HESCH HE 5411 User manual

# 340411 | Version 1.7

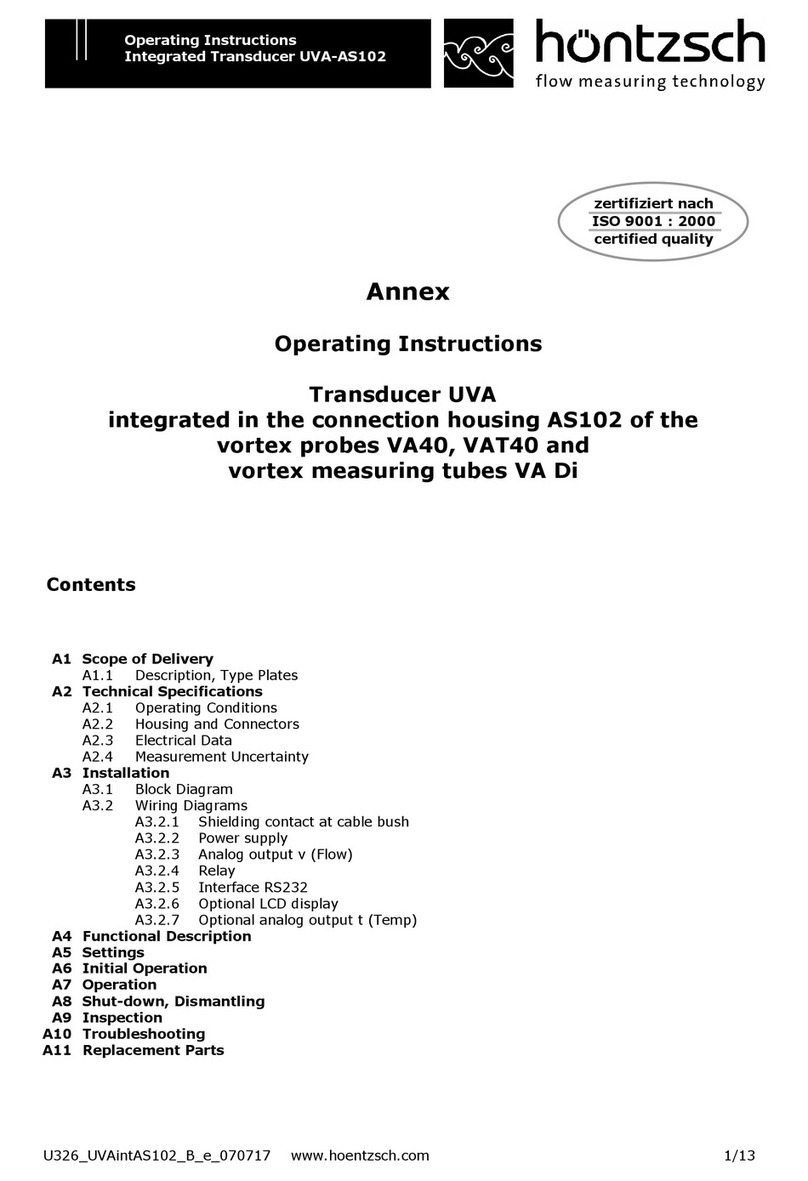

Differential pressure transducer with limit signal

HE 5411

Operating Instructions

(Translation of Original German version)

2

HE 5411 Operating Instructions

#340411 | version 1.7

Imprint

HESCH Industrie-Elektronik GmbH

Boschstraße 8

31535 NEUSTADT

GERMANY

Phone: +49 5032 9535-0

Fax: +49 5032 9535–99

Internet: www.hesch.de

Email: [email protected]

Hanover District Court

Commercial Register 111184

VAT.-Id. No. DE813919106

General Management

Walter Schröder, Werner Brandis

Editor:

HESCH Industrie-Elektronik GmbH, Documentation Department

Copyrights

© Copyright 2020 HESCH Industrie-Elektronik GmbH. All rights reserved.

The content including pictures and the design of these operating

instructions are subject to copyright protection and other laws for the

protection of intellectual property. The operating instructions may only be

distributed as a complete document and only with reference to the source.

The modification of the contents of this operating instructions is prohibited.

In addition, this content may not be copied, distributed, modified or made

available to third parties for commercial purposes.

HE 5411 Operating Instructions

#340411 | version 1.7

3

Document history

Date / Version

Description / Author

16.09.2019 / 1.0

First version / Bg

25.09.2019 / 1.1

Chapter 3: Basic accuracy and temperature drift

removed for analogue output; Chapter 8.1:

Adaptation of heading; Chapter 8.3: Steps 9 and

10 supplemented; Chapter 9: Note removed /

Bg

15.01.2020 / 1.2

Chapter 3: free from silicone, cable diameter

and mean times (MTBF, MTTF) added

Chapter 11: new article number for USB/TTL

adapter added / Bg

03.04.2020 / 1.3

Chapter 3: technical data for relay contact added

/ Bg

14.04.2020 / 1.4

Chapter 3: technical data for relay contact

adapted and service interface added / Bg

12.05.2020 / 1.5

All 24 VDC devices can now be used in EX zone

2 as well, except for the devices with a

measuring range of ±1.25 mbar (Sensirion

sensor).

Chapter 6.1 Electrical connections, Relay output

(limit value): graphical explanation

Chapter 8.5 Setting the measuring range: “mbar”

changed to “pressure”.

21.10.2020 / 1.6

Chapter 9.1 Parameter table: Damping and

creep flow suppression added after software

modification

Chapter 10 Error messages: Error E.CAL,

E. Sen. and E.Par added after software

modifications

08.12.2020 / 1.7

Chapter 3 Technical data: sensor with ± 350

mbar measuring range added / Bg

4

HE 5411 Operating Instructions

#340411 | version 1.7

TABLE OF CONTENTS

1LEGAL PROVISIONS................................................................................................................................... 5

2SAFETY INFORMATION ............................................................................................................................. 6

2.1 SYMBOLS AND BASIC SAFETY INSTRUCTIONS...................................................................................................... 6

2.2 SIGNAL WORDS ........................................................................................................................................... 6

2.3 SAFETY IN THE INDIVIDUAL OPERATING PHASES................................................................................................... 7

2.4 DEVICE IDENTIFICATION................................................................................................................................. 8

3TECHNICAL DATA.................................................................................................................................... 10

4MOUNTING ............................................................................................................................................ 13

4.1 DIMENSIONS ............................................................................................................................................. 13

4.2 OPENING THE DEVICE.................................................................................................................................. 14

4.3 MOUNTING THE DEVICE............................................................................................................................... 14

5DEVICE DESCRIPTION.............................................................................................................................. 15

5.1 SUMMARY OF DEVICE VERSIONS .................................................................................................................... 15

5.1.1 HE 5411 Lite (without limit signal)................................................................................................ 15

5.1.2 HE 5411 Basic (without limit signal) ............................................................................................. 15

5.1.3 HE 5411 Premium (with limit signal)............................................................................................. 15

