HESHBON HL-25H User manual

English Version

HBN-H-301-09/VER. 2.0

HL-25H OPERATION MANUAL

HESHBON CO., LTD. developed this document for its licensees and customers. The information

contained herein is the property of HESHBON CO., LTD. and may not be copied, used, or

disclosed to others without prior written approval from HESHBON CO., LTD.. Users are

cautioned that the material contained herein is subject to change by HESHBON CO., LTD. at any

time and without prior notice

HESHBON CO., LTD.

673-52, Gyeongseo-dong, Seo-gu Incheon 404-170, KOREA

Copyright HESHBON CO., LTD. ⓒ2002

First Printing, February 2002

Printed in Korea

LIFT

DECLARATION OF CONFORMITY

according to EN45014(09/1989)

We, HESHBON Co., LTD.

(supplier's name)

673-52, Gyeongseo-dong, Seo-gu Incheon 404-170, KOREA

(address)

declare under our sole responsibility that the product

product : Car Lift

Type : HL-2500E, HL-26K, HL-31X, HL-3000N, HL-41G, HL-51G

HL-25H , HL-26P, HL-31S , HL-32S, HL-32F , HL-3300J , 3300W, HL-46H

Serial Number:

(name, type or model, lot, batch or serial number, possibly sources and numbers of items)

to which this declaration relates is in conformity with the following standard(s) or other normative

document(s); (title and /or number and date of issue of the standard(s) or other normative document(s))

EN292-1(1991)

Safety of machinery-Basic concepts, general principles for design

Part 1 : Basic terminology, methodology

EN292-2(1991)

Safety of machinery-Basic concepts, general principles for design

Amd A1(1995)

Part 2 : Technical principles and specifications

EN60204-1(1997)

Safety of machinery-Electrical equipment of machines

Part1 : General requirement

EN1493(1999)

Vehicle Lifts

EN50081-2(1994)

Electromagnetic compatibility . Generic emission standard

Part 2: Industrial environment

EN50021-2(1995)

Electromagnetic compatibility . Generic emission standard

Part 2: Industrial environment

following the provisions Directive(s);

98/37/EC

Directive on the approximation of the laws of Member States relating to

machinery(OJ L207-23.7.98)

73/23/EEC

Directive on the laws of Member States relating to electrical equipment

designed for use with certain voltage limits(OJ L76 26.3.73);amended by

Directive 93/68/EEC(OJ L220 30.8.93)

89/336/EEC

Council Directive on the approximation of laws of the Member States

relating to electromagnetic compatibility (OJ L139 23.5.89); amended by

Directives, 92/31/EEC(OJ L126 12.5.92)and 93/68/EEC(OJ L220 30.8.93)

HBN-H-301-09/VER. 2.0

Document Revision Guide

Version

Date

Changes

Pages

affected

1.0

2/2002

Initial Release

2.0

1/2009

Modify Content

Document Revision Guide

S1

HBN-H-301-09/VER. 2.0

NOTE TO THE USER

Thank you for purchasing HESHBON'S

CAR LIFT.

Please read this instruction carefully for

safe and proper use of the car lift,

and keep it handy for future reference.

- ANY PART OF THIS PRIN-T MUST NOT BE REPRODUCED IN ANY FORM

WITHOUT PERMISSION.

- THIS PRINT IS SUBJECT TO CHANGE WITHOUT NOTICE.

Copyright (C) HESHBON CO., LTD

This Manual is for model ; HL-25H

1. AS FOR THE ASSURANCE OF SAFETY IN DESIGN

AND CONSTRUCTION OF CAR LIFT, READ THIS

MANUAL FIRST.

2. PLEASE MAKE SURE THAT THIS MANUAL IS

DELIVERED TO END USERS FOR THEIR

IMPLEMENTATION OF SAFETY.

3. DON'T USE THE CAR LIFT IN A POTENTIALLY

EXPLOSIVE ATMOSPHERE.

NOTE TO THE USER

S2

HBN-H-301-09/VER. 2.0

WARRANTY

The warranty period of the Car Lift shall be for a period of one year from

the date of delivery to sales agent.

