Herutu 21D-265C User manual

Wireless Production Control Indicator Controller

21D-265C

Instruction Manual V1.90

Please use this Instruction manual correctly on reading well.

Please keep it carefully to be able to read immediately, when required.

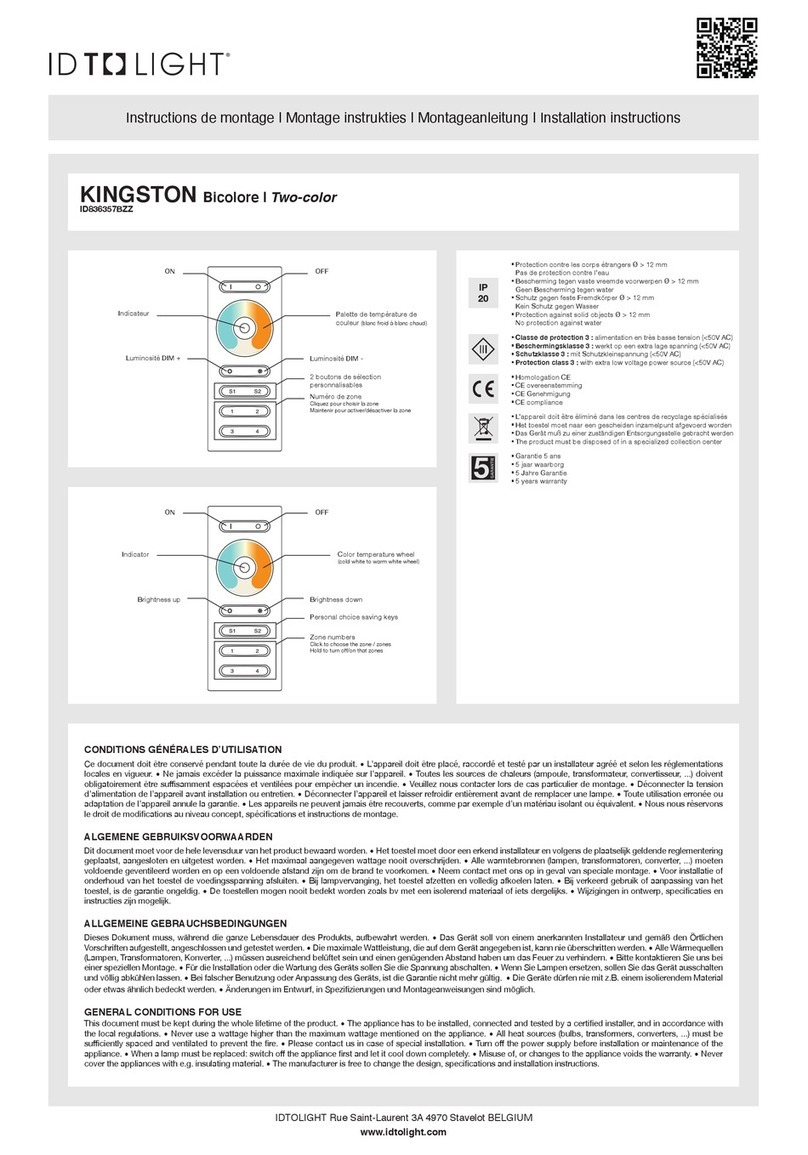

[21D] Notational Conventions for Series Model

Set (Controller+Display)

1

Machine

types

2

Items

3

Communica

tion

4

Display type

5

LED color

21

***

-

***

-

***

-

***

-

***

D

2

429

123

G

D5

3

265

523

R

DW

4

124

D5W

524

DE

152

DEW

15

12

52

23

24

1523

1524

For the Controller only, the contents of 3 Communication are as follows:

429C

265C

For the Display only, the contents of 3 Communication are as follows:

429D

265D

485D

1. Machine types: D→Large-sized 4-digit Single side,D5→Large-sized 5-digit Single side,

DW→Large-sized 4-digit Double side, D5W→Large-sized 5-digit Double side,

DE→Middle-sized 5-digit Single side,DEW→Middle-sized 5-digit Double side

2. Item : 2 - 4 items

3. Communication:429→Specific small-current radio wave

265→Microradio wave

485→Wire-type

*For the 485 type, only the Display is available.

