Herutu SD-4 User manual

Compact Production Control Indicator

【SD-4】

Operation Manual

V1.50

FCC for United States ofAmerica

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

IC for CANADA

This classA digital apparatus compliance with Canadian ICES-003.

Cet appareil numérique de la classeA est conforme à la norme NMB-003 du Canada.

CONTENTS

Chapter 1 Before Use.................................................................................................................. 1

1-1 Introduction........................................................................................................................ 1

1-2 Accessories........................................................................................................................ 1

1-3 Safety precautions (Be sure to read)............................................................................... 1

1-4 General description........................................................................................................... 3

1-5 Specifications..................................................................................................................... 4

1-6 Exterior features ................................................................................................................ 5

1-6-1 Main body .................................................................................................................... 5

1-6-2 Terminal block............................................................................................................. 6

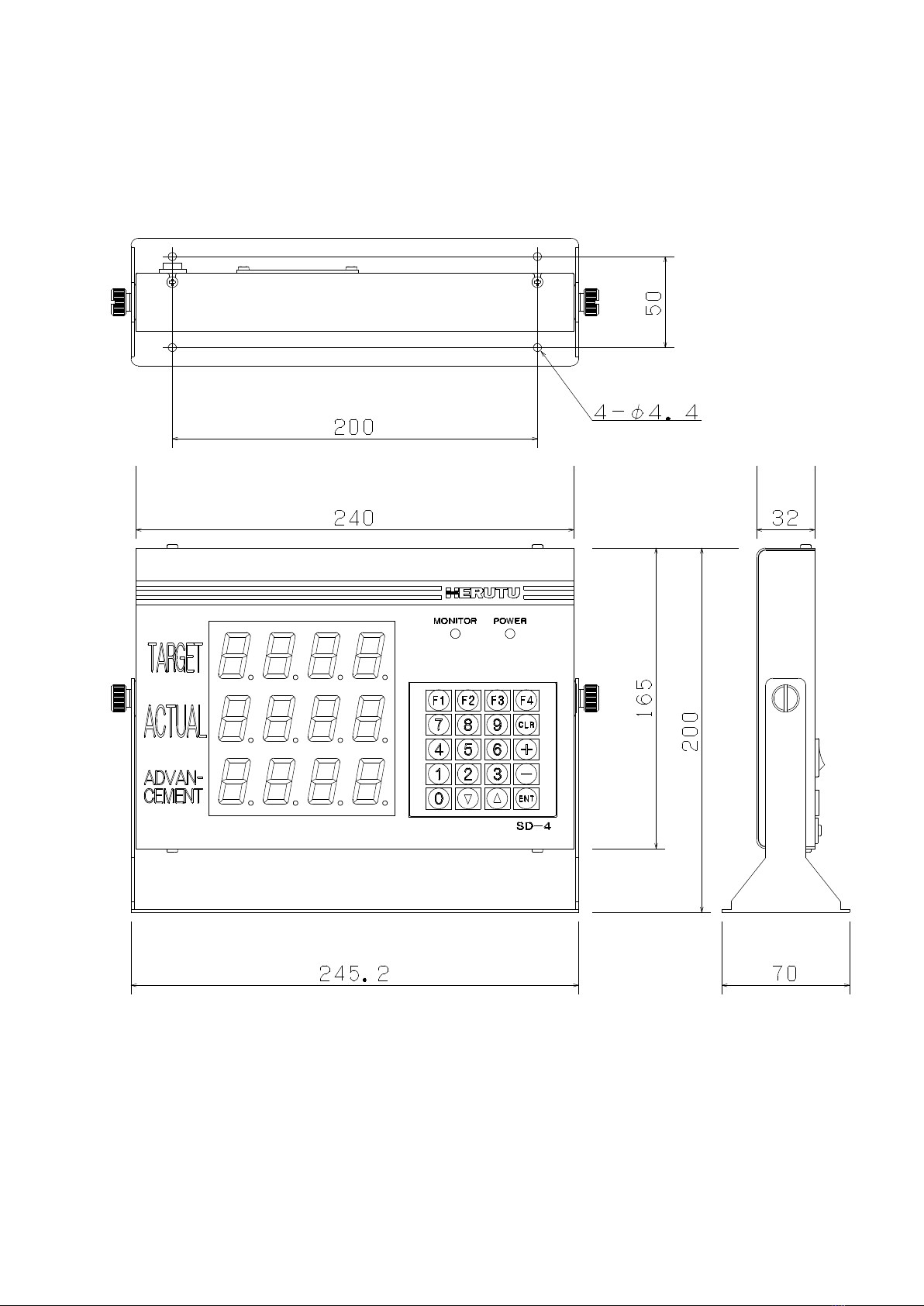

1-7 Dimensional drawing......................................................................................................... 7

