MH-0003 Rev. 082719 www.hessaire.com

Dimension Key

Symptom Possible Cause(s) Corrective Action

Fan will not start 1. Tripped circuit breaker 1. Reset circuit breaker

2. Defective motor 2. Repair or replace

3. Incorrectly wired 3. Shut off power, check for proper connections

4. Electricity turned off 4. Contact local power company

Excessive noise or vibration 1. Blade is hitting housing 1. Free blade of obstruction

2. Blade is bent 2. Replace blade

3. Fan not securely anchored 3. Secure properly

4. Bad/noisy bearings 4. Replace motor

Insufficient airflow 1. Incorrect voltage applied 1. Wire properly

2. Defective motor 2. Replace motor

3. Propeller is damaged 3. Replace propeller

4. Blocked Airflow 4. Remove obstructions

5. Not enough intake air 5. Add additional air intake openings

6. Fan is dirty 6. Clean fan guards/screens, motor and propeller

Motor overheats or trips out 1. Over/under line voltage 1. Contact local power company

2. Defective motor 2. Replace motor

3. Fan is dirty. 3. Clean fan guards/screens, motor and propeller

4. Not enough intake air 4. Add additional air intake openings

Troubleshooting Guide

Performance

High CFM CFM/Watt

Model HP F.L.A. Volt. Ph Hz Fan

RPM

0.00"

SP

0.05"

SP

0.10"

SP

0.15"

SP

0.00"

SP

0.05"

SP

0.10"

SP

0.15"

SP

Db @

7ft

Spd Bess Labs

Test #

36SW550 3/4 1 6.4/3.2 115/230 1 60 709 11,420 10,790 10,170 9480 19.5 17.6 15.9 14.2 73 16135

425SW550 3/4 1 6.4/3.2 115/230 1 60 465 13,207 11,993 10,747 9,698 21.2 18.1 15.3 13.4 70 -

425SW750 1 1 9.4/4.7 115/230 1 60 580 16,780 15,913 14,956 14,016 17.5 15.8 14.2 12.7 74 -

425SW750-2 1 2 7.0/3.5 230 1 60 565 16,277 15,436 14,507 13,596 17 15.3 13.8 12.3 73 -

48SW750-N 1 9.4/4.7 115/230 1 60 625 21,100 20,100 18,900 17,700 20.4 18.9 17.3 15.8 77.21 16140

48SW750-2N 1 7.0/3.5 230 1 60 595 20,780 19,700 18,750 17,400 20.1 18.7 17.1 15.6 77.12 -

485SW750 1 1 9.4/4.7 115/230 1 60 455 20,045 18,995 17,766 16,550 19.4 17.8 16.1 14.6 71 -

485SW750-2 1 2 7.0/3.5 230 1 60 440 19,444 18,425 18,605 16,054 18.8 17.3 15.6 14.2 70 -

54SW750 1 1 9.4/4.7 115/230 1 60 575 25,935 24,605 22,990 19,190 22.4 20.3 18.5 16.2 76.4 -

Maintenance

Periodic maintenance schedules should be set to assure reliability and performance of the fan.

Check for excessive vibration while fan is running.

Periodically inspect and tighten all set screws and hardware—check torque on propeller, bearings and pulleys.

Assure all mounting hardware, chains, etc. are properly secured.

Motors feature permanently sealed ball bearings and require no further lubrication.

The fan propeller should be periodically cleaned to assure proper balance and performance.

Grease pillow block bearings seasonally. Use caution not to apply too much grease as it may damage the seals.

