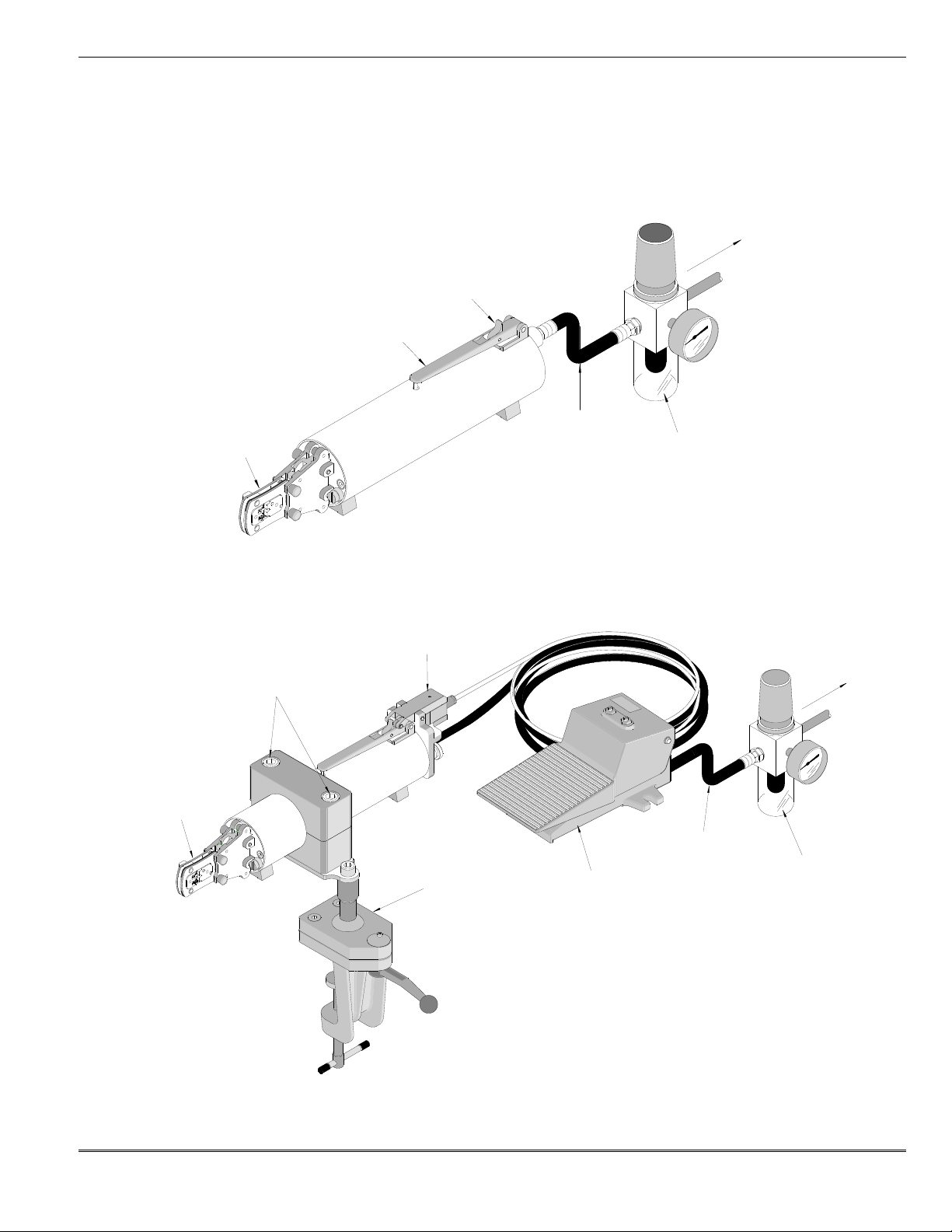

Air Powered Tool

Order No: TM-638160100 Release Date: 02-20-08 UNCONTROLLED COPY Page 3 of 17

Revisio : B Revisio Date: 05-28-10

Section 1

Safety War i gs a d I formatio

Read a d understand all of the i structio s a d safety i formatio i this

ma ual before operati g or servici g this tool.

Keep this ma ual available whe usi g this tool.

Replaceme t ma uals are available upo request at o charge at

www.molex.com.

