

B2

B1

B2

Dipper

Size

Front

Mount Tabs

(A1)

Rear

Mount Tabs

(A2)

Overall

Height

(A3)

Face Plate

to Front

(B1)

Face Plate

Length

(B2)

Face Plate

to back

(B3)

Medium 125 205 355 35 400 215

Large 125 175 430 30 500 300

A2

A1

installation instructions | 11

Important

information

Top View, Closed Position

Screen

C2

D1

D2

C1 C3

Dipper

Size

Front

mounting

hole (C1)

Overall

Length

(C2)

Rear

mounting

hole (C3)

Overall

Width

(D1)

Mounting

hole Width

(D2)

Medium 15 6500 50 405 380

Large 15 830 40 505 480

12 | installation instructions

Important

information

Front View, closed position

D3

D1

Dipper

Size

Overall

Width (D1)

Face Panel

Width (D3)

Medium 405 400

Large 505 500

installation instructions | 13

Important

information

FRONT

Front 3D View

1. Motor

2. Pivot Frame

3. Main Frame

4. Skyhook Plate

5. Mounting Tabs

6. Face Panel

1

23

4

5

6

14 | installation instructions

Mechanical

Installation

Mechanical Installation

The first crucial step, like any projector installation, is to determine where to put

the Dipper in the ceiling. The Dipper should be installed so that the projector

lens is centered horizontally to the screen, and the distance from the screen

depends on the projector’s throw distance.

Work out the maximum and minimum throw distances for the projector and

place the Dipper somewhere in between. It is better for the projector to be

closer to the screen, but don’t place it at an extreme—leave yourself some

room to adjust the zoom in either direction.

Screen

Screen center

Lens center

Projector center

Note: when aligning the Dipper

make sure that the projector

lens is centered on the screen,

which is not necessarily the

projector center.

Throw Distance

installation instructions | 15

Mechanical

Installation

The Dipper comes with a 12mm undercoated MDF face panel and an aluminium

ceiling trim.

We recommend that you paint this panel before fixing the Dipper in the ceiling.

In the case of a non-plasterboard ceiling, you may choose to fabricate your own

ceiling panel (eg from the same timber/material as the ceiling itself) to match.

We recommend you leave a 2mm gap around all edges of the Dipper’s face

panel.

Supplied is a plastic trim that you may use to finish off the edge of the hole. The

cutout dimensions given below assume that you will use this ceiling trim.

