HFT Pipestoppers Accu-Freeze 3000 User manual

USER INSTRUCTIONS

HFT PIPESTOPPERS

®

PIPESTOPPERS TM

ACCU - FREEZE (Patented)

Accu-Freeze Operating Instructions

© HFT®

HFT Pipestoppers®

ACCU-FREEZE™

(patented)

PAGE 2

HFT PIPESTOPPERS

®

INDEX

Copyright © HFT®. All rights reserved.

This publication may not be reproduced by any means without the written

permission of Huntingdon Fusion Techniques HFT®.

All logos, names, trademarks are the property and ownership of HFT®.

E&OE

Index 2

Operating Instructions 3

Safety Precaution when working with liquid nitrogen 3

General Information 3

System requirements to apply freeze seal 4

Freeze seal setups 4

Therma couple installation 5

AF 3000 Temperature Controller setup 6-8

Initiate Freeze Seal 8

Perform desired maintenance 9

Terminate Freeze Seal 9

Additional Information 9-14

HFT Pipestoppers®Product Range 15-16

Other languages in progress 17

Customer support and worldwide care 18

Warranty 19

Address and Contact Details 20

PAGE 3

HFT PIPESTOPPERS

®

OPERATING INSTRUCTIONS

1. Safety precautions when working with liquid nitrogen (LN2)

1.1 LN2 can cause asphyxiation. Work in a well ventilated area.

1.2 Avoid freeze burns. Wear protective gloves, and a face shield when

tightening or opening LN2 connections.

1.3 To maintain the freeze plug during maintenance, duration of the work

must be considered before commencing. Consideration of additional LN2

tanks and methods to be used to change tanks during the freeze are

required to be pre-planned.

2. General information

2.1 Low pressure LN2 tanks are recommended for use. These are normally

supplied as 22 Psi tanks and 22 Psi is the minimum LN2 tank pressure

required for proper operation. The control solenoid valve is capable of

operating with a maximum of 60 Psi differential pressure.

2.2 Some familiarity with the LN2 tank pressure builder system, relief

systems and level indication system are required. Ask your gas supplier

how these systems work on the tanks you are using and how to tell when

the LN2 tank is nearing empty. These indications change with the tanks

you are using.

2.3 These tanks are normally congured with a Vent connection, and a

Liquid connection. Ensure the LN2 tank connection to the freeze coil is

made at the liquid connection.

PAGE 4

HFT PIPESTOPPERS

®

Freeze times may vary due to actual working conditions. The pipe should

be at ambient temperature. If ambient temperature is in excess of 32˚C

(90˚F), add 15 minutes to the freeze time indicated in table 1 for every 4

degrees above 32˚C (90˚F) for pipe size up to 6", add 15 minutes to the

freeze time indicated in table 1 for every 2 degrees above 32˚C (90˚F) for

pipe size greater than 6". If the freeze is being performed in direct sunlight

some method of providing shade over the freeze area is recommended.