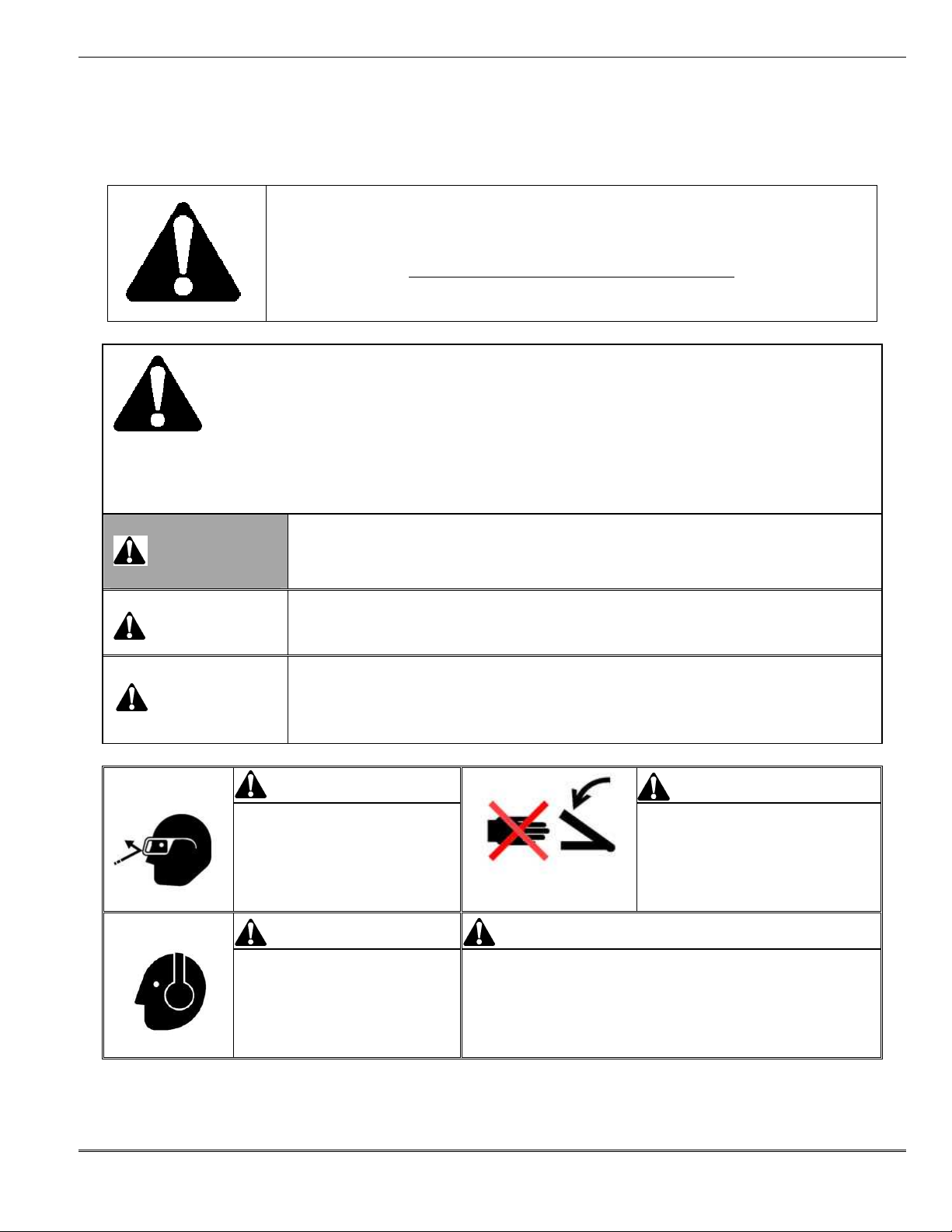

SA ETY

ALERT

SYMBOL

This symbol is used to call your atte tio to hazards or u safe practices which could result i a i jury

or property damage. The sig al word, defi ed below, i dicates the severity of the hazard. The message

after the sig al word provides i formatio for preve ti g or avoidi g the hazard.

DANGER

DANGER:

I dicates a immi e tly hazardous situatio which, if ot avoided, will result i

death or serious i jury.

WARNING

WARNING:

I dicates a pote tially hazardous situatio which, if ot avoided, will result i

death or serious i jury.

CAUTION

CAUTION:

I dicates a pote tially hazardous situatio which, if ot avoided, may result i

mi or or moderate i jury. CAUTION may also be used to alert agai st u safe

practices associated with eve ts that could lead to perso al i jury.

WARNING WARNING

Wear eye protectio whe operati g

or servici g this tool.

Failure to wear eye protectio could

result i serious eye i jury from flyi g

debris.

Pi ch poi ts:

Keep ha ds away from the crimpi g

head whe crimpi g.

Failure to observe this war i g could

result I severe i jury or death.

WARNING WARNING

Wear appropriate ear protectio whe

operati g this tool.

Failure to wear ear protectio could

result i loss of heari g over a period

of time.

I spect tool a d dies before use. Replace a y wor or damaged parts.

A damaged or improperly assembled tool ca break a d strike someo e

earby.

Failure to observe this war i g could result i severe i jury or death.