6ELECTRICAL COMMISSIONING ................................................................................................................ 16

6.1 ELECTRICAL CONNECTIONS ........................................................................................................................... 17

6.2 ASSEMBLY OF MEASURING HOSE ONTO PRESSURE CONNECTION........................................................................... 18

7DISPLAY AND OPERATING ELEMENTS ..................................................................................................... 19

7.1 LIMIT LED ................................................................................................................................................ 21

7.1.1 “Limit threshold” mode ................................................................................................................. 21

7.1.2 “Limit window” mode.................................................................................................................... 22

8OPERATION ............................................................................................................................................ 23

8.1 OFFSET FOR ZEROING.................................................................................................................................. 23

8.2 OFFSET FOR ZEROING WITH DEVICE KEYPAD (HE 5411 PREMIUM)....................................................................... 24

8.3 LIMIT VALUE PARAMETER SETTING WITH DEVICE KEYPAD (HE 5411 PREMIUM)...................................................... 25

8.4 ANALOGUE OUTPUT SETTING ....................................................................................................................... 26

8.5 SETTING THE MEASURING RANGE................................................................................................................... 26

8.6 TEST MODE .............................................................................................................................................. 27

9PARAMETER SETTING WITH SERVICE PC ................................................................................................. 28

9.1 PARAMETER TABLE..................................................................................................................................... 29

10 ERROR MESSAGES............................................................................................................................... 36

11 ACCESSORIES ...................................................................................................................................... 37

12 MAINTENANCE AND SERVICE.............................................................................................................. 39

HE 5411 Operating Instructions

#340411 | version 1.7

5

1 Legal Provisions

Manufacturer

HESCH Industrie-Elektronik GmbH, Boschstraße 8, 31535 NEUSTADT, GERMANY

Intended use

The HE 5411 differential pressure transducer is a universal pressure transducer,

mainly used in dedusting technology. It can also be used in the measurement of

overpressure in clean rooms.

The device can be operated within the operating and environmental conditions

approved in these operating instructions without impairing its safety.

The manufacturer is not liable for improper use and any resulting personal injury or

material damage; the risk is borne solely by the user. Failure to comply with the above

criteria for intended use will result in the expiry of the warranty and liability for the

device.

Personnel qualification

All work on the differential pressure transducer may only be carried out by qualified electricians

with sufficient knowledge in the field of electrical engineering.

Device Safety

The device has been constructed and tested in accordance with VDE 0411 / EN 61010-1 and

has left the factory in perfect safety condition. To maintain this condition and ensure safe

operation, the user must observe the notes and warnings described in this manual.

Declaration of conformity

The valid declaration of conformity can be found on the internet on www.hesch.de.

6

HE 5411 Operating Instructions

#340411 | version 1.7

2 Safety Information

2.1 Symbols and Basic Safety Instructions

This chapter contains important safety regulations and notes. To protect against personal injury

and material damage, it is necessary to read this chapter carefully before working with the

device.

Symbols used

The following symbols are used in this manual. All safety instructions have a uniform structure.

Personal Injury Warning!

The severity of the danger is indicated by the respective signal word.

Explosive region warning sign!

High Voltage Warning!

Warning of material damage caused by electrostatic charge!

Property Damage Warning!

Note!

Identifies possible malfunctions and indicates optimum operating

conditions.

2.2 Signal Words

DANGER!

Indicates an imminently hazardous high risk situation, which, if not avoided, will result in death

or serious injury.

WARNING!

Indicates a potentially hazardous medium risk situation, which, if not avoided, could result in

death or serious injury.

CAUTION!

Indicates a hazardous low risk situation, which, if not avoided, could result in minor or moderate

injury.

HE 5411 Operating Instructions

#340411 | version 1.7

7

2.3 Safety in the individual operating phases

When installing the device and during operation, the following safety instructions must be

observed.

Danger of Electrocution!

Before working on the device, switch off all power supplies used. The

electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring lines must be laid

separately from the mains leads.

Attention!

The device must never be put into operation even if damage is

recognisable.

Warning!

Ensure protection against short circuiting in the supply circuit.

Attention!

During installation, commissioning, maintenance and troubleshooting,

observe the accident prevention regulations applicable to your system,

e.g. DGUV Regulation 3 "Electrical installations and equipment".

Attention!

Clean dirty contacts with oil-free compressed air or with spirit and a lint-

free cloth.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to BS EN 61340-51/-3 to avoid

electrostatic discharge!

Power Connection!

The electrical cables must be laid according to the respective national

regulations (in Germany VDE 0100). The measuring lines must be laid

separately from the mains leads.

Explosion Prevention!

HE 5411 Lite, Basic and Premium with a supply voltage of 19…36 V DC

are suitable for use in explosion zones 2 and 22, provided that the lid is

closed.

HE 5411 Lite, Basic and Premium with a supply voltage of 100…240 V

AC are only suitable for use in explosion zone 22, provided that the lid is

closed.

Devices with a measuring range of ± 1.25 mbar (regardless of the device

version) do not have an ATEX certification and must not be used in

potentially explosive areas.

Before opening the device, e.g. for parameter setting, it is essential to

ensure that no explosive environmental conditions, such as formation of

dust, exist.