3. System requirements to establish freeze seal

3.1 Process uid must be static.

3.2 Pipe coating should be removed from area to be frozen.

3.3 Pipe should be free of dirt, oils, etc.

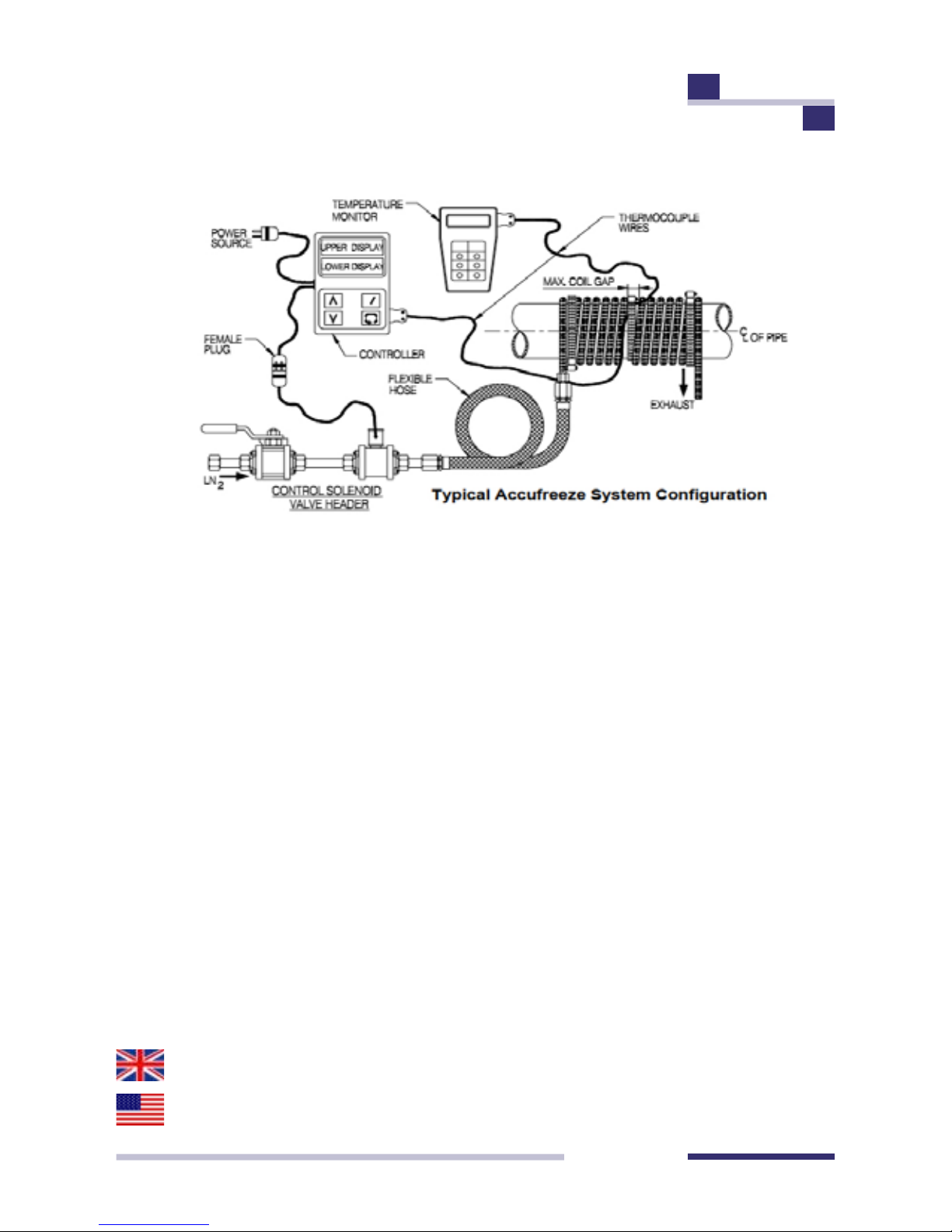

4. Freeze seal setups

4.1 Coil copper tubing around freeze location (see table 1 for freeze

wrap recommendations). Copper tubing should be wrapped tightly with

each successive wrap in contact with previous wrap. Coil wraps may be

separated up to ¾ inche to allow for thermocouple placement (see 5.1

for direction on thermocouple placement).

4.2 Connect the Control Solenoid Valve Header to the liquid

nitrogen (LN2) tank liquid supply and the LN2 supply exible hose to the

Control Solenoid Valve Header.

4.3 Check Control Solenoid Valve isolation valve closed.

OPERATING INSTRUCTIONS

Continued

PAGE 5

HFT PIPESTOPPERS

®

4.4 Connect the exible hose to inlet side of wrap tubing.

4.5 Direct vented side of wrap tubing away from equipment thatmay be

damaged by Liquid Nitrogen emission. A catch bucket may be used.

Note: If more than one Control Solenoid Valve Header and exible sup-

ply hose is being used connect the system a described above and

connect the supply hoses to a tee at the wrap inlet (see attachment 1).

5. Thermocouple installation

5.1 Place thermocouples at desired locations in the freeze seal area. The

control thermocouple should be placed near the wrap tubing linear center

at least ¼" from nearest copper tubing. Each thermocouple should be

placed at least ¼" from nearest copper tubing, if a thermocouple is in

contact with the copper tubing the reading will be inaccurate.

5.2 Thermocouples may be held in place with hose clamps,Velcro straps,

or other suitable devices such that the thermocouple is held rmly in

contact with the pipe.

5.3 Connect the thermocouple wires to the AF 3000 controller and

the temperature monitor. Ensure the control thermocouple is attached to

the controller.

