man_SF_Online_EN_ 072323 www.hessaire.com

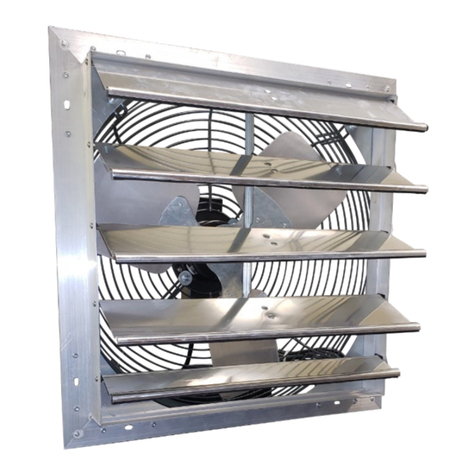

Performance/Specifications (Models Without Thermostat)

Wall Mount Junction Box

Extendable Temperature

Probe Up to 48”

Performance/Specifications (Models Including Thermostat)

Thermostat

Model: TH120C

Rough-In Dims.

Wiring

Diagram

Black (line)

White (common)

Green (ground)

Motor

Thermostat

Control

Incoming

Power

Black

P1

120 VAC

Variable Speed Capable Models DO NOT include control. Variable speed control sold separately.

A

2 1

Model:

High

CFM

Area

Cov.

Sq Ft

Prop

Dia. HP Ph Volts High

Amps Spd

Rough-In

Opening

Dim. A

Dim.

B

In.

Dim.

C

In.

Dim.

D

In.

Dim.

E

In.

8SF 300 150 8” 1/25 1 115 .6 Var. Cap. 8.5 5.7 6.0 8.0 11.0

10SF 650 200 10” 1/25 1 115 .6 Var. Cap. 10.5 5.7 6.0 10.0 13.0

12SF 900 250 12” 1/15 1 115 1.0 Var. Cap. 12.5 5.7 6.0 12.0 15.0

12SF4T50C 1100 300 12” 1/12 1 115 1.0 3 12.5 5.7 6.0 12.0 15.0

14SF 1350 325 14” 1/10 1 115 1.1 Var. Cap. 14.5 5.7 7.0 14.0 17.0

16SF 1400 350 16” 1/10 1 115 1.1 Var. Cap. 16.5 5.7 7.0 16.0 19.0

16SF4T60C 1325 325 16” 1/12 1 115 1.1 3 16.5 5.7 6.0 16.0 19.0

18SF 1785 400 18” 1/10 1 115 1.1 Var. Cap. 18.5 5.7 7.0 18.0 21.0

18SF180 3130 800 18” 1/4 1 115 2.8 Var. Cap. 18.5 5.7 11.0 18.0 21.0

20SF 3340 900 20” 1/4 1 115 2.8 Var. Cap. 20.5 5.7 11.0 20.0 23.0

20SF4T90C 2860 775 20” 1/8 1 115 1.3 3 20.5 5.7 7.0 20.0 23.0

24SF 4160 1100 24” 1/3 1 115 3.0 Var. Cap. 24.5 5.7 12.0 24.0 27.0

24SF240 4450 1300 24” 1/3 1 115 3.2 Var. Cap. 24.5 5.7 12.0 24.0 27.0

24SF6D240C 4450 1300 24” 1/3 1 115 3.2 2 24.5 5.7 12.0 24.0 27.0

30SF8N240 5895 1750 30” 1/3 1 115 3.8 1 30.5 5.7 12.0 30.0 33.0

36SF8N370 8860 2200 36” 1/2 1 115 5.6 1 36.5 5.7 13.0 36.0 39.0

Model:

Thermostat

Included

High

CFM

Area

Cov.

Sq Ft

Prop

Dia. HP Ph Volts High

Amps

Thermostat Rough-In

Opening

Dim. A

Dim.

B

In.

Dim.

C

In.

Dim.

D

In.

Dim.

E

In.

Electrical

Rating

Probe

Length

In.

