Hi-Force TWS-N Series Instruction Manual

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

1

OPERATING INSTRUCTION MANUAL

TWS-N SERIES | HYDRAULIC TORQUE WRENCHES

- SQUARE DRIVE

Hi-Force TWS-N series of lightweight aluminium Square Drive Hydraulic Torque Wrenches are designed to

handle the toughest bolting jobs quickly and accurately. All models provide a torque accuracy of ± 3%. The

reaction arm allows the user to easily position the tool and if necessary react off the tool body in confined

situations. TWS-N Torque wrenches are available in torque capacities up to 36992 N·m at a maximum

working pressure of 700 bar (10,000 psi). This manual applies to the Hi-Force TWS-N series Hydraulic

Torque Wrenches Only. It contains the latest product information available at the time of publication and

approval. For information relating to the servicing of a Square Drive Hydraulic Torque Wrench, see the

servicing instructions, which are available on the Hi-Force website. Hi-Force reserves the right to make

changes to this document at any time without notice.

This ‘Original instructions’ document assumes that the operator carrying out any operation with this

product is trained and competent to do so. This manual does not attempt to cover all details or variations

in the equipment. Nor does thismanual claim to provide for every possible contingencymet in connection

with the installation, operation, or maintenance thereof. Should further information be desired, or should

a particular problem arise which is not covered in sufficient detail, the matter should be referred to

Hi-Force.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

2

Table of Contents

1.0 Inspection upon Receipt .................................................................3

2.0 Safety Precautions...........................................................................3

3.0 Declaration of Incorporation/Conformity......................................6

4.0 Component Identification................................................................7

5.0 Installation/Setup ............................................................................8

6.0 Operation........................................................................................14

7.0 Maintenance and Storage..............................................................16

8.0 Specifications.................................................................................17

9.0 System Components/Accessories ..............................................18

10.0 TWS-N Torque Conversion Charts.............................................19

11.0 Troubleshooting...........................................................................20

12.0 Contact Details ............................................................................22

NOTE: Images contained within this document are for illustrative purposes ONLY.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

3

1.0 Inspection upon Receipt

Upon receipt of the product, visually inspect the item for any evidence of shipping damage. Please note:

the warranty does not cover shipping damage. Notify the courier immediately if shipping damage is found

and refrain from putting the product into service. The carrier is responsible for repair and replacement costs

resulting from damage that occurred in transit.

2.0 Safety Precautions

2.1 Introduction

Read and follow all the instructions and safety warnings carefully before handling, installation or

use of any hydraulic equipment. Failure to do so could lead to equipment damage, equipment

failure, personal injury or even death. Hi-Force will not be held responsible for any damage to the

equipment, injury or death resulting from the unsafe use of, lack of maintenance to, or incorrect operation

of the product. If in doubt on the correct use of any Hi-Force equipment, contact your nearest Hi-Force office

or distributor. Onlyqualified personnel should be allowed to operate hydraulic equipment. If an operator has

not been trained on high-pressure hydraulic equipment and its safe usage, consult your local Hi-Force sales

office or distributor who can offer training courses for operators.

2.2 Work Area Safety

Keep work areas clean and well lit. Cluttered spaces and inadequate lighting can result in

unnecessary accidents.

Keep bystanders clear of any hydraulic tool activity. Personnel working in close-range should be

made aware of all high-pressure work before commencing.

2.3 General Hydraulic System Safety Precautions

Failure to observe and obey the following safety precautions could result

in property damage, significant personal injury or death;

When operating any hydraulic equipment, all operators should ensure that all necessary personal

protective equipment (PPE) is worn, as specified by their employer. Steel toe-cap safety shoes,

safety glasses/visor and protective gloves should be worn at all times. All relevant risk assessments

should be completed before the use of the equipment.

Keep hydraulic equipment away from open flames and direct heat.

NEVER use a coupler as a tool handle, especially if the system is pressurised.

Inspect hoses regularly for damage and wear.

NEVER use hoses that are frayed, kinked, abraded or leaking.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

4

NEVER handle a pressurised hydraulic hose. Hydraulic fluid escaping under pressure from a

ruptured hose can penetrate the skin and lead to a significant medical emergency, and in some

cases, death. Should this incident occur, seek out medical attention immediately.