Subject to the limitations set forth below,

Contractor warrants that the Car Lift will be free from defects in material

and workmanship and undertakes to, at parts, including repaired or replaced parts,

in the which are (1) due solely to defective material and/or poor workman -ship

on the parts of contractor and/or its sub-contractors and (2) for which notice

there of is duly given to contractor in writing or by FAX. Confirmed in writing

within thirty (30) days after discovery of any defects of which claim made

hereunder.

This warranty is subject to the following conditions ;

1) Car Lift shall be properly used and operated by the company's operator

solely in accordance with the specifications and operating instruction

provided by contractor.

2) This warranty shall not be constructed to cover any defects due to ;

- Normal wear and tear;

- Bad operation and maintenance not in accordance with the

operating and maintenance manuals to be provided by contractor;

- Operation under conditions more severe than those in the

specification and drawings;

- Change in design or other modification by company

without contractor's consent;

- Movement or transfer without contractor's consent;

- Consumable items in normal operating;

- Any other carelessness not attributable to contractor.

Contact your sales agent for warranty coverage.

HESHBON CO., LTD.

673-52, Gyeongseo-dong, Seo-gu Incheon 404-170, KOREA

Tel ) INT +82-32-585-3570 FAX ) INT +82-32-585-3485

WARRANTY

S3

HBN-H-301-09/VER. 2.0

- TABLE OF CONTENTS

- COVER SHEET

- Declaration of Conformity

- Document Revision Guide

- NOTE TO THE USER

- WARRANTY

- Table of Contents

CHAPTER 1. SAFEGUARDS

1-1 Important Notices ...............................................................1-1

1-2 Qualified Personnel .............................................................1-2

1-3 Danger Notices ..................................................................1-3

1-4 Principle safety objective......................................................1-4

1-5 Safety notices ....................................................................1-5

1-6 Essential Safety Checks (ESC's).......................................... 1-10

1-7 Safety Signs and Warnings location ..................................... 1-11

1-8 Illumination ...................................................................... 1-13

1-9 Level of sound pressure..................................................... 1-13

1-10 Training ......................................................................... 1-13

CHAPTER 2. OVERVIEW OF MACHINE

2-1 Specification......................................................................2-1

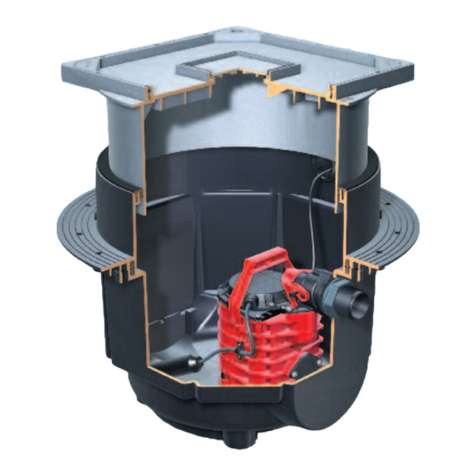

2-2 Description of Construction ..................................................2-2

2-3 Flowchart for operation........................................................2-9

2-4 Safety device ................................................................... 2-10

CHAPTER 3. TRANSPORTATION AND INSTALLATION

3-1 Preparation for installation.................................................... 3-1

3-2 Precaution during installation ................................................3-2

3-3 Transportation....................................................................3-3

3-4 Installation.........................................................................3-4

CHAPTER 4. OPERATION

4-1 Warning for use ..................................................................4-1

4-2 Checking point before operation............................................4-1

4-3 Preparation before operation ................................................4-2

4-4 Description of control panel..................................................4-2

4-5 Operation ..........................................................................4-4

4-5 How to lower manually the lift during emergency ......................4-5

TABLE OF CONTENTS

S4

HBN-H-301-09/VER. 2.0

CHAPTER 5. TROUBLESHOOTING

5-1 Inspection and repair...........................................................5-1

CHAPTER 6. MAINTENANCE

6-1 General caution during maintenance ......................................6-1

6-2 Check List and periodic maintenance .....................................6-1

6-3 Lubricant...........................................................................6-3

APPENDIX

1. ELECTRIC DRAWING

2. RECOMMENDED SPARE PARTS LIST

S5

HBN-H-301-09/VER. 2.0

CHAPTER 1. SAFEGUARDS

Please read carefully this chapter first for safe and proper

use of the car lift. This company will not be held responsibilities

for any injuries or accidents which occur due to the car lift

being operated without having understood the contents of the

instruction manual. Keep the Instruction Manual close to the car lift

so that anyone can refer to when necessary.

