Page 5

HERZ - Pump group Simple 3 F532

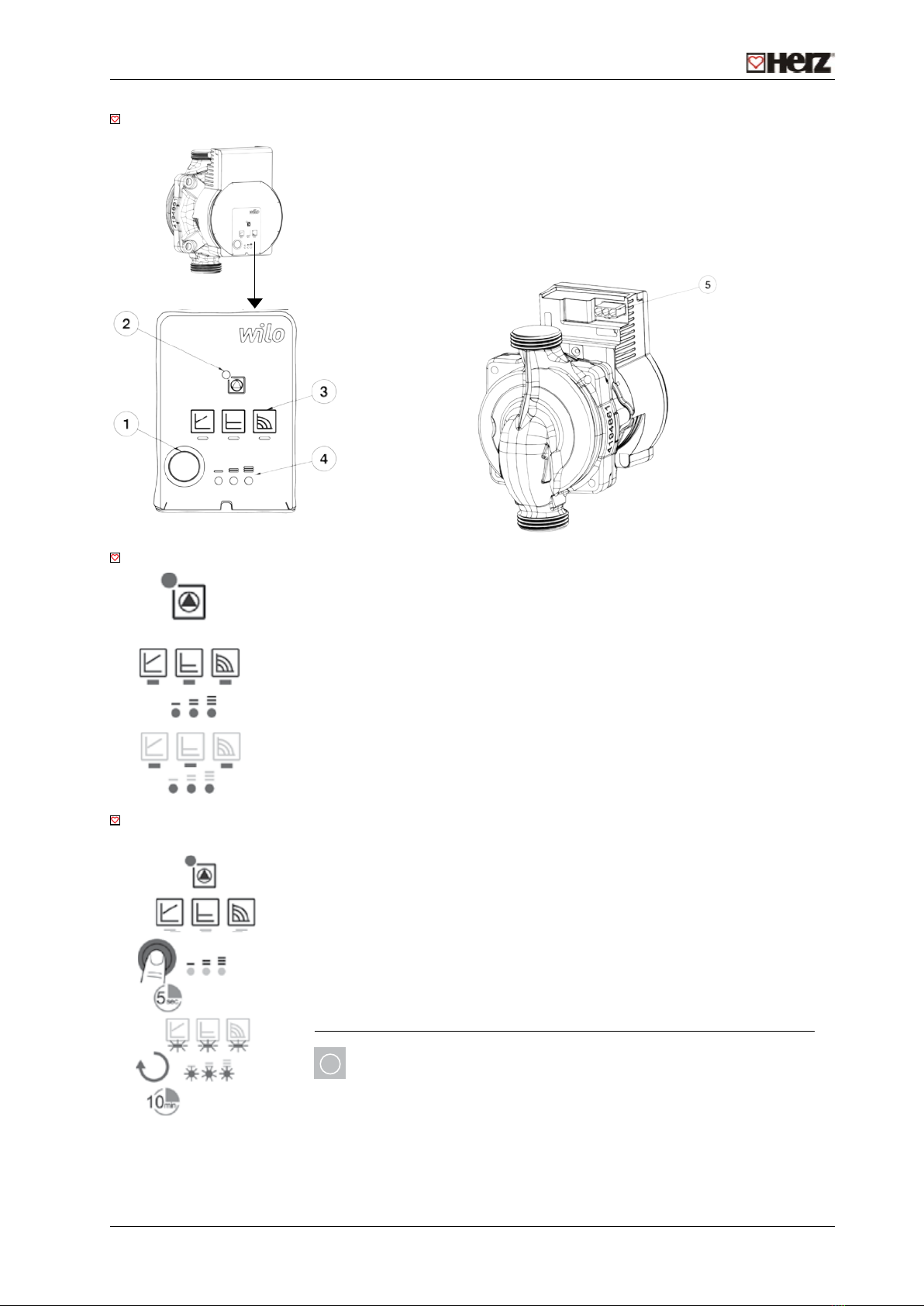

Product description

1. Operating button for pump adjustment

2. Run signal/fault signal LED

3. Display of selected control mode

4. Display of selected characteristic curve (I, II, III)

5. Mains connection: 3-pin plug connection

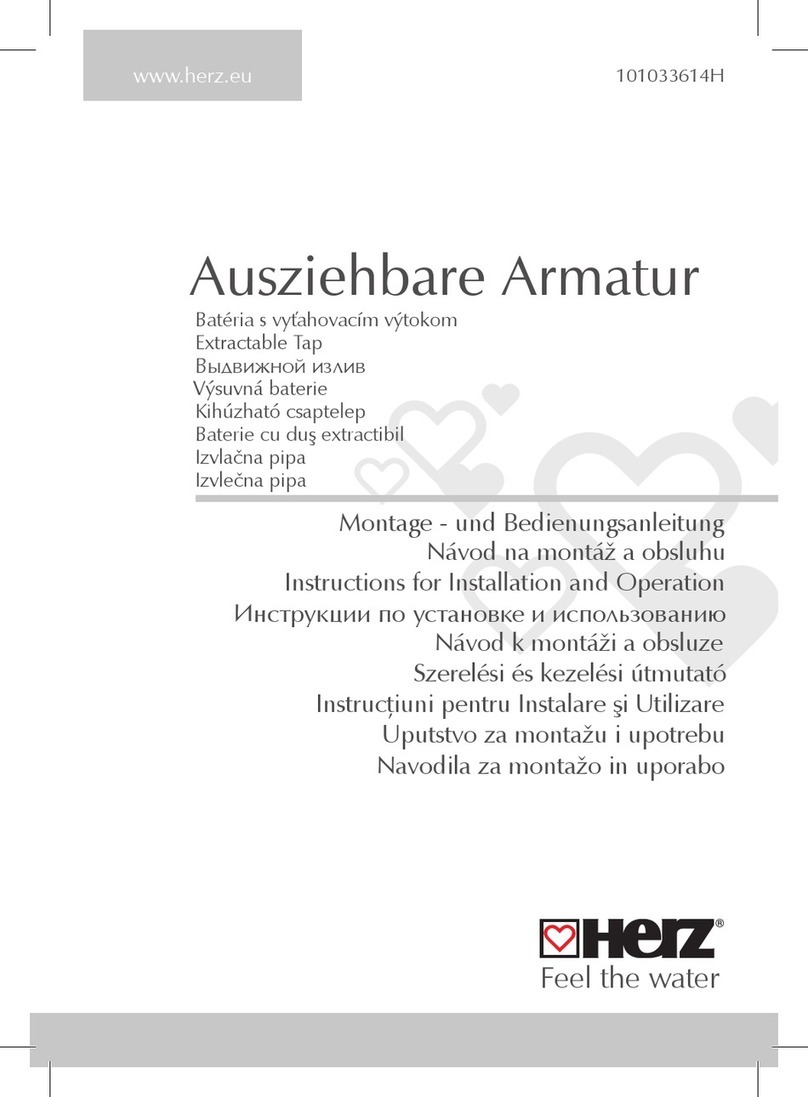

Indicator lights - LEDs

- Signal display

• LED is lit up in green in normal opertaion

• LED lights up/ashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualied technicians.

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

- Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

• The restart function is initiated, and lasts max. 10 minutes.

• The LEDs ash in succession clockwise.

- To cancel, press and hold the operating button for 5 seconds.

NOTICE

After the restart, the LED displays shows the previously set values of the

pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

iNOTICE

After the restart, the LED displays shows the previously set values of the pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

iNOTICE

After the restart, the LED displays shows the previously set values of the pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

iNOTICE

After the restart, the LED displays shows the previously set values of the pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

iNOTICE

After the restart, the LED displays shows the previously set values of the pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

iNOTICE

After the restart, the LED displays shows the previously set values of the pump.

Page 5

HERZ - Mixing set

Pump data