OPERATING INSTRUCTIONS

Continued

PAGE 6

HFT PIPESTOPPERS

®

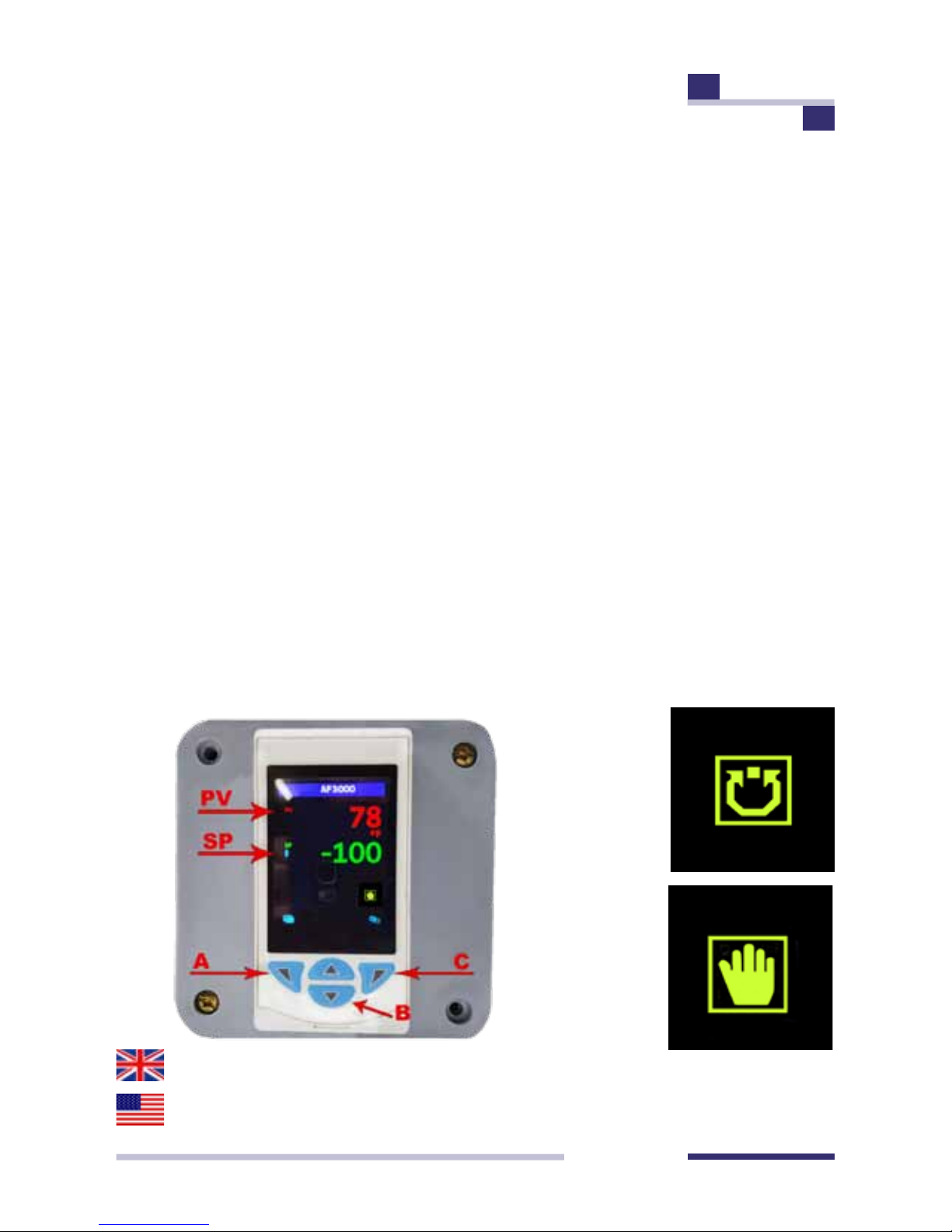

6. AF 3000 Temperature Controller setup.

6.1 Verify Power is on by presence of light indications on display.

6.2 Verify controller is in AUTO MODE (check for Auto Control Mode Icon

in lower right section of the display screen). If in MANUAL, press the right

button (C) on the controller to place in AUTO MODE.

6.3 Adjust the AF3000 as follows

1. Press the left button (A) key to access the operator menu.

2. Press the down button (B) to enter CONFIGURE MODE.

3. Select by pressing the right button (C).

4. Press the down button (B) until BASIC is highlighted.

5. Press the right button (C) to select BASIC.

6. You should see the BASIC SETUP.

7. Press the right button (C) to enter BASIC SETUP.

8. Press the down button (B) until LOOP 1 SETPOINTS.

9. Press the right button (C) to enter LOCAL SETPOINT 1 sub

section.

