HESCH HE 5731 Compact User manual

# 373344 | Version 1.5

Solenoid valve control

HE 5731Compact / Modular

Operating instructions

(English translation

German original version)

HE 5731 Operating instructions

2

# 373344, Version 1.5

Imprint

HESCH Industrie-Elektronik GmbH

Boschstraße 8

31535 NEUSTADT

GERMANY

Phone: +49 5032 9535-0

Fax: +49 5032 9535–99

Internet: www.hesch.de

Email: [email protected]

Hanover District Court

Commercial Register 111184

VAT.-Id. No. DE813919106

General Management:

Werner Brandis

Editor:

HESCH Industrie-Elektronik GmbH, Documentation Department

Copyrights

© Copyright 2021 HESCH Industrie-Elektronik GmbH. All rights reserved.

The content including pictures and the design of these operating

instructions are subject to copyright protection and other laws for the

protection of intellectual property. The distribution or modification of the

contents of this manual is not permitted. Furthermore, this content may not

be copied, distributed, changed or made accessible to third parties for

commercial purposes.

HE 5731 Operating instructions

3

# 373344, Version 1.5

Table of Content

1. FOREWORD .............................................................................................................................................. 5

1.1. INSTRUCTIONS FOR USE ................................................................................................................................. 5

1.2. LEGAL PROVISIONS ....................................................................................................................................... 5

2. SAFETY INFORMATION ............................................................................................................................. 6

2.1. SYMBOLS AND BASIC SAFETY INSTRUCTIONS...................................................................................................... 6

2.2. SAFETY IN THE INDIVIDUAL OPERATING PHASES................................................................................................... 7

3. TECHNICAL DATA...................................................................................................................................... 9

4. DEVICE DESRIPTION................................................................................................................................ 11

4.1. OVERVIEW................................................................................................................................................ 11

4.2. DISPLAY AND OPERATING ELEMENTS.............................................................................................................. 15

4.3. DIFFERENTIAL PRESSURE COLUMN ................................................................................................................. 17

5. ASSEMBLY .............................................................................................................................................. 18

5.1. DIMENSIONS ............................................................................................................................................. 18

6. ELECTRICAL COMMISSIONING ................................................................................................................ 20

6.1. READ OUT AND SET PASSWORD ..................................................................................................................... 21

6.2. SUPPLY VOLTAGE........................................................................................................................................ 21

6.3. VALVE CONNECTIONS.................................................................................................................................. 26

7. PARAMETERISATION .............................................................................................................................. 28

7.1. PARAMETERISATION WITH DEVICE KEYBOARD.................................................................................................. 28

7.2. PARAMETER TABLE ..................................................................................................................................... 29

7.3. OFFSET FOR ZEROING.................................................................................................................................. 32

7.4. PARAMETERISATION WITH SERVICE PC........................................................................................................... 32

7.5. ENABLE /DISABLE PRECOATING.................................................................................................................... 33

7.6. RESET DEFAULT SETTINGS............................................................................................................................ 33

8. OPERATION OF THE CONTROL ................................................................................................................ 34

8.1. NORMAL OPERATION.................................................................................................................................. 34

8.2. TEST FUNCTION ......................................................................................................................................... 35

8.3. SPECIFIC KEY COMBINATIONS........................................................................................................................ 35

8.4. DIFFERENTIAL PRESSURE MEASUREMENT......................................................................................................... 36

9. ERROR MESSAGES .................................................................................................................................. 38

10. OPTIONS............................................................................................................................................. 41

10.1. TERMINAL EXTENDER CURRENT INPUT /OUTPUT........................................................................................... 41

10.2. PRESSURE SWITCH.................................................................................................................................. 44

11. MAINTENANCE AND SERVICE.............................................................................................................. 45

12. DECLARATION OF CONFORMITY ......................................................................................................... 46

HE 5731 Operating instructions

4

# 373344, Version 1.5

Foreword

Date/

Version

Description

Author

04.10.2018

/ 1.0

Translation

Bg

12.12.2018

/ 1.1

Modification of name plate for sole-

noid valve control and control unit

Bg

15.08.2019

/ 1.2

Chapter Electrical Commissioning:

Note added for entering password

prior to commissioning.

