HESHBON HL-32X Manual

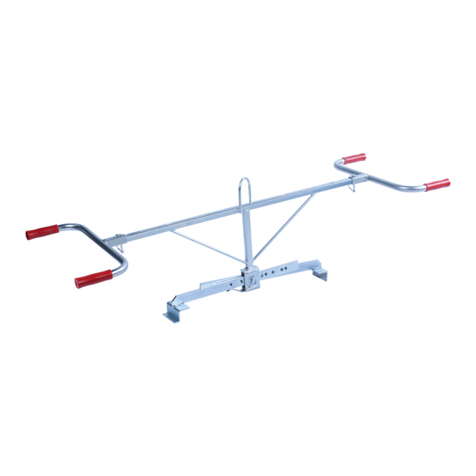

HL-32X

HESHBON SCISSORS LIFT

Installation/Operation & Maintenance Manual

Please read this manual before you get started.

You must read and understand the precautions for safety to protect your safety

and any damage to your property.

NO. 32X081101A

ⓒ Copyright Heshbon Co.,Ltd. MIT Design Group 2008 All rights reserved.

NOTE TO THE USER

Thank you for purchasing HESHBON CAR LIFT

Please read this instruction carefully for safe and proper use of the car lift,

and keep it handy for future reference.

This Manual is for model : HL - 32X

As for the assurance of safety in design and construction

of car lift, read this Manual first.

Please make sure that this manual is delivered to end users

for their implementation of safety.

Don’t use the car lift in a potentially explosive atmosphere.

ANY PART OF THIS PRINT MUST NOT BE REPRODUCED IN ANY

FORM WITHOUT PERMISSION.

THIS PRINT IS SUBJECT TO CHANGE WITHOUT NOTICE.

Introduction

Features and characteristics

Part’s name

Control pannel

Specification

Caution Sticker layout

1

1

3

5

6

7

Installaion procedures

Check list before installing

Place of installation - lay out

Check of anything is missing

Installation procedures

11

11

12

13

14

Safety

Danger/warning/caution

9

9

Operation

Check points before operation

Operation

Proper car lift method (the weight setting)

16

16

17

18

PART LIST

26

Maintenance

Equipment maintenance and service

Trouble shooting

Check list and periodic maintenance

20

20

24

25

■This manual was prepared in November. 2008 the product specifications

contained in this manual are subject to change without notice.

TABLE OF CONTENTS

Introduction

SafetyInstallation

Operation

Mainternance

Part List

Introduction

1

Features and characteristics

■ Realization of the lower

ground lift

▶Cars are entered easily and minimize

lift drop accident from minimum height

140mm realization.

Introduction

Slide Realization of the

Min. height 140mm

Application of

DU bearing

Dual hydraulic

cylinder

synchronization

system

Onground and inground

are freely available

2

Introduction

Introduction

■ Double high-pressure seals

▶Powerfull hydraulic cylinder with

double u-packing seals.

■High performed upper roller

▶DU bearing in roller for reduces

noise and durability.

■ Onground and inground

are freely available

▶As workshop situation, freely change

types.

■ Slide of platform

▶Slide bar is applied to the platform

for van or longer vehicle.

■ Dual hydraulic cylinder

synchronization system

▶Use four cylinders for

synchronization performance.

Realization of the

Min. height 140mm

3

Names of each part are described

Introduction

Extension

Platform

▶Platform extension for

safety to various length

car.

▶Adjustable lift

platform

▶Adjustable lift base.

▶Control panel

▶Single-phase plug

and compressed air

coupling for auxiliary

tools.

▶Operates the

platform of the main

lift.

Base

Remote

controller

(Option)

Command Box

Power centre

Main cylinder

Introduction

See page “PARTS LIST”

4

Main no. 1 link

Main no. 2 link

▶Ascents and descents

the main platform.

▶Ascents and descents

the main platform.

Introduction

5

Control panel

(1) Power Lamp

(2) Descent button

(3) Power Cam switch

(4) Ascent button

(1)

(2)

(3)

(4)

(1) Power Lamp

(2) Descent button - Descends the main platform

(3) Power Cam Switch - Supply or isolate the power of the lift.