Also, designate a person to take care of the manual.

1-1 Important Notices

Car lift must be considered to be a potential hazard to the health

and safety of the car lift's operator and service personnel.

It is important that this car lift is installed, maintained and operated

according to the instructions set out within this manual.

This is a responsibility imposed on the customer by the

EU Council Directive 89/655/EEC, concerning the minimum safety

and health requirements for the use of work equipment by workers at work.

Any modification, alternation or addition to the car lift or the

fitting of ancillary equipment must comply with the EU

Council Directive(s).HESHBON MACHINERY can not accept

any liability whatsoever, which may result in legal action form

failure to comply with the regulations, or any consequential loss,

claim or counter claim for damage, personal injury, or death arising

as a result of any modification, alteration or addition to the

fitting of ancillary equipment.

EU Council machinery Directive 98/37/EC.

The above machinery directive requires all new machinery

to carry the CE mark, declaring conformity with all relevant

EN standards in respect of safety systems and car lift construction.

All HESHBON MACHINERY carry the CE mark and thus

conform with the EU Directives. Any modification to the car lift

may invalidate the original CE certificate, and therefore always

refer to HESHBON MACHINERY as reassessment may be required.

SAFEGUARDS

1-1

HBN-H-301-09/VER. 2.0

This document provides the information required for

the intended use of car lift. The documentation is written for

technically qualified personnel such as engineers or maintenance

specialists who have been specially trained and

who have the specialized knowledge required in the field

of industrial machinery.

A knowledge of the safety instruction and warnings contained

in this document and their appropriate application are

prerequisites for safe installation and commissioning as well

as safety in operation and maintenance of the car lift described.

Only qualified personnel have the specialized knowledge

that is necessary to correctly interpret the general guidelines

relating to the safety instructions and warnings and implement

them in each particular case.

For the sake of clarity, not all details of all versions of

the product are described in this documents, nor can it cover

all conceivable cases regarding installation, operation and

maintenance. Should you require further information or face special

problems that have not been dealt with insufficient detail in this

document, please contact the manufacturer specified on cover page.

We would also point out that the contents of this product

documentation shall not become a part of or modify

any prior or existing agreement, commitment or legal relationship.

The purchase agreement contains the complete and

exclusive obligations of HESHBON Co., Ltd.

Any statements contained in this document do not create

new warranties or restrict the existing warranty.

1-2 Qualified Personnel

Persons who are not qualified should not be allowed to

handle the car lift. Non-compliance with the warnings contained

in this document or appearing on the car lift can result in

severe personal injury or damage to property.

Only qualified personnel should be allowed to work on this car lift.

SAFEGUARDS

1-2

HBN-H-301-09/VER. 2.0

Qualified persons as referred to in the safety precautions

in this document as well as on the car lift itself are defined as follows;

●Operating personnel who have been trained work

with the car lift and are conversant with the contents of

the documents in as far as it is connected with the actual

operation of the car lift;

●Service personnel who are trained to repair such the

car lift and who are authorized to energize, clear, ground

and tag circuits, equipment and systems in accordance with

established safety practices.

1-3 Danger Notices

The safety precautions in this manual are classified

into the following four levels. Please be particularly careful

when performing operations that have a high degree of danger.

DANGER : Failure to follow this safety precaution may result in

a great physical danger to the operator, or even death.

CAUTION : Failure to follow this safety precaution may result in a

great physical danger to the operator, or severe damage

to the car lift.

WARNING : Failure to follow this safety precaution may result in

an injury to the operator, or damage to the car lift.