Seek medical attention immediately if a hydraulic injection injury (no matter how minor) occurs.

The system operating pressure MUST NOT exceed the pressure rating of the lowest-rated

component in the system.

Only use hydraulic torque tools in a complete and tested, coupled system. NEVER attempt to use

a torque tool that is not correctly coupled to its operational pump.

NEVER pressurise an unconnected male coupler/s.

NEVER attempt to disconnect a hose from a hydraulic system until the system’s pressure has been

completely released. Doing so can result in that pressure becoming trapped within the system and

relieving trapped pressure can be dangerous.

NEVER try to relieve trapped hydraulic pressure in the system by loosening or attempting to remove

the coupler. Trapped hydraulic pressure can cause a loosened coupler to dislodge unexpectedly

with great force. This action could result in serious personal injury or death.

Loosening a coupler under pressure can result in the escape of hydraulic oil at high pressure, which

can penetrate the skin and cause significant injury or death.

NEVER use a hammer and punch to unseat a coupler check valve that is under pressure. Doing so

could result in the sudden, uncontrolled release of hydraulic oil at high pressure, which could cause

significant injury or death.

NEVER attempt to solve, or clean-up leaks in the system while the system is pressurised.

Immediately replace any worn or damaged parts using genuine Hi-Force parts only.

DO NOT use any hydraulic equipment if you are under the influence of alcohol, drugs or medication.

Lack of attention whilst operating high-pressure hydraulic tools can result in personal injury or death.

Failure to observe and obey the following safety precautions could result

in property damage, equipment damage or minor/moderate personal

injury;

NEVER lift, carry or move any hydraulic components by the hose or hoses connected to them.

Avoid damaging hydraulic hoses. ALWAYS route hoses to ensure that they are free from sharp

bends and kinks. Using a sharply bent or kinked hose will result in severe back-pressure, which can

lead to hose failure.

NEVER use a coupler/s to lift, carry or position a tool.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

5

Servicing of hydraulic equipment must only be undertaken by a qualified technician.

DO NOT drop or place heavy objects on a hydraulic hose, as this may cause

internal damage, which could result in rupture of the pressurised hose. A

ruptured hose could cause significant damage to components and possible

severe injury to personal operating nearby.

DO NOT let familiarity gained with any hydraulic tools allow you to become complacent.

Complacency with any tooling can result in a lack of discipline toward working guidelines and safety

principles.

ALWAYS operate the system under no-load conditions before the actual operation, to ensure there

is no air trapped in the hydraulic circuit.

DO NOT remove any labels from the product. Replace any damaged or unreadable labels

immediately.

Avoid loose clothing and jewellery that could get caught in moving parts, tie back long hair.

2.4 Hydraulic Torque Wrench Specific Safety Precautions

Failure to observe and obey the following safety precautions could result

in property damage, serious personal injury or death;

NEVER exceed the maximum rated pressure of any hydraulic equipment. Hi-Force manufactures

its TWS-N torque wrenches to operate at a maximum working pressure of 700 bar (10,000 psi).

DO NOT connect a pump with a higher pressure capacity rating to any Hi-Force tool of this model

series.

NEVER attempt to connect or disconnect, hydraulic equipment while the system is under pressure.

DO NOT weld any items to the torque wrench or modify it in any way from its delivered condition.

Your warranty may be invalidated, and it could lead to serious personal injury.

ALWAYS ensure there is clear communication between the pump operator and the tool operator.

DO NOT operate the pump unless the tool operator indicates it is safe to do so.

Take extra care when multiple tools are being operated by a single pump. Make sure all tool

operators have given the go-ahead before operating the pump.

NEVER operate the torque wrench without both hydraulic hoses connected to it.

This tool will exert very large reaction forces. Use proper mechanical support and correct reaction

arm positioning to control these forces. DO NOT position the reaction arm so that it tilts the tool off

the axis of the bolt and NEVER use the uni-swivel coupling as a reaction point.

NEVER attempt to use your hands or any other body parts as a reaction point for the tool during

operation.

This tool is NOT ATEX RATED. I.e. NOT suitable for work which takes place in explosive

environments.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

6

This tool is NOT insulated against electric shock. When using this tool with a pump that has an

electrical power source or circuits, follow the pump instructions for proper grounding.

