HESCH HE 5409 User manual

Version # 341539 1.4

Differential pressure measuring

transducer

HE 5409

Operating instructions

(Original in German)

HESCH Industrie-Elektronik GmbH

2

HE 5409, version 1.4, # 341539

Legal information

HESCH Industrie-Elektronik GmbH

Boschstrasse 8

31535 Neustadt

Telephone: +49 5032 9535–0

Fax: +49 5032 9535-99

Website: www.hesch.de

Local court of Hanover

Commercial register (under HRB 111184)

VAT no.: DE813919106

Management:

Walter Schröder, Werner Brandis

Publisher:

HESCH Industrie Elektronik GmbH, documentation department

Document historyfor item no. # 341539

Date - version

Description

31.08.2017 / 1.0

Revised version according to redesign of device

08.3.2018 / 1.1

Cover picture updated

27.03.2019 / 1.2

Chapter 6 Technical data: Operating

temperature in EX Zone added

12.08.2019 / 1.3

Chapter 3.1: bilingual type label added

Chapter 5: clean gas / raw gas corrected

20.01.2020 / 1.4

Chapter 6: new cable connection M 20, because

from now on the housing of HE 5411 is used

(according to change request 5409xxx from

18.09.2019)

Copyrights

© Copyright 2020 HESCH Industrie-Elektronik GmbH Copyrights reserved

Content including illustrations and design of these operating instructions are

subject to copyright protection and other laws for the protection of

intellectual property. The distribution or modification of the content of these

operating instructions is not allowed. Moreover, this content shall not be

copied, distributed, modified or made accessible to third parties for

commercial purposes.

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

3

Table of content

1. Legal conditions....................................................................................... 4

2. Safety instructions................................................................................... 5

2.1 Symbols and general safety instructions ............................................................................ 5

2.2 Signal words........................................................................................................................ 5

2.3 Safety during the individual operating phases.................................................................... 6

2.4 Device identification............................................................................................................ 7

3. Device description ................................................................................... 9

3.1 Device view......................................................................................................................... 9

4. Assembly ................................................................................................ 10

5. Commissioning ...................................................................................... 12

6. Technical data ........................................................................................ 14

7. Accessories............................................................................................ 15

8. Maintenance and service....................................................................... 16

HESCH Industrie-Elektronik GmbH

4

HE 5409, version 1.4, # 341539

1. Legal conditions

Manufacturer

HESCH Industrie-Elektronik GmbH, Boschstrasse 8, D-31535 Neustadt, Germany

Intended use

The differential pressure measuring transducer HE 5409 is an universal measuring

transducer for small and medium pressures.

The device can be operated within the authorised application and ambient conditions

without compromising its safety.

The manufacturer is not liable for improper use and personal and material damages

resulting thereof; the user bears the risk alone. Not complying with the above mentioned

criteria regarding the intended use will result in expiration of warranty and liability for the

device.

Qualification of personnel

Only skilled electricians with sufficient knowledge in electrical engineering shall perform all

work at the measuring transducer.

Device safety

The device has been built and tested according to VDE 0411 EN 61010-1 and has left the

factory in a safety-related impeccable condition. The user must observe the mentioned

instructions and warnings in this manual to keep this condition and to ensure a safe operation.

Declaration of conformity

Please refer to www.hesch.de

for a valid declaration of conformity.

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

5

2. Safety instructions

2.1 Symbols and general safety instructions

This chapter consists of important safety regulations and instructions. Prior to operating the

device, it is mandatory to read this chapter thoroughly to prevent personal and material

damages.

Symbols used

Following symbols are used in these operating instructions. All safety instructions are

standardised.

Warning against personal injuries!

The respective signal word indicates the level of danger.

Warning against explosive atmosphere!

Warning against dangerous electrical current!

Warning against material damages due to electrostatic loading!

Warning against material damages!

Please note!

Indicates possible malfunctioning and provides instructions for optimal

operating conditions.

2.2 Signal words

DANGER!

