Hickory 5.5 E User manual

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 1 of 15

HickoryRotisseries USA

InstallationManual

Models: N/5.5E

TotalPowerRating

Elements/Spits

Electrical Rating

TemperatureRange

Timer

Delivery Date:

Machine Type N / 5. 5 E

6000or8400Watts

4Elementswith5Spits

208/240Vor380/410V

200ºF-550ºF

Manual orFully Automatic

FinalInspection:

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 2 of 15

1.0InstallationInstructions 3

1.1 GeneralInformation 4

1.2 DescriptionoftheDataPlate 4

1.3 MachineDrawingsandDimensions 6

1.4 ElectricalConversionandAdjustmentInstructions 7

1.5 CookingCycle 7

1.6 Maintenance,ResponsetoTechnicalProblems 7

1.6.1 ReasonsforProblemsandSolutions 8

1.7 SpitDriveMechanism 9

1.8 N/5.5EPartsList 10

1.9 N/5.5EExplodedView 12

TableofContents

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 3 of 15

a. Wheninstallingtheseunits,itisimportanttocomplywiththemostrecently

establishedrulesandregulationsasdeemedpertinentbythelocalandnational

electrical,ventilation,sanitation,andfirecodes. Theseunitsareclassified

byUnderwritersLaboratories,Inc.asElectricallyHeatedFoodServiceEquipment.

b. Electricunitsmustnotbedirectlyconnectedtoaflueorexhaustvent. However,

electricunitsmayrequireoperationinconjuctionwithacanopytypeexhausthoodif

deemednecessarybylocalauthorities.

c. Theunitsmustbeinstalledinsuchawaythatproperventilationandheatexchangeis

assured. Theroommustbeventilatedinaccordancetothevalidcodesand

regulations.

d. Theunitsaretobeinstalledsecurelyandhorizontally. Theunitsmaybeinstalledon

combustiblefloors. Theunitsmustbeinstalledwithadjustablelegsifplacedona

combustiblesurface.

e. Theminimumclearancetotherearorsidewallsmustbe13inches. Itisalso

importanttoinsurethatthebottomoftheunitsiskeptclearsothat properventilation

orairexchangecanoccur.Rearclerancecanbereduced to1"withtherepalcementof

therearglasswithmetalpanels.

f. Normally,theunitswillbesenttotheoperatoralreadysetupfortheparticular

electricalserviceavailableattheirlocation. However,unlessotherwisespecified,the

electricunitsaresetupfor208V,3Phase,60Hzuse. Beforeinstallingandusingthe

unitsforthefirsttime,itisimportanttomakesurethattheelectricalpowerindicated

onthedataplatematchesthetypeofelectricalpoweravailableinthelocation.

Shouldthisnotbethecase,itisimperativetochangeorconverttheunitstothe

neededtypes.

g. Electricunitsmustbehard-wiredorfittedwithapowercordbyalicensed

electrician.

1.0 InstallationInstructions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 4 of 15

1.1 GeneralInformation

TheOperatingInstructionsaretobegiventotheoperatoroftherotisserie. Allunit

operatorsaretobefamiliarwiththefunctionsoftherotisserie.

TheOperatingInstructionsshouldbekeptinalocationclosetotherotisserie. Itshouldbe

easilyrecognizeableandeasilyaccessible.

Electricunitscanbeorderedtomeetmostelectricalspecifications.

Itisrecommendedthatarepairandmaintenancecontractbesignedwiththe

manufacturer'sagent,distributor,orserviceagency.

1.2 DescriptionoftheDataPlate

WARNING!

Thisunitmustbeinstalledandconnectedinaccordancetothelatestregulations

andmayrequireoperationinconjunctionwithaforcedventilationorexhausthood.

Thisunithasbeendesignedforprofessionaluseonly

andmayonlybeinstalledorrepairedbylicensedserviceagencies!

Beforeinstallingorusingthisequipment,readtheseinstructions!