OPERATING INSTRUCTIONS

Continued

PAGE 7

HFT PIPESTOPPERS

®

10. Press the right button (C) to access the PROGRAM MODE.

11. Enter your desired setpoint following the on-screen prompts.

12. Press the right button (C) to select OK and lock your settings.

13. Press the left button (A) key to return to the section menu.

14. Press the down button (B) until LOOP 1 CONTROL.

15. Select by pressing the right button (C).

16. Select the ON/OFF HYSTERESIS with the right button (C)

and enter the number (5 deg. For F, 3 deg. For C)

17. Press the left button (A) key to return to the section menu.

*DO NOT ENTER THE LOOP 1 TIME PROP OR ALARMS OFF SECTION. IF

ANY CHANGES ARE MADE CONTACT FACTORY*

18. Press the left button (A) key until you see the OPERATOR

LEVEL screen.

19. The PV and SP should be displayed.

20. Verify the controller is in AUTO MODE if not repeat section

OPERATING INSTRUCTIONS

Continued

Auto Mode

Icon

Manual Mode

Icon

PAGE 8

HFT PIPESTOPPERS

®

6.4 Adjust AF 3000 temperature reading by following the above process

except select LVL 3 and depress the lower right push button until the

readout displays O.AdJ. Use the up or down arrows to offset the display

reading to correspond to the reading indicated on the temperature moni-

tor (this sets the controller temperature at the surface temperature of the

pipe as indicated on the temperature monitor at the start of the freeze).

Press lower right push button once more to return to process and control

temperature readout as described above.

6.5 Adjust control set point (lower display temperature readout using

the up/down arrow switches on the controller face to desired freeze seal

control set point. A control temperature of -34˚C (-30˚F) for carbon steel

pipe and -62˚C (-80˚F) for StainlessSteel pipe is recommended. The

control temperature maybe set colder to compensate for high ambient

conditions or high system heat conditions. If colder temperatures are used

the controller should be returned to these recommended temperatures

after the plug is established.

7. Initiate Freeze Seal

7.1 Open LN2 tank liquid valve.

7.2 Open the control solenoid header isolation valve, observe LN2 Flow

and freeze seal formation. LN2 ow is indicated by the sound of escaping

nitrogen gas and observing condensation at the coil exhaust.

OPERATING INSTRUCTIONS

Continued

PAGE 9

HFT PIPESTOPPERS

®

8. Perform desired maintenance

8.1 The Accu-Freeze equipment should be monitored for proper and

continuous operation while system repairs are being performed.

9. Terminate Freeze Seal

9.1 The freeze seal can be thawed in a controlled manner if desired by

raising the AF 3000 set point to allow for thermal soaking of the pipe.

9.2 If thermal soaking is not required close the control solenoid header

isolation valve and the LN2 tank liquid valve.

9.3 The freeze seal can continue to be monitored using the temperature

monitor until seal has moved or the pipe has returned to baseline

temperature (COB Industries,Inc. recommends continued monitoring

until all thermocouples indicate it is safe to touch the freeze area with

bare hands and the freeze plug has thawed before restarting system

equipment).

9.4 After the freeze has warmed sufciently, disassemble the Freeze

wrap, and Accu-Freeze equipment.

10. Additional Information

10.1 The Accu-Freeze kit includes additional type T Thermocouple wire

and connectors.

OPERATING INSTRUCTIONS

Continued

PAGE 10

HFT PIPESTOPPERS

®

Thermocouples can be made by cutting the wire to the desires lenght and

connecting one end to a male or female connector (as appropriate). The

copper colorered thermocouple wire should be connected to the copper

colored connector (also marked +) and the light colored wire connected

to the light connector (marked -). The other end should be stripped bare,

approximately 1inch and the two wires twisted tightly togehter to form

the thermocouple junction.

10.2 Connectors may be put on both ends of the thermocouple wire,

observing connection polarity, to form thermocouple extensions if the

monitoring and control equipment is placed away from the freeze area.

Table 1 Recommended Pipe Size Wrapping Table

*These are estimated times only, actual eld tests have not been

performed.

OPERATING INSTRUCTIONS

Continued

Pipe Size Copper Tube Wrap

Lenght

Time -

Hrs./Mins

1/4 through 3/4” 3” 0:10

1” 6” 0:18

1 1/2” 6” 0:25

2” 8” 0:40

3” 8” 1:20

4” 12” 2:15

6” 18” 3:40

8” 24” 5:30*

10” 36” 8:30*

12” 36” 12:30

PAGE 11

HFT PIPESTOPPERS

®

COB Industries, Inc. recommends 1/4" copper tubing for all freeze wraps

up to and including wraps on 6" diameter pipe. 5/16" copper tubing

should be used for all freeze wraps on 8" diameter pipe and larger and

may be used for all freeze seal wraps.