1-8 Installation.......................................................................................................................... 8

1-8-1 Installation procedure ................................................................................................ 8

1-8-2 Input terminal block.................................................................................................... 8

Chapter 2 How to Use.................................................................................................................. 9

2-1 Function settings............................................................................................................... 9

2-1-1 Setting an operation type..........................................................................................11

2-1-2 Setting use or no use of the Working hour............................................................ 13

2-1-3 Setting the stop input logic ..................................................................................... 14

2-1-4.Setting use or no use of the function which plan stop at Target....................... 15

2-2 Basic operations.............................................................................................................. 16

2-2-1 Initial screens............................................................................................................ 17

2-2-2 Setting the Internal clock......................................................................................... 18

2-2-3 Setting the Working hour pattern............................................................................ 20

2-2-4 Setting the Working hour......................................................................................... 21

2-2-5 Setting the Tact ......................................................................................................... 26

2-2-6 Setting the Target...................................................................................................... 27

2-2-7 Setting the Plan......................................................................................................... 28

2-2-8 Setting the Actual...................................................................................................... 29

2-2-9 Setting the Advancement......................................................................................... 30

2-2-10 Setting the Accomplishment rate.......................................................................... 32

2-2-11 Setting the Clear time............................................................................................. 33

2-2-12 Post-setting tests.................................................................................................... 34

2-3 Description of the function keys.................................................................................... 35

2-4 Stop function.................................................................................................................... 36

2-5 MONITOR LED (operating status LED).......................................................................... 37

2-6 Error messages................................................................................................................ 38

Chapter 3 Handling Information............................................................................................... 39

3-1 Handling precautions...................................................................................................... 39

3-2 If something is wrong...................................................................................................... 40

3-3 Warranty............................................................................................................................ 40

1

1-1 Introduction

This operation manual contains necessary information for using the product, such as general

description, installation, and operation of the product.

Read the manual carefully before using the product. Also, keep it at a safe place for ready

reference at anytime.

1-2 Accessories

Mounting fittings: 1 set

Nameplate stickers (Japanese): 1 set

Fixture for wire fixing:1 piece

1-3 Safety precautions (Be sure to read)

The description here highlights the precautionary matters which must be strictly observed in

order to prevent physical harm to the user or other persons and damage to the property.

The following pictorial symbols are used to classify and explain the criticality levels of harms or

damages that may result from using the product in an improper way while ignoring the

instructions.

The Caution indication means that “failure to observe the instructions

may result in human injury, or physical damage alone.”

For handling this machine:

This machine is a wireless communication device composed of precision parts.

Do not overhaul/remodel. It may cause an accident or a machine trouble.

For working/storage environment:

To minimize the possibility of trouble, characteristic degradation, fire, or electrical

shock, avoid using or storing the product in the following locations:

•Locations subject to direct sunlight.

•Locations where liquids, foreign objects, corrosive gas, or flammable gas may

enter the product.

•Locations exposed to high humidity, oily smoke, dust, sand, or the like.

•Locations with less stability such as the top surface of an unsteady table or an

inclined surface.

The Warning indication means that “failure to observe the instructions

may result in death or serious injury.”

For handling this machine:

Do not use this product for such applications as require an extremely high level

of reliability relating to human life.

Do not use this product in locations where there is uncertainty about the

coverage of radio waves.

Chapter 1 Before Use

!

Caution

Prohibited

Prohibited

Prohibited

!

Warning

Prohibited

2

For handling the power supply:

Always observe the following precautions to prevent the power cord from being heated,

damaged, or ignited.

Do not bring the power cord close to fire nor put it into fire. The power cord

may be broken or ignited, resulting in an accident.

Use the AC adapter and the main body only with the specified power voltage to

protect them against damage or fire accidents.

Do not use the main body in a wettable atmosphere. It may cause accidents or

troubles such as heating, igniting, and electrical shock.

Do not touch the main body, the power cord, or the plug outlet with wet hands.

It may lead to accidents such as electrical shock.

