Hi-Force TWS-N Series User manual

TDS1288

Page 1 of 7

www.hi-force.com

OPERATION MANUAL

Hi-Force®TWS-N SERIES

SQUARE DRIVE HYDRAULIC TORQUE WRENCHES

NOTICE

Series TWS-N Series Square Drive Hydraulic Torque Wrenches are designed for installing and removing

threaded fasteners requiring precise high torque during bolt makeup and maximum torque during bolt

breakout.

0609

WARNING

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS

MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY.

PLACING TOOL IN SERVICE

•Always operate, inspect and maintain this tool in accordance with International Standards ISO9001

and ANSI B30.1.

•This tool will function using an air or electric powered hydraulic pump. Adhere to the pump safety

requirements and follow instructions when connecting the pump to the tool.

•Use only equipment rated for the same pressure and torque.

•Use only a hydraulic pump capable of generating 10,000 psig (700 bar) maximum pressure with this

tool.

•Use only twin line hydraulic hose rated for 10,000 psig (700 bar) pressure with this tool.

•Do not interchange the male and female swivel inlets on the tool or the connections on one end of the

hose. Reversing the inlets will reverse the power stroke cycle and may damage the tool.

•Do not use damaged, frayed or deteriorated hoses and fittings. Make certain there are no cracks,

splits or leaks in the hoses.

•Use the quick connect system to attach the hoses to the tool and pump. Make certain the spring-loaded

retaining rings are fully engaged to prevent the connectors from disengaging under pressure.

•When connecting hoses that have not been preloaded with hydraulic oil, make certain the pump reservoir is not

drained of oil during start-up.

•Do not remove any labels. Replace any damaged label.

USING THE TOOL

•Do not handle pressurised hoses. Escaping oil under pressure can penetrate the skin, causing serious injury.

If oil is injected under the skin, see a doctor immediately.

•Never pressurise uncoupled couplers. Only use hydraulic equipment in a coupled system.

•Always wear eye protection when operating or performing maintenance on this tool.

•Always wear head and hand protection and protective clothing when operating this tool.

The use of other than genuine Hi-Force replacement parts may result in safety hazards, decreased tool

performance, and increased maintenance, and may invalidate all warranties.

NOTICE

Repairs should be made only by authorised personnel. Consult your nearest Hi-Force Authorised

Service centre.

Refer All Communications to the Nearest Hi-Force Office or Distributor.

TDS1288

WARNING

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY

USING THE TOOL

•Keep hands, loose clothing and long hair away from the reaction arm and working area during

operation. Do not attempt to support the tool with your hands during operation.

•This tool will exert a strong reaction force. Use proper mechanical support and correct reaction arm

positioning to control these forces. Do not position the reaction arm so that it tilts the tool off the axis

of the bolt and never use the swivel inlets as a reaction stop.

•Avoid sharp bends and kinks that will cause severe back-up pressure in hoses and lead to premature

hose failure.

•Use accessories recommended by Hi-Force.

•Use only impact sockets and accessories. Do not use hand (chrome) sockets or accessories.

•Use only sockets and accesssories that correctly fit the bolt or nut and function without tilting the

tool off the axis of the bolt.

•This tool is not designed for working in explosive atmospheres

•This tool is not insulated against electric shock. When using this tool with a pump having an electrical

power source or circuits, follow the pump instructions for proper grounding.

Always wear eye protection when operating

or performing maintenance on this tool.

Always wear eye protection when operating

or performing maintenance on this tool.

Always turn off the pump and

disconnect the power before installing,

removing, or adjusting any accessory on

this tool, or before performing any

maintenance on this tool.

POWER

OFF ON

POWER

OFF ON

Always wear ear protection

when operating this tool.

Page 2 of 7

www.hi-force.com 0609

!

The Torque Reaction Arm must be positioned

against a positive stop. Do not use the Arm as a dead

handle. Take all precautions to make certain the

operator’s hand cannot be pinched between the Arm

and a solid object.