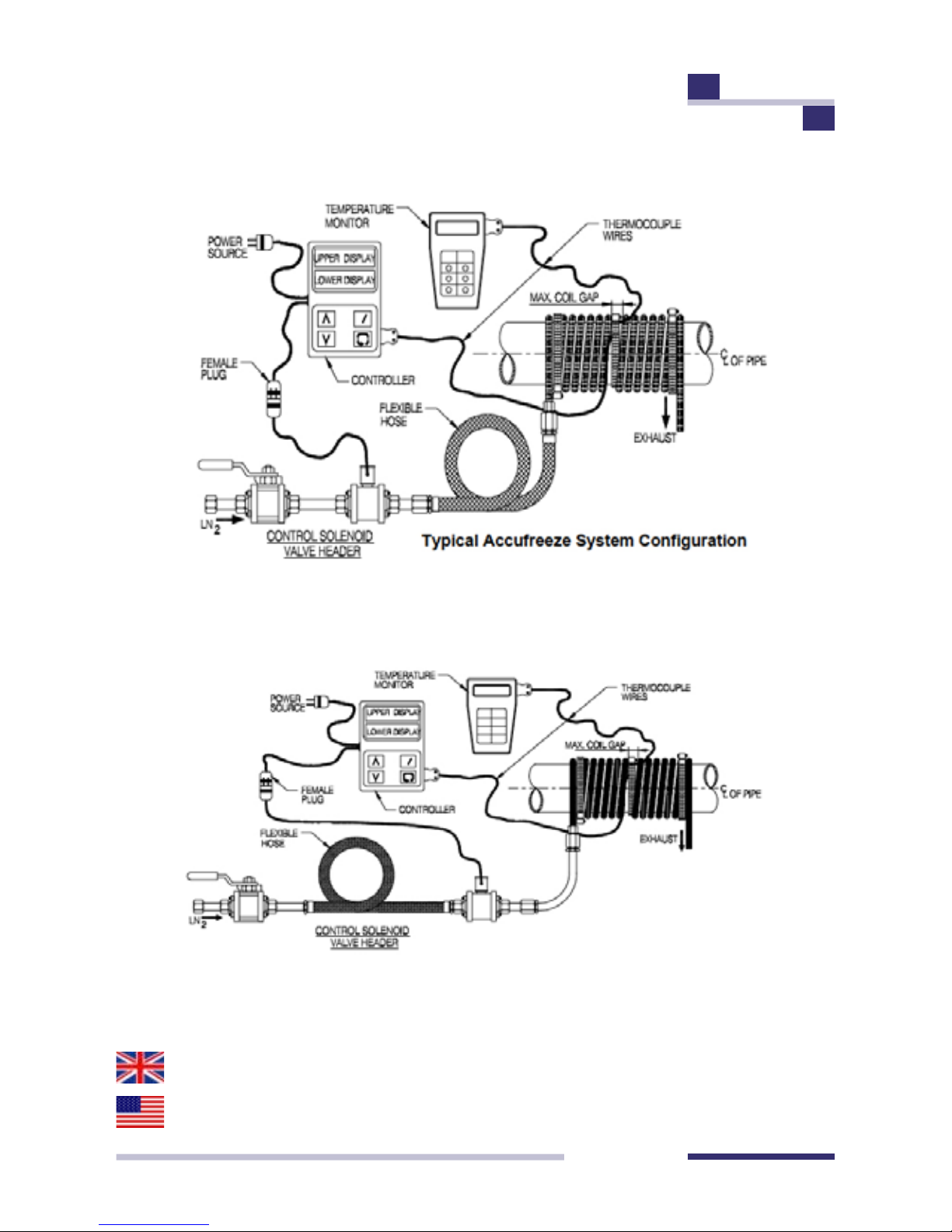

This coil conguration should be used on 6 inch diameter pipe and smaller.

See step 4.1 for coil placement.

This coil conguration should be used on 6 inch diameter pipe and

larger. See step 4.1 for coil placement. When this conguration is used

care should be taken to assure equal length of the coils from the tee to

exhaust to allow balanced LN2 ow in both legs of the coil.