NOTICE : Failure to follow this safety precaution may result in

a damage to the car lift.

SAFEGUARDS

1-3

HBN-H-301-09/VER. 2.0

1-4 Principle safety objective

1) The principle safety objective is to remove the possibility

of any hazard or risk to the health or safety of the car lift's

operator or service personnel.

2) Extreme caution must be exercised while servicing or

installing the car lift.

3) The only safe policy when working or inspecting the car lift

is to follow the instructions in this manual. Wherever possible

shut off all electrical power and follow the procedures outlined

in this manual.

4) Accident prevention should become part of the standard working,

operating and maintenance procedures, and training should be

provided to ensure safety standards are understood.

Part of safety training should

include the instructions detailed in this section.

5) If ancillary equipment is to be fitted ensure this is done in

accordance with the relevant standards or EU Directives,

and that all requirements for safety are fully met.

6) Always ensure servicing and maintenance tasks are carried

out by suitable qualified personnel. The operator should

understand the limits of their responsibility, and the

training should reinforce the importance of not exceeding them.

7) The essential routine safety checks have an important

function in ensuring the car lift continues to work in

a safe manner. These checks must be carried out according

to the instruction and at the recommended intervals.

8) If there are any questions or doubts regarding any

aspect of car lift safety or operation or maintenance,

please contact the company shown on the front of this manual.

SAFEGUARDS

1-4

HBN-H-301-09/VER. 2.0

1-5 Safety notices

To protect the operator or service personnel from any injuries or

accidents during operating the car lift, please read this section and

carefully for safe and proper use of the car lift.

◈General Safeguards

1.Please read carefully this instruction manual for safe and proper

use of the car lift.

2.Only qualified personnel should be allowed to work on this car lift.

3.Checking before operation and routine inspection should be carried

out in accordance with the procedures described in the manual.

4.When the abnormal condition not specified at this instruction manual is

occurred during operating, stop the operation of car lift and contact

the manufacturer specified on cover page or distributor.

5.This car lift should be only for repairing the car.

◈Danger Notices

DANGER

Do not enter under the car lift during lifting the car.

You may result in a great physical danger or

even death.

Do escape to the safety zone without staying

under car lift when the car is possible to fall down.

You may crush under car and then, result in a

great physical danger or even death .

SAFEGUARDS

1-5

HBN-H-301-09/VER. 2.0

◈Caution Notice

CAUTION

Only qualified personnel should be allowed to

work on this car lift.

Unexpected accidents may be happened

due to wrong operation.

Do not lower the lift in the state of supporting

a car by a stick to attach or detach components.

The car may fall down.

Do not shake the lifted-up car.

The car may fall down.

Do not move up the lift in the condition of

putting only one side of car into the lift.

A car may fall down or damage. And also,

the lift may damage.

Never modify a safety devices.

If a safety devices are not operated, a

serious accident may be happened.

During lowering the lift, be careful to not

put foot under a table.

Serious injury may be happened.

SA

F

E

G

U

A

R

D

S

1-6

HBN-H-301-09/VER. 2.0

◈Warning Notice

CAUTION

Use the lift after reading carefully the instruction

manual and understand the contents of them for

safe and proper use of the car lift.

If a user does not follow a warnings, a serious accident

may be happened.

When the car enter into the lift, keep the balance of

before and behind, and right and left of the car.

A car may fall down during vibration, attachment or

detachment of components.

Electric shock.

When opening a control panel, be careful to the electric

shock.

Serious injury or death may be happened.

WARNING

Use the lift after reading carefully the instruction manual and understand the

contents of them for safe and proper use of the car lift.

< During preparation>

1. This Lift is only for repairing the car. Do not use for other purpose.

2. Do not use the lift whenever any one of safety devices is not normally

operated.

3. When the car is entered into the lift or gone out from the lift, please drive a

car smoothly without the sudden stop or drive.

4. Be careful to not slide when a tire or arm is wet.

SAFEGUARDS

1-7

HBN-H-301-09/VER. 2.0

WARNING

< During lifting and lowering the lift >

5. During moving up or down the lift, you should always watch the car without

looking at something else.