8

HE 5411 Operating Instructions

#340411 | version 1.7

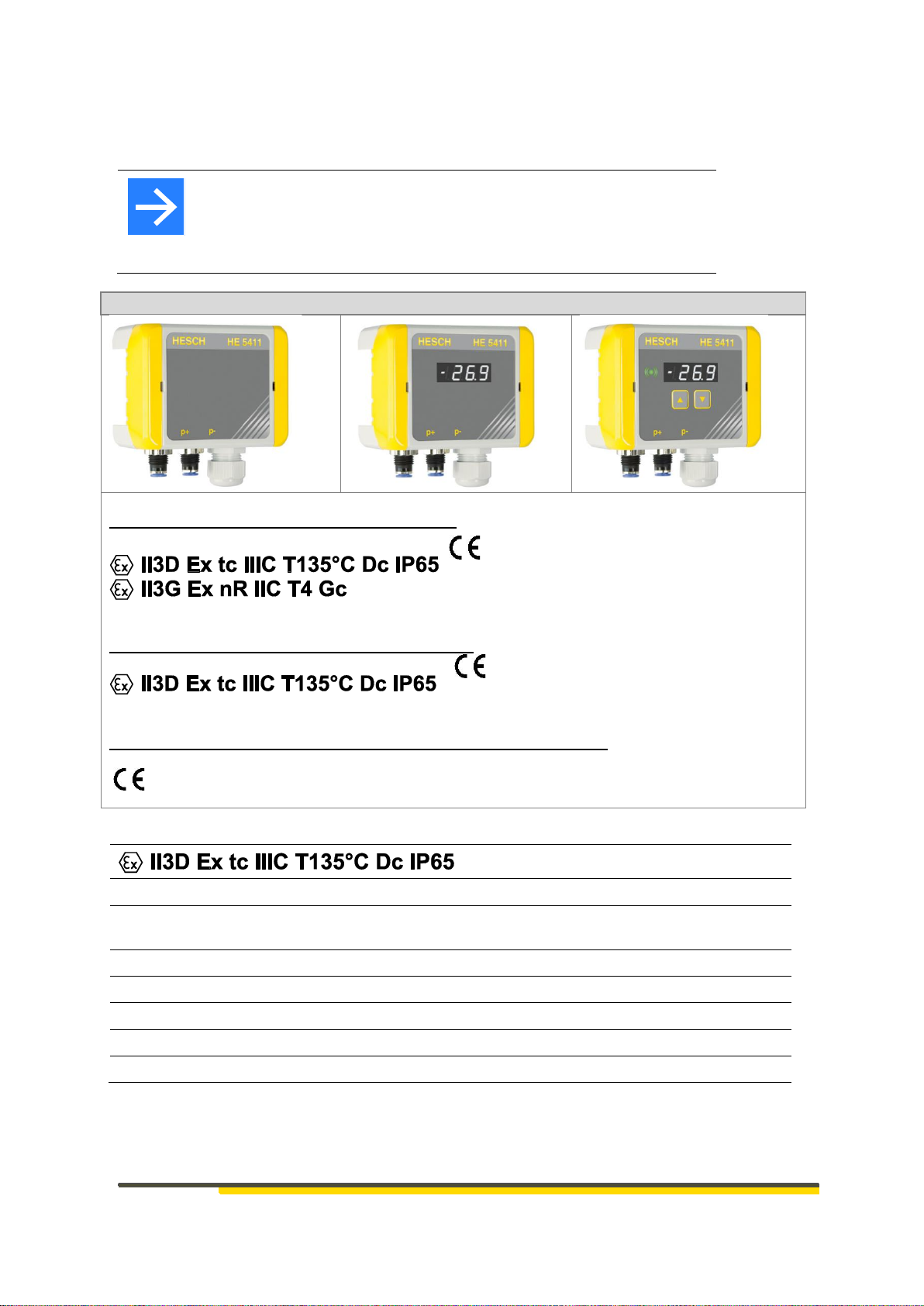

2.4 Device Identification

Note!

The HE 5411 differential pressure transducer is available in three

different designs. The corresponding device identification can be seen on

the nameplate. Devices with a measuring range of ± 1.25 mbar

(regardless of the device version) do not have any ATEX certification!

HE 5411 Lite

HE 5411 Basic

HE 5411 Premium

The devices with 19…36 V DC are marked with:

The devices with 100…240 V AC are marked with:

The devices with a measuring range of ±1.25 mbar are marked with:

II3D

Device category:

Use in Zone 22 for dust during normal operation

Ex

Denotes electrical equipment.

Standards of the EN 60079-0ff. series have been applied.

tc

Type of ignition protection:

Protection by housing

IIIC

Explosion group:

conductive dusts

T135°C

Temperature class:

maximum permissible surface temperature

Dc

Device protection level:

Use in Zone 22 for dust

IP65

Protection type:

dust-tight and protected against water jets

HE 5411 Operating Instructions

#340411 | version 1.7

9

II3G

Device category/

Ex. Atmosphere:

Use in Zone 2 for gas during normal operation

Ex

denotes electrical equipment.

Standards of the EN 60079-0ff. series have been applied.

nR

Type of ignition protection:

Protection by restricted breathing housing

IIC

Explosion group:

Certified for gases with an ignition power of <60µJ

(e.g. hydrogen)

T4

Temperature class:

maximum permissible surface temperature

(135°C)

Gc

Device protection level:

Use in zone 2 for gas

IP65

Protection type:

dust-tight and protected against water jets

Troubleshooting!

At the beginning of troubleshooting, all possible sources of faults on

additional devices or supply lines (measuring lines, wiring, downstream

devices) should be taken into consideration. If the fault is not found after

checking these points, we recommend sending the device to the supplier.

Decommissioning!

Switch off the power supply on all poles if the device is to be

decommissioned. Secure the device against unintentional operation!

If the device is connected to other devices and / or equipment, the effects

must be considered and appropriate precautions taken before switching

off.

The following special regulations must be observed:

The cables must be correctly inserted through the cable ducts by a professional.

Cable ducts not required must be furnished with sealing bolts by a professional.

The ATEX certification only maintains its validity if the installation is carried out correctly by a

professional under the safeguarding of the protection class specified on the marking.

Cleaning of the housing is only permitted with moist cleaning materials to avoid static charging.

Cleaning is necessary to prevent increased dust generation on the device.

Operation under voltage, in zone 22 and 2, only in closed state.

Before closing, ensure that the device housing is free of dust.