4. Display type :1→Target 2→Actual 3→Advancement 4→Accomplishment rate 5→Plan

5. LED color : G→Green, R→Red

*For the Middle-sized type, only red color is available.

To use this product in safety and comfort, (Be sure to read)

Thank you very much for purchasing our product.

This operation manual contains the precautions necessary for preventing an accident caused by the use

in an improper ways.

Read it carefully while thoroughly understanding the meanings of pictorial symbols.

Using in an improper way while ignoring this pictorial symbol might

cause a serious human injury.

Using in an improper way while ignoring this pictorial symbol might cause

a human injury or physical damage.

■The type of precautions that should be observed, are classified using the following pictorial symbols.

This pictorial symbol indicates a “Reminder”to attract an attention.

This pictorial symbol indicates a “Prohibition”to prohibit a certain action.

■For the usage to be commonly applied in all the models:

●Avoid using in a place with a plenty of humidity or dust. Otherwise, absorbing a dust

or water contents may cause machine trouble, fire or electrical shock.

■For handling this machine:

●This is the electronic devise or wireless radios composed of the precision parts.

Do not overhaul/remodel. It may cause accident or machine trouble.

!Warning

!Caution

!

tyuui

!Caution

■For handling this machine:

●Do not use this product for the application needing the high reliability

related to human lives.

●Do not use this product in a place where it is uncertain about whether or

not radio waves reach.

■For handling the power source:

Be sure to observe the following precautions to prevent the AC adapter and Power cord from being

heated, damaged or ignited.

●Do not approximate theAC adapter and Power cord to a fire, or do not put

them into a fire. The AC adapter and Power cord can be broken or ignited,

resulting in an accident.

●You can use theAC adapter and main body only with the specified power

voltage to protect them from the damage and fire accident.

●Do not use theAC adapter and main body in a wettable atmosphere.

It may cause accidents or troubles such as heating, igniting or electrical shock.

●Do not touch theAC adapter, main body, Power cord and Plug outlet with

wet hands. It may cause an electrical shock.

●Do not damage the Power cord.

A short-circuit or heating may cause a fire or electrical shock.

●Do not use the Power plug with dust being adhered.

A short-circuit or heating may cause a fire or electrical shock.

●Do not give a strong impact onto the AC adapter.

It may cause an accident or machine failure.

●If you find out deformed AC adapter, do not use it.

It may cause an accident or machine failure.

●do not use this product in a place where flammable gas can be generated.

It may cause a fire accident.

●Never overhaul theAC adapter.

It may cause an accident or machine failure.

■When trouble happens during use:

Since it may cause a fire or electrical accident, disconnect a power plug, and immediately ask outlet

store or our company torepair.

●When smoke or abnormal odors are generated, stop using, immediately

disconnect a power plug, and ask outlet store or our company torepair.

●Once the Power cord is damaged, do not use it.

Using it as is may cause a fire or electrical accident.

!

!Warning

※This operation manual is translated a product for Japan into English/

This product is based on Japanese Wireless law.

Before use:

This machine is based on Japanese Wireless law of micro radio waves.

1. Do not use it for the application which may possibly cause loss of human life or damage of other

equipment or units.

Also, do not use it near the units which may be malfunctioned by the radio wave emitted from

this machine.

2. This machine is only for use in Japan.

Different Radio Law does not allow the application outside Japan.

It is also impossible to use it while the machine is being connected to the electrical

communication line.

3. The communication capacity may vary with the surrounding conditions. Make sure if

communication is possible before installation.