Indicates an immediate danger with high risk, which can lead to death or severe personal injury

if it is not prevented.

WARNING!

Indicates an immediate danger with medium risk, which can lead to death or severe personal

injury if it is not prevented.

CAUTION!

Indicates an immediate danger with low risk, which can lead to minor or moderate personal

injury if it is not prevented.

HESCH Industrie-Elektronik GmbH

6

HE 5409, version 1.4, # 341539

2.3 Safety during the individual operating phases

Following safety instructions must be observed during the assembly of the device.

Danger due to electric shock!

All utilised power supplies must be switched off prior to the work. The

electric cables must be installed according to the respective country

regulations (German VDE 0100). The measuring cables must be installed

separately from the power cord. The connection between the protective

ground conductor connection (in the respective device carrier) and a

protective ground conductor must be established.

Danger due to electric shock!

Due to any disconnection of the protective ground conductor in the device

carrier the device can become dangerous. Intended disconnections are not

permitted. The device must be shut down and secured against unintended

use in case it is assumed that a safe operation is no more possible.

Danger due to electric shock!

Do not open live devices! Active parts can be exposed during opening

devices or removing covers. Connection points can be active as well!

Attention!

The device shall never be operated despite visible defects.

Attention!

Observe the applicable accident prevention regulations for your system,

such as e.g. the German Statutory Accident Insurance Association

(DGUV) regulation 3 "electrical systems and operating materials" during

assembly, commissioning, maintenance and removal of defects.

Attention!

Clean contaminated contacts with oil-free compressed air or spirit and a

lint-free cloth.

Material damages due to electrostatic loading!

Observe the safety measures according to DIN EN 61340-51/-3 to prevent

an electrostatic loading!

Electrical connection!

The electric cables must be installed according to the respective country

regulations (in Germany VDE 0100). The measuring cables must be

installed separately from the power cord. The connection between the

protective ground conductor connection (in the respective device carrier)

and a protective ground conductor must be established.

Explosion protection!

It is permitted to use the device in explosion zone 22 and 2 with closed

lid. It is mandatory to ensure that no explosive ambient conditions, such

as e.g. development of dust, exist prior to opening the device for e.g.

parametrisation.