Face Panel

L x W mm

Cutout required with ceiling trim

L X W mm

Medium Dipper 400 x 400 410 x 410

Large Dipper 500 x 500 510 x 510

Ceiling Opening

16 | installation instructions

Mechanical

Installation

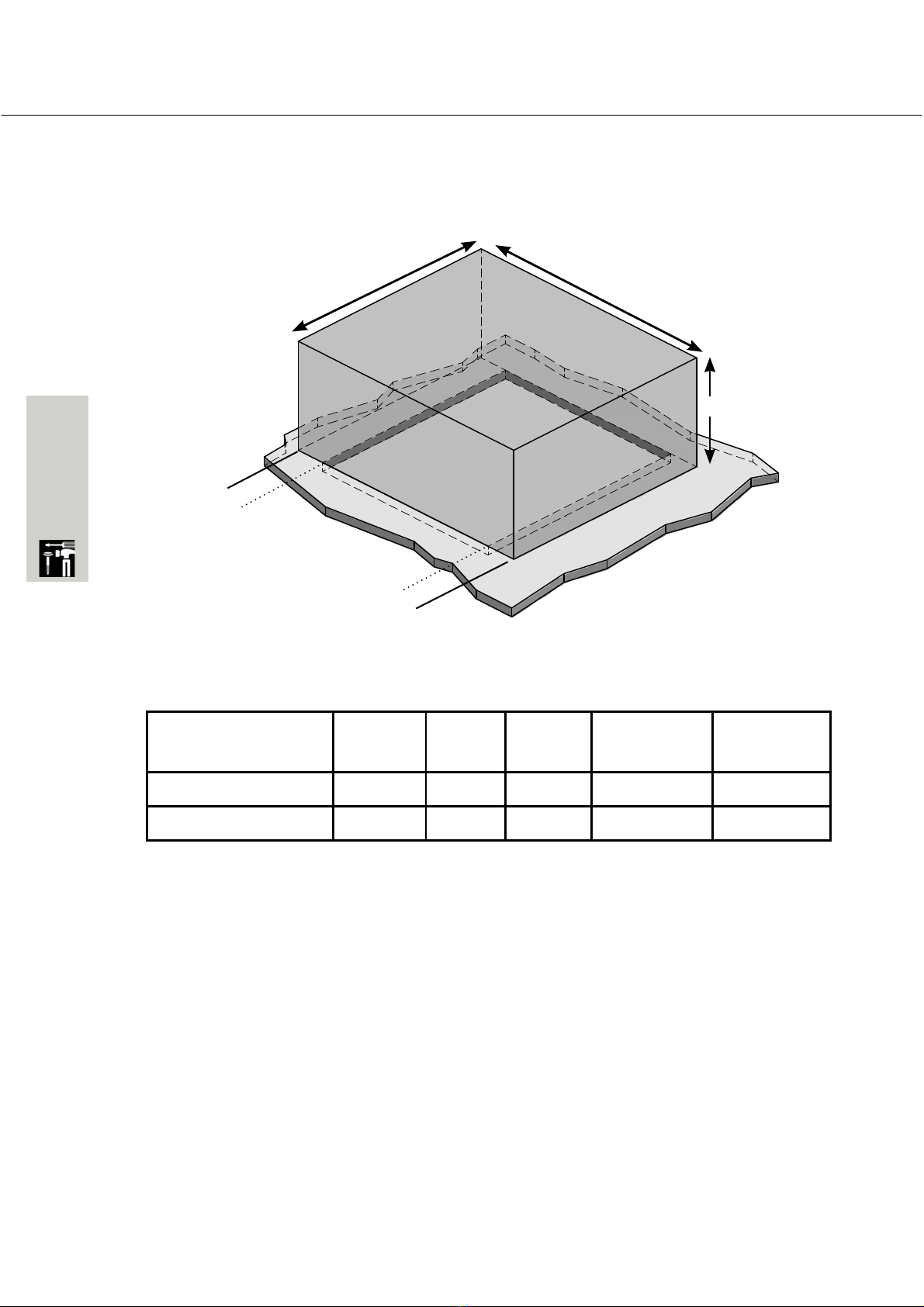

The following diagrams show the position of the ceiling cutout in relation to the

Dipper frame, and the space required above the ceiling.

Ceiling Space - Standard Dipper

Size Length

(L)

Width

(W)

Height

(H)