Contents

1. General Description............................................................................................................ 1

1-1. Scope............................................................................................................................1

1-2. Outline ..........................................................................................................................1

1-3. Type selection...............................................................................................................1

2. Specifications ..................................................................................................................... 3

3. Names and Functions of each section............................................................................... 6

3-1. Names and Functions of each section.........................................................................6

3-2. Terminal block...............................................................................................................8

3-3. AC Adapter ...................................................................................................................9

4. Installation methods ......................................................................................................... 10

4-1. Installation of Controller..............................................................................................10

4-2. I/O circuit.....................................................................................................................11

5. Function settings .............................................................................................................. 13

5-1. Function settings ........................................................................................................13

5-2. Setting the equipment No. Command[0] .................................................................14

5-3. Setting the wireless channel Command[1]..............................................................14

5-4. Setting the operation type Command [2].................................................................16

5-5. Setting the digit-number Command [3]....................................................................17

5-6. Setting the tact precision Command [4] ..................................................................17

5-7. Setting with or without Tact reserve function Command [5]....................................18

5-8. Setting with or without working hours Command [6]...............................................20

5-9. Setting the password function Command [7]...........................................................21

5-10. Setting the pre-scale Command [8].......................................................................22

5-11. Setting with/without Advancement judging Command [9]....................................23

5-12. Setting the Transmit mode Command [10]..........................................................24

5-13. Setting with/without latch display Command [11]..................................................26

5-14. Setting with/without the stop a calculation at the PLAN=TARGET [12]...................26

6. Basic operation................................................................................................................. 27

6-1. Setting the Internal clock Key [4].............................................................................33

6-2. Setting the Working hour pattern Key [6]...............................................................34

6-3. Setting the Working hour Key [5].............................................................................35

6-4. Setting the Tact Key [0]............................................................................................38

6-5. Setting the Target Key [1] ........................................................................................39

6-6. Setting the Plans Key [1] or [2]................................................................................40

6-7. Setting the Actual Key[2] or [3] ..............................................................................41

6-8. Setting the Advancement Key [3].......................................................................42

6-9. Setting the Accomplishment rate Key [3].................................................................43

6-10. Setting the Clear time Key [7]..............................................................................44

6-11. Setting the Pre-scale Key [8].................................................................................45

6-12. Setting theAdvancement judging function Key [9]................................................47

7. Applied operation.............................................................................................................. 48

7-1. Working setting 2,3-Setting the Tact reservation (With working hour)....................50

7-2. Working setting A - Operation when “No” for working hour setting is set(Without Tact

reserve function)................................................................................................................58

7-3. Working setting B,C - Operation when “No” for working hour setting is set(With Tact

reserve function)................................................................................................................61

8. Handling precautions........................................................................................................ 62

9. Maintenance..................................................................................................................... 63

10. Warranty......................................................................................................................... 63

Dimensional drawing............................................................................................................ 66

21D-265C

1

General Description

1. General Description

1-1. Scope

This operation manual describes about the Controller [21D-265C] (hereinafter called “the

machine”) of Wireless Production Control Indicator [21D-265] Series.

For the Wireless Production Control Indicator [21D-265] Display, see another operation

manual.

1-2. Outline

The Production Control Indicator unit [21D-265] series consists of the Controller section and

Indicator section. This machine is the Controller for Wireless Production Control Indicator unit

[21D-265], which displays the contents of ever-processing process and the quantity of

production at your factory. Once combined with the Indicator unit, it helps you grasp the

present status of production at a glance and also provides you with a great effect on the

rationalization of production such as production process analysis, worker’s self-administration

and etc.

1-3. Type selection

The combination of “Target”, “Actual”, “Advancement”, Accomplishment rate”and “Plan”

allows you to select several kinds of types. Normally, the type is already set before shipment.

However, it can be changed after purchasing. You may select the item suitable for your

application after understanding the contents of each item. In this manual, the type is replaced

with the numeric value and alphabet.

Items

Contents

Numeric

notation

Alphabetical

notation

Target

The target quantity of production today

1

T

Actual

The quantity of production up to the present

2

A

Advancement

The degree of advancement in either “+”or “-“sign to

the planned quantity of production at the present

3

a

Accomplishment

rate

The Accomplishment rate (%) of actual to the planned

quantity of production at the present

4

t

Plan

The planned quantity of production at the present

5

P

21D-265C

2

General Description

Types

Numeric notation

Alphabetical notation

Target/Actual/Advancement

123

TAa

Plan/Actual/Advancement

523

PAa

Target/Actual/Accomplishment rate

124

TAt

Plan/Actual/Accomplishment rate

524

PAt

Target/Plan/Actual

152

TPA

Target/Plan/Actual/Advancement

1523

TPAa

Target/Plan/Actual/Accomplishment rate

1524

TPAt

●How to calculate each item

“Plan”=Elapsed time within working hours ÷Tact

“Accomplishment rate”(%) =(Actual÷Plan) x100

“Advancement”=Actual-Plan

* Decimal places of theAccomplishment rate are all cut off.