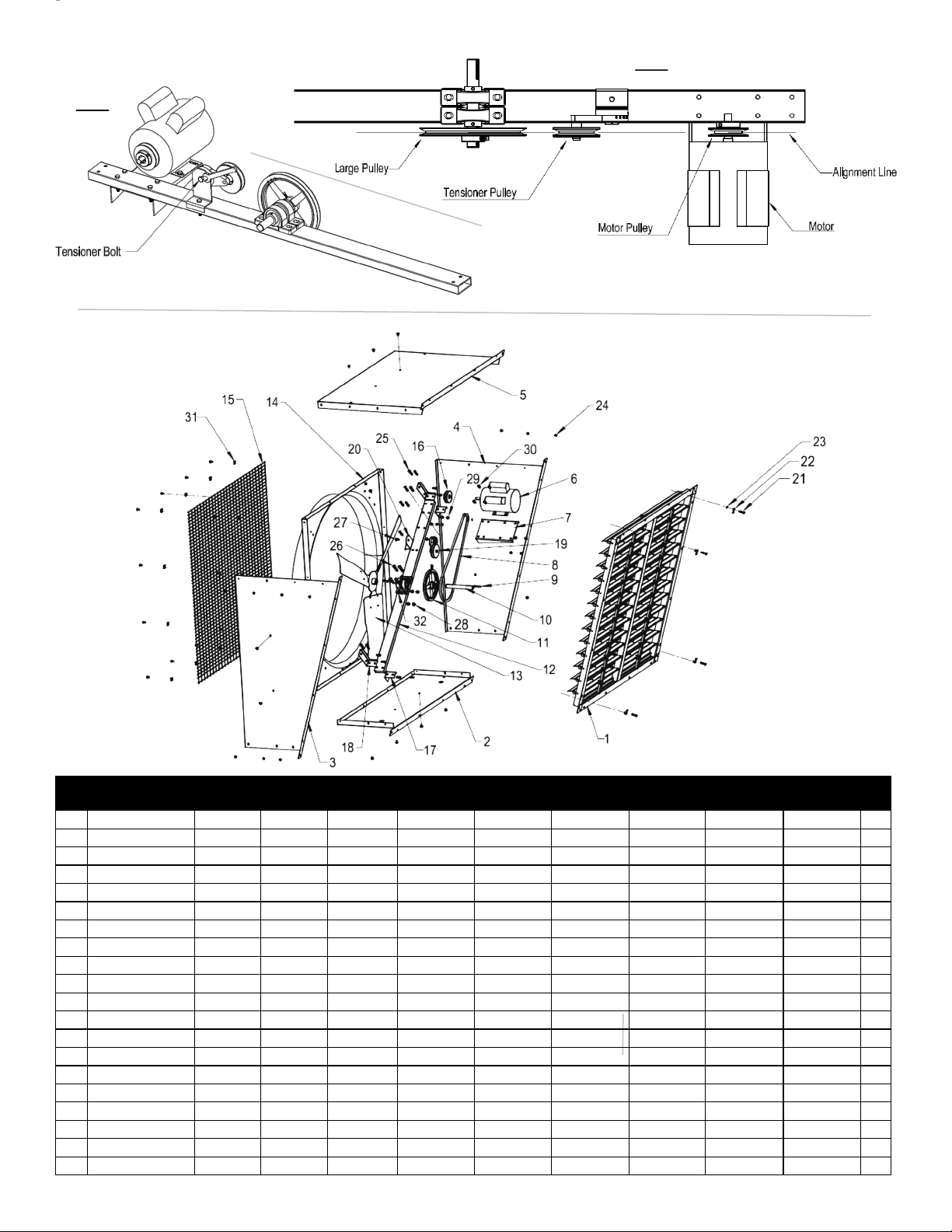

Periodically check for proper pulley/belt alignment. See Fig. 1

If necessary, belt tensioner can be adjusted by loosening bolt on back of bracket and moving tensioner pulley arm. See Fig. 2

Note: Please contact the dealer/distributor where you purchased the fan from with any questions regarding the fan, manual

or if you are in need of replacement parts.

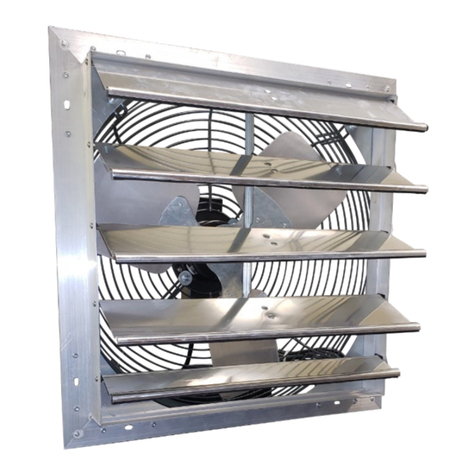

Caution: Before operating your new fan, check blade for proper torque, check all fasteners for tightness and assure

screens and/or shutters are securely in place.