Bg

11.03.2020

/ 1.3

Chapter 5 Electrical Commissioning:

Note for entering password deleted,

Chapter 5.2 Readout and set pass-

word: added

Chapter 6.1 Parameterization with de-

vice keyboard: revised

Chapter 6.6 Reset Default settings: re-

vised,

Current chapter 6.6 Parameter Protec-

tion / Password: deleted

Bg

08.06.2020

/ 1.4

Chapter 5.4 Valve connections: soft-

ware versions adapted according to

change request #373154 from

05.06.2020

Bg

11.02.2021

/ 1.5

Changes according to change request

532,

Chapter 7.1 pictures adapted,

Chapter 5.3.3 designation of connec-

tions changed

Chapter 6.2.1 new pictures of opening

housing,

document structure adapted, safety

notes adapted.

Bg

Document history

HE 5731 Operating instructions

5

# 373344, Version 1.5

Safety Information

1. Foreword

1.1.Instructions for use

Chapter 1

Foreword

Information about structure, versions, intended use and device safety.

Chapter 2

Safety instructions

Important safety instructions when using the valve control.

Chapter 3

Description oft he device

Description of the valve control, display and control and technical

data.

Chapter 4

Assembly

Dimensions of the device and scope of delivery.

Chapter 5

Electrical installation

Electrical supply, communication and valve connections.

Chapter 6

Parameterisation

Parameterisation using the device keyboard or a service PC.

Chapter 7

Operating the control

Information about operation, differential pressure measurement and

error messages.

Chapter 8

Error messages

Chapter 9

Options

Description of the optionally available additional functions.

Chapter 10

Declaration of conformity

Chapter 11

Maintenance and service

Information about inspection tasks and disposal.

1.2.Legal provisions

HESCH Industrie-Elektronik GmbH, Boschstraße 8, 31535 NEUSTADT, GERMANY

The solenoid valve control HE 5731 is used for cleaning industrial filter systems. The

number of valves is from 1 to a maximum of 64, and can be scaled, using modular exten-

sion units. The cleaning and de-dusting with HE 5731 can be carried out time-controlled

or differential pressure-controlled. It can be operated with, as well as without an actual

valve control. A total of 64 valves can be controlled at one time.

The controller can be operated within the operating and environmental conditions ap-

proved in this manual without impairing its safety.

The manufacturer is not liable for improper use and any resulting personal injury or mate-

rial damage; the risk is borne solely by the user. Failure to comply with the above criteria

for intended use may result in the expiry of the warranty and liability for the device.

All work on the solenoid valve control may only be carried out by qualified electricians

with sufficient knowledge in the field of electrical engineering.

This documentation is intended for all electrically qualified people, who design, install, set

up, and adjust the HE 5731 filter controller.

The device has been constructed and tested in accordance with VDE 0411 / EN 61010-1

and has left the factory in perfect safety condition. To maintain this condition and ensure

safe operation, the user must observe the notes and warnings described in this manual.

Manufacturer

Intended Use

Personnel

qualification/

Target group

Device safety

HE 5731 Operating instructions

6

# 373344, Version 1.5

Safety Information

2.Safety Information

2.1.Symbols and Basic Safety Instructions

This chapter contains important safety regulations and notes. To protect against personal

injury and material damage, it is necessary to read this chapter carefully before working

with the device.

The following symbols are used in this manual. All safety instructions have a uniform

structure.

Personal Injury Warning!

The severity of the danger is indicated by the respective signal word.

Explosive atmosphere warning sign!

High Voltage Warning!

Warning of material damage caused by electrostatic charge!

Property Damage Warning!

Note!

Identifies possible malfunctions and indicates optimum operating

conditions.

DANGER!

Indicates an imminently hazardous situation, which, if not avoided, will result in death or

serious injury.

WARNING!

Indicates a potentially hazardous situation, which, if not avoided, could result in death or

serious injury.

WARNING!

Indicates a hazardous situation, which, if not avoided, could result in minor or moderate

injury

All safety information in this manual are identically designed. The pictogram indicates the

kind of danger.

SIGNAL WORD (indicates the kind of danger)

A text describes the danger and indicates how it can be avoided.

Symbols used

Signal words

Design of safety

instructions

HE 5731 Operating instructions

7

# 373344, Version 1.5

Safety Information

2.2.Safety in the individual operating phases

When installing the control unit and during operation, the following safety instructions

must be observed.

Danger of Electrocution!

Before working on the device, switch off all power supplies used. The

electrical cables must be laid according to the respective national regula-

tions (in Germany VDE 0100). The measuring lines must be laid sepa-

rately from the mains leads. The connection between the connection for

the functional earth (in the respective device carrier) and a protective

conductor must be established.

Danger of Electrocution!

