INSTRUCTIONS INST. OPERATION AND

MAINTENANCE

BV2506X DN15 a DN300

Code

MAN-2506X-EN

Edition

0

Date and responsible

14/01/19

Page

3 de 15

3

1. General

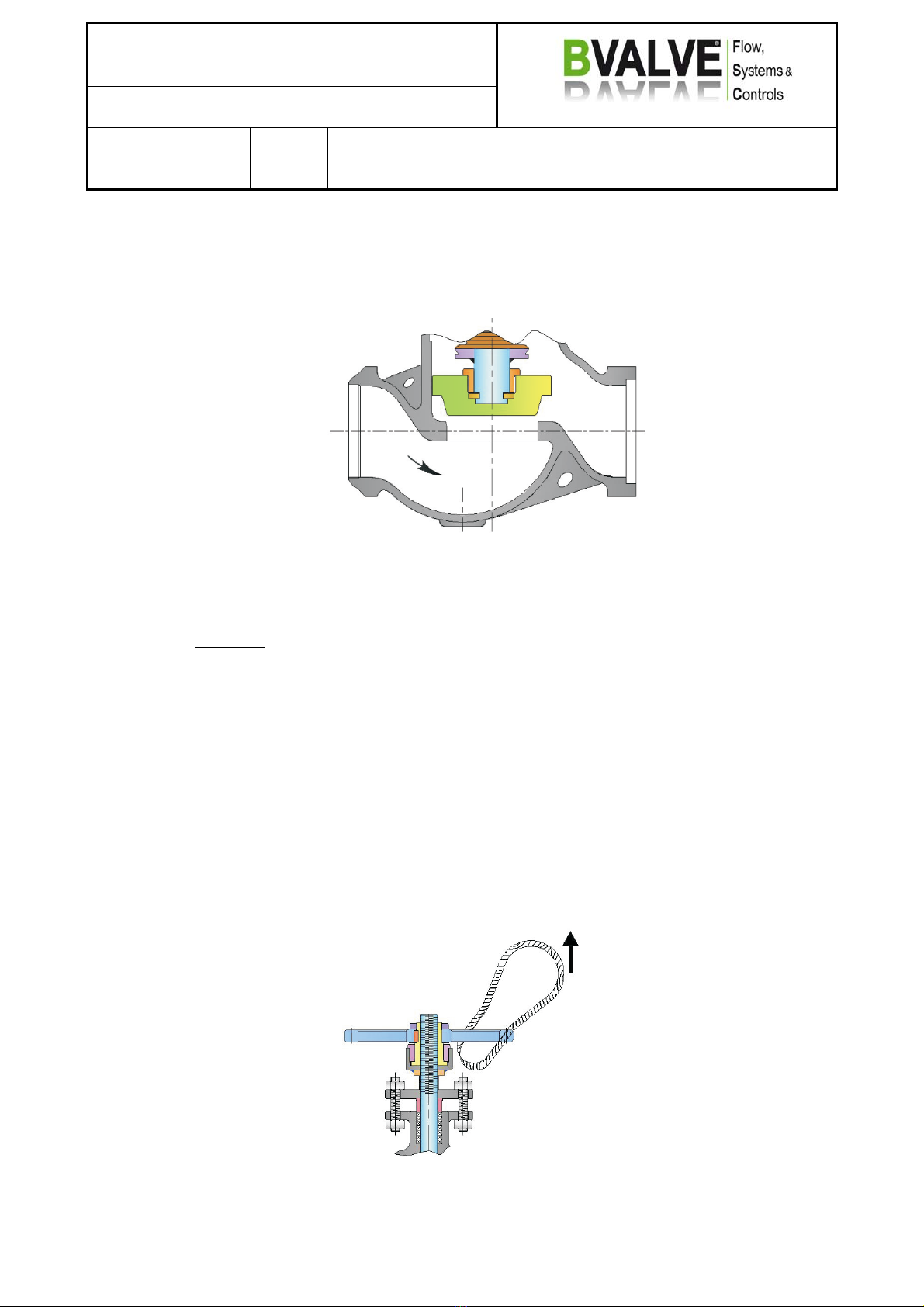

ThisdocumentappliestotheglobebellowsealedvalvesdeliveredbyBVALVEFSC,S.L.U.