10

HE 5411 Operating Instructions

#340411 | version 1.7

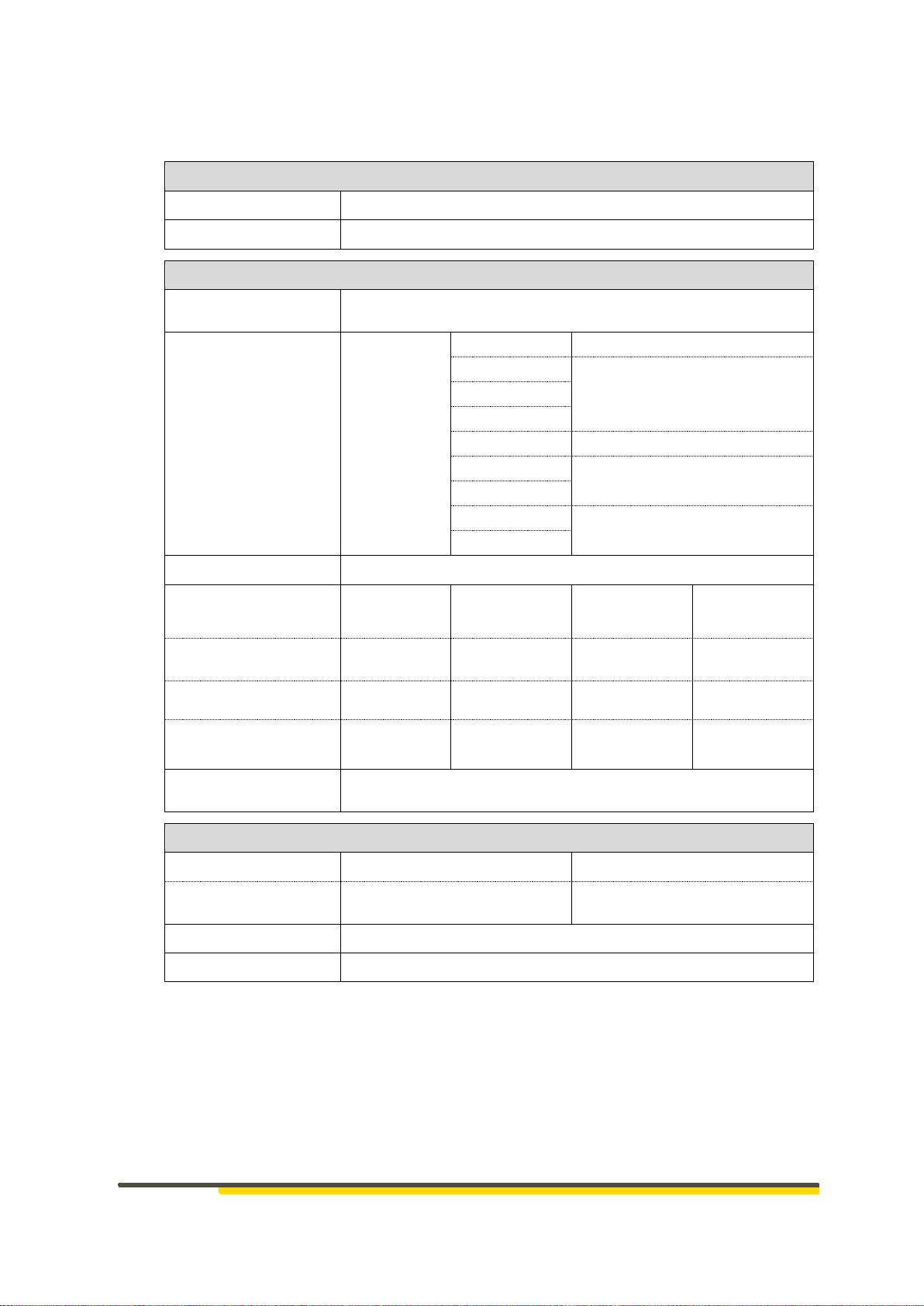

3 Technical Data

Electric supply

Voltage

19…36 V DC or 100…240 V AC

Power consumption

Max. 2 W

Sensor system

Measuring range

(mbar)

± 1.25, ± 2.5, ± 5, ± 10, ± 25, ± 50, ± 100, ± 350, ± 1000

in accordance with the information on the name plate

Max. differential

pressure

Measuring

range

± 1.25 mbar

< 1 bar

± 2.5 mbar

< 0.35 bar

± 5 mbar

± 10 mbar

± 25 mbar

< 0.5 bar

± 50 mbar

< 1 bar

± 100 mbar

± 350 mbar

< 5 bar

± 1000 mbar

Medium

Air and dry, non-aggressive gases

Measuring system

Thermal

(Bypass

Technology)

Piezoresistive

Piezoresistive

Piezoresistive

Measuring ranges

(mbar)

± 1.25

± 2.5…± 10

± 25…± 100

± 350…± 1000

Basic accuracy

-

± 1.5 % FSO

T = 25 °C

± 1.0 % FSO

T = 25 °C

± 0.5 % FSO

T = 25 °C

Total error

± 3 % FSO

T = -20…85°C

± 2 % FSO

T = 0…60°C

± 1.5 % FSO

T = 0…60°C

± 1.0 % FSO

T = 0…60°C

Pressure connection

Push-in bulkhead fittings for 6 mm hose –outer diameter (4 mm

with reduction, see chapter 11 Accessories)

Input / Output

Analogue output:

0…10 V

0(4)…20 mA

Max. permissible

load

RL ≥1 kΩ

RA ≤500 Ω

Relay output

1 changeover contact 250 VAC, 5 A as limit value relay

Service interface

USB / TTL adapter HE 5851 required (see chapter 11 Accessories)

FSO = Full Scale Output

HE 5411 Operating Instructions

#340411 | version 1.7

11

Housing

Type

Dust-tight polycarbonate housing

Dimensions

113 × 80 × 60 (W × H × D)

113 × 110 × 60 (W × H × D) incl. connection

coupling

Protection type

IP 65

Mounting

Wall-mounted, vertical mounting position

Cable gland

1 × M20 × 1,5 N (for cable diameters 6-12 mm)

with multiple sealing insert for 2 x cables Ø 6

mm

Identification

Device identification/explosion protection

See chapter 2.4 Device Identification

Climatic environmental conditions

Storage

-20°…+60° C

Transport

-20°…+85° C

Operation

-20°…+55° C

In EX zone: -20 °C…+40 °C

Relative air humidity

75% rel. humidity, no condensation

Air and creepage distances

Pollution degree

2

Overvoltage category

II

Material group

IIIa

Rated voltage

< 150 V AC, ≤ 250 V AC

Test voltage (basic insulation):

1250 V AC, 1 min

Test voltage (added insulation):

3000 V AC, 1 min

Power connection

Connection type

Push-in-spring connection

Wire size

0.2 mm²…1.5 mm²

Flexible wire size

0.2 mm²…1.5 mm²

AWG wire size / kcmil

24…16

Flexible wire size with ferrule without

plastic sleeve

0.2 mm²…1.5 mm²

Flexible wire size with ferrule with plastic

sleeve

0.2 mm²…0.75 mm²

Extras

Special characteristics

Free from silicone1

1

Silicone is not used in the production process.