Failure to observe and obey the following safety precautions could result

in property damage, equipment damage or minor/moderate personal

injury;

ALWAYS wear appropriate personal protective equipment (PPE) when carrying out maintenance

on this tool.

When connecting hoses that have not been pre-filled with hydraulic oil, make certain the pump

reservoir is not drained of oil during start-up.

ONLY use impact sockets and accessories. DO NOT use hand (chrome) sockets or accessories.

ONLY use Hi-Force recommended accessories.

ONLY use sockets and accessories that correctly fit the nut/bolt and function without tilting the tool

off the axis of the bolt.

DO NOT interchange the male and female swivel inlets on the tool or the connections on one end

of the hose. Reversing the inlets will reverse the power stroke cycle and may damage the tool.

To protect your warranty, only use the hydraulic oil grade specified in Section 8.1.

3.0 Declaration of Incorporation/Conformity

Hi-Force declares that this product has been tested and complies with the standards set out in

2006/42/EC - The Machinery Directive. The Declaration of Incorporation/Conformity is included

as Annex A to this instruction document and is supplied with all shipments of this product.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

7

4.0 Component Identification

1

Drive Unit

5

Male ‘Retract’Coupler (90 bar)

2

Square Drive (Reversible)

6

Female ‘Advance’ Coupler (700 bar)

3

Shroud

7

Reaction Arm (Multi-Position)

4

360° Uni-Swivel

-

Figure 4.1: Component Identification

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

8

5.0 Installation/Setup

5.1 Before Each Use

Check the exterior of the tool for signs of mechanical damage and/or oil leaks. If either is present,

DO NOT use the equipment until it has been serviced and returnedto its proper operating condition.

5.2 Hydraulic Connections

TWS-N torque wrenches are double-acting torque tools (powered in both the advance

and retract directions) and MUST be connected to the pump via both, the advance and

retract couplers. DO NOT pressurise the pump/system if there are any disconnected

couplers in the system.

ALWAYS use Hi-Force HTWH hoses to make connections.

Hi-Force TWS-N torque wrenches are fitted with dual flat-face quick-connect couplers.

Make sure both coupler halves are clean before connecting.

If you are NOT using a Hi-Force Torque Wrench pump, or if the pump or hoses have

been modified, make sure that the wrench is connected correctly so that the female

high-pressure advance coupler (2) is connected to the advance port on the pump.

Failure to do so may result in leakage, tool damage or personal injury.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

9

5.2.1 Connections (See figure 5.1)

Connections between couplers are made by simply [1] pressing the male coupler into the female coupler

until [2] the locking collar springs forward and locks the couplers together.

Make certain the spring-loaded retaining rings are fully engaged to prevent the

connectors from disengaging under pressure. A gentle tug on the hose should be

enough to make sure the hose is correctly connected.

5.2.2 Disconnections (See figure 5.2)

Always make sure the pump is switched off and pressure has been fully released before

disconnections are made.

To disconnect couplers; [1-1] twist the locking collar on the female coupler in the direction of arrow and

[1-2] pull back toward the female couplerbody. [2] With the locking collar retracted, pullthe male and female

couplers apart. Fit dust caps after disconnections are made.

Figure 5.1: Hydraulic Connections

Figure 5.2: Hydraulic Disconnections

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

10

5.2.3. Connecting a Torque Wrench to the Pump

Connect the female coupler on the red hose to the male advance coupler on the pump.

Connect the male coupler on the black hose to the female retract coupler on the pump.

Connect the free end of the red hose to the advance port on the torque wrench.

Connect the free end of the black hose to the retract port on the torque wrench.

Figure 5.4: Connecting the Torque Wrench

Figure 5.3: Connecting to the Pump

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

11

5.3 Setting the Direction of Rotation of the Square Drive

The position of the Square Drive when looking toward the Shroud will determine if the tool is set to tighten

or loosen the nut/bolt (See below).

Looking at the front of the tool, with the reaction arm pointed away from you;

When the square drive extends to the RIGHT, the tool is set to TIGHTEN the nut/bolt.

When the square drive extends to the LEFT the tool is set to LOOSEN the nut/bolt.

To change the direction of rotation, proceed as follows:

Press in the push-button release on the drive retaining plate and at the same time pull the square

drive out of the housing.

Release the push button on the retaining plate and allow the retaining plate to drop out of the tool

body into your hand.