(4) Ascent button - Ascends the main platform

Introduction

Introduction

Specification

6

Model Name

Capacity

Used Hydraulic Pressure

Overall Max.Height

Min.Runways Height

Stroke

Lifting Time

Lowering Time

Standard Motor

Net Weight

Layout Dimension

HL-32X

3,000 Kg

250 Kgf/㎠

1,953 mm

140 mm

1,813 mm

Approx. 55 ~ 65 sec

Approx . 50 ~ 65 sec.

1ph 2.5HP 220V 60Hz / 3ph 2HP 220,380V 60Hz

1,050 kg

3,841 × 140 × 2,065 mm

Introduction

Introduction

7

Caution Sticker layout

Caution/Warning/Danger

Introduction

Introduction

8

Heshbon Lift

Capacity

Heshbon logo

Heshbon symbol

Hand&Foot Warning

Introduction

Warning before using the equipment

Safety

9

Danger/warning/caution

Make sure you follow the

instructions, otherwise critical

injury or death can occur.

Make sure you follow the

instructions, otherwise critical

injury or damage can occur.

Make sure you follow the

instructions; otherwise, injury or

damage can occur

The terms are described to enhance

the understanding of the equipment.

Information to use the equipment

efficiently.

Precautions or check points for the

use of the equipment.

Please refer to the page

Rules for illustrations

in the Manual.

Do not come

under the vehicle

during operation.

▶ This can cause

injury or death.

Evacuate to a safe

place instantly in

the event that the

vehicle tips.

▶ This can cause

injury or death.

Do not overload

the rated capacity.

▶ This can cause

injury or death.

※Not following

the instructions

can lead to a

critical accident

involving your

life. Make sure

you follow the

instructions.

Only trained

personnel may

operate the

equipment.

Inexperience can

cause accidents.

Position the

vehicle to make

sure that it is

balanced front

and rear, right and

left(otherwise the

vehicle may fall

off).

Do not operate

damaged

equipment(a

critical accident

could occur -

contact your

Heshbon supplier)

After that a

vehicle is placed

on the lift make

sure that the hand

brake is applied.

Passenger

transport is

forbidden.

These are the

rules for the

illustrations in the

manual. Make sure

that you read them

and understand

them. The rules

are applied only

to the manuals of

Heshbon Co., Ltd.

Precautions

for safety

Warning before using the equipment

Warning when

operating

Warning while operating

Warning while operating

10

Precautions

for safety

Safety

Before lowering

the lift, check

that there are

no obstructions

under the

vehicle or the lift

arms.

When the vehicle

is lifted, do not

rock it as this

may dislodge it.

Do not lift a

vehicle using

one pair of arms

only.

To avoid injury,

keep your feet

clear of the arms

and carriages.

Before going

under the lift,

make sure that

the safety pawls

are engaged.

To avoid being

electrocuted,

disconnect the

main power before

opening the

control panel.

Do not modify

the control panel

or the safety

functions as this

may impair their

function.

Do not rock

the vehicle

when lifted. Do

not use a high

pressure cleaner

as the vehicle

lower part.

Read and fully

understand the

manual before

using the lift

Check the

safety devices

to see that they

are clean and

operable.

If the lift is idle

for a long time,

disconnect the

main power supply.

In the event of

thunder storm.

disconnect the

main power supply.

Allow no

unauthorized

persons in the

work area.

11

Installation

Installation

Installation site

Installation site

Checklist before installing

The site must be

flat and horizontal.

The floor must have

minimum 160mm

depth of reinforced

concrete.

Surface load under

the posts must be

minimum 25N/㎟.

To maintain the warranty,

the lift is intended for

indoor installation

only. In the event that

it is installed outside it

should be protected from

snow and rain. Outdoor

installation makes the

warranty invalid.

Installation site

Ambient

temperature

10℃ to 50℃.

Do not operate

under freezing

conditions.

Vehicle access to

the lift must be

safe and easy.

There must be

a safe working

distance of

minimum 1m

between the lift

and the wall or any

fixed object.