12

HE 5411 Operating Instructions

#340411 | version 1.7

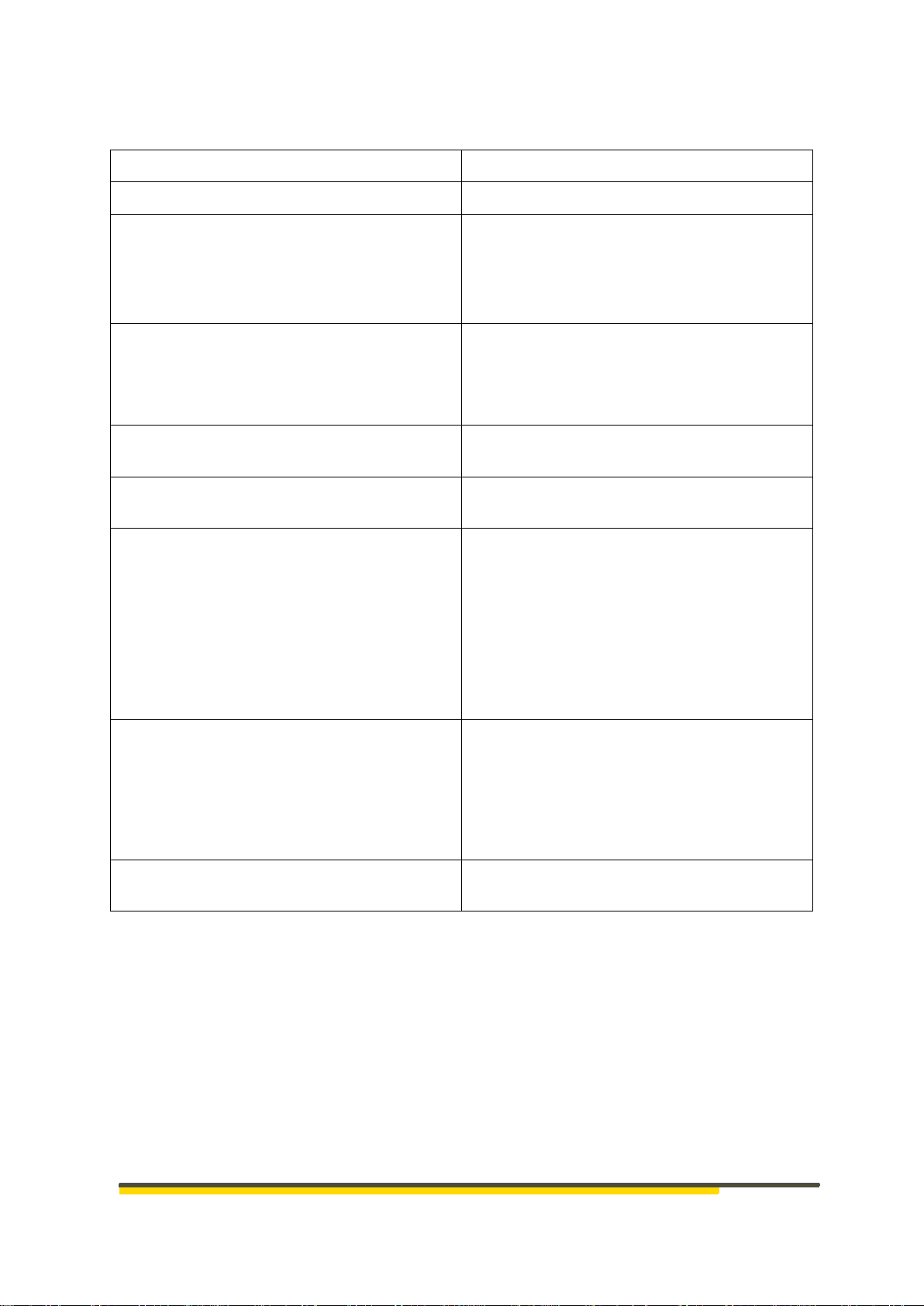

Mean Time Between Failures

MTBF [a2]

Power supply

19…36 V DC

without limit

signal

Power supply

100…240 V AC

without limit signal

Power supply

19…36 V DC

with limit signal

Power supply

100…240 V AC

with limit signal

Without

display

545

167

-

-

With

display

486

161

431

119

Mean Time to Dangerous Failure

MTTFd[a]

Power supply

19…36 V DC

without limit

signal

Power supply

100…240 V AC

without limit signal

Power supply

19…36 V DC

with limit signal

Power supply

100…240 V AC

with limit signal

Without

display

1090

334

-

-

With

display

972

322

862

238

2

anno

HE 5411 Operating Instructions

#340411 | version 1.7

13

4 Mounting

The ambient temperature at the installation point must not exceed the

permissible temperature for nominal use specified in the technical data. The special regulations

for use in EX ATEX Zones must be observed (see chapter 2.3 Safety in the individual operating

phases)

Note!

A drill template can be found on the internet on: www.hesch.de.

When you print it, please ensure to print out Document 1:1.

Ensure the size accuracy of the print-out before drilling.

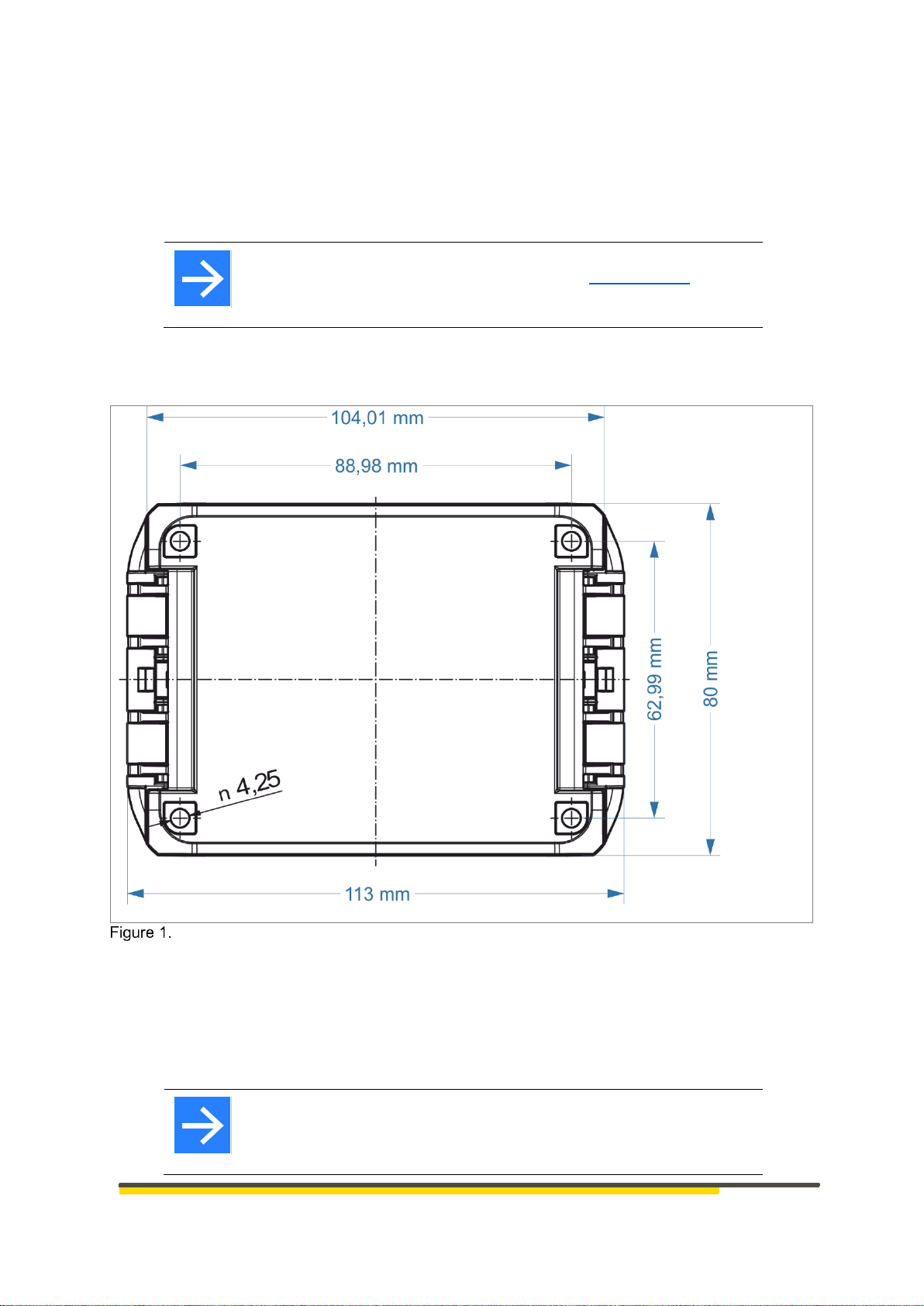

4.1 Dimensions

Back of housing

The dimensions including the connection couplings are 113 × 110 × 60 mm.