Insert the square drive into the cavity on the opposite side of the tool body (where the retaining plate

was previously)

Secure the square drive by installing the push-button release retaining plate onto the end of the

drive.

5.4 Setting the Torque

After determining the required torque, use either the torque conversion chart engraved on the shroud or the

torque conversion charts on page 19 of this manual to determine the pressure necessary to achieve the

desired torque output.

Refer to the pumps operating instructions manual for a detailed procedure for setting the pumps output

pressure to that determined above.

Figure 5.5: Direction of Rotation of the Square Drive

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

12

5.5 Reaction Surfaces

The function of the reaction arm/surface is to hold the tool in position against the forces generated to tighten

or loosen bolts or nuts. Hydraulic wrenches generate tremendous torque (rotational) forces.

5.5.1 Setting the Reaction Arm

Make sure the reaction arm is positioned correctly. (See Figure 5.7)

The reaction arm can be positioned in numerous positions within a 360° circle. However, for the arm to be

correctly positioned, it MUST be set within a 90° quadrant of that circle. That quadrant is the area located

between the protruding square drive and the bottom of the housing awayfrom the swivel inlets. It will always

be toward the lower half of the housing and on one side of the housing when tightening and the other side

when loosening.

Figure 5.7: Correct Reaction Arm Quadrants

Figure 5.6: Reaction Surfaces

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

13

To remove the reaction arm, simply pull down on the release latch and pull the reaction arm away from the

tool body.

To replace the reaction arm, orient it to the desired position and push onto the reaction arm location plug

until it latches into place. A simple tug on the reaction arm will be enough to tell if it has attached correctly.

NOTE: Under certain conditions, it is possible for the reaction arm location plug to be pushed slightly into

the body. This can happen as a result of the tool being dropped or hit against a solid object while

the arm is not fitted. Once this has occurred the reaction arm may not latch into place correctly.

The problem is very simply cured and in many cases will rectify itself before the operator is even

aware it has occurred. To return the plug to its correct position simply connect the tool to a pump

and cycle themechanism backwards and forwards a couple of times. In alot of cases just switching

the pump on will be enough. The reaction arm should then latch on correctly.

5.5.2 Extended Reaction Arm

The extended reaction arm can only be positioned in one orientation i.e. the flat of the reaction surface at

90° to the side of the torque wrench body.

NOTE: The extended reaction arm is purchased separately as an accessory. For further information please

contact your nearest Hi-Force office/distributor.

5.6 Bleeding Trapped Air from the System

Refer to the pumps operating instructions for the correct procedure.

Figure 5.8: Extended Reaction Arm Orientation & Reaction Surface

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

14

6.0 Operation

Hi-Force TWS-N Torque Wrenches require a suitable double-acting Hydraulic Torque Wrench pump for

operation. Make sure you read this manual in conjunction with the Torque Wrench Pumps operating

instruction manual to ensure correct and safe operation of all hydraulic equipment in the system.

Before applying pressure to the system make sure you observe the following points

You are aware of the correct operation of the Torque Wrench Pump.

You are aware of the maximum working pressure of the Torque Wrench/s.

You are aware of the maximum torque/tension the stud/bolt can withstand.

You are aware of the required working pressure/s that must be applied to the Torque Wrench/s.

You have read and fully understood the torquing sequence and procedure.

You have performed the relevant risk assessment/s and have a method statement (safe system of

work) for all operators to follow.

6.1 Operating the Wrench

Hi-force recommends that operation of the pump/wrench combination be a minimum 2

person job, one to operate the pump and one to operate the wrench. An additional

operator will be required for each addition wrench connected to the pump.

To reduce the likelihood of a finger/hand trapping accident, at least one of the

operators MUST be trained in the safe usage of the equipment and a clear system of

communication MUST be established.

To ensure the safety of the torque tool operator/s, the pump MUST ONLY be operated

once all torque wrench/tool operators have indicated it is safe to do so.

The position of the Square Drive relative to the Shroud determines whether the action will tighten or loosen

the nut. The power stroke of the Piston Assembly will always turn the Square Drive toward the Shroud.

Figure 6.1: Positioning the Torque Wrench

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

15

1. Place the chosen socket on the squared drive shaft and insert the socket retainer ring and pin.

2. Place the socket on the nut/bolt to be tightened/loosened. (Make sure the square drive and socket

are the correct size for the nut/bolt and that the socket fully engages it).