To ensure that the

anchor is secure,

the hole for an

anchor bolt must

be more than 2/3

of the bolt length.

Skilled engineers

of Heshbon or its

sale representative

agency shall install

the lift, otherwise a

failure may occur.

Please contact

Heshbon

head office or

distributors for the

removal of lifts.

Checkpoints before selecting the place of installation

① Distance from the wall or any fixed object

② Drive-on direction

③ Position of power post and slave posts

④ Ceiling height

Place of installation (Layout)

12

Installation

Installation

13

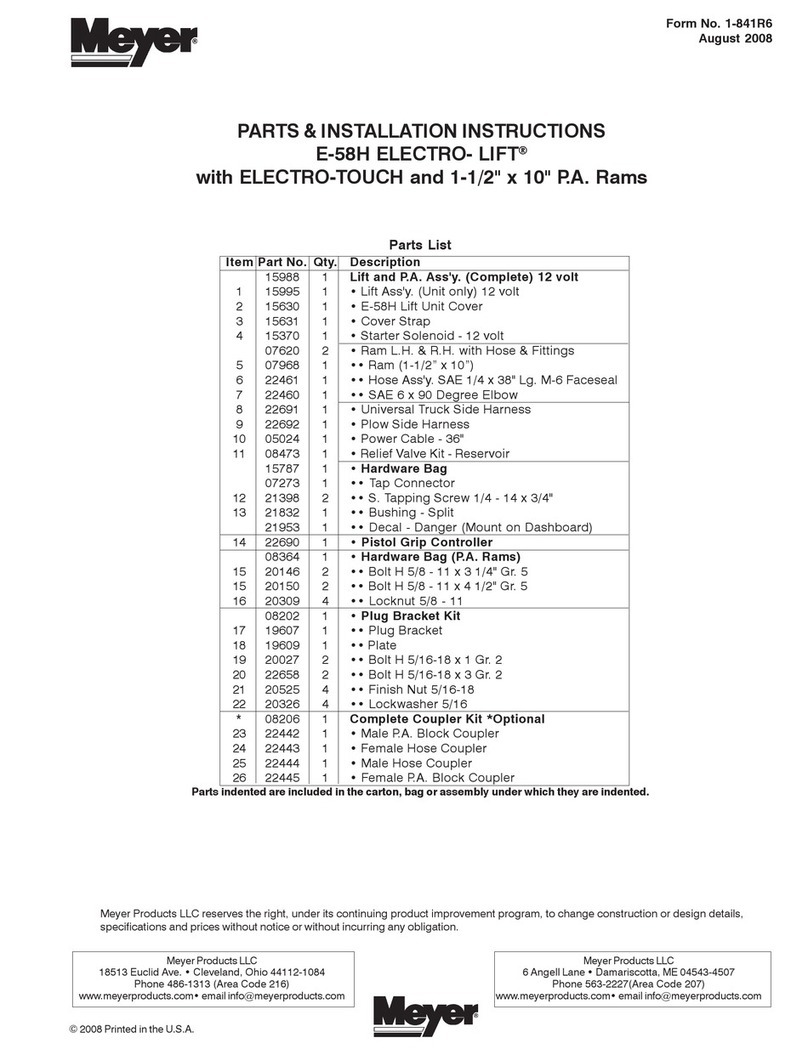

Check if anything is missing

■ Check the items of HL-32X

1

2

3

4

7

8

910

13

11

12

5 6

14

15

16

17

Check the items : If any of

these items is missing from

the box,contact

your sales representative.

Preparation for installation

: Deploy the items in the

installation site as specified

in the layout. Check the

positions of power and slave

posts,

drive-on direction,safe

working area.