Do not damage the power cord. A short circuit or heating may result, causing

fire or electrical shock.

Do not use the power plug with dust adhered on it. A short circuit or heating

may result, causing fire or electrical shock.

Do not give a strong impact onto the power cord.

It may cause an accident or a machine trouble.

Do not use the power cord if you find out deformation etc. in it.

It may cause an accident or a machine trouble.

Do not charge the main body in locations where flammable gas could be

generated.

It may result in igniting or a fire accident.

Never overhaul the main body.

It may cause an accident or a machine trouble.

When something erroneous has occurred during use:

Since it may cause fire, electrical shock, or the like, remove the power plug from the plug

outlet and ask the outlet store or us for repair.

When smoke or abnormal odors come out, immediately remove the power plug

from the plug outlet and ask the outlet store or us for repair.

Do not use the power cord if it is damaged.

Using the damaged power cord may result in fire or electric shock.

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Attention

Prohibited

3

1-4 General description

This machine is a compact type indicator unit that displays the constantly changing production

quantity on the shop floor. It helps you grasp the ongoing status of production at a glance and

also contributes greatly to the rationalization of production such as analysis of manufacturing

processes and improvement of workers’self-control.

With a built-in microprocessor, the machine allows you to set or change the six types of basic

data: Tact, Target,Actual, Advancement, Clock, and Working hour.

As for a production quantity, the machine counts up the signals from limit switches etc.,

calculates the advancement based on the tact and working hours, and displays each of the

data. The machine also features a number of functions, which include the “Clear time

function”for automatically clearing the Plan, Actual, and Advancement when a preset time is

reached, and the “Stop function” for temporarily suspending the Plan calculation even during

working hours.

Low in price.

Compact, lightweight, and space-saving.

Bright & easy-to-see 1-inch red color 7-segment LED display.

Equipped with a built-in microprocessor and a timer.

Offers a range of display variations and allows you to change display types by keyboard

operation.

Includes the stop function.

Includes the data backup function, which allows data to be maintained even at a power

failure.

Can select between use and no use of the Working hour.

When the Working hour is not used, a switchover is made between the operating and

stopped status in response to ON/OFF of external contact inputs.