Front Gap

L1

Rear Gap

L2

Medium Dipper 650 405 355 32 212

Large Dipper 830 505 430 27 297

L

W

L1

L2

FRONT

H

installation instructions | 17

Mechanical

Installation

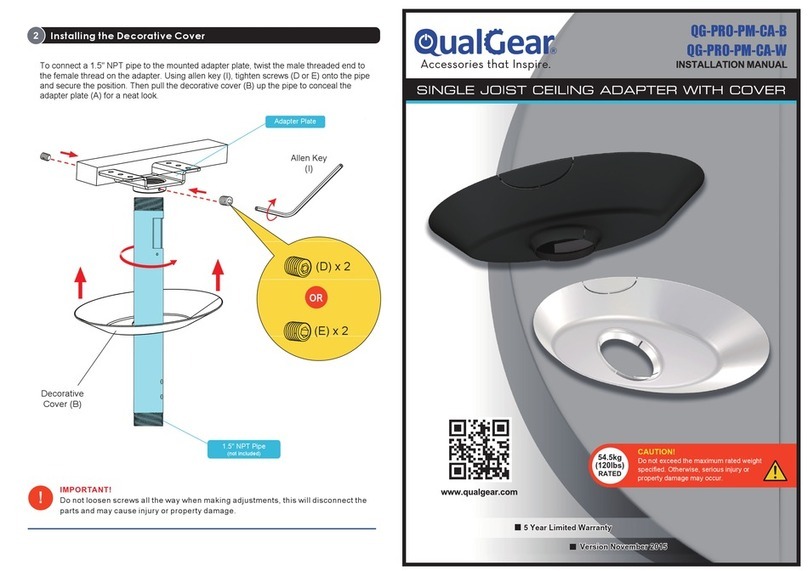

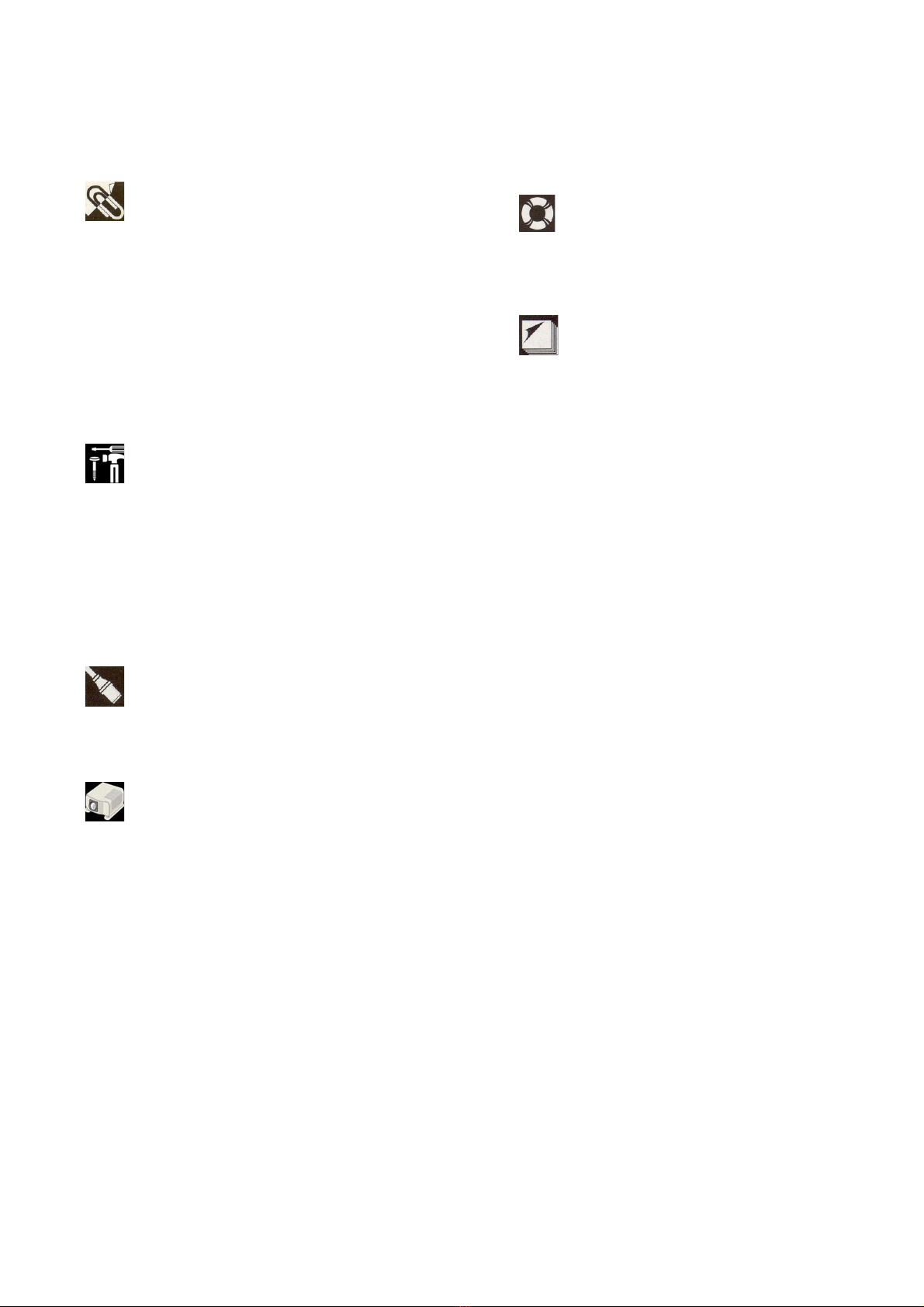

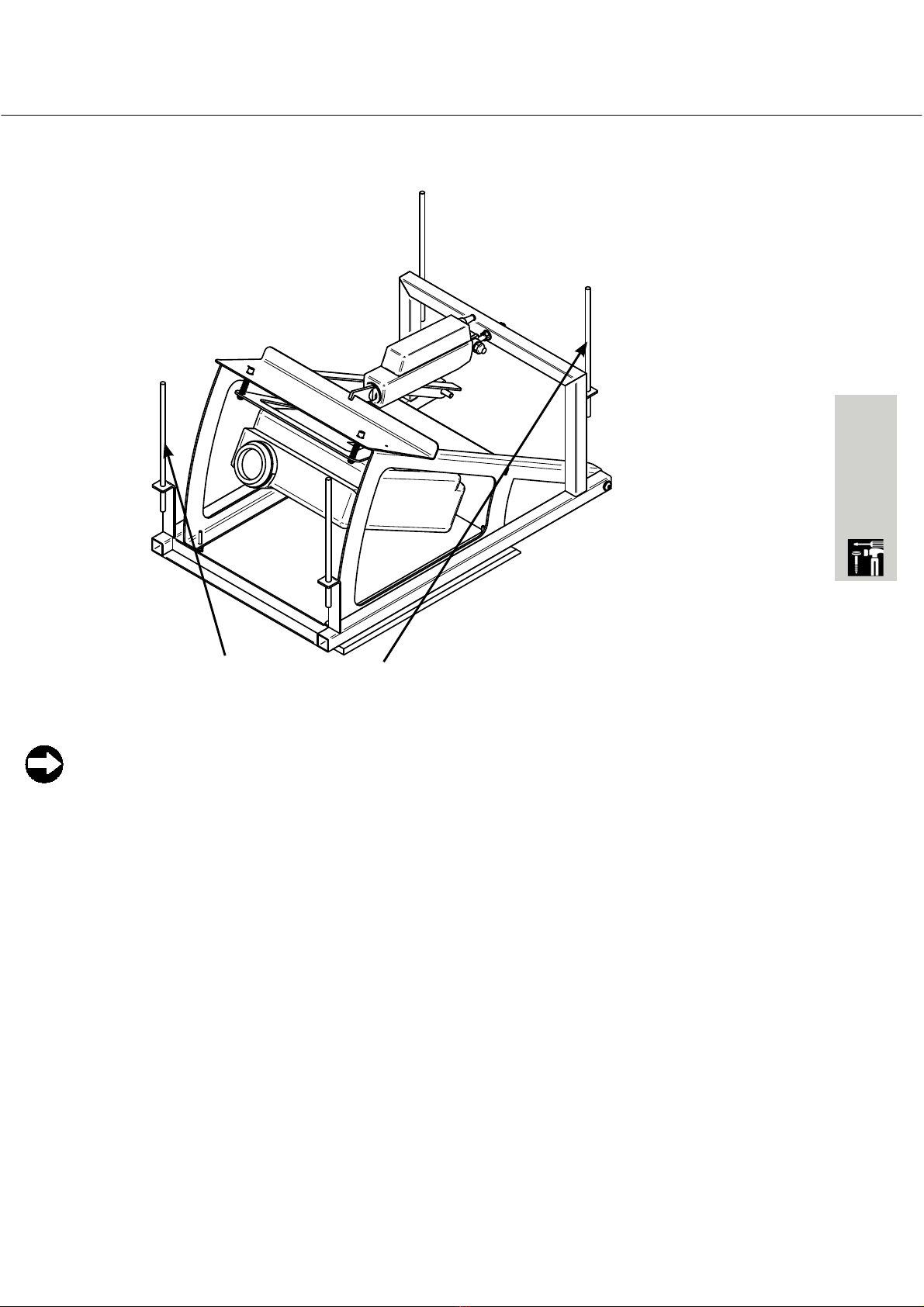

Ceiling Fastening - Suspended Ceiling

For suspended ceilings you can suspend the Dipper itself through the four

mounting holes using threaded rod.

You can use the nuts to adjust the height of the Dipper once

installed, so you can get it exactly flush with the ceiling.