HL-32X (Ground type)

1. Main body

2. Control panel : 1ea

3. Entrance plate at front side

(Ground type) : 2ea

4. Entrance plate at rear side

(Ground type) : 2ea

5. Synchronization cover

(Ground type) : 1ea

6. Stopper at rear side

(Ground type) : 2ea

7. Hose cover1 : 1ea

8. Hose cover2 : 1ea

9. Component box for

shipment : 1ea

10. Manual : 1ea

1. Main body

2. Control panel : 1ea

9. Component box for

shipment : 1ea

10. Manual : 1ea

11. Entrance plate at front side

(Inground type) : 2ea

12. Hose cover

(Inground type) : 1개

13. Entrance plate at rear side

(Inground type) : 2ea

14. Extension beam SET-1 (1ea)

15. Extension beam SET-2 (1ea)

16. Extension beam SET-3 (2ea)

17. Extension beam SET-4 (2ea)

HL-32X (Inground type)

HL-32X (Option)

Installation

Installation

14

Installation procedures

Anchor bolt installation.

① Drill a hole (ⓓ: hole depth)

② Clean the inside of the hole

③ Put the anchor bolt into the hole

and hammer in until it reaches the

bottom of the hole

④ Tighten the bolt with a spanner.

(ⓐ35~45mm)- Torque : 80~100N.m

■Fixation horizon of the base

▶After adjust horizon of the product

precisely, fix up using anchor bolt.

After measure the horizontal status, lay

down the lie.

Adjustment the level of the base.

1

After adjust the level, fix up the base

platform using anchor.

Fixation of base (anchor)

2

■ Landing down the product at the place to be installed

▶Place the lift main body at the place to be installed referring to layout document.

▶Fixing the product after checking the caution notes.

In case of the

forklift use

In case of the

crane use

■Fixing the base with anchor bolt

▶Fix the 6pcs Anchor bolt of the

base plate and 2pcs Anchor bolt of

the control panel after supporting lift

using liner.

Installation

Installation

15

■Connection of oil pressure hose

▶Connect oil pressure hose by referring oil pressure

line diagram. (Refer to part list oil pressure circuit)

Installation

Installation

Operation

Operation

16

Check points before operation

■ Test operation

▶Operate ascent and descent 2~3

times under no load condition.

Before loading the lift, check the

following points.

Inspect the lift everyday to operate

the lift safely for a long time.

■ Switch operation

▶Check that the ascent and descent

push buttons are working correctly.

■ Hydraulic check

▶Check if there are no hydraulic leaks

from either cylinders, pipes, or hose

joins.

■ Mechanical check

▶Check the tightness of all nuts,

bolts, etc.

■ Exterior check

▶Check the exterior of the lift to

ensure that there is no obvious

damage.

■ Cleanliness

▶Check every day that the lift is clean

and that the work area is clean and

free from debris or obstructions.

17

Operation

Check that the platforms are parked

at floor level by using the descent

button. Check that the auxiliary lift is

at the down position.

Prior to use

1

Check that the position of the

righthand (movable) platform is

suitable for the majority of the

vehicles to be lifted. Fix the platform

at this position with the bolts

provided.

Prior to vehicle entry

2

Press the decent switch and descend

to the position(140mm height), and

return the platform slide plate to the

original place, and descend to the

bottom postion.

▶Extract the car after checking it

is descended to the bottom place

completely.

Descent lift

5

Perform the necessary repairs and/

or maintenance on the vehicle. After

completion,lower the auxiliary lift. As

soon as the vehicle load is firmly on

the platforms,stop the descent of the

auxiliary lift, remove the rubber pads,

push in the extensions, and lower to

bottom position.Lower main lift.

Press the ascent switch, and lift up to

the 140mm height

Extract the platform slide plate at the

140mm height and adjust position to be

lifted safely

(use rubber support)

Vehicle repair

Lift up the lift to the second descent position

4

3

Attention the

sudden stop.

Remove the humidity

of the tire before you

enter.

After you drive

into the lift, get

out of the car.

After you drive

into the lift, hold

the side brake.

Attention before you enter

Installation

Installation

Table of contents

Other HESHBON Lifting System manuals

Popular Lifting System manuals by other brands

rav

rav KPX315WK Translation of the original instructions

Jacka Industries

Jacka Industries JackaJay user guide

JLG

JLG G5-18A Operation manual

Smart Lift

Smart Lift SL 400 Skylifter instruction manual

Extreme Max

Extreme Max Boat Lift Boss installation instructions

mydocking.com

mydocking.com L300 installation manual