Operate at 10,000 psig (700

bar) maximum pressure.

10,000 psig

(681 bar)

10,000 psig

(700 bar)

Do not carry the tool by the

hose. Do not use damaged, frayed or

deteriorated hydraulic hoses and fittings.

Keep body stance balanced and firm. Do not

overreach when operating this tool.

PLACING THE TOOL IN SERVICE

CONNECTING THE TOOL

1. Attach the twin line hose to the uni-swivel coupling of the Square Drive Torque Wrench using the spring–

loaded quick connect ends. Make certain that they are fully engaged.

2. Connect the opposite ends of the hose to the Pump in the same manner.

ADJUSTMENTS

SETTING THE SQUARE DRIVE FOR

ROTATION

The position of the Square Drive when looking toward the Shroud will determine if the tool is set to tighten or

loosen the nut. When the Square Drive extends to the left when looking at the Shroud from the front, the tool is

set to loosen the nut. When the Square Drive extends to the right, the tool is set to tighten the nut. To change

the direction of rotation press the push button release on the drive retaining plate and pull the Square Drive out

of the Housing. Insert the Square Drive into the opposite side of the Housing and secure it by installing the push

button release retaining plate into the end of the drive.

TDS1288

SETTING THE TORQUE

After determining the desired torque, use the torque conversion chart on the Shroud or the torque conversion

charts on page 5 to determine the pressure that is necessary to achieve that torque.

1. Connect the tool to the power supply and turn the pump on.

2. Depress the advance remote control button causing the pressure to be shown on the gauge.

3. Adjust the pressure by first loosening the nut that locks the pressure adjustment handle and then rotate the

handle clockwise to increase the pressure and counter clockwise to decrease the pressure.

When decreasing pressure, always lower the pressure below the desired point and then bring the pressure

gauge back up to the desired pressure.

4.When the desired pressure is reached, retighten the lock nut and cycle the tool again to confirm that the

desired pressure setting has been obtained.

SETTING THE REACTION ARM

The function of a reaction device is to hold the tool in position against the forces generated to tighten or loosen

bolts or nuts. Hydraulic wrenches generate tremendous force.

WARNING

An improperly positioned reaction arm may

result in operator injury or damaged tooling.

Make sure the Reaction Arm is positioned correctly. (Refer to Drawing 01).

The Reaction Arm can be positioned in numerous places within a 360O circle. However, for the Arm to be

correctly positioned, it must be set within a 90Oquadrant of that circle. That quadrant is the area located

between the protruding Square Drive and the bottom of the Housing away from the Swivel Inlets. It will always

be toward the lower half of the Housing and on one side of the Housing when tightening and the other side

when loosening.

OPERATING THE WRENCH

The position of the Square Drive relative to the Shroud determines whether the action will tighten or loosen the

nut. (Refer to Dwg. 02 for application examples).

The power stroke of the Piston Assembly will always turn the Square Drive toward the Shroud.

WRENCH POSITIONS

1. Place the Square Drive in the socket, insert the socket retainer ring and pin, and place the socket on the nut.

Make certain the Square Drive and socket are the correct size for the nut and that the socket fully engages the

nut

2. Position the reaction arm against an adjacent nut, flange or solid system component. Make certain that there

is clearance for the hoses and uni-swivel coupling. DO NOT allow the tool to react against the hoses, or uni-

swivel coupling. When reacting directly off the tool body ie., with reaction arm removed DO NOT react off the

exposed End Plug Spigot.

3. After having turned the Pump on and presetting the pressure for the correct torque, depress the remote

control advance button to advance the Piston Assembly

4. When the wrench is started, the reaction surface of the wrench or Reaction Arm will move against the contact

point and the nut will begin to turn. Once the piston reaches the end of its stroke depress the remote control

return button to retract the piston.

5. Continue this cycling operation of advance

and retract until the nut is no longer turning and the Pump Gauge reaches the preset pressure. The piston rod

will retract when the retract button is pressed and under normal conditions, an audible “click” will be heard as

the tool resets itself.