* If the Accomplishment rate is over 9999% or it cannot be calculated, “9999”appears for the

calculation results.

21D-265C

3

Specifications

2. Specifications

Items

Descriptions

Remarks

Model

21D-265C

Frequency

Optional one wave of 41 waves ranging

264.500-265.500MHz(25KHz in step)

A conformity

standard

Micro radio wave method of Japanese law

Antenna

1/4λ Whip antenna

Input power

voltage

DC12V(DC11.0-28.0V)

①DC Jack for AC adapter x1

②Terminal block(screw-type) x1

Current amount of 300mA or

more can be steadily supplied

Current

consumption

About 50mA in DC12V

When I/O terminal is not

connected

Working

environment

Temperature:0-50℃

Humidity:85% or less, no dew drop

Size

222W x155H x 40Dmm

(Projection excluded)

Weight

About 650g

Buzzer

Used for checking the key input and error

Keyboard

Membrane switch with 20 keys

[F1]-[F4]

[0]-[9]

[▲](UP),[▼](DOWN)

[+],[-]

[CLR],[ENT]

Display

LCD

16-digitx2-line LED backlight built-in

Switch

Power switch x 1(Locker switch)

Input

Non-voltage contact input x 5-point

5V 15mA can be stably turned

ON/OFF

Output

Open collector output x4-point

Max output voltage DC50V

Max output current 1.5A

*1

Data backup

About 2 weeks

*1:Use the diode for preventing the back electromotive force when turning on/off the coil inductive

load.

21D-265C

4

Specifications

Also, use an extreme care when controlling the lamp load and etc having a high inrush current.

Even if only slightly exceeding the maximum output current, it may damage the drive circuit.

21D-265C

5

Specifications

Operating specifications

Items

With working hour

Without working hour

Labor hour

Max 23 hours 59 minutes

Max 1 month

Working hour

For 20 working hours

Number of sets: 40

Impossible to set

Working hour

pattern

6 patterns

Impossible to set

Tact

0.1-9999.9 second or 0.01-999.99 second

Target

4-digit type:0-9999 5-digit type:0-99999

Plan

4-digit type:0-9999 5-digit type:0-99999

Actual

4-digit type:0-9999 5-digit type:0-99999

Advancement

4-digit type:0-±999 5-digit type:0-±9999

Accomplishment

rate

4-digit type:0-999(%) 5-digit type:0-9999(%)

Tact reservation

For twenty types at max

<Reserved contents>

Set-up time 0-998-min *1

Tact 1-9999.9 second or 0.01-999.99 second

Production target quantity 4-digit-type:0-9999 5-digit-type:0-99999

Clear time

For 3-time max

Pre-scale value

1-99999(Multiple number) 1-99999(Batch number)

Advancement

judging set value

0-9999(+side) 0-9999(-side)

*1:It can be set only when Working hour setting “Yes”is set.

*Internal clock may possible cause approximately 1-min/month in error depending on the working

environment(0 to 50℃).