4

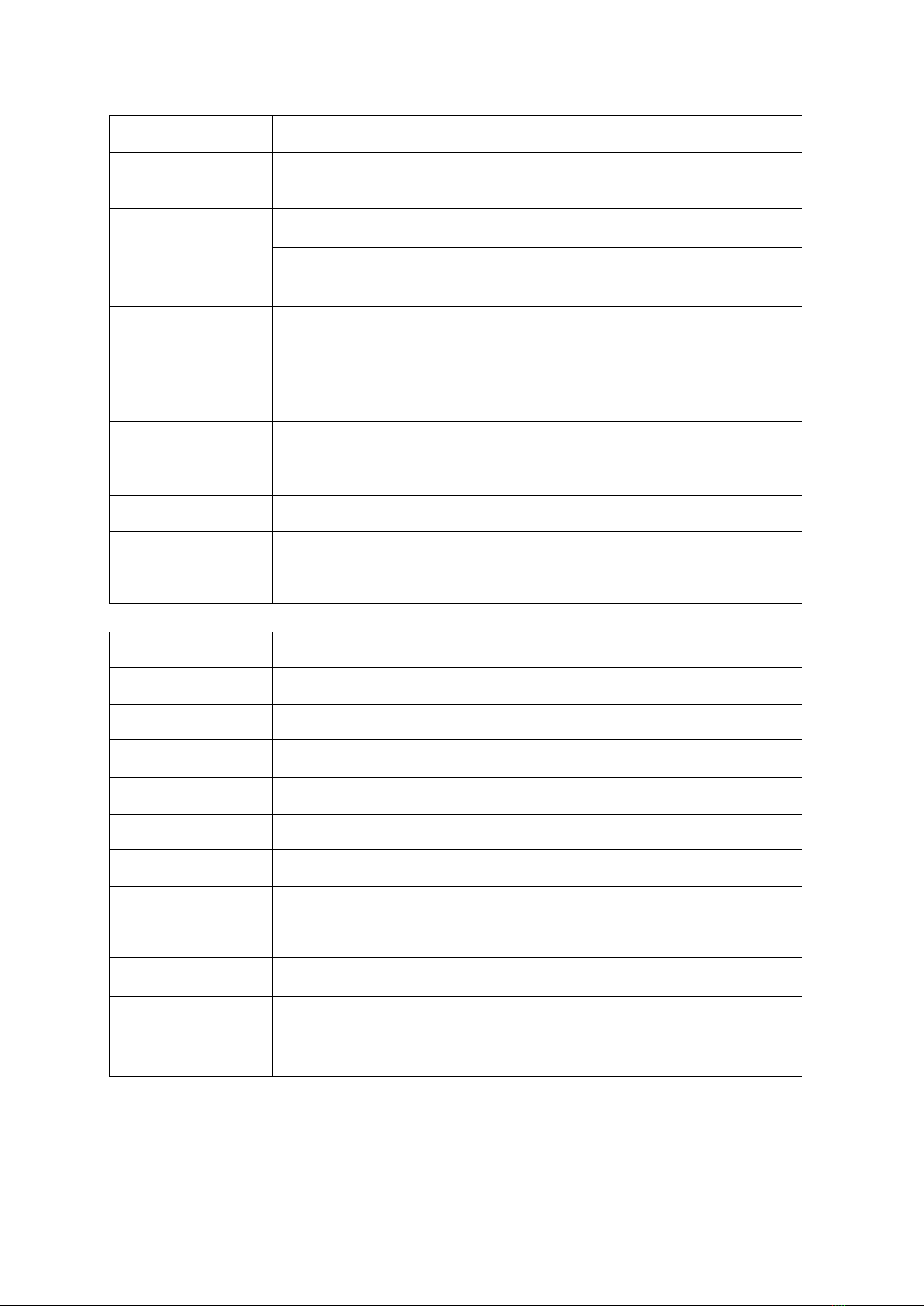

1-5 Specifications

Items

Specifications

Input

Non-voltage contact input x 2:

• Actual count x 1

• Stop input x 1

Display

4-digit x 3-line Single-sided

High-luminance 7-segment LED Character height: 25.4mm

Operating status monitor LED x 1:

・LED colors: 2 (red/green) *1

Power LED x 1

Switch

Power switch x 1

Operating power

voltage

DC12V (input voltage range: DC11 - 15V) / 0.8A or more

Operating power

supply

DC jack

Applicable plug: φ2.1(I.D.) x φ5.5(O.D.) mm Center negative

Power consumption

200mA (at DC12V)

Working

environment

Temperature: 0-50˚C Humidity: 80% or less (no condensation)

Dimensions

240(W) x 165(H) x 32(D) mm (projections excluded)

Weight

1.5kg

Clock backup

Approx. 5 years Coin type lithium battery (CR2032)

<Operating specifications>

Items

Specifications

Labor hour

Max 23 hours 59 minutes/day *2

Working hour

For 20 working hours (periods)/day *2

Working hour

pattern

6 patterns *2

Tact

0.1-9999.9 seconds

Target

0-9999

Plan

0-9999

Actual

0-9999

Advancement

-999 - +999

Accomplishment

rate

0-999

Clear time

3 times/day

cumulative operat-

ing time limitation

Cumulative operating time for no use of Working hour: Max 1 month

*1: The term “orange”used in the following refers to the color produced by simultaneous