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

7

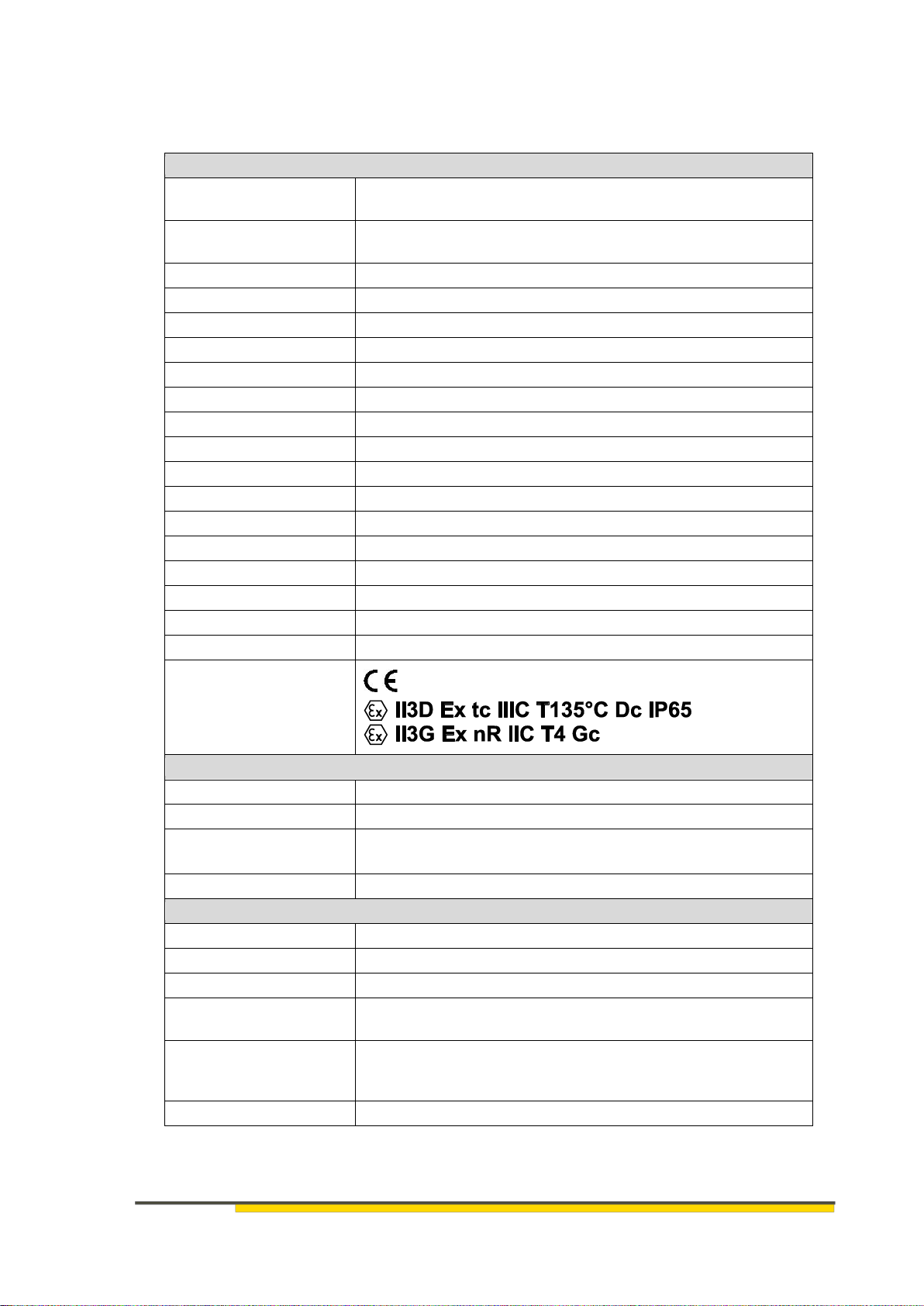

2.4 Device identification

The device bears the following label:

II3D

Device category:

Use in zone 22 for dust in standard operation.

Ex

Indicates an electrical operating material standards of series EN 60079-0ff. were

applied.

tc

Ignition protection type:

Protection by housing

IIIC

Explosion group:

Conductive dust

T135 °C

Temperature setting:

Maximum permitted surface temperature

Dc

Device protection level:

Use in zone 22 for dust

IP65

Protection type:

Dust proof and splash-water protected

II3G

Device category/

Ex-atmosphere:

Use in zone 2 for gas in standard operation

Ex

Indicates an electrical operating material.

Standards of series EN 60079-0ff. were applied

nR

Ignition protection type:

Protection by smoke-restricted housing

IIC

Explosion group:

Permitted for gases with an ignition power of <60µJ

(e,g. hydrogen)

T4

Temperature setting:

Maximum permitted surface temperature (135 °C)

Gc

Device protection level:

Use in zone 2 for gas

IP65

Protection type:

Dust proof and splash-water protected

Troubleshooting!

All possibilities of trouble sources at add-on devices respectively supply

lines (measuring lines, wiring, sequential devices) must be considered at

the beginning of the troubleshooting. We recommend to send the device

to the supplier in case the error has not been detected after reviewing

these points.

Decommissioning!

Disconnect the power supply at all poles to decommission the device.

Secure the device against unintended operation!

Prior to the disconnection the impacts must be considered and respective

measures must be taken if the device is connected to other devices and /

or equipments.

HESCH Industrie-Elektronik GmbH

8

HE 5409, version 1.4, # 341539

Following special regulations must be observed:

Cables must be professionally connected in the screw fitting.

Not required housing bores must be professionally closed by a locking bolt.

The ATEX certification remains valid only if the installation is professionally performed according to

the protection type mentioned on the labelling.