OPERATING INSTRUCTIONS

Continued

PAGE 12

HFT PIPESTOPPERS

®

Typical Accu-Freeze System Conguration When Using

Flexible Hose Lengths Greater Than 30 Feet.

Note: the solenoid valve should be attached to the copper coil in a

near upright position

OPERATING INSTRUCTIONS

Continued

PAGE 13

HFT PIPESTOPPERS

®

OPERATING INSTRUCTIONS

Continued

PAGE 14

HFT PIPESTOPPERS

®

Table 2

LN2 Operating Pressure Recommendations

Single freezes up to 4 inch diameter pipe 22 Psi

Single freezes >4 inch to 8 inch diameter pipe 35 Psi

Single freezes >8 inch diameter pipe 35 Psi

Double freezes 3 inch to 6 inch diameter 35 psi

Double freezes > 6 inch diameter pipe 35 Psi

Feezes where distance from LN2 source to freeze wrap is >

20 feet and < 50 feet

35 Psi

Freezes > 50 feet and < 100 feet 35 Psi

Freezes > 100 feet from LN2 source to feet wrap are not

recommended with supplied system. Additional equipment

is recommend.

Contact

Vendor

OPERATING INSTRUCTIONS

Continued

PAGE 15

HFT PIPESTOPPERS

®

HFT Pipestoppers®

Product Range

© HFT®

HFT Pipestoppers®Nylon Pipe Plugs

are suitable for a myriad of applications.

They are mostly used for weld testing,

leak testing of pipework fabrications, weld

purging or simply stopping to prevent

the ingress of dirt, rodents and other

unwanted material. These plugs will

provide airtight seals and in tests with

plastic pipes they are capable of sealing

against pressures from 60 Psi - 4 bar, to

over 100 Psi - 7 bar.