Scope of Delivery

HE 5411 differential pressure transducer

Operating Instructions

Note!

Upon receipt, check the delivery for completeness and visible defects. In

the event of a complaint, contact your responsible HESCH representative

immediately.

14

HE 5411 Operating Instructions

#340411 | version 1.7

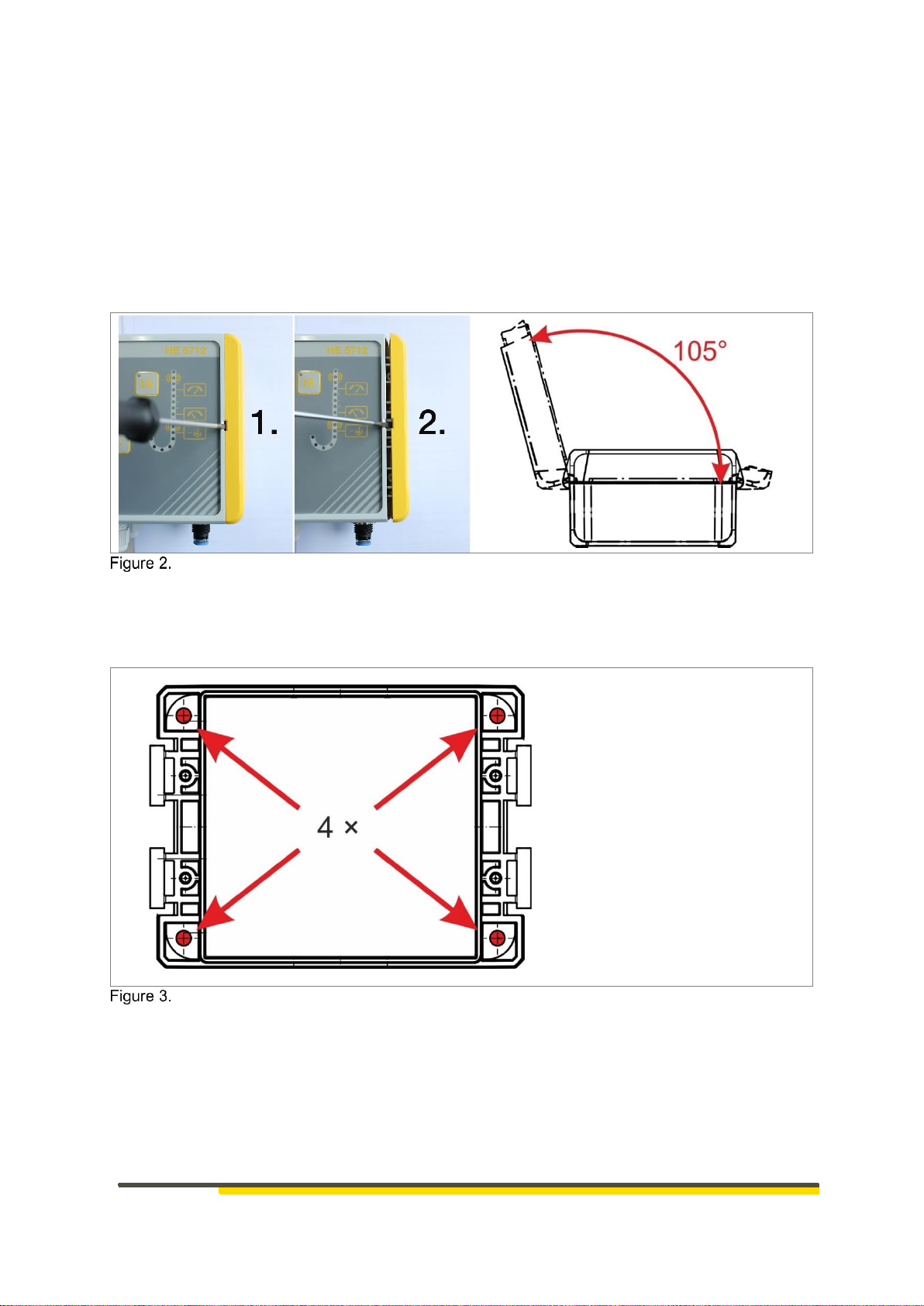

4.2 Opening the device

The opening and closing is without screws by means of hinge technology. A flat-tip screwdriver

is needed to open the device. Apply the screwdriver to the position intended for this on the

housing lid, in order to lift up the hinge. Open the case cover to the left up to an angle of 105°.

Optionally, the housing lid can be closed with 4 additional screws (see chapter 11 Accessories)

in order to protect it from unauthorised access.

The screwless hinge closure is recommended for rapid service access.

Open the housing lid to the left. (The illustration does not show the HE 5411, but one with

a structurally identical housing. The opening principle is identical.)

4.3 Mounting the device

4 screws are required to fasten the device to the wall. (Not included in the scope of delivery!)

Base of the housing

Alternative: Fastening to the wall with wall brackets. (see chapter 11 Accessories)

HE 5411 Operating Instructions

#340411 | version 1.7

15

5 Device Description

The differential pressure transducer records the differential, over- and negative pressure

between two pressure inputs, and converts the measurement value into a linear or square-

rooted output signal of 0(4)…20 mA or 0…10 V.

The 4-digit 7-segment display also allows the display of negative pressures.