The housing shall only be cleaned with damp cleaning cloths to prevent static loading.

Cleaning is required to prevent increased dust on the device.

Operation at live parts, in zone 22, only in closed condition.

Ensure the device housing is dust-free prior to closing it.

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

9

3. Device description

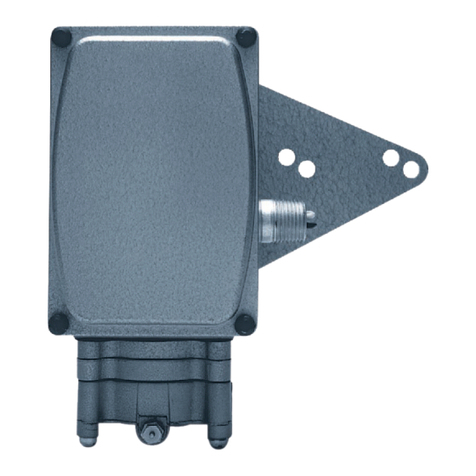

3.1 Device view

Assembly of measuring hose at the pressure connection

Illustration 1. Assembly of hose at push-in bulkhead connector

A Connect hose

Push hose with 6 mm outer diameter into the connection.

B Release hose

1. Press on the blue locking ring to open the closure

2. Pull the hose out of the connection

1. Press

2. Pull hose

Pressure connection and supply

line for electrical connection

Type label

A

B

HESCH Industrie-Elektronik GmbH

10

HE 5409, version 1.4, # 341539

4. Assembly

Please note!

Regarding a drilling template please refer to our website:

www.hesch.de

Please ensure during printing that the document is printed 1:1. Ensure

the dimensional accuracy of the printout prior to drilling.

The assembly of the measuring transducer HE 5409 should possibly not take place in the

vicinity of heat sources. The ambient temperature at the assembly site must not exceed the

permitted nominal temperature for operation mentioned in the "Technical Data" (page 14). It is

permitted to assemble the device in areas of explosion class EX ATEX zone 22 and 2. The

special regulations must be observed, see chapter 2.4 device identification on page 7.

Dimensions

Illustration 2. Reverse side of the housing

Scope of delivery

HE 5409

Operating instructions

Please note!

After receipt, check the delivery for completeness and visible defects.

Immediately inform your respective HESCH agent in case of a claim.

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

11

Opening of the device

Opening and closing is performed by hinge technology without screws. A slit screwdriver is

required to open the device. The screwdriver must be positioned at the intended position at

the housing lid to break the hinge open. The housing lid must be opened to the left up to an

angle of 105 °.

Optional, in addition, the housing lid can be closed by 4 screws (see accessory list, item no.3

on page 15) to protect it from unauthorised access.

The hinge closure without screws is recommended for a quick service access.

Illustration 3. Open housing lid to the left

Assembling of the device

Screws are required for wall mounting. (Not included in the scope of delivery)

Illustration 4. Housing base

Alternative: wall mounting with wall brackets. (See accessories list on page 15, chapter 7)

HESCH Industrie-Elektronik GmbH

12

HE 5409, version 1.4, # 341539

5. Commissioning

Illustration 5. HE 5409 with open housing lid

A Zero point setting

Please note!

The correct value of the device has been set in the factory and does not

need to be changed.

A warm-up time of 30 minutes must be considered if the zero point must be set.

The zero point of the measuring transducer is set on 4 mA by the potentiometer.

B Test switch

The output signal can be switched from 4...20 mA to 10 mA by the switch to control the correct

connection.

C Pressure inputs

The pressure inputs must be connected via short hoses.

Attention: p+ (raw gas) greater than p- (clean gas).

+-

A

B

D

C

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

13

D Electrical connection

The device is suitable for the connection at 10…36 V DC. Pay attention to the correct value of

the power supply voltage. Otherwise the device will be destroyed.

The connection takes place via spring force terminals for 0.2 … 1.5 mm² conductors.