Type: WILO PARA 15-130/6-43/SC

Thread: G 1"

Overall length: 130 mm

Energy Efficiency Index (EEI): ≤ 0,20

Max. delivery head: 6,7 m

Max. volume flow: 3,2 m3/h

Max. operating temperature: 100 °C

Maxi. operating pressure: 10 bar

Mains connection: 1~230 V +10%/-15%, 50/60 Hz (tensiune standard /IEC 8 standard voltage)

Protection class: IPx4D

Insulation class: F

Minimum suction head at suction port to avoid cavitation at water pumping temperature

Minimum suction head at 50/95 °C: 0.5 / 4.5 m

Pump hydraulic operation area

Product description

1 Operating button for pump adjustment

2 Run signal/fault signal LED

3 Display of selected control mode

4 Display of selected characteristic curve (I, II, III)

5 Mains connection: 3-pin plug connection

Indicator lights - LEDs

- Signal display

•LED is lit up in green in normal opertaion

•LED lights up/flashes in case of a fault

- Display of selected control mode Δp-v, Δp-c and constant speed

- Display of selected pump curve (I, II, III) within the control mode

- LED indicator combinations during the pump venting function, manual restart

and key lock

Commissioning

Commissioning only by qualified technicians.

Manual restart

The pump attempts an automatic restart upon detecting a blockage. If the pump

does not restart automatically:

-Activate manual restart via the operating button: press and hold for 5 seconds,

then release.

•The restart function is initiated, and lasts max. 10 minutes.

•The LEDs flash in succession clockwise.

-To cancel, press and hold the operating button for 5 seconds.

i

NOTICE

After the restart, the LED displays shows the previously set values of the pump.