emission of red and green LED’s.

*2: Specifications for use of the Working hour.

5

1-6 Exterior features

1-6-1 Main body

Items

Descriptions

POWER LED

Illuminates at power on.

MONITOR LED

(LED for operating)

LED for checking the operating status.

Illuminates in “red”/“green”/“orange” depending on the operating status.

Keyboard

Keyboard for operations.

Data display

4-digit x 3-line 7-segment LED display.

Power switch

Power-on/off switch.

Terminal block

Input terminal block for the Actual count/stop.

DC jack

DC12V input

Applicable plug: φ2.1(I.D.) x φ5.5(O.D.) mm, center negative

Mounting stay

Dedicated stay for installation.

FCC label

FCC Note for a Class A digital device or peripheral

POWER LED

MONITOR LED (for operating)

Keyboard

Data display

Power switch

Terminal

block

DC jack

Mounting stay

Mounting

stay

FCC label

6

1-6-2 Terminal block

The terminal block is located on the back of the main body. The functions of individual

terminals are shown below.

Terminal

Input

Function

GND

―――

Common GND

COUNT

UP

Input

Actual count input. (Actual + 1 per signal input)

GND

―――

Common GND

STOP

Input

Input terminal for stop/operating. (Stop input terminal)

* For each input terminal, connect a non-voltage contact.