The input is bipolar and can be connected as needed. The measuring value of the differential

pressure corresponds to the power consumption of the device.

Connection diagram

Mains

10…36

V DC

HE 5409

(bipolar)

Measuring

input

4…20 mA

HESCH Industrie-Elektronik GmbH

14

HE 5409, version 1.4, # 341539

6. Technical data

Technical data

Measuring range

0–10 mbar; 0–25 mbar; 0–50 mbar; 0–100 mbar; 0–1000 mbar

According to the information on the type label

Max. differential

pressure

750 mbar

Max. ambient pressure

1000 mbar

Medium

Air and dry, not aggressive gases

Basic accuracy

± 1 % of final value

Temperature drift

± 0.05 % / K of final value

Hysteresis

± 0.05 % / of final value

Measuring system

Semiconductor sensor

Auxiliary power

Ub= 10…36 V DC

Analogue output

4…20 mA, 2-conductor technology

Max. load resistance

RA≤ (Ub–9 V) / 0.02 A

Pressure connection

Push-in bulkhead connectors for 6 mm hose outer diameter

Housing

Dust-protected housing

Dimension

113 × 80 × 60 (W × H × D)

Protection type

IP 65

Assembly

Wall mounting, assembly position vertical

Connection

Spring force terminal

Cable screw connector

1 × M 20 × 1.5 N for cable diameters of 6…12 mm

Device identification/

explosion protection

Climatic ambient conditions

Storage

-20 ° … +70 °C

Transport

-40 ° … +85 °C

Operation

-20 ° … +55 °C

In EX zone: -20° C…+40° C

Relative humidity

75 % relative humidity, no condensation

Safety related operating figures

MTBF

646 years

MTTFd

1292 years

Service life

Max. 10 years

Category according to

EN-ISO 13849

B

Calculation methods

according to EN-ISO

13849

Parts count

Ambient temperature

50 °C

Subject to technical modifications!

HESCH Industrie-Elektronik GmbH

HE 5409, version 1.4, # 341539

15

7. Accessories

Hesch offers a series of optimal accessories for assembly and connection technology of HE

5409

Item

no.

Illustration

Name

Order number

1

Wall brackets

for alternative

mounting of housing of

HE 5409

Colour:

Light grey

Upon request

2

Housing hinge closure

Available in different

colours:

Light grey, graphite grey,

bright red, ultramarine

blue

Upon request

3

Screw set (4 pc.)

for optimal screw

connection of the

housing

Factory standard 1412,

30×18×10, crosspoint,

left hand thread

B SHR

4

p-connector set

for HE 54xx and p-

magnetic valve controls.

PVC hose

Ø i=4 mm Ø a=6 mm

# 54109999

5

Universal adapter set

for push-in screw, PU

hose Ø i=4 mm / Ø a=6

mm

on Whitworth pipe thread

G¼"

# 54210099

Accessories for magnetic valve controls

6

HESCH premium valve cable

Incl. of plug and core end sleeve

0.65 m

# 63500006

2.50 m

# 63500002

5.00 m

# 63500003

8.00 m

# 67250004

HESCH Industrie-Elektronik GmbH

16

HE 5409, version 1.4, # 341539

8. Maintenance and service

Maintenance and repair

The device must be cleaned regularly to prevent increased dust on the device.

Disposal

Put metals and plastics for recycling. Electro and electronic components must be collected

separately and disposed accordingly. Dispose equipped circuit boards in a professional

manner.