3. Position the reaction surface against an adjacent nut, flange or other solid, system component. (Make

sure that there is clearance for the hoses and uni-swivel coupling assembly).

DO NOT allow the tool to react against the hoses or uni-swivel coupling.

When the reacting directly of the tool body i.e. with the reaction arm removed.

DO NOT react off the exposed end plug spigot.

When first placed, there will be a gap between the reaction surface and the contact

point, creating a potential pinch point.

Make sure the wrench is held/supported in such a way that no body part is ever

placed between the tool and the reaction surfaces.

4. After turning on the pump and pre-setting the pressure for the correct torque, signal the pump operator

to depress the advance button on the control pendant and advance the piston assembly. (See pump

manual)

When started, the reaction surface of the wrench or reaction arm will move against the contact point

and the nut will begin to turn. Once the piston reaches the end of its stroke, the pressure will rise

rapidly.

5. Retract the wrench fully.

On a pump with a ‘2 button’control pendant, press and hold the retract button to retract the piston. On

a pump with a single button pendant (automatic retract), release the button to retract the tool. Under

normal conditions, a series of audible clicks will be heard as the tool retracts.

6. Continue this cycling operation of advance and retract. As the nut tightens and the applied torque

increases the nut rotation will slow and fewer audible clicks will be heard on retraction.

7. Continue to cycle the tool until it “stalls” (no further audible clicks will be heard on retraction) and the

pre-set pressure/torque has been attained.

8. Once the nut stops rotating, cycle the tool on last time to achieve total torque.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

16

7.0 Maintenance and Storage

Carry out basic maintenance on a regular basis to keep the torque wrench operating in a trouble-free

manner. Maintenance intervals are determined by the frequency of use and the operating conditions on

site.

Keep the unit clean.

After use, always retract the tool fully before disconnecting the attached hoses. Fit dust caps to the

couplers, every time disconnections are made.

Routinely perform a visual inspection of the tool for signs of damage.

Store in clean and dry conditions.

Apply lubrication as necessary

Lubrication

Lubricant: Molybdenum Disulphide Grease

Marine Grade Moly Lube is formulated not to wash out of the tool in areas where lubrication is critical.

Lubrication frequency is dependent on factors known only to the tool user.

Whenever lubrication is required, lubricate as follows:

1. Remove the Drive Plate, Ratchet, Segment Pawl and Drive Sleeves and wash the components in a

suitable cleaning solution, in a well-ventilated area. (See figure 6.3)

2. After drying the components, wipe a film of Moly Lube (Marine Grade) onto the wear surfaces of

both Drive Sleeves and the ends of the Ratchet.

3. Spread a light film of Moly Lube (Marine Grade) onto the inner face and both sides of the Drive

Plate.

IMPORTANT: DO NOT pack the teeth of the Segment Pawl or Ratchet with lube. Doing so can

prevent the teeth from engaging properly.