7

1-7 Dimensional drawing

8

1-8 Installation

1-8-1 Installation procedure

(1) Mount the mounting stay to the installation area with wood screws or small screws.

Mount the main body onto the mounting stay with ornamental screws loosely tightened.

* In the case the mounting stay is attached to the main body, remove the two ornamental

screws from both sides and detach the mounting fittings.

(2) To the Actual count (UP terminal) on the input terminal block, connect the non-voltage

contact for counting up the input signals from relays, micro switches, limit switches, etc.

Also, establish a connection to each of the other input terminals as needed.

(3) Determine the angle at which the display panel (data display and LED’s) is easy to see

and operate, and then fix the main body by fully tightening the ornamental screws on

both sides.

(4) Insert an applicable plug firmly into the DC jack and supply the power of DC12V/0.8A or

more. (Applicable plug: φ2.1(I.D.) x φ5.5(O.D.) mm with center negative)

The main body has a build-in microprocessor, which means there is a possibility that the data

may collapse due to power fluctuation or flicker. Take power supply from a location free from

power fluctuation or flicker.

For the non-voltage contacts to be connected to the input terminal block, use the ones with less

chattering that can steadily turn on/off the voltage/current of 12V/10mA.

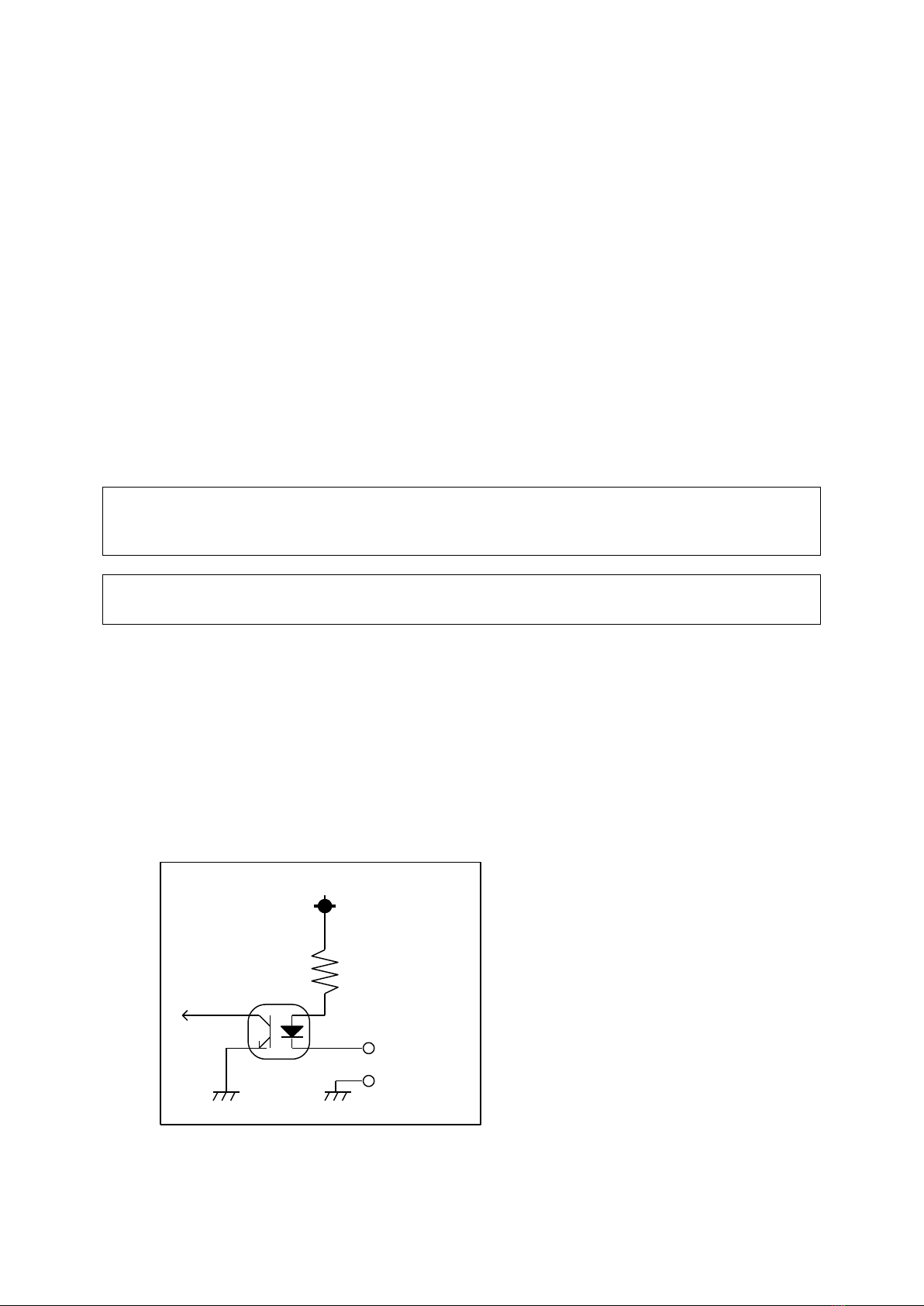

1-8-2 Input terminal block

For the input signals to be connected to the terminal block, use the ones with less chattering

that can steadily turn on/off the voltage/current of 12V/10mA. Keep a time interval of at

least 50msec between input signals. Also, keep 50msec or more from when one input

signal is turned off till another input signal is turned on.

<Input circuit>

Non-voltage contact input circuit (rating: DC12V/10mA)

R

フォトカプラ COM

INPUT

+12V

Photocoupler

9

Chapter 2 How to Use

2-1 Function settings

Before using the machine, you need to make settings for the following items. Read the

description carefully and make suitable settings for your intended application.

Setting an operation type

Select an item shown on the display of the machine to set a desired operation type.

For an operation type, you may make a choice from among the seven patterns in all by a

combination of “Target,”“Actual,”“Advancement,” “Accomplishment rate,”“Plan,”and “Tact.”

Setting use or no use of the Working hour

When the Working hour is used, the machine calculates the planned quantity based on the

registered data of working hours.

When the Working hour is not used, the machine calculates the planned quantity based on

ON/OFF of external input signals.

Setting the stop input logic

Set “Positive” or “Negative” for the logic of a stop input signal.

The resulting operation (operating/stop) differs depending on whether the Working hour is set

to be used or not used.