Service

HESCH Industrie-Elektronik GmbH

Boschstrasse 8

31535 Neustadt

Germany

Telephone: + 49 5032 9535-0

Table of contents

Other HESCH Transducer manuals

Popular Transducer manuals by other brands

S+S Regeltechnik

S+S Regeltechnik PREMASGARD 711x Series Operating Instructions, Mounting & Installation

Petroline-A

Petroline-A TP-140D Operation manual

Siedle

Siedle novotechnik TX2 Series manual

Omega

Omega PX276 instruction sheet

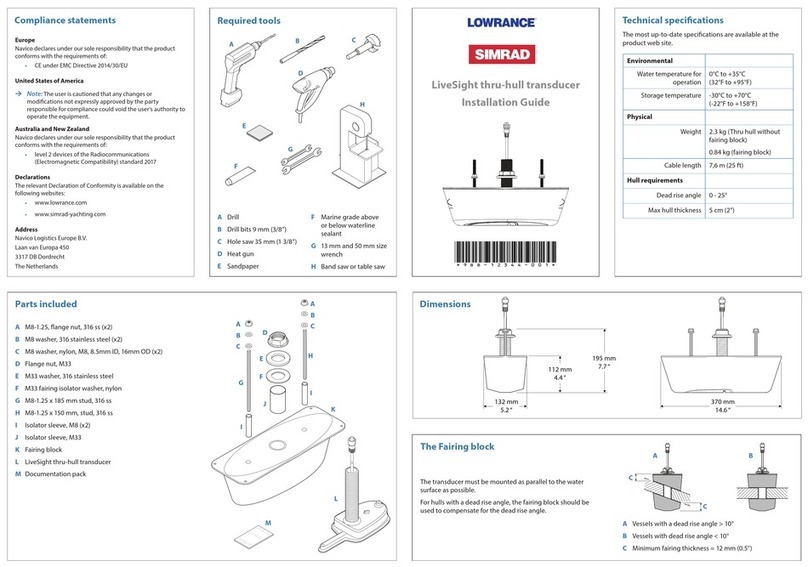

Lowrance