8SF-TH 300 150 8” 1/25 1 115 .6 16A 400V 48 8.5 5.7 6.0 8.0 11.0

10SF-TH 650 200 10” 1/25 1 115 .6 16A 400V 48 10.5 5.7 6.0 10.0 13.0

12SF-TH 900 250 12” 1/15 1 115 1.0 16A 400V 48 12.5 5.7 6.0 12.0 15.0

14SF-TH 1350 325 14” 1/10 1 115 1.0 16A 400V 48 14.5 5.7 7.0 14.0 17.0

16SF-TH 1400 350 16” 1/10 1 115 1.0 16A 400V 48 16.5 5.7 7.0 16.0 19.0

18SF-TH 1785 400 18” 1/10 1 115 1.0 16A 400V 48 18.5 5.7 7.0 18.0 21.0

20SF-TH 3340 900 20” 1/4 1 115 2.8 16A 400V 48 20.5 5.7 11.0 20.0 23.0

24SF-TH 4160 1100 24” 1/3 1 115 3.2 16A 400V 48 24.5 5.7 12.0 24.0 27.0

A

D

D

C

E

E

B

Exterior

Rough-In

Opening

Interior

Troubleshooting Guide

Propeller

Motor

Guard

Model: Prop Guard Motor Shutter

8SF 9001655 G7SF E030-4 S7SF

10SF 9001656 G10SF E030-4 S10SF

12SF 9001657 G12SF E035-4 S12SF

12SF4T50C 9001694 G12SF E060-43C S12SF

14SF 9001695 G14SF E075-4 S14SF

16SF 9001658 G16SF E075-4 S16SF

16SF4T60C 9001696 G16SF E060-43C S16SF

18SF 9001959 G18SF E075-6 S18SF

18SF180 9001660 G12SF B180-4 S18SF

20SF 9001652 G20SF B180-4 S20SF

20SF4T90C 9001494 G20SF E090-43C S20SF

24SF 9001665 G24SF B180-6 S24SF

24SF240 9001664 G24SF B240-6 S24SF

24SF6D240 9001664 G24SF B240-6/2 S24SF

30SF8N240 9001666 G30SF B250-8F S30SF

36SF8N370 9001667 G36SF B370-8F S36SF

Model: Prop Guard Motor ThermostatShutter

8SF-TH 9001655 G7SF E030-4 TH120CS7SF

10SF-TH 9001656 G10SF E030-4 TH120CS10SF

12SF-TH 9001657 G12SF E035-4 TH120CS12SF

14SF-TH 9001695 G14SF E075-4 TH120CS14SF

16SF-TH 9001658 G16SF E075-4 TH120CS16SF

18SF-TH 9001959 G18SF E075-6 TH120CS18SF

20SF-TH 9001652 G20SF B180-4 TH120CS20SF

24SF-TH 9001665 G24SF B180-6 TH120CS24SF

Periodic maintenance and component cleaning schedules should be set to assure

reliability and performance of the fan.

Periodically inspect and tighten all set screws and hardware—check torque on prop.

Assure all mounting hardware remains properly secured.

Motors feature permanently sealed ball bearings and require no further lubrication.

Note: Please contact the dealer/distributor where you purchased the fan from

with any questions regarding the fan, the manual or replacement parts.

Maintenance

Replacement Parts Breakdown

Thermostat

Symptom Possible Cause(s) Corrective Action

Fan will not start

1. Tripped circuit breaker 1. Reset circuit breaker

2. Defective motor 2. Repair or replace

3. Incorrectly wired 3. Shut off power, check for proper connections

4. Electricity turned off 4. Contact local power company

Excessive noise or

vibration

1. Propeller is bent or hitting housing 1. Free propeller of obstruction/replace propeller

2. Fan / shutter not securely anchored 2. Secure properly

3. Bad/noisy bearings 3. Replace motor

Insufficient airflow

1. Incorrect voltage applied 1. Wire properly

2. Defective motor 2. Replace motor

3. Propeller is damaged 3. Replace propeller

4. Blocked Airflow 4. Remove obstructions

5. Not enough intake air 5. Add additional air intake openings

6. Fan is dirty 6. Clean fan guards/screens, motor and propeller

Motor overheats or trips

out

1. Over/under line voltage 1. Contact local power company

2. Defective motor 2. Replace motor

3. Fan is dirty 3. Clean fan guards/screens, motor and propeller

4. Not enough intake air 4. Add additional air intake openings

Shutter