Any interruption of the protective conductor in the device carrier can lead

to the device becoming dangerous. Intentional interruptions are not per-

mitted. If it is suspected that safe operation is no longer possible, the de-

vice is to be decommissioned and secured against unintentional opera-

tion.

Danger of Electrocution!

Do not open the device while it is live! When opening the devices or re-

moving covers and parts, live parts may be exposed. Connecting points

can also be live!

WARNING!

The device must never be put into operation despite any visible damage.

WARNING!

During installation, commissioning, maintenance and troubleshooting, ob-

serve the accident prevention regulations applicable to your system, e.g.

DGUV Regulation 3 "Electrical installations and equipment".

WARNING!

Clean dirty contacts with oil-free compressed air or with spirit and a lint-

free cloth.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to BS EN 61340-51/-3 to avoid

electrostatic discharge!

HE 5731 Operating instructions

8

# 373344, Version 1.5

Technical data

Explosion Prevention!

The device is suitable for use in explosion zone 22. Before opening the

device, it is essential to ensure that no explosive environmental condi-

tions, such as dust generation, exist.

Troubleshooting!

At the beginning of troubleshooting, all possible sources of faults on addi-

tional devices or supply lines (measuring lines, wiring, downstream de-

vices) should be taken into consideration. If the fault was not found after

checking these points, we recommend sending the device to the supplier.

Decommissioning!

Switch off the power supply on all poles if the device is to be decommis-

sioned. Secure the device against unintentional operation!

If the device is connected to other devices and / or equipment, the effects

must be considered and appropriate precautions taken before switching

off.

Machine Identification

The HE 5731 (Figure 1) is marked with:

II3D

Device category:

Use in Zone 22 for dust during normal operation

Ex

Designates an electrical equipment

Tc

Type of ignition protection:

Protection by housing

IIIC

Dust group:

Conductive dusts

T135°C

Temperature class:

Maximum permissible surface temperature

Dc

Device protection level:

Use in Zone 22 for dust

IP65

Protection class:

Dust-tight and protected against water jets

The following special regulations must be observed:

Connect cables professionally in glands.

Close not needed housing bores with locking bolts.

Cleaning of the housing is only permitted with moist cleaning agents to avoid

static charging.

Cleaning is necessary to prevent increased dust generation on the device.

Operation under voltage, in zone 22, only in closed state.

Before closing, ensure that the device housing is free of dust

HE 5731 Operating instructions

9

# 373344, Version 1.5

Technical data

3.Technical data

Intended use:

Solenoid valve control for cleaning industrial filter

systems

Models:

HE 5731 in compact housing as master

control with 16 valve outputs maximum

HE 5731 operating unit as control panel built-

in casing (the valve outputs are located on

the control unit)

extension units as slave controls, a total of 64

valves can be controlled

Supply voltage:

(Please refer to the

nameplate on the device)

100…240 VAC / 50…60 Hz

24 VDC ±10% (option) safety extra-low

voltage (SELV)

Extension units are supplied by the master controller

Power consumption:

30 VA with 100…240 VAC control

Max. 30 W with 24 VDC controls

Valves:

24 V DC, max. 1 A

16 valves per device, 64 valves per system

Pulse time:

0.01...9.99 seconds adjustable

Break time:

1.0... 999 seconds adjustable

Display:

7-segment display, 3-digit, 14 mm height, white

for differential pressure/valve display, parameter and

alarm values

LEDs:

14 LEDs for status displays, 16 LEDs for differential

pressure column

Keys:

PARA (ESC), UP, DOWN, ENTER, TEST

Analogue output:

4…20 mA + sensor supply for differential pressure

sensor, 24 VDC max. 80 mA

Digital inputs:

Start post-cleaning release

Relay output:

1 change-over contact 250 VAC, 5 A as combined

operating and fault signal

Interfaces:

USB device, type B for writing and reading the

parameters (USB / TTL adapter required)

RS 485 as internal communication bus

Air / creepage distances:

Pollution degree 2, overvoltage category II

EMC:

Interference emission: BS EN 61000-6-4

Resistance to interference: BS EN 61000-6-2

HE 5731 Operating instructions

10

# 373344, Version 1.5

Technical data

Housing:

Polycarbonate

Device designation

Housing dimensions:

Compact housing

231 × 125 × 90 mm

Modular

(panel mounting)

200 × 122 × 30 mm

Modular

(control unit)

192 × 128 × 63 mm

Connection set for

the compact housing

3 × M32×1.5 with multiple sealing insert for 6 cables

3 × M16×1.5 for supply and communication

Electrical

connections:

