-1-

-2-

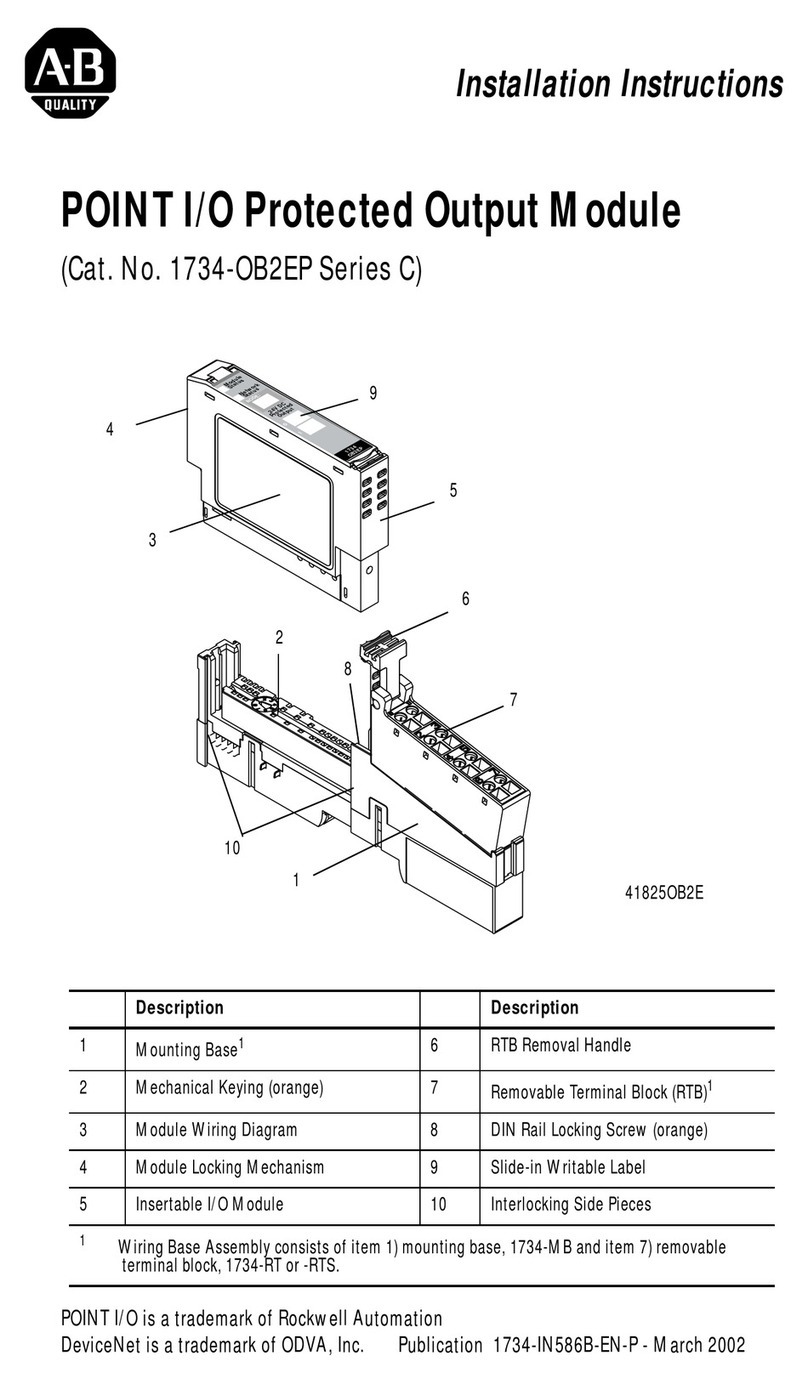

3. Character

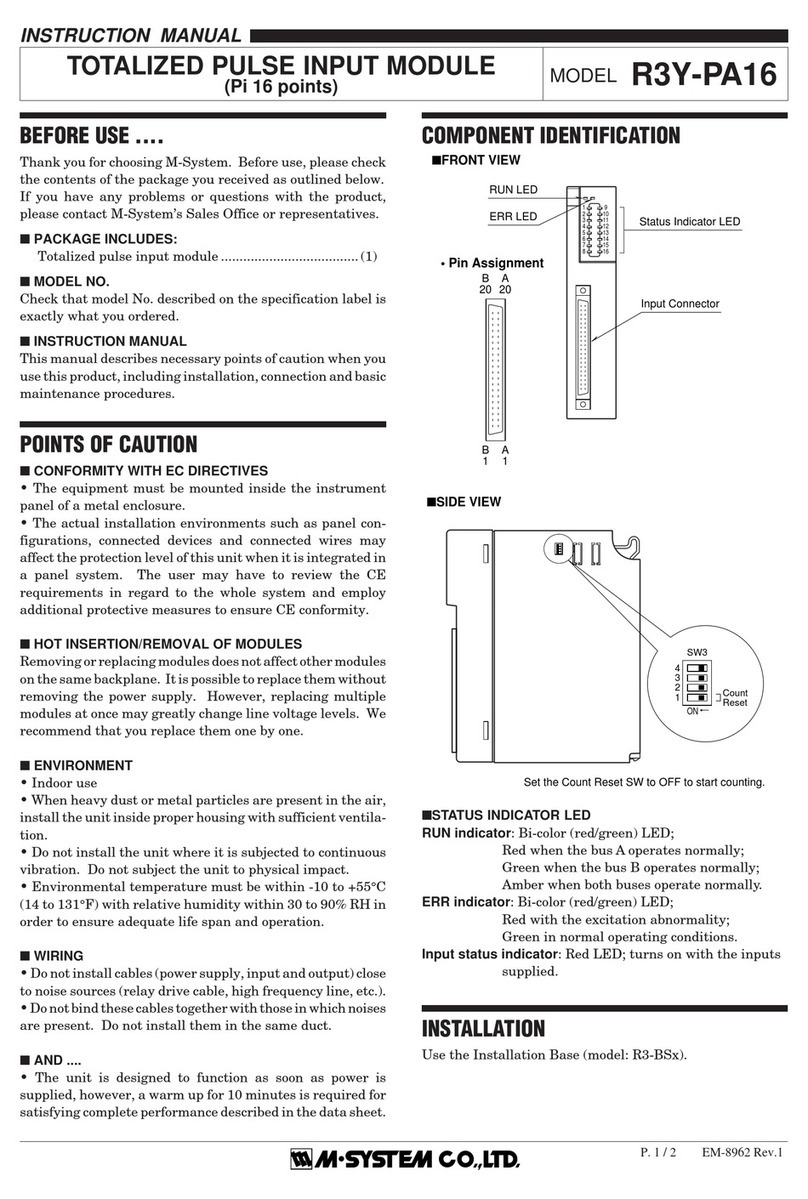

4. Model Contrast and Main Dimension

Electrical valve

CKF 3325

Intellectual Property Rights Explanation:

Warning:

The symbol means the unit is being installed,

it may cause electrical shock hazard during

maintaining, so please make sure it is operated

by the professional technical worker.