21D-265C

6

Names and Functions of each section

3. Names and Functions of each section

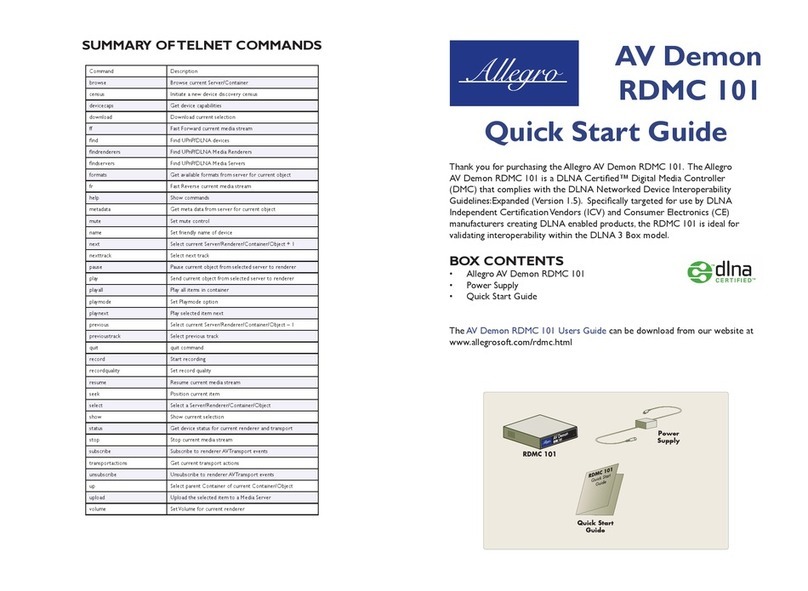

3-1. Names and Functions of each section

①Antenna

②LCD display

③Buzzer slot

④Keyboard

⑤Terminal block cover

⑦I/O Terminal block

⑥Power input Terminal block

⑨DC Jack IN

⑩Power switch

⑧Mounting slot

(4-point)

⑪Nameplate seal

21D-265C

7

Names and Functions of each section

①Antenna

1/4λ whip antenna

(Set it perpendicular to the installation face during use.)

②LCD Display

16-digit x 2-line display LCD

③Buzzer slot

Slot for buzzer sound

④Keyboard

Membrane switch with 20 keys

⑥Power input terminal

block

Terminal block for inputting power source of 12VDC

(DC11.0-28.0V)

⑦I/O Terminal block

Screw-type I/O terminal block

⑧Mounting slot

Mounting slot for installing the machine: Φ4.5mm x 4-point

(For the mounting slot positions, see the Dimensional drawing.)

⑨DC Jack IN

DC Jack entry for dedicated AC adapter (DC12V)

⑩Power switch

Power source switch

⑪Nameplate seal

Model and production number are described.