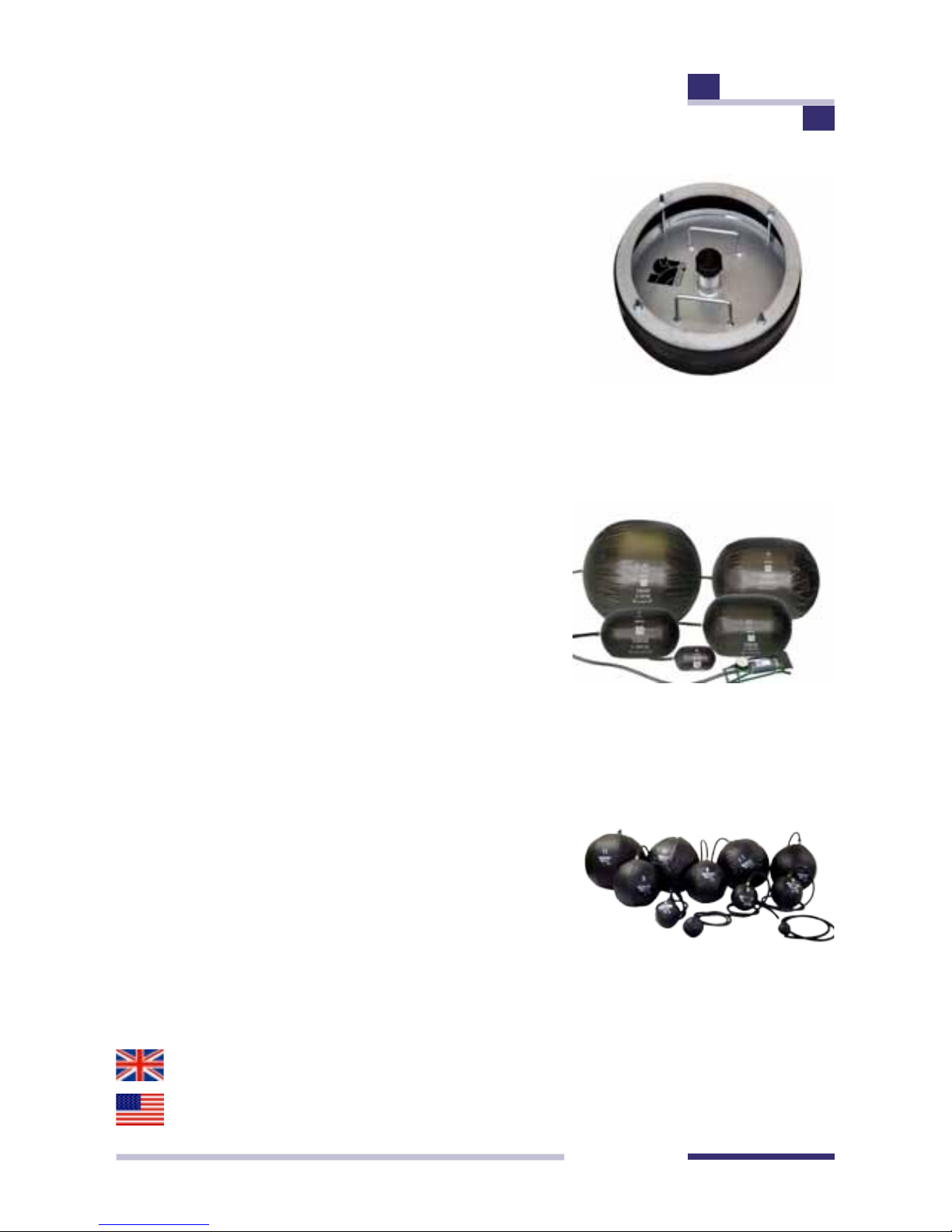

HFT®manufactures a large range of

Aluminium Plugs, suitable plugs for leak

testing and isolation, to compliment the

range of small diameter Nylon Plugs.

All natural rubber rings can be replaced

with silicone, nitrile, neoprene or viton

for chemical and temperature resistance.

Steel Expanding Single & Double

Plugs for increased stability and higher

pressure duties. For pressure testing and

stopping all pipework from 1.5 inch (38

mm) upwards. The test pressure capability

of the single stoppers is limited and the

double versions increase that capability,

while offering a greater stability in the

pipe.

PAGE 16

HFT PIPESTOPPERS

®

HFT Pipestoppers®

Product Range continued

© HFT®

Rim Fastening Steel Plugs, single and

double port, for pressure testing and

stopping all pipework from 17"(432 mm)

up to 95"(2400 mm). Rim Fastening

Steel Plugs, especially the large sizes,

have the advantage over centre locking

plugs, that the nuts enable plates to be

closed together evenly with ease and

even seal in pipes that have slight out of

roundness.