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 110-120VOLTS 60 CYCLE AC

CURRENT

WATTS SINGLEPHASE 3 RPM

HEATING ELEMENTS 208VOLTS 60 CYCLE

3 PHASE AC

CURRENT

1400WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 6000

MFG. DATE

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 110-120VOLTS 60 CYCLE AC

CURRENT

WATTS SINGLEPHASE 3 RPM

HEATING ELEMENTS 208VOLTS 60CYCLE

1 PHASE AC

CURRENT

1400WATTS PERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGE PERLAMP 40WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 6000

MFG. DATE

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 5 of 15

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 208-220VOLTS 60 CYCLE ACCURRENT

WATTS SINGLEPHASE 3 RPM

HEATING ELEMENTS 208VOLTS 60 CYCLE

3 PHASE AC

CURRENT

1400WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 6000

MFG. DATE

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 110-120VOLTS 60 CYCLE ACCURRENT

WATTS SINGLEPHASE 3 RPM

HEATINGELEMENTS 208VOLTS 60CYCLE

3 PHASE AC

CURRENT

2000WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 8000

MFG. DATE

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 208-240VOLTS 50 CYCLE ACCURRENT

WATTS SINGLEPHASE 3 RPM

HEATING ELEMENTS 208VOLTS 50 CYCLE

1 PHASE AC

CURRENT

1400WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 6000

MFG. DATE

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 208-240VOLTS 50 CYCLE ACCURRENT

WATTS SINGLEPHASE 3 RPM

HEATINGELEMENTS 208VOLTS 50CYCLE

3 PHASE AC

CURRENT

1400WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 6000

MFG. DATE

HICKORY INDUSTRIES, INC.

NORTH BERGEN, NJ 07047

MODEL: N/5.5 E M SERIAL NO.

MOTOR: 208-240VOLTS 50 CYCLE ACCURRENT

WATTS SINGLEPHASE 3 RPM

HEATING ELEMENTS 208VOLTS 50 CYCLE

3 PHASE AC

CURRENT

2000WATTSPERELEMENT

MINIMUM INSTALLATION

CLEARANCES

SIDES: 13 INCHES

BACK: 13 INCHES

MAXIMUMWATTAGEPER LAMP40 WATTS

LISTED

607C ELEMENTS

®

4

TOTAL WATTAGE 8000

MFG. DATE

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 6 of 15

FrontView RightSideView

1.3 MachineDrawingsandDimensions

ThefollowingdrawingoftheFrontView,SideView,andTopViewindicatewherethe

dimensionsaretakenandshouldbeusedtoplantheinstallationoftheunits.

N/ 5.5 E

TopView

Height 29" 737

Width 39-1/4" 997

Depth 22-1/16" 560

N/5.5E inches mm

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 7 of 15

1.4 ElectricalConversionandAdjustmentInstructions

Beforeconvertingoradjustingthemachinetoanothertypeofelectricity,itisimperativethat

electricalpowertothemachinesshouldalsobeturnedoff. Whenconverting,makesurethat

theproperelectricaldiagramisfollowedandthatthemotorandtimermatchtheconnected

singlephasevoltage!

1.5 CookingCycle

Inordertostartthecookingcycle,theelementsmustbepowered. Theheatingcyclewill

startonlywhenthefollowingprocedureisfollowed:

a. TheTEMPERATUREswitchisturnedto"on".

b. Acookingtemperaturemustbesetonthethermostat(i.e.450°F).

c. Thecookingtimermustbeactivated(seeOperatingInstructions).

Oncethesestepsarecompleted,theunitwillcallforheatandthecookingcyclewillbe

activated. Themaincontactor,whichpowerstheheatingelements,willstayonuntilthe

setcookingtemperatureisreached,assensedbythethermocoupleattachedtothethermostat.