Setting

Terminal input

Working

hours

Stop input logic

ON

OFF

Used

Negative

Stop

Operating

Positive

Operating

Stop

Not used

Negative

Operating

Stop

Positive

Stop

Operating

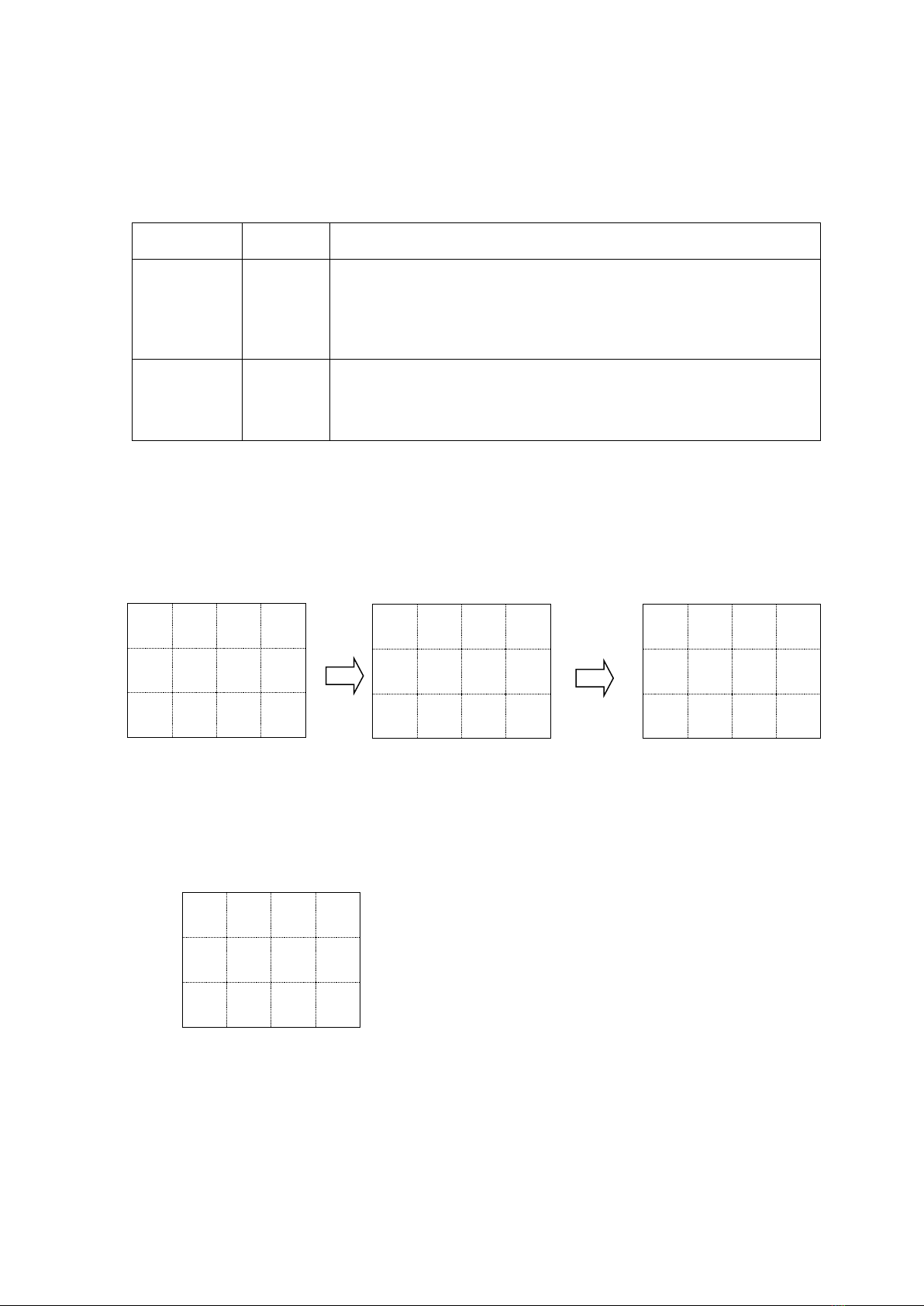

■Setting use or no use of the function which the planned quantity stop at Target.

Setting use or no use of the function which the planned quantity calculation stop, when the

planned quantity reached target.

When choosing the operation type which includes target of display “Plan“,

“Advancement“and “Accomplishment rate“can’t be set any more.

(The case of setting “1”)

10

How to call up the function settings screen

Turn on the power switch while pressing the [F1] key. The [Function settings screen]

appears after the [Initial screen 1] is displayed for about 1.5 seconds.

On the [function settings screen] shown above, select the following sub commands to make

your settings.

* Default values

The factory settings are as follows:

Operation type: → 123 (Target/Actual/Advancement)

Use/no use of Working hour: → Used

Stop input logic: → Negative logic

Use or no use of the function

which the planned quantity stop at Target →Not used

*

*.

*

Program version

[Initial screen 1]

F

1

[Function settings screen]

Sub

command

Description

Setting

1

Sets an operation type.

Select from seven patterns.

2

Sets use/no use of the Working hour.

0: Not used

1: Used

3

Sets the stop input logic.

0: Negative logic

1: Positive logic

4

Setting use or no use of the function

which the planned quantity stop at Target.

0: Not used

1: Used

About 1.5 sec. later

11

2-1-1 Setting an operation type

The machine is so designed that a setting can be made from among seven operation types.

When using the machine with any operation type other than the type 123

(Target/Actual/Advancement), affix the attached command sticker onto the case.

Display items [1] Target: The target production quantity of the day (fixed

value).

[2]Actual: The production quantity up to the present time.

[3]Advancement: The degree of advancement relative to the

planned production quantity at the present

time.

[4]Accomplishment rate: The rate of accomplishment to the planned

production quantity at the present time.

[5] Plan: The planned production quantity at the present

time (changes over time).

[6] Tact: The time required for production per product

(shown in seconds).

Operation type

Description

*123

Target/Actual/Advancement

523

Plan/Actual/Advancement

124

Target/Actual/Accomplishment rate

524

Plan/Actual/Accomplishment rate

152

Target/Plan/Actual

126

Target/Actual/Tact

526

Plan/Actual/Tact

* Default values

<How to set>

(1) On the function settings screen, press the [1] key on the keyboard.

The currently set operation type appears after the sub command “C1” is displayed for

0.75 seconds.

F

1

[Function settings screen]

C

1

The sub command is

displayed.

*

*

*

The set operation type

appears.