Threaded Rod and Nuts

18 | installation instructions

Mechanical

Installation

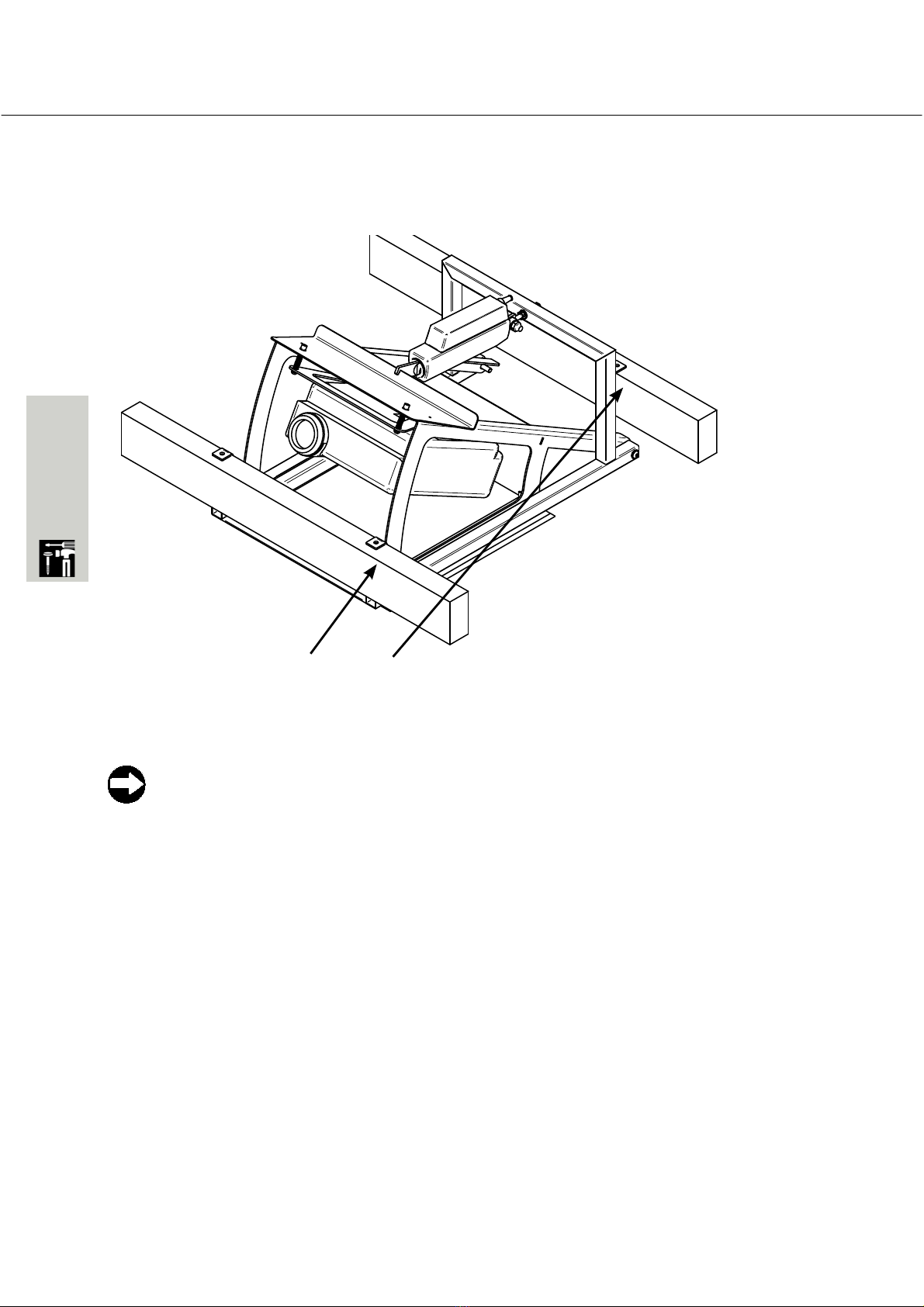

Ceiling Fastening - Trussed Ceiling

For some ceilings, you will need to construct a support structure for the Dipper

to rest in - this can be as simple as two appropriately spaced bearers at the

right height. See the previous pages for the relevant dimensions.

Allow yourself some way to easily adjust the height of the Dipper once

installed, so you can get it exactly flush with the ceiling.