6. Continue to cycle the tool until it “stalls” and the preset psi/torque has been attained.

7. Once the nut stops rotating, cycle the tool one last time to achieve total torque.

Page 3 of 7

www.hi-force.com 0609

TDS1288

Square Drive Position for Loosening and Tightening

(Dwg. 02)

Square Drive Hydraulic Wrench

Reaction Points (Dwg. 01)

Page 4 of 7

www.hi-force.com 0609

TDS1288

Page 5 of 7

www.hi-force.com 0609

PLACING THE TOOL IN SERVICE

LUBRICATION

Marine Grade Moly Lube

Lubrication frequency is dependent on factors known only to the user. The amount of contaminants in the work

area is one factor. Tools used in a clean room environment will obviously require less service than a tool used

out-doors and dropped in loose dirt or sand. Marine Grade Moly Lube is formulated not to wash out of the tool in

areas where lubrication is critical.

Whenever lubrication is required, lubricate as follows:

1. Remove the Drive Plate, Ratchet, Segment Pawl and Drive Sleeves and wash the components in a suitable

cleaning solution in a well–ventilated area.

2. After drying the components, wipe a film of Moly Lube (Marine Grade) onto the wear surface of both Drive

Sleeves and the ends of the Ratchet.

3. Spread a light film of Moly Lube (Marine Grade) onto the inner face and both sides of the Drive Plate.

Do not pack the teeth of the Segment Pawl or Ratchet with lube. It can prevent the teeth from engaging

properly.