Cross-section rigid/flex:max. 2.5 mm², flex.: max. 2.5 mm2

without ferrule

Rest: cross-section rigid: max. 1.5 mm2, flex.: max. 0.75

mm2 with ferrule

Mounting:

Compact housing

Wall mounting. Mounting position: vertical

Modular

Panel-mounting housing, vertical mounting position

Control unit: standard rail

Ambient conditions

Climate

Storage

- 20°C…+ 70°C

Transport

- 25°C…+ 85°C

Operation

Compact housing

-20°C…+50°C

in EX zone 22: -20°…+40°C

Modular

-20°C…+50°C

-No EX approval

Relative humidity

Relative humidity 95%, no condensation allowed,

KUF according to DIN 40400

Subject to technical changes.

HE 5731 Operating instructions

11

# 373344, Version 1.5

Device desription

4.Device desription

The solenoid valve control HE 5731 is available in different versions.

4.1.Overview

4.1.1. HE 5731 Compact

HE 5731 (Compact)

HE 5731 E (Expansion unit) in Compact housing

HE 5731 Operating instructions

12

# 373344, Version 1.5

Device desription

HE 5731 (Compact) Connections

4.1.2. HE 5731 Modular

The operating unit HE 5731 can be installed with a distance of up to 100 metres away

from the control unit. The operating unit itself has no valve outputs. The valve outputs are

located on the control unit (see Figure 6). Operating and control unit are connected with a

patch cable (Cat5 or higher). (The patch cable is not within the scope of supply).

HE 5731 Operating instructions

13

# 373344, Version 1.5

Device desription

HE 5731 Operating unit

HE 5731 (Modular) Operating unit

Rear panel HE 5731 (Modular) Operating unit

HE 5731 Operating instructions

14

# 373344, Version 1.5

Device desription

HE 5731 Control unit

The control unit for standard rail mounting has 16 valve outputs maximum.

4 control units maximum can be connected to the operating unit (see also chapter 6.3).

Figure 6 shows the control unit where external display devices are connected via a con-

nection adapter (see chapter 10 Options).

HE 5731 (Modular) Figure 7 shows the control unit where the connection adapter is inte-

grated.

HE 5731 (Modular) control unit in standard rail enclosure (100…240 V AC)

(connection adapter optional)

HE 5731 (Modular) control unit in standard rail enclosure (100…240 V AC)

(without connection adapter)

HE 5731 Operating instructions

15

# 373344, Version 1.5

Device desription

4.2. Display and Operating Elements

HE 5731 Display and Operating Elements

Symbols

Meaning

Operating message

Cleansing active

Alarm active

Pulse time

Break time

The number of valves is shown in the display and can be

changed

Post-cleaning cycles are shown in the display and can be

changed

Total / partial cycle is shown in the display and can be

changed

Interruption due to defective valve line or solenoid valves

Short circuit of a valve line (overcurrent)

Differential pressure is shown in the display

The active valve number is shown in the display

HE 5731 Operating instructions

16

# 373344, Version 1.5

Device desription

Symbols

Meaning

PARA key: parameterisation mode On/Off

UP key: increase the displayed value

DOWN key: decrease the displayed value

ENTER key: Confirm the displayed value

TEST key: Test mode On/Off

Display

Normal operation: current differential pressure, cur-

rent valve

Parameterisation mode: parameter values and

alarm notes

Switch with UP / DOWN keys

HE 5731 Operating instructions

17

# 373344, Version 1.5

Device desription

4.3. Differential pressure column

Differential pressure column

In normal operation, the LEDs display the differential pressure. In parameterization mode,

the selected parameter value blinks to show that it is operational.

Delta-p-measuring range

High alarm

Upper threshold –start cleaning

Lower threshold –stop cleaning

Low-Alarm

Post-cleaning threshold

Zeroing

HE 5731 Operating instructions

18

# 373344, Version 1.5

Assembly

5.Assembly

The ambient temperature at the installation point must not exceed the permissible

temperature for nominal use specified in the technical data. The device version in

compact housing may be mounted in areas of explosion class EX ATEX Zone 22 (see

nameplate on device housing). The special regulations must be observed, see chapter

2.2 Safety in the individual operating phases.

5.1. Dimensions

5.1.1. HE 5731 Compact

Dimensions of compact housing (without screw connections)

HE 5731 Operating instructions

19

# 373344, Version 1.5

Electrical Commissioning

5.1.2. HE 5731 Modular

Dimensions operating unit (panel mounting housing)

Scope of delivery

HE 5731

Operating instructions # 373344

Drilling jig #373222 (only for the operating unit HE 5731 Modular)

Note!