Withthetemperaturereached,theelectricalpowertotheelementswillbecutoffasthe

thermostatshutsoffthepowertothecontactor. Whenthetemperaturedropsbelowtheset

point,electricalpowerisagainsenttotheheatingsystem,thusstartingtheheatingprocess

allover. Thesystemwillcycleonandoffasneededtomaintainthesetcookingpoint.

1.6 Maintenance,responsetotechnicalproblems.

Shouldatechnicalproblemariseforanyreason,shutoffthemachineandcallfortechnical

service.

Aroutinemaintenanceshouldbecarriedoutatleastonceayear. Contactyourlocal,

certifiedservicecompanyformaintenance.

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 8 of 15

Solution

1. MakesurethattheTEMPERATURE

switchison.

2. Thermostatmustbeset(i.e.550°F).

Thecookingtimermustbeoperational

(cookcycle).

3. AredLEDon theTEMPERATURE

switchindicatesthatthecontactoris

supplyingpowertotheheating

elements.

4. Usingtheelectricaldiagram,make

surethattheentiresystemisfully

functional.

a. Tocookchickens,wesuggestthatthe

temperaturebesettoMAXIMUM. If

thechickensare"burning",whichis

usuallyduetosugarsinthemarinade

orrub,thenthetemperaturemustbe

reducedaccordingly.

b. Whenprogrammingthetimer,itwill

onlyheatuptherotisseriewhena

"cookpot"appearsonthedisplay.

Beforesettingacookingtime,make

surethatenoughtimeisprogrammed!

c. Aloadof20chickens,eachabout

3.25lbs.,willtakeabout1hourand

30minutestocookina6400Watt

unit. Thelargerthechickens,the

longerthecookingtime.

d. Makesurethatthehot,neutral,and

groundleadsareproperlymatchedup.

Alsomakesurethatallofthephases

arelive.

e. Thetwolowerheatingelementshave

twoconcavedeflectorswhichdirect

theheattowardsthecenterofthe

chamber. Acommonerroristo

covertheelements,preventingtheheat

fromreachingthecenteroftheunit.

Problem

Unitdoesnotheat.

Unittakestoo

longtocook.

Cause

a. Rotisserienot"on".

a. Temperaturesettoolow.

b. Timerisnotproperlyset.

c. Chickenaretoobig.

d. Notenoughpowerisbeing

suppliedtotheunit.

e. Thelowermetaldeflectors

areonbackwards.

1.6.1 ReasonsforProblemsandSolutions

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 9 of 15

1.7 SpitDriveMechanism

This unit is equipped with a planetary motion spit drive system. This means that each spit is

turning upon its axis at the same time that they turn about the center shaft. When the motor

switch is turned to on, the disks and the spits will begin to turn. Insure that the mechanism

turns smoothly when testing the unit.

CenterShaft

Spit

Beforecooking,it isimperativethat thecentershaft becoveredandprotectedwithaluminumfoil. Thiswill

preventfatsfromcarbonizingontheshaft,makingthe removalofthealuminumdisksmucheasierinthe

future. Ifthe shaftis notprotected, itmayeventually beimpossible toremove thedisksshould therebe a

probleminthespitdrivemechanism.

The driven and the stationary drive gears are located behind the aluminum drive disk. These can be

viewed by taking out the removable aluminum disks. The driven gears and the stationary gear should

be viewed once a week to check for fat or carbonization build-up. Any fat or dirt should be cleaned

off since a build-up will eventually damage the drive system.