TDS1288

Page 6 of 7

www.hi-force.com 0609

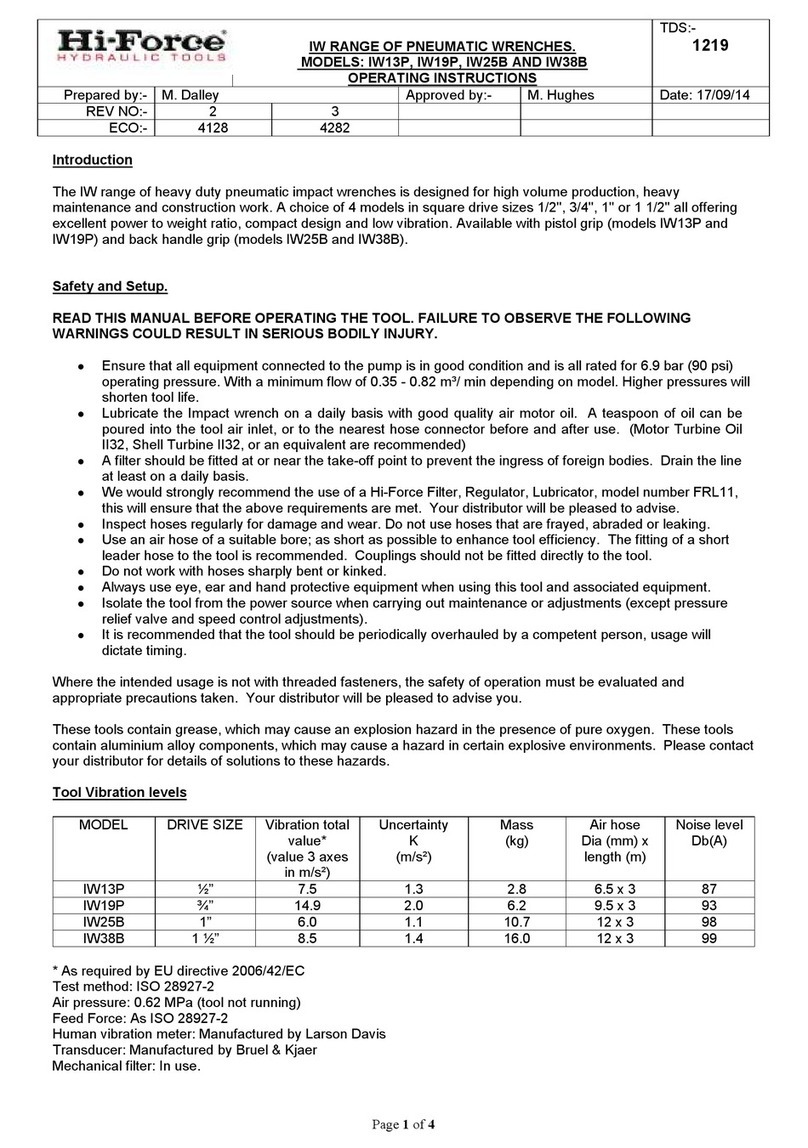

TWS-N SERIES TORQUE CONVERSION CHART

PSI / lbf.ft BAR / Nm

TWS17N TWS45N TWS100N

TWS150N

TWS370N

TWS17N

TWS45N

TWS100N

TWS150N

TWS370N

PSI lbf.ft lbf.ft lbf.ft lbf.ft lbf.ft BAR

Nm Nm Nm Nm Nm

1000 125 332 738 1,106 2,729 100

246 652 1,449 2,174 5,362

1500 188 498 1,106 1,659 4,094 150

370 978 2,174 3,261 8,043

2000 251 664 1,475 2,213 5,458 200

493 1,304 2,899 4,348 10,725

2500 314 830 1,844 2,766 6,823 250

616 1,630 3,623 5,435 13,406

3000 376 996 2,213 3,319 8,187 300

739 1,957 4,348 6,522 16,087

3500 439 1,162 2,581 3,872 9,552 350

862 2,283 5,072 7,609 18,768

4000 502 1,328 2,950 4,425 10,916 400

986 2,609 5,797 8,696 21,449

4500 564 1,494 3,319 4,978 12,281 450

1,109 2,935 6,522 9,783 24,130

5000 627 1,660 3,688 5,532 13,645 500

1,232 3,261 7,246 10,870 26,812

5500 690 1,826 4,056 6,085 15,010 550

1,355 3,587 7,971 11,957 29,493

6000 752 1,992 4,425 6,638 16,374 600

1,478 3,913 8,696 13,043 32,174

6500 815 2,158 4,794 7,191 17,739 650

1,601 4,239 9,420 14,130 34,855

7000 878 2,324 5,163 7,744 19,103 690

1,700 4,500 10,000 15,000 37,000

7500 941 2,490 5,531 8,297 20,468

8000 1,003 2,656 5,900 8,850 21,832

8500 1,066 2,822 6,269 9,404 23,197

9000 1,129 2,988 6,638 9,957 24,561

9500 1,191 3,154 7,006 10,510 25,926

10,000 1,254 3,320 7,375 11,063 27,290

TDS1288

Troubleshooting Guide

Trouble Probable Cause Solution

Couplers are not securely

attached to the tool or pump

Check the Coupler connections

and make certain that they are

connected.

Coupler is defective Replace any defective Coupler.

Defective remote control unit Replace the button and/or control

pendent

Piston will not advance or

retract

Dirt in the direction-control

valve of the pump unit Disassemble the pump and clean

the direction-control valve.

Hose connections reversed

Make certain the advance on the

pump is connected to the advance

on the tool and retract on the

pump is connected to the retract

on the tool.

Retract hose not connected Connect the retract hose securely

Piston will not retract

Retract pin broken Replace the broken pin and/or

spring

Piston Seal and/or End Plug

Seal leaking Replace any defective O-rings

Cylinder will not build up

pressure Coupler is defective Replace any defective Coupler

Grease or dirt build up in the

teeth of the Ratchet and

Segment Pawl

Disassemble the Ratchet and

clean the grease or dirt out of the

teeth

Square Drive will not turn Worn or broken teeth on

Ratchet an/or Segment Pawl Replace any worn or damaged

parts

Defective relief valve Inspect, adjust or replace the relief

valve

Air supply too low or air hose

too small

Make certain the air supply and

hose size comply with the pump

manual recommendations.