21D-265C

8

Names and Functions of each section

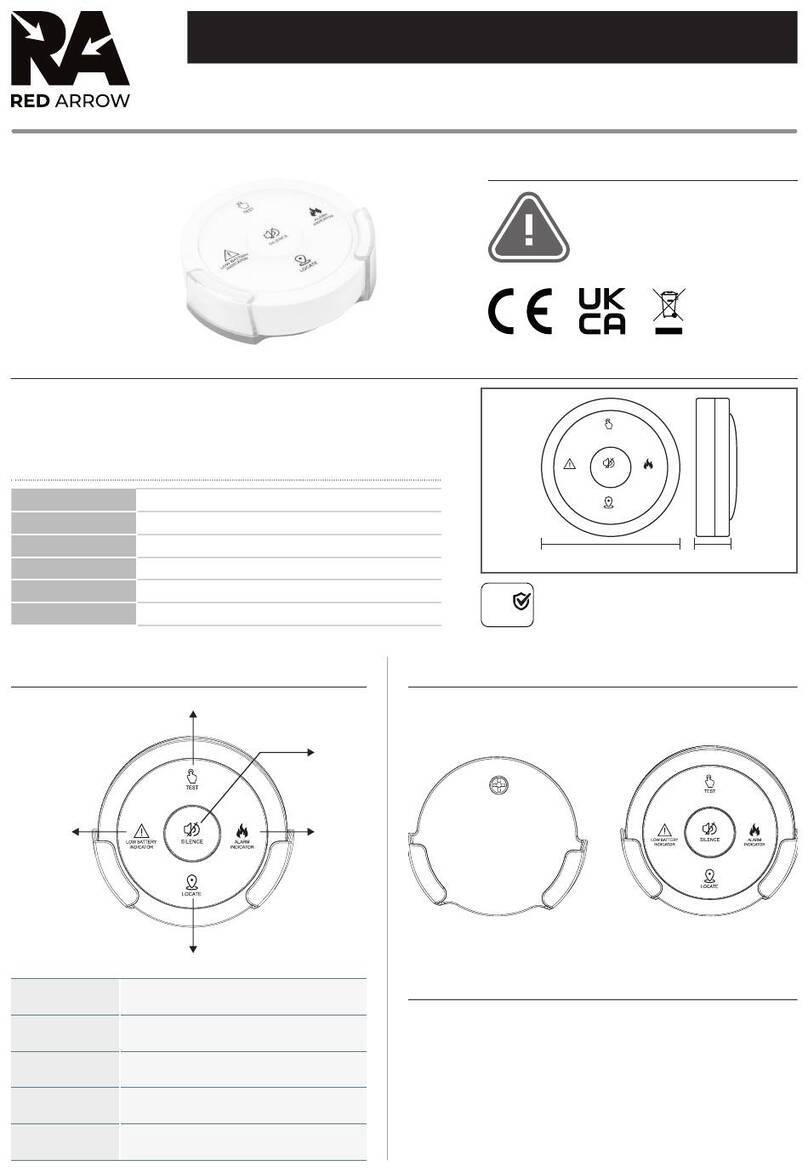

3-2. Terminal block

[Terminal block layout]

Power input

DC12V

(DC11.0-28.0V)

Input the power voltage.

Non-voltage

contact

input

Actual input

Increases the production actual

Subtraction input

Decreases the production actual

Clear input

Clears the Actual/Plan.

Tact switch input

Switches tact reserve No. into next reserve No. *1

(effective only when Tact reserve function is used)

Stop input

Operating

input

“With Working hour”is

set

“Stop input”turns on during inputting so that the

planned quantity calculation stops.

“Without Working hour”

is set

“Operating input”turns on during inputting so that

the planned quantity calculation runs.

Open

collector

output

Advancement judging output

“+”

It turns on while Advancement exceeds

“+advancement judging value”.

Advancement judging output

“-”

It turns on while Advancement does not exceed

“-advancement judging value”.

“During setup”output

“During setup”turns on. *2

“During setup”turns off for other than Working

hour.

“During

stop”

output

“With Working

hour”is set

“During stop”turns on while Stop input terminal is

ON.

“Without Working

hour”is set

Not used

Power

source

Input

Output

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

■

GND

+12V

GND

Actual input

GND

Subtraction input

Clear input

GND

Tact switch input

Stop input/Operating

input

GND

Advancement

judging+output

GND

Advancement

judging -output

GND

“

During setup

”

output

GND

“

During stop

”

output

Top face

↑

21D-265C

9

Names and Functions of each section

*1:When switching from the final reserve No, the reserve No. 1 comes back.

*2:This is only effective when “Yes”for use of working hour is set while “Yes”for use of Tact

reserve function is set.