12

(2) Input the operation type of your choice with a 3-digit number. For example, to set the

type 523, input [5][2][3]. The resulting display is as follows:

(3) Press the [ENT] key to set the operation type you input. If you have inadvertently press

a wrong type No., press the [CLR] key and re-input the correct data.

* * * Error * * *

If you have input any number other than the type Nos. and pressed the [ENT] key, then an

error will result. In this case, the display blinks the following screen and automatically

returns to the re-input status without changing the preset type.

The operation type you set appears on the last three digits of the top line on the [Initial screen

2] (see page 17).

5

2

3

1

0

0

13

2-1-2 Setting use or no use of the Working hour

This machine is so designed that use or no use of the Working hour can be set.

Note that the resulting operation differs depending on whether the Working hour is set to be

used or not used.

Setting

Set value

Description

Working

hour:

Not used

0

[5] (Register working hour) and [6] (Select working hour pattern)

are disabled.

The Plan calculation is carried out based on the status of external

input signals.

No recalculation function is available.

*Working

hour:

Used

1

[5] (Register working hour) and [6] (Select working hour pattern)

are enabled.

The Plan calculation is carried out based on the registered data of

working hours.

*Default values

<How to set>

(1) When on the function settings screen, press the [2] key on the keyboard.

The currently set value appears after the sub command “C2” is displayed for 0.75

seconds.

(2) As the value you want to set, input either [0] (Not used) or [1] (Used).

<e.g.> To set the Working hour to be used, input [1]. The resulting display is as follows:

(3) Press the [ENT] key to set the change you input. If you have inadvertently input a

wrong data, press the [CLR] key and re-input the correct data.

F

1

[Function settings screen]

C

2

The sub command is

displayed.

*

The set value appears.

1

14

2-1-3 Setting the stop input logic

The machine is so designed that the logic of a stop input signal can be set to either “Negative

logic” or “Positive logic.” Note that the resulting operation differs depending on whether the

Working hour is set to be used or not used.

Setting

Set value

Description

Negative logic

*0

See the table below.

Positive logic

1

See the table below.

* Default values

Setting

Terminal input

Working hour

Stop input logic

ON

OFF

Used

Negative

Stop

Operating

Positive

Operating

Stop

Not used

Negative

Operating

Stop

Positive

Stop

Operating

<How to set>

(1) When on the function settings screen, press the [3] key on the keyboard.

The currently set value appears after the sub command “C3” is displayed for 0.75

seconds.

(2) As the value you want to set, input either [0] (Negative logic) or [1] (Positive logic).

<e.g.> To set the stop input logic to Negative logic, input [0]. The resulting display is as

follows:

(3) Press the [ENT] key to set the value you input. If you have inadvertently set a wrong

data, press the [CLR] key and re-input the correct data.

F

1

[Function settings screen]

C

3

The sub command is

displayed.

*

The set value appears.

0

15

2-1-4.Setting use or no use of the function which plan stop at Target.

Setting use or no use of the function which the planed quantity calculation stop when plan

reached target. It can use that choosing the type which includes target of display.

Setting

Set

value

Description

Plan=Not stop at target

※0

Plan=Plan doesn’t stop when plan reached target.

Plan>Plan indication is possible.

Plan=stop at target

1

Plan=Plan stops when plan reached target.

Plan>Plan indication is not possible.

※Default values.

<How to set>

①When on the function settings screen, press the [4] key on the keyboard.

The currently set value appears after the sub command “C4” is displayed for 0.75 seconds.

②As the value you want to set, input either [0] (Not used) or [1] (Used).

To set the Plan calculation stopped when the plan reached target to be used, input [1].

The resulting display is as follows:

③Press the [ENT] key to set the change you input. If you have inadvertently input a wrong

data, press the [CLR] key and re-input the correct data.

※When choosing the operation type which includes target of display 「Plan」「Advancement」

「Accomplishment rate」can’t be set any more.

(The case of setting “1”)

F

1

[Function settings screen]

C

4

The sub command is

displayed.

*

The set value appears.

1

Table of contents

Other Herutu Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Martin

Martin N2 operating instructions

Keller

Keller CellaTemp PK Series quick start guide

Bosch

Bosch ABC 150 operating instructions

PCB Piezotronics

PCB Piezotronics 320C03 Installation and operating manual

Halma

Halma Sensitron SMART 3 NC Short installation manual

Isspro

Isspro EV Installation instructions manual