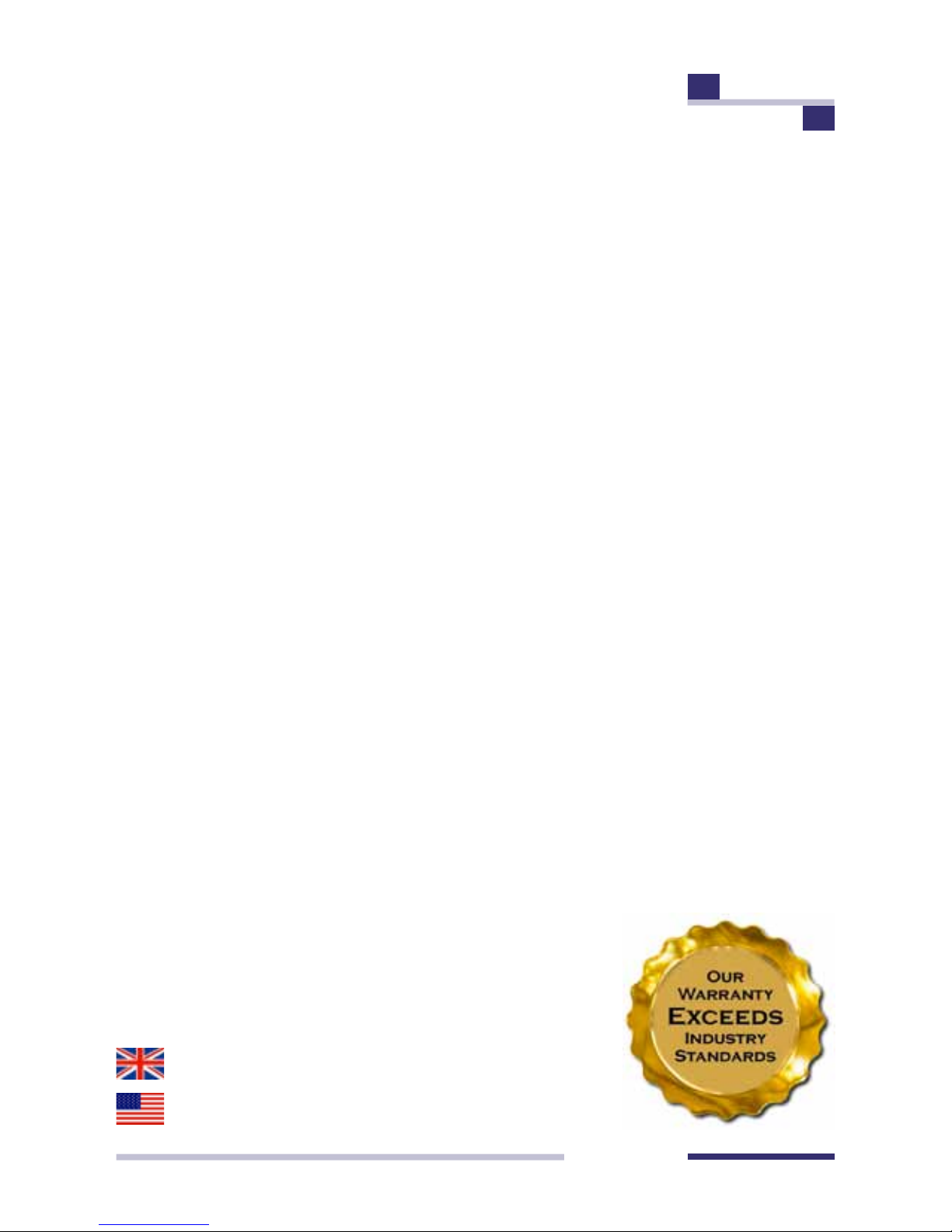

HFT Pipestoppers®Inatable Stoppers

and Test Plugs, an easy way to stop the

ow of gas or liquid along a pipe or duct,

for collection of debris and to prevent

ingress of unwanted material or animals.

All Inatable Stoppers are manufactured

with a strong internal inatable bag made

to the required shape and covered in

waterproof sewn polyurethane coated

nylon for low friction and to prevent the

production of static electricity or accidental

sparking. The Inatable Stoppers range

includes; Spherical, Cylindrical, Heat

Resistant and the Specials.

PAGE 17

HFT PIPESTOPPERS

®

Otros idiomas son actualmente en progreso. Para ahora, contacta

por favor su Distribuidor local

Andere Sprachen sind momentan im Gange. Kontaktieren Sie

vorläug, bitte Ihren örtlichen Verteiler

Les autres langues sont actuellement dans le progrès. Pour le

moment, s’il vous plaît contacter votre Distributeur local

Other LANGUAGES in PROGRESS

PAGE 18

HFT PIPESTOPPERS

®

For further information and support, please contact us at:

Internet: www.huntingdonfusion.com

Email: [email protected]

Tel: +44 (0) 1554 836 836

Worldwide Ofces, Partners and Distributors are listed on our website

or contact us and we will direct you to the correct location

CUSTOMER SUPPORT and

WORLDWIDE CARE

PAGE 19

HFT PIPESTOPPERS

®

All products are thoroughly tested to our Quality Control Procedures

prior to leaving our manufacturing facility. Should you encounter

a problem with your product, please notify us immediately upon

receipt.

Huntingdon Fusion Techniques HFT® warrants this product to be

free of defects in workmanship and material, with exceptions stated

below.

Warranty applies for normal and intended use of the product.

Huntingdon Fusion Techniques HFT®will not be held responsible

for any incorrect use of the product.

For further warranty information, please refer to our terms and

conditions.

All warranties shall not apply to any product or component which

has been repaired or altered by anyone other than Huntingdon

Fusion Techniques HFT®.

Huntingdon Fusion Techniques HFT®shall not be liable for indirect,

special, incidental or consequential damage or penalties and does

not assume any liability of Purchaser, or to others, for injury to

persons or property.

This warranty is in lieu of all other warranties, expressed and implied.

E&OE

WARRANTY

ACCU-FREEZE UI A5 AF91 - 26-04-2018 ME

HFT Pipestoppers®a division of Huntingdon Fusion Techniques HFT®

Stukeley Meadow Burry Port Carms SA16 0BU United Kingdom (UK)

Telephone +44 (0) 1554 836 836 Fax: +44 (0) 1554 836 837

www.pipestoppers.net www.huntingdonfusion.com

Copyright © HFT®. All rights reserved. This publication may not be reproduced by any means without the written permission

of Huntingdon Fusion Techniques HFT®

HUNTINGDON FUSION

TECHNIQUES HFT

© HFT®

This manual suits for next models

1

Table of contents