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

17

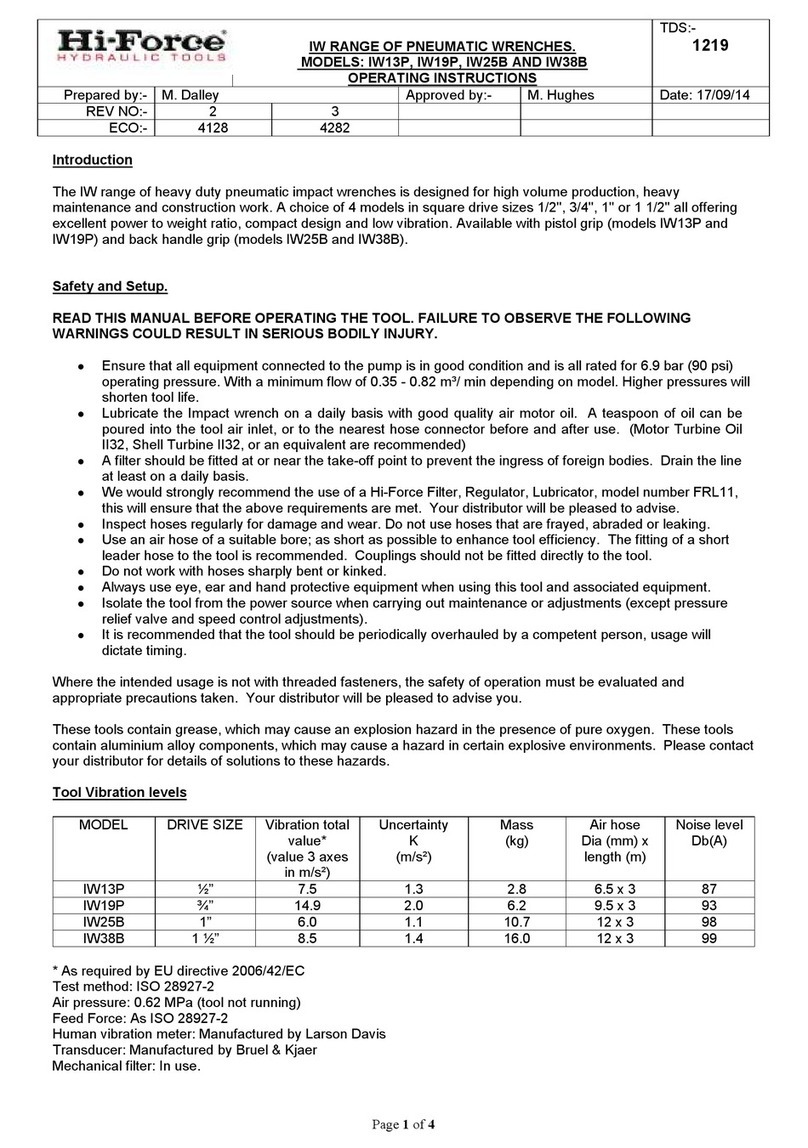

8.0 Specifications

8.1 Oil Specifications

Hi-Force tools will use 1 of 2 grades of oil, dependant on the pump used. The tools are designed to operate

at temperatures between -20°C and 80°C. Details of the oil used can be found in the chosen Hi-Force

pump’s operating manual, in the section: FILLING OF PUMP WITH OIL.

Hi-Force

Model Number

ISO Hydraulic Oil Grade

Temperature Range: Degrees Celcius (°C)

From:

To:

HFO15

ISO15

-23

44

HFO46

ISO46

-2

73

8.1 TWS-N Specifications

Refer to the engraved detail on the torque wrench body for model identification.

TWS-N | Square Drive Hydraulic Torque Wrenches

Model Number

Torque Capacity

Square Drive

Size

Weight

(kg)

Nm at

700 bar

lbf.ft at 10,000psi

TWS17N

1727

1254

¾”

1.9

TWS45N

4529

3289

1”

4.8

TWS100N

10064

7427

1½”

9.0

TWS150N

14974

10873

1½”

15.0

TWS370N

36992

26860

2½”

32.5

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

18

9.0 System Components/Accessories

(Refer to the Hi-Force website or latest Hi-Force catalogue, for further details)

HTWH Series High-Pressure Hydraulic Hoses (Up to 100m).

HTWR1 Torque Wrench Hose Reel

High-Pressure Quick-Release Male and Female Half Couplers.

Metric & Imperial Hexagon AF Size Heavy Duty Sockets.

Metric & Imperial Allen Hex Drives

Extended Reaction Arms (See below)

Removable Handle Kits

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

19

10.0 TWS-N Torque Conversion Charts

Operating Instruction Manual:

OM-TWS-N-01

Serial Numbers:

All

20

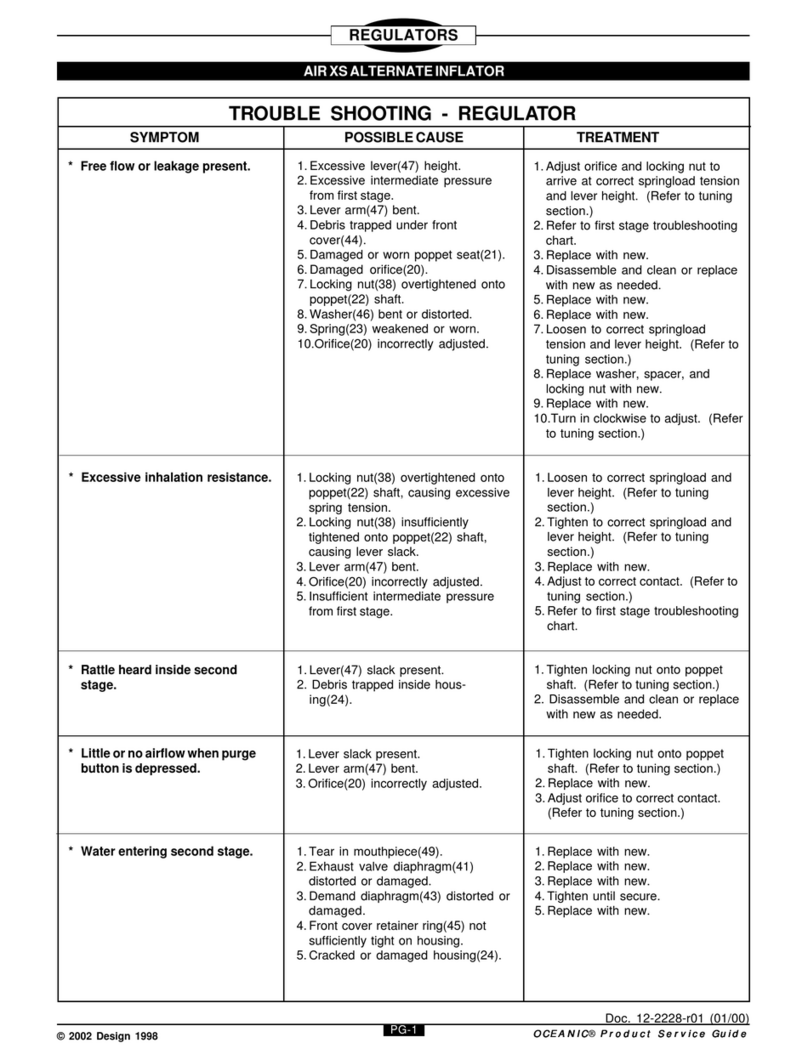

11.0 Troubleshooting

Hi-Force TWS-N Square Drive Torque Wrenches should be serviced and repaired only by authorised

Hi-Force repair centres. The following table gives possible causes and solutions for common problems.

TROUBLESHOOTING GUIDE

Problem

Possible Cause

Solution

1. Piston will not advance

or retract.

a. Couplers not securely attached to

the tool or pump.

Check the coupler connections and make

sure they are connected correctly and fully

engaged.

b. Defective coupler.

Replace defective coupler.

c. Faulty control pendant.

Contact your local Hi-Force office/distributor.

d. Pump malfunction.

See pump manual or contact your local

Hi-Force office/distributor.

e. Oil level too low.

See pump manual.

2. Tool will not retract.

a. Hose connections reversed.

Make sure the advance coupler on the pump

is connected to the advance coupler on the

tool and that the retract coupler on the pump

is connected to the retract coupler on the tool.

b. Retract hose not connected.

Connect the retract hose securely.

c. Retract pin broken.

Replace the broken pin and/or spring.

3. Tool will not build/hold

pressure.

a. Piston seal and/or end plug seal

leaking.

Replace defective seals.

b. Defective coupler.

Replace defective coupler.

4. Square drive will not

turn.

a. Lubricant or dirt build-up in the

teeth of the ratchet and segment

pawl.

Disassemble the ratchet and clean the grease

or dirt out of the teeth.

b. Worn or broken teeth on the

ratchet and/or pawl segment.

Replace worn or damaged parts.

5. Tool advances

automatically, without

a pendant button being

pressed.

a. Tool Incorrectly connected.

Swap Hose connections at the tool.

6. Pump will only reach

80-90 bar in advance

mode, but higher in

retract mode.

a. Tool Incorrectly connected.

Swap Hose connections at the tool.

Other manuals for TWS-N Series

1

This manual suits for next models

5

Table of contents

Other Hi-Force Power Tools manuals

Popular Power Tools manuals by other brands

Würth

Würth 1952 004 530 Translation of the original operating instructions

M7

M7 PB-2402 user manual

Sealey

Sealey CP1920 Instructions for use

BIRDIE

BIRDIE RSD-50 Instruction book and parts list

King Tony

King Tony 9TY522-50 Operation manual

Tyco Electronics

Tyco Electronics Simel SIMABLOC 80+ Technical handbook