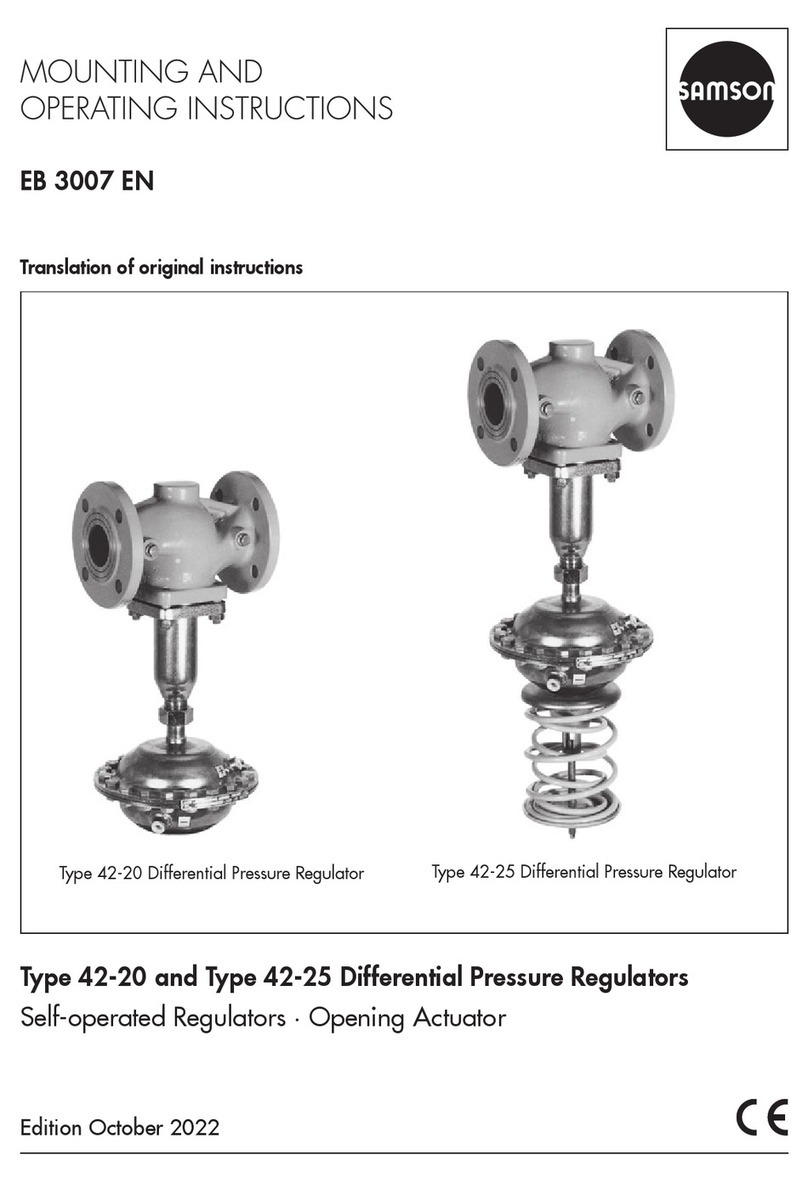

3-3. AC Adapter

Model:ADB12100

Input voltage:AC90-264V

Output voltage:DC12V 1A

-+

コネクタ

Connector

21D-265C

10

Installation methods

4. Installation methods

4-1. Installation of Controller

①Install the machine in a place near each I/O signal as far as possible using the mounting slots

while the machine can be easily controlled and its antenna on the Display can be easily

overlooked.

Install the machine so that Antenna is not in parallel to the metal objects.

②Connect the signal cables necessary for I/O terminals.

Connect the actual input signal and necessary I/O signal cables to the Terminal block.

③Feed the specified voltage without fluctuation and instantaneous stoppage into the power

source.

If AC Adapter is used, insert the AC adapter connecting section into the DC jack of the

machine.

If DC power source is used, connect the power source, which can stably supply 300mA or

more up to the specified voltage, into the Terminal block.

Besides, the wire rod for power source should be securely mounted on the Terminal block.

* To assure the safety, turn off power source before mounting the wire rod.

Operating power voltage:DC12V(DC11.0-28.0V),300mA or more

*The power voltage should be connected to either DC IN for AC adapter or terminal block power

input.

Power input

Actual input

Connect at your own

discretion depending on

the functions used.

Mounting slot Φ4.5-4

Connect the AC Adapter

(AC100V)

21D-265C

11

Installation methods

4-2. I/O circuit

[Configuration of Input circuit] [Configuration of Output circuit]

●Connecting to the input terminal

For the Non-voltage contact input to be connected to the Actual input, use the circuit with less

chattering which can steadily turn on/off the voltage/current of 5V/15mA.

Keep a time interval of 50mSec or more between input signals. Also for the time interval

between the time when input signal is turned off until the time when next signal is

turned on, keep 50mSec or more.

For the input signal, be sure to connect the non-voltage contact signal.

●Examples of connection (Output side)

Contact output(LED lights up with ON)

Use it within the driving current per terminal. If the specified power voltage or driving current

are exceeded, connect the drive circuit like relay during use.

Or, if inductive load such as lamp or relay is connected, take necessary actions for inrush

current.

R

PS2701 COM

INPUT

VCC

TD62308

COM

OUTPUT

Absolute max rating DC50V1.5A

【Relay load】

OUT

COM

【Lamp load】

Exterminal

power source

External power

(GND)

OUT

COM

External

power source

External power

(GND)

Resistance for

preventing inrush corrent Lamp

Diode for preventing the

back electromotive force

Relay

21D-265C

12

Installation methods

[Terminal block rating]

Cable size to be connected :0.14-1.5mm2

(AWG26-AWG16)

Electric cable naked length :6mm

Terminal screw nominal dia :M3

Absolute max rating :DC50V 1.5A

Table of contents