Electric power source is too

low

Make certain the amperage,

voltage and any extension cord

size comply with the pump manual

requirements

Defective Gauge Replace the Gauge

Low oil level Check and fill the pump reservoir

Pump will not build up

pressure

Clogged filter Inspect, clean and/or replace the

pump filter

Pressure reading erratic Defective Gauge Replace the Gauge

Nut Returns with retract

stroke Ball Plungers are not engaging

the Drive Sleeves Thread the Ball Plungers to the

correct depth in the Housing.

NOTICE

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

Page 7 of 7

www.hi-force.com 0609

Other manuals for TWS-N Series

1

This manual suits for next models

5

Table of contents

Other Hi-Force Power Tools manuals

Popular Power Tools manuals by other brands

BROWIN

BROWIN 810001 Instructions for use

Ingersoll-Rand

Ingersoll-Rand 1100PS4 Series Operation and maintenance manual

Hakko Electronics

Hakko Electronics FV-310 instruction manual

Aicon Air

Aicon Air DAC3050 Instructions for use

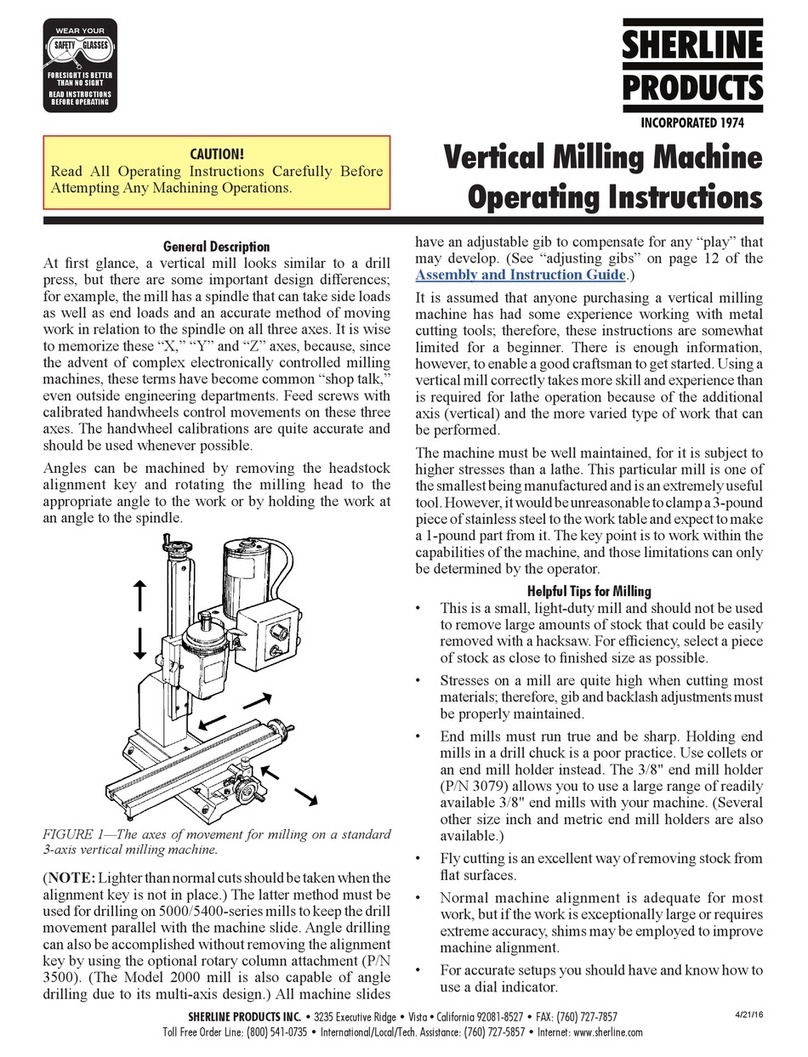

Sherline Products

Sherline Products 5000 series operating instructions

HIKOKI

HIKOKI M 12VE Handling instructions