Screwed Straight into Bearers

installation instructions | 19

Mechanical

Installation

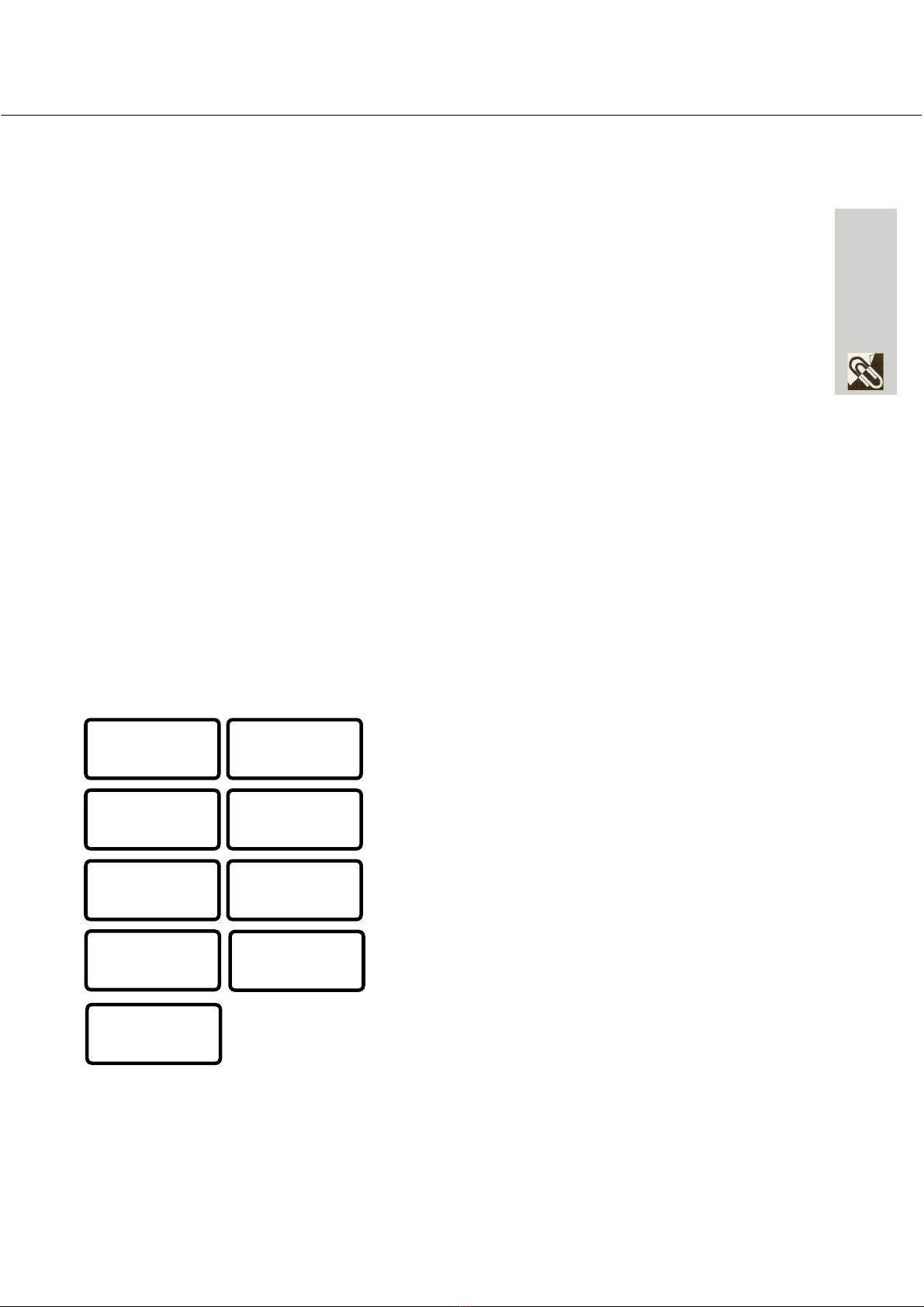

Once the Dipper frame is install you should attached the face panel.

We recomend you paint the face panel to match the room before installing it.

1. Insert 4 x countersunk bolts, washers and springs as shown through face panel

from the underside.

2. Adjust the level so that it is exactly flush with the underside of the ceiling.

3. Once full adjusted, cover holes with stick pads. (for more information, refer to

Page 15)

Front

M4 Washer

M4 CS Bolt

Spring

Face Plate Installation

Stick Pad

20 | installation instructions

Electrical

Installation

Electrical Installation

The Dipper is supplied with a unique control unit that can be adapted to just about

any installation requirement.

It operates via dry contacts, but can be easily upgraded to a 12V trigger, Infra Red,

Radio Frequency remote control, or even RS232.

A Maintained, Single Pull, Single Throw Switch (a normal light switch) comes

supplied as standard. or alternatively you can use a single relay. Open circuit is

up, close circuit is down.

You do not need to be a qualified electrician to wire the Dipper, as all circuiting is

24V, however Herma will not accept responsibility for damage incurred by faulty

or incorrect wiring.

The power supply and motor are pre-wired, so all you need to do is attach relay

or motor cable and switch as shown in the following diagram. The switch needs

to be wired into the “Switch Up” and “Common” terminals.

PROTECTIVE ENCLOSURE CONTROL UNIT

POWER SUPPLY + IEC LEAD

WALL SWITCH

Table of contents