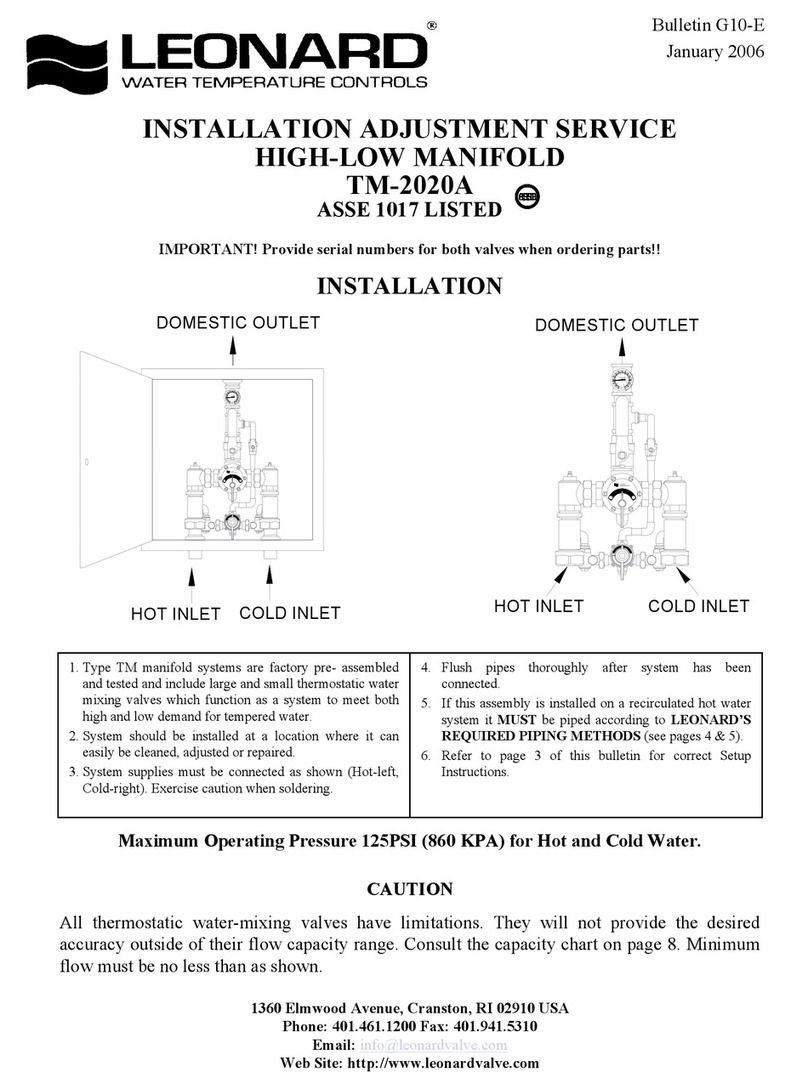

1. Summarize

CKF series of Electrical Valve is good at on the on-off conversion

controlling of Heating Air Condition Water System, be consist of a

driver and a valve body .The driver adopts the synchronous motor

drive, spacing-contactor inside, can make the valve complete

Power-on or complete power-off. Valve body is plated with rustproof

brass, and its surface also be spray the sand and phosphated.

Provided with the manual switch, be very convenient to alive

adjustment or press adjustment, it will recover automatically when

the power is on.

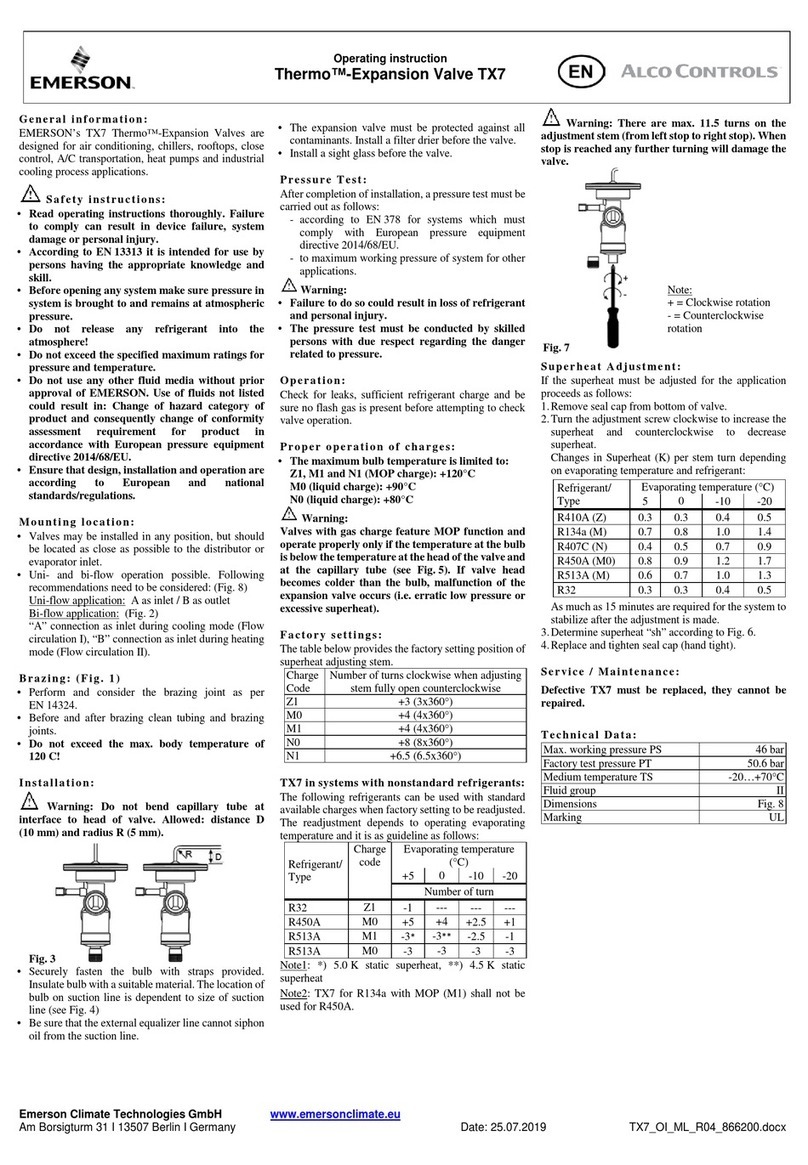

2 Technique Requirements.

Driver Voltage: AC230V+/-10%,50/60Hz (Special made 110V or 24V)

Power Consume:4VA(only when the valve is open)

Running Time: Power on -18 sec. Powe off-15sec.