2. Intendeduse

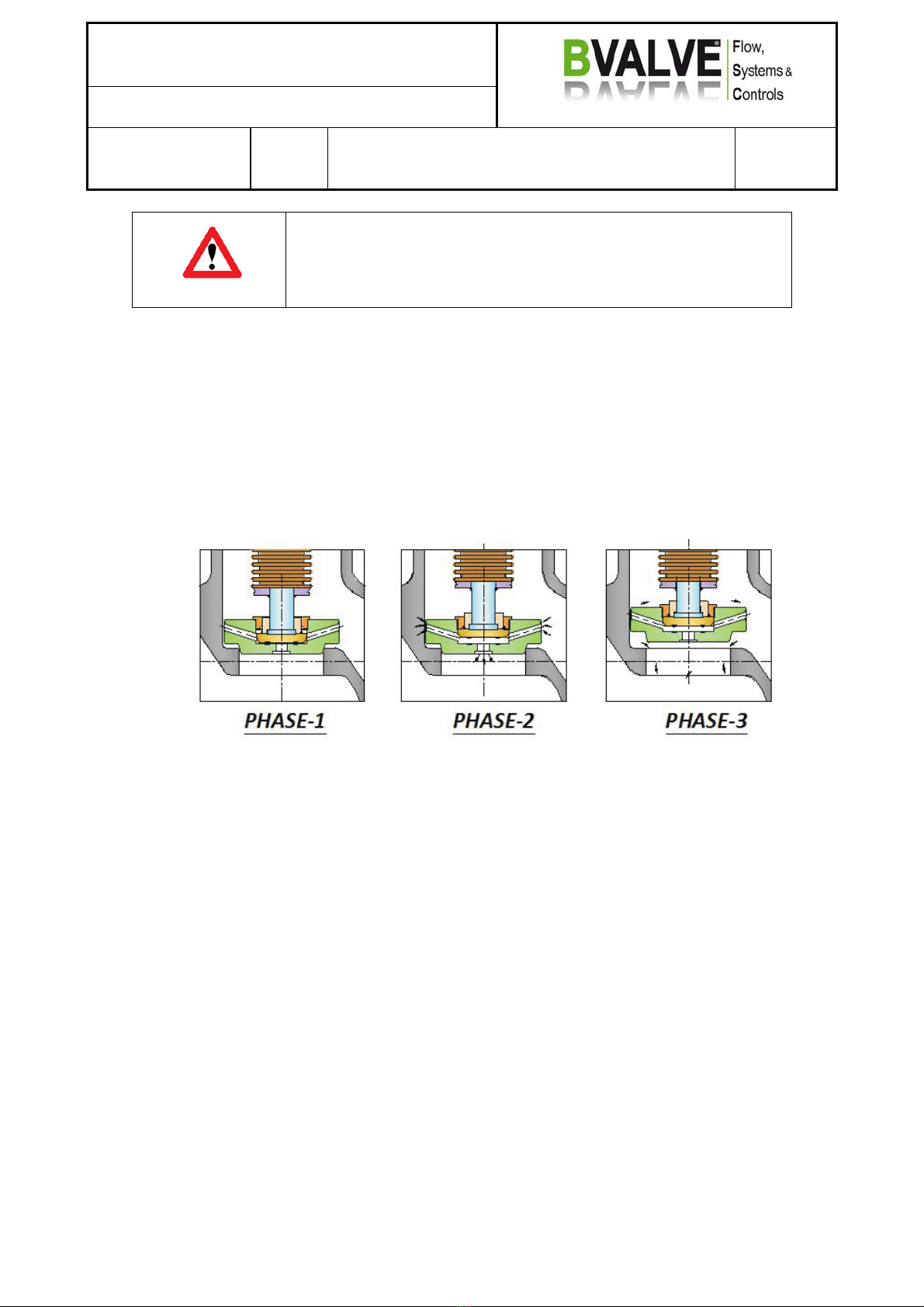

Aftertheirinstallationinapiping system(eitherbetween flanges orbywelding) theuse of theglobe

valvesisexclusivelydefinedastostoporcontroltheflowofmediaforon‐off/regulatingapplicationwithin

thepermissiblepressureandtemperaturelimitsbymanual/actuatedoperation.

Valvesaredesignedandmanufacturedasperthespecificationandinputsgivenbythecustomerduring

enquiryorpurchaseorder.Usageofthevalveforapplicationotherthanspecifiedmanufacturersisnot

responsible.