6. If several lift are installed, the respective allocation of the switch shall be

clear.

7. Do not move up a car exceeding the rated capacity of the lift.

8. Do not lift a car with persons or other load.

9. Check if oil or foreign material is in the arm.

10.Move up the lift after checking if the car is properly positioned.

11.Stop the operation of lift when the lift is reached to the limited height.

12.When the lift moves up or down, wait for 1 ∼2 seconds before the next

operation is carried out.

13.Be careful to not shake the car during lifting and lowering the lift. If the car

settling to one side, stop immediately the operation of lift.

14.If the lift is not lowered in spite of pressing a down switch, move up the lift

and then press the down switch again.

15.After the lift is completely moved down, the car should be entered into the lift

or gone out from the lift.

16.When the lift is moved up and down, prohibit the unauthorized persons from

accessing to the lift.

17.Do not operate the lift with which a tool or component puts into the driving

parts of the lift. The lift may be broken, or a car may fall down.

18.During lowering the lift, check if the person or an object is around the lift or

car.

SAFEGUARDS

1-8

HBN-H-301-09/VER. 2.0

WARNING

< During repairing the car >

19.Check if the safety lock device is properly operated before operation.

20.Prohibit the unauthorized persons from accessing to the lift.

21.When the operator is not in the lift for a long time, or the lift is not operating,

lower completely the lift.

< Other >

22.Do not change or modify the lift without permission. If the lift is modified or

changed, the lift may not fulfill its function, or serious accident may be

happened.

23.When you find the fault of lift during using or checking the lift, stop the

operation of lift, and request the maintenance to the sales agency. Do not

use the lift until the lift is repaired.

24. Please note that this lift is not designed for water-proof. Do not use the lift

in the hot place, car-washing use or outdoor use.

Use the lift after reading carefully the instruction manual and understand

the contents of them for safe and proper use of the car lift.

SAFEGUARDS

1-9

HBN-H-301-09/VER. 2.0

1-6 Essential Safety Checks (ESC's)

The essential safety checks are the most important part of the operators

responsibility. The purpose of the ESC's is to ensure the safety features

of the car lift are functioning properly, and thus the car lift is in a safe condition for use.

In addition to the operator it is recommended that regular additional ESC's are

carried out by the responsible person and that a record is maintained in

accordance with the EU machinery Regulations.

If any of the ESC's are in the "Fail" condition do not operate the car lift,

immediately notify the responsible person within the company and contact

the manufacturer as soon as possible.

ESSENTIAL SAFETY CHECKS (ESC'S)

GROUP 1 GENERAL - Visual Inspection

ESC

Description

O.K.

Fail

1A

Machine guarding

1B

Electrical system including protective earth

grounding

GROUP 2 Electrical isolator switch

Set the electrical isolator switch to OFF position and check the following conditions.

ESC

Description

O.K.

Fail

2A

All functions have been disabled

SAFEGUARDS

1-10

HBN-H-301-09/VER. 2.0

1-7 Safety Signs and Warnings location

SAFEGUARDS

1-11

HBN-H-301-09/VER. 2.0

N

0

Warning Label

1

2

3

4

5

6

7

SAFEGUARDS

1-12

HBN-H-301-09/VER. 2.0

1-8 Illumination

This machine is not provided with a local lighting since it is designed for

indoor use only. The sufficient illumination of the working area must be

fulfilled by the factory in accordance with the appropriate code of

practice and factory regulations. Minimum 300 lx is required. Flicker,

dazzling, shadows and stroboscopic effects must be avoided to prevent a risk.

1-9 Level of sound pressure

The equivalent continuous A-weighted sound pressure levels of car lift

do not exceed 85dB (A).

1-10 Training

Contact the manufacturer specified on cover page for information on training

courses to aid you in becoming familiar with this car lift.

The factory must provide operator(s) with the appropriate measures

including but not limited to an ear protection and a warning sign(s)

if the sound pressure of 85dB (A) is exceeded.

WARNING

!

SAFEGUARDS

1-13

Table of contents

Other HESHBON Lifting System manuals