Length of Down-lead:100cm

Normal Pressure:1.6MPa

Closed Pressure differential: 2-way 0.3MPa; 3-way 0.15MPa

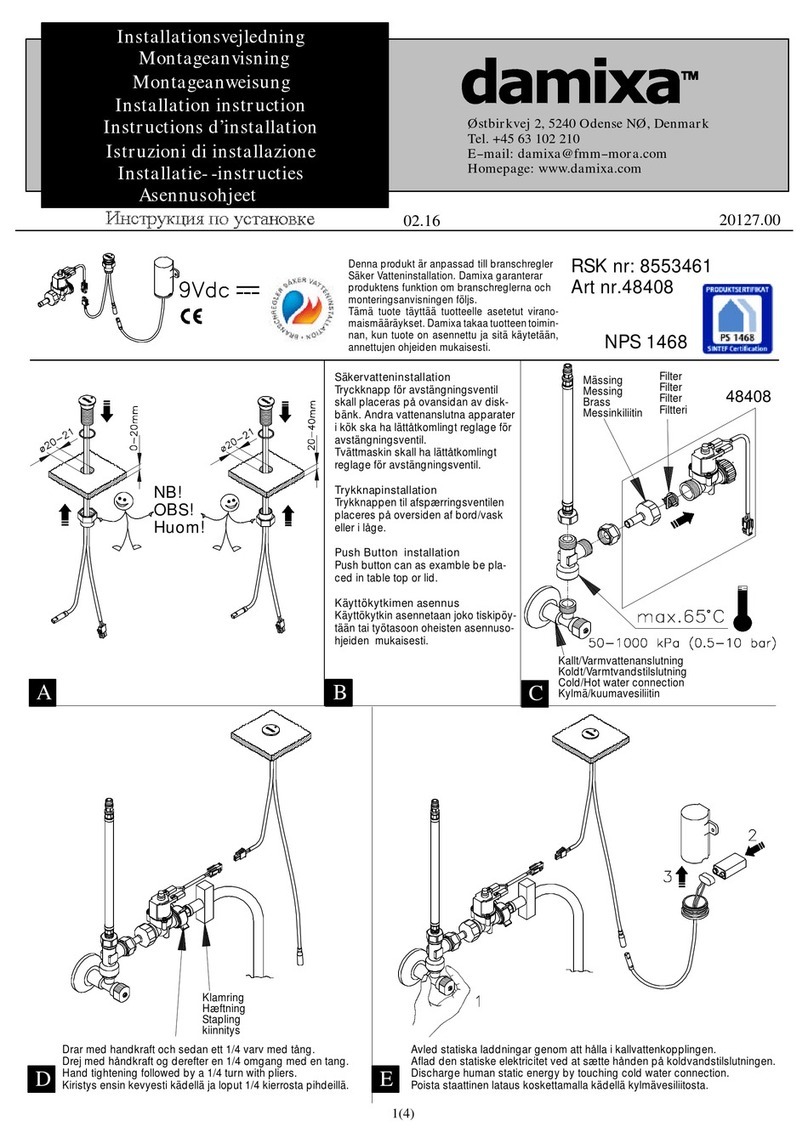

Connected mode: tube screw thread G

(Can not be connected with taper screw thread)

Medium of application: cold and frozen water, hot water and t

50% etylene glycol.

Temperature of Medium:2-75 ℃

he dilution

of water

1.

.

.

.

.

Rustproof brass valve body with high intensity, the pressure is big during its

installing.

2 Low Power Consume, it only takes 4w power when the valve is open or closed.

3 Provided with spacing-contactor inside in order to make sure the long using life

of motor.

4 Open the valve for 50 by manual, after debugging press-testing, it will auto-

replace when it is gave the power.

5 The driver can be unloaded and connected expeditiously, simple to manipulate.

6 Valve is made uniquely, make sure it is closed intensively

%

L

20.05.2011

Installation Manual