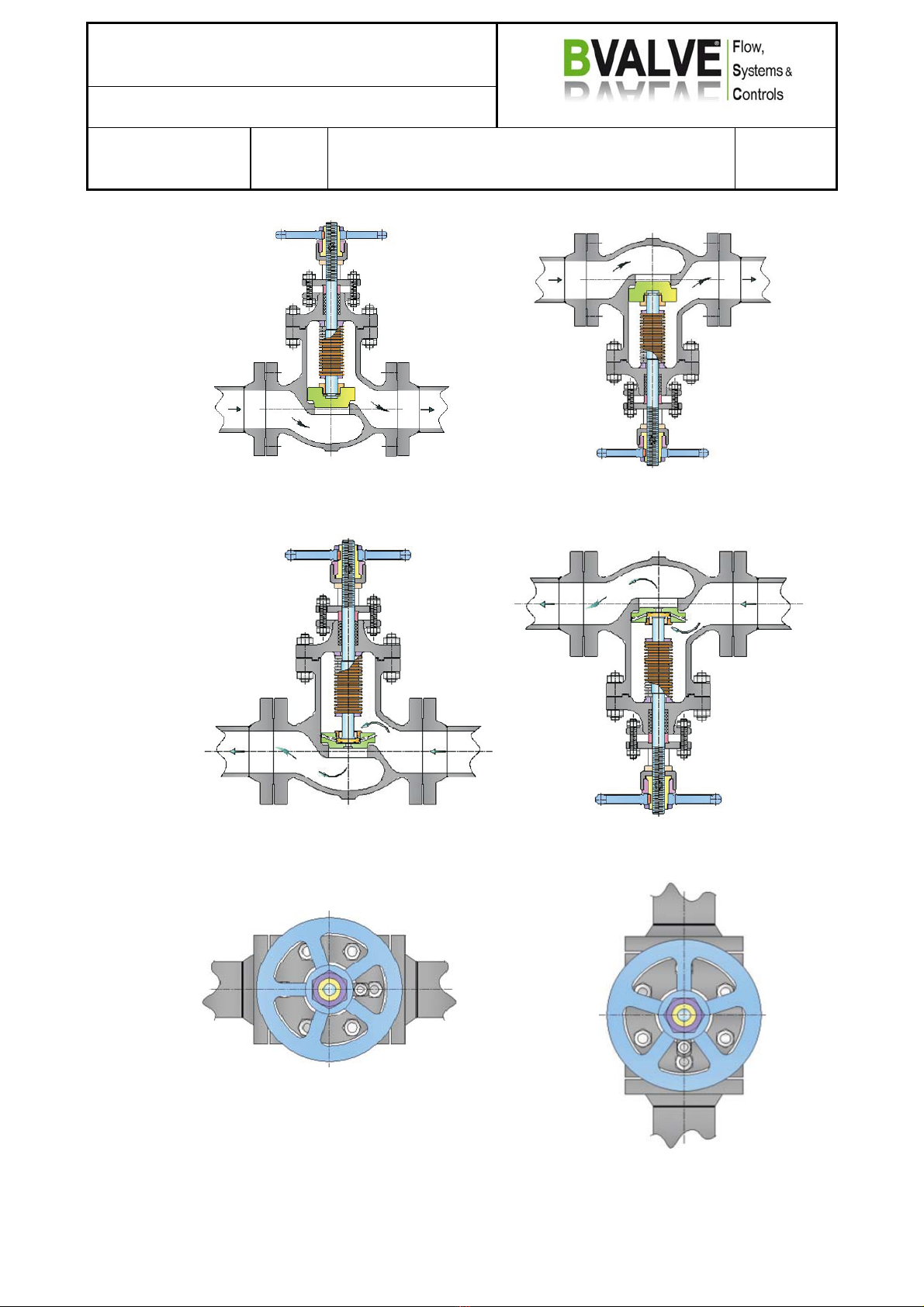

3. Limitconditionsforoperation

The valves, according essential safety requirements stablished inthePressureEquipmentDirectiveis

appropiate to work with all media classified as Group I (liquidsorgases),asperselecteddesignand

constructionmaterials.

During selection phase of the valve, customer is always informed about selected materials for valve

construction. In this way, customer can verify suitability of such materials and add any comment or

informationthereon.

Theselectionandoperationofthevalveswillneverexceedthefollowingpressure/temperaturelimits.

WORKING CONDITIONS

Model DN PN

Temperature, ºC

-60/-10 -10/100 100/120 150 200 250 300 350 400

Maximum admissible pressure, bar

BV25061 DN15-300 16 - 16,0 16,0 14,4 12,8 11,2 9,6 - -

BV25063 DN15-200 25 - 25,0 25,0 24,3 23,0 21,8 20,0 17,5 -

BV25064 DN15-300 16 - 16,0 16,0 15,5 14,7 13,9 12,8 11,2 -

BV25065 DN15-300 40 - 40,0 - 35,2 33,3 30,4 27,6 25,7 23,8

BV25065 DN65-300 16 - 16,0 - 14,0 13,3 12,1 11,0 10,2 9,5

BV25066 DN15-300 40 40,0 40,0 - 36,3 33,7 31,8 29,7 28,5 27,4

Table1:workingconditionsforBvalvevalvesmodelBV2506X