Upon receipt, check the delivery for completeness and visible defects. In

the event of a complaint, contact your responsible HESCH representative

immediately

Section

170 × 105 mm

HE 5731 Operating instructions

20

# 373344, Version 1.5

Electrical Commissioning

6.Electrical Commissioning

Before switching on the device, observe the following points:

Danger of Electrocution!

Electrical installation must only be carried out when the power is discon-

nected.

Danger of Electrocution!

Work on the electronics may only be carried out by qualified personnel.

Explosion prevention!

The device is suitable for use in explosion zone 22 with closed lid only.

Before opening the device, it must be ensured that no explosive environ-

mental conditions, such as dust exist.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to BS EN 61340-51/-3 to avoid

electrostatic discharge!

Material damage caused by wrong supply voltage!

The power supply must correspond to the voltage indicated on the name-

plate.

Note!

Connect the cable firmly to the glands.

Note!

The temperature restrictions specified for the use of the device must be

observed before and during operation.

Note!

Ensure that the FE conductor is connected.

Note!

The patch cable between the control unit and the operating unit may only

be plugged/unplugged when switched off.

This manual suits for next models

1

Table of contents

Other HESCH Control System manuals

Popular Control System manuals by other brands

WattMaster

WattMaster Auto-Zone CV Design, installation and operation

CALEFFI

CALEFFI 210510 Installation and commissioning manual

LLURIA

LLURIA DE-5-DMX-6A quick start guide

Electrex

Electrex X3M user manual

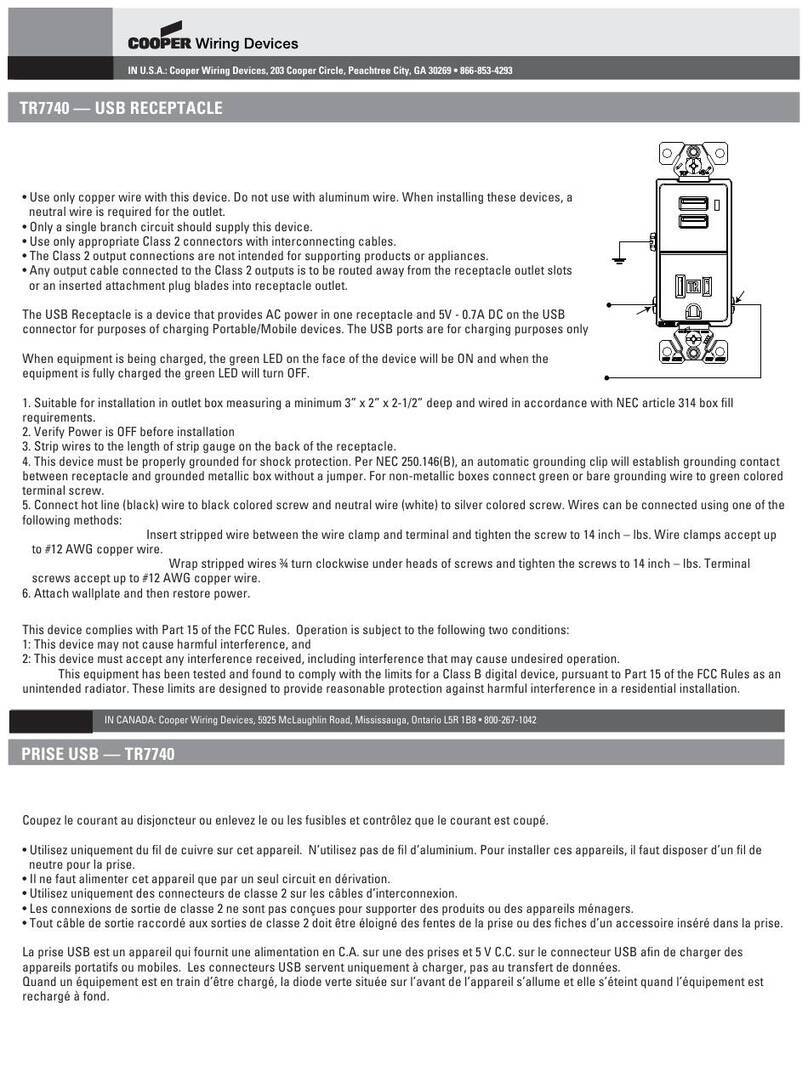

Cooper Wiring Devices

Cooper Wiring Devices TR7740 quick start guide

Alutech

Alutech BV-5-868 Assembly and operation manual