5.1 Summary of device versions

5.1.1 HE 5411 Lite (without limit signal)

Front view HE 5411 Lite

5.1.2 HE 5411 Basic (without limit signal)

Front view HE 5411 Basic

5.1.3 HE 5411 Premium (with limit signal)

Front view HE 5411 Premium

16

HE 5411 Operating Instructions

#340411 | version 1.7

6 Electrical Commissioning

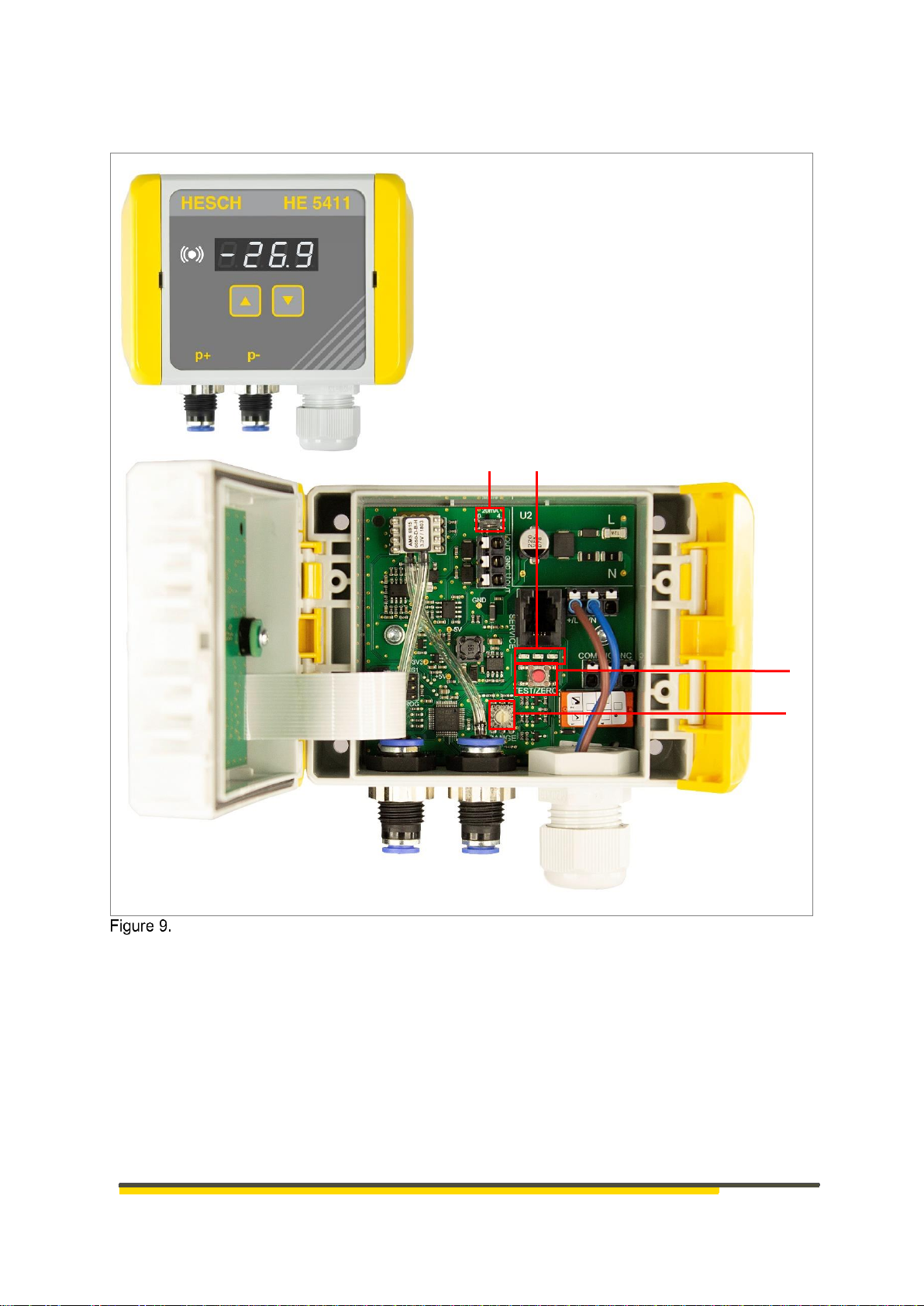

HE 5411 differential pressure transducer, 24 V DC (interior view)

.

Note!

Before commissioning, please note the information on the nameplate!

A

B

C

D

+ -

D

HE 5411 Operating Instructions

#340411 | version 1.7

17

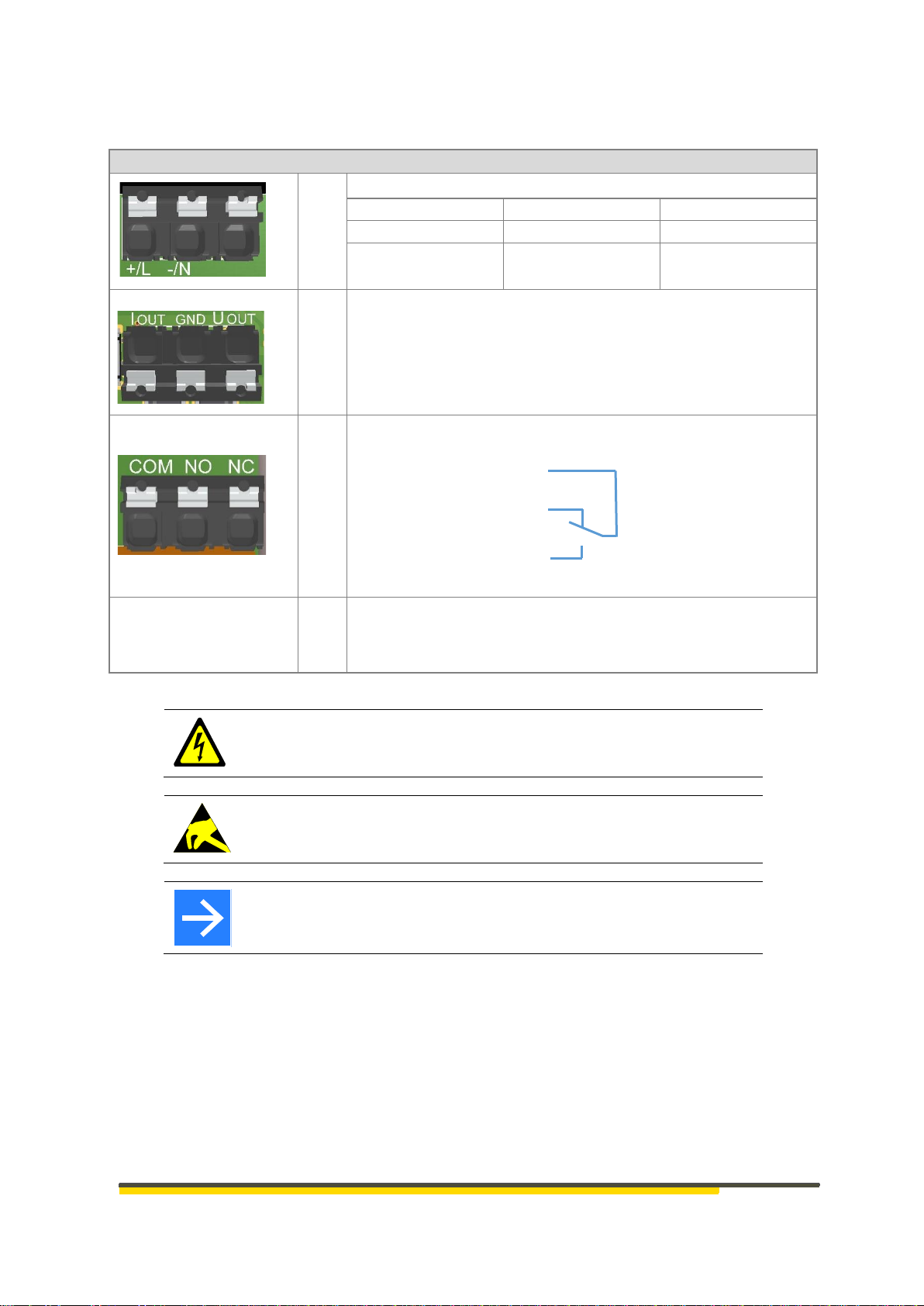

6.1 Electrical connections

Connections

Meaning

B

Supply voltage (Figure 7 shows 24 V DC device)

Connection

DC Signal Version

AC Signal Version

+/L

19…36 V DC

100…240 V AC

-/N

GND

N

A

Analogue output

I OUT Current output 0(4)…20 mA

GND GND

U OUT Voltage output 0…10 V

C

Relay output (limit value)

D

Pressure inputs

The pressure inputs are to be connected with the shortest

possible hoses. These hoses must be:

p+ (raw gas) larger than p- (clean gas)

Danger of Electrocution!