Lowrance SIMRAD installation guide

Baker Hughes

Baker Hughes Masoneilan 8000 instruction manual

Clark Synthesis

Clark Synthesis Prosound429 installation guide

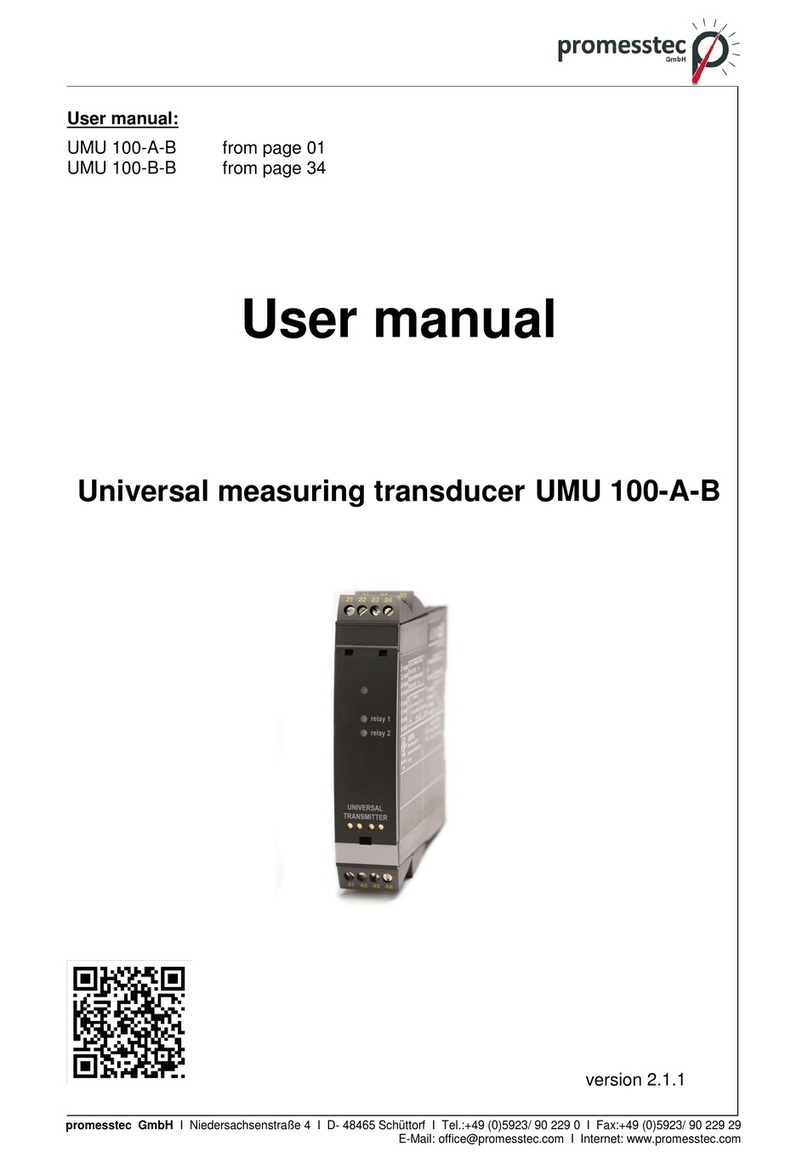

promesstec

promesstec UMU 100-A-B user manual

Simrad

Simrad ES70-7C - INSTALLATION REV B installation manual

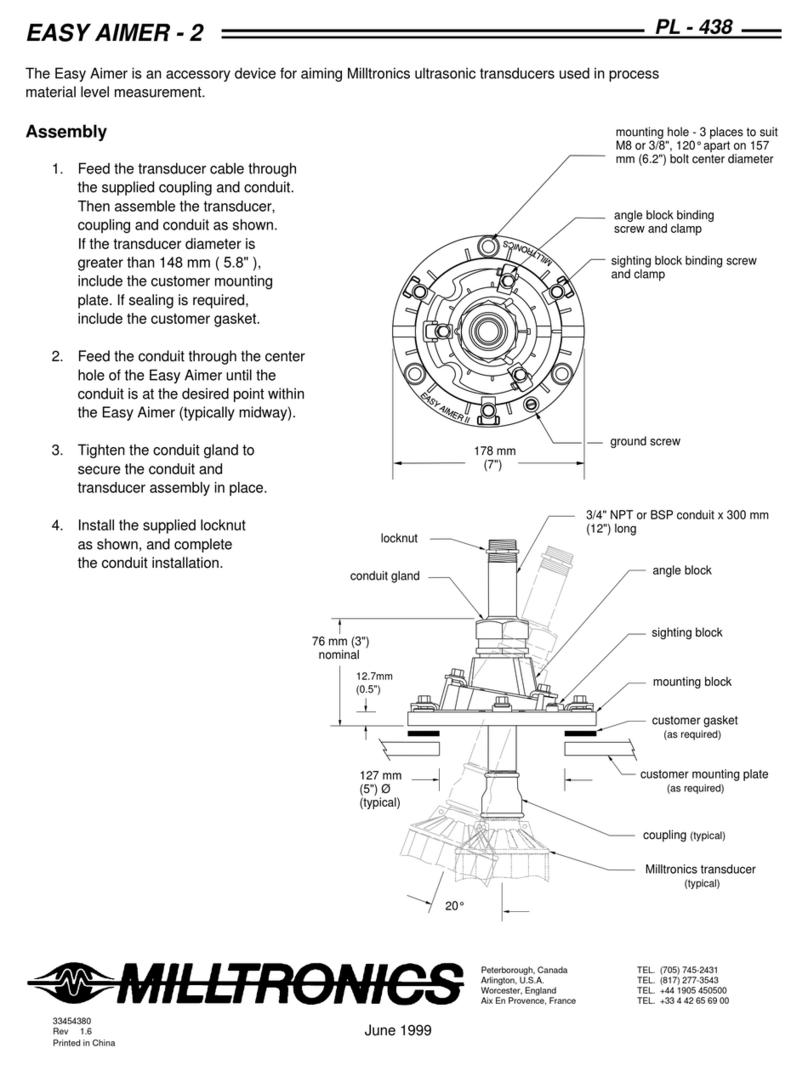

Milltronics

Milltronics EASY AIMER 2 manual

Simrad

Simrad ES333-7CD - REV A installation manual

TJERNLUND

TJERNLUND COP2 installation instructions