Electrical installation must only be carried out when the power is

disconnected.

Warning of material damage caused by electrostatic charge!

Observe the safety measures according to DIN EN 61340-51/-3 to avoid

electrostatic discharge!

Note!

Work on the electronics may only be carried out by qualified personnel.

Take the value of the correct supply voltage from the nameplate!

There are device versions with 100-240 V AC and device versions with 19-36 V DC supply

voltage.

Before switching on the device, observe the following points:

The cables must have been connected by a professional.

The power supply must correspond to the voltage indicated on the nameplate.

The device may only be operated in closed condition.

The temperature restrictions specified for the use of the device must be observed before

and during operation.

COM

NC

NO

18

HE 5411 Operating Instructions

#340411 | version 1.7

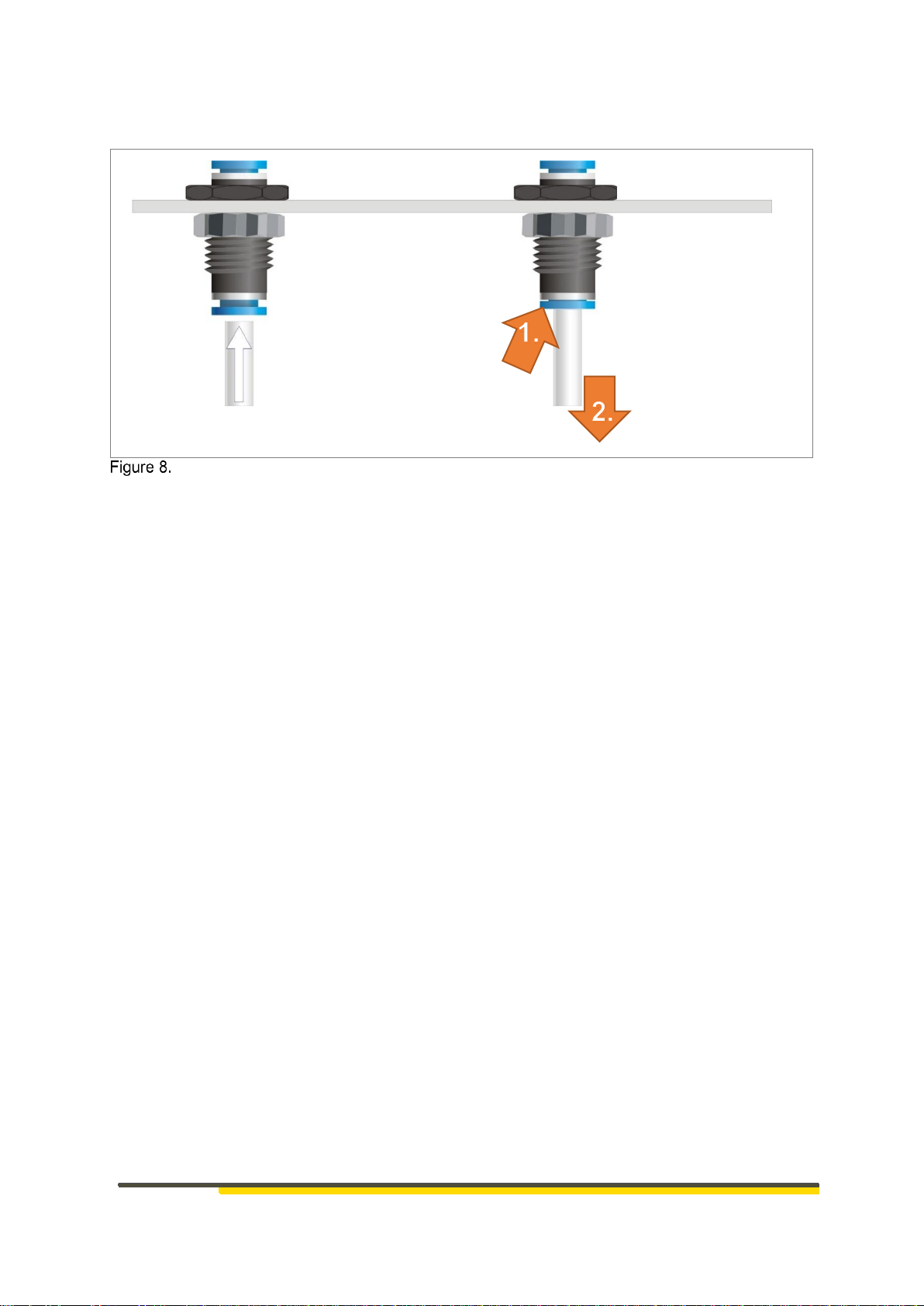

6.2 Assembly of measuring hose onto pressure connection

Assembly of hose onto push-in bulkhead fitting

A Hose connection

Insert hose with 6 mm outer diameter into the connection.

B Hose disconnection

1. Press the blue retaining ring to open the lock.

2. Pull the hose out of the connection.

A

B

1. Push

2. Pull hose

HE 5411 Operating Instructions

#340411 | version 1.7

19

7 Display and Operating Elements

HE 5411 Premium Display and Operating Elements (outside and inside)

A 0(4)…20 mA switch

B LEDs

C Test button

D Rotary coding switch

C

A

D

B

20

HE 5411 Operating Instructions

#340411 | version 1.7

Symbols/Displays

Meaning

UP key: increase the displayed value

DOWN key: decrease the displayed value

Three-coloured Limit LED with colour changes to show status.

Display:

• Normal operation: current differential pressure

• Parameter setting mode: Limit value set

• Switch between the two with UP / DOWN keys

A

The slide switch lets you switch the analogue output between

0…20 mA (left)

4…20 mA (right)

B

LEDs (from left to right)

Flashes continuously (o—o—o—o) when the differential pressure

is in the range of ± 10 % from the measuring range end value to

the zero point.

Flashes continuously (o-o—o-o—o-o), when an offset has been

programmed.

Lights up as soon as the supply voltage is present

Lights up when the differential pressure measured is ≥ the limit

value set

Flashes when the device is in test mode

C

TEST button for zeroing / Test mode

D

Rotary coding switch, 16 levels (0…F) to set the measuring

range.

Table of contents

Other HESCH Transducer manuals

Popular Transducer manuals by other brands

Agilent Technologies

Agilent Technologies IMG-300 instruction manual

Siemens

Siemens Echomax XCT Series Operation manual

Camille Bauer

Camille Bauer SINEAX I 542 operating instructions

GHM Greisinger

GHM Greisinger GRMU2000 MP operating manual

Thyracont

Thyracont VSC43MV operating instructions

Daiichi Electronics

Daiichi Electronics AETT2-91A instruction manual