AluminumDrive

Disk

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 10 of 15

1.8 N/5.5EPartsList

Item Qty. Description Material Length Size Manufacturer

553 1 Shaft5/8(RemovableDrums-Center) SS 5/8" Hickory

554 1 ShaftLockingSlide SS Hickory

519 1 DriveBearingHolder(Left- with brassbearing) Steel(Chromed) Hickory

520 1 DriveBearingHolder (Right - withteflonbearing) Steel(Chromed) Hickory

1 BrassShaftBearing Brass Hickory

566 1 TeflonShaftBearing Teflon Hickory

501 1 Aluminum Disk Drive(Bare) CastAluminum Hickory

502 1 AluminumDiskSlave(Bare) CastAluminum Hickory

503 1 Alum.DiskDrv.(Completew/SpitDriven Gears) Hickory

504 1 Alum.DiskSlave(Completew/SpitSupports) Hickory

514 1 DiskRetainingPin Steel 1-1/2" 5/32" Hickory

564 5 TeflonSpacers-1/4"round Hickory

505 Aluminum DiskTeflonCoating Hickory

561 5 SpitDrivenGearAssembly Steel(Chromed) Hickory

555 5 SnapRing(Gears) Steel Hickory

559 5 SpitDrivenGearBearingHolder Steel(Chromed) Hickory

560 5 SpitDrivenGear Steel(Chromed) Hickory

565 5 TeflonSpitDrivenGearBearing 1/4" Hickory

563 1 StationaryGear Steel Hickory

562 5 SpitSupport Steel(Chromed) Hickory

510 1 Chain (Roller-5.5) Steel Hickory

511 1 Chain Link (Roller - 5.5) Steel Hickory

521 1 DriveSprocket-Roller Chain Steel Hickory

522 1 Driven Sprocket-RollerChain Steel Hickory

1 DriveShaft

512 1 ChainTensioner Steel Hickory

509 1 BussFuse0.5Amp Buss

527 1 FuseHolder0.5Amp

538 4 LampCover Steel(Chromed) Hickory

541 3 MicroSwitch &Toggle Marquardt

567 1 Thermostat200-550

568 1 ThermostatKnob

569 1 Timer(without Adapter) Eaton

569a 1 Adapter (for Timer) Eaton

542 1 Motor Gear-120V Bodine

539 1 Lamp,120V Hickory

540 4 LampSocket Ceramic Leviton

120 1 DripPan(5.5) SS Hickory

121 1 DripPanPlug Brass Hickory

122 1 DripPanReceptacle Brass Hickory

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 11 of 15

1.8 N/5.5EPartsList(Contd.)

Item Qty. Description Material Length Size Manufacturer

123 1 ElectricalGroundingCap Hickory

ElectricalWire JanorWire

106 1 BuchananContactSection824 Buchanan

107 1 BuchananContactSection830 Buchanan

550 1 Relay(Contactor)3Pole220V GE

1 Capacitor GE

525 8 ElementHolder Hickory

129 4 ElementPorcelainInsulator Hickory

523 4 Element,Straight220V-1400Watt Glenn

524 4 Element,Straight240V-1400Watt Glenn

549 2 Reflector SS Hickory

513 2 GlassHinge SS Hickory

515 2 DoorBearingBrass Brass Hickory

516 1 DoorHandle(Metal) Steel Hickory

518 1 DoorSpring(Mechanical) Steel Hickory

545 1 PneumaticSpring

532 1 GlassTemperedLarge(Door) Glass 28.94"x16.5" Hickory

533 1 GlassTempered(Rear) Glass 28.94"x12" Hickory

534 1 GlassTempered(Rear-Small) Glass 28.94"x4.5" Hickory

526 4 FeetAdjustablePlastic Plastic Hickory

556 5 SpitComplete(incl.allskewers&screws) SS Hickory

185 5/Spit SkewerDouble SS Hickory

186 5/Spit SkewerSingle SS Hickory

219 1/Skw.ThumbScrew Steel Hickory

557 1 SpitTurkeyCenteronly SS Hickory

225 2 TurkeySkewersSingle SS Hickory

506 5 BasketHanging Steel(Chromed) Hickory

507 5 BasketBearingBrass Brass Hickory

439a Angle(V) Spits (Option!) SS Hickory

508 BasketSpits( Steel(Chromed) Hickory

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 12 of 15

1.8 N/5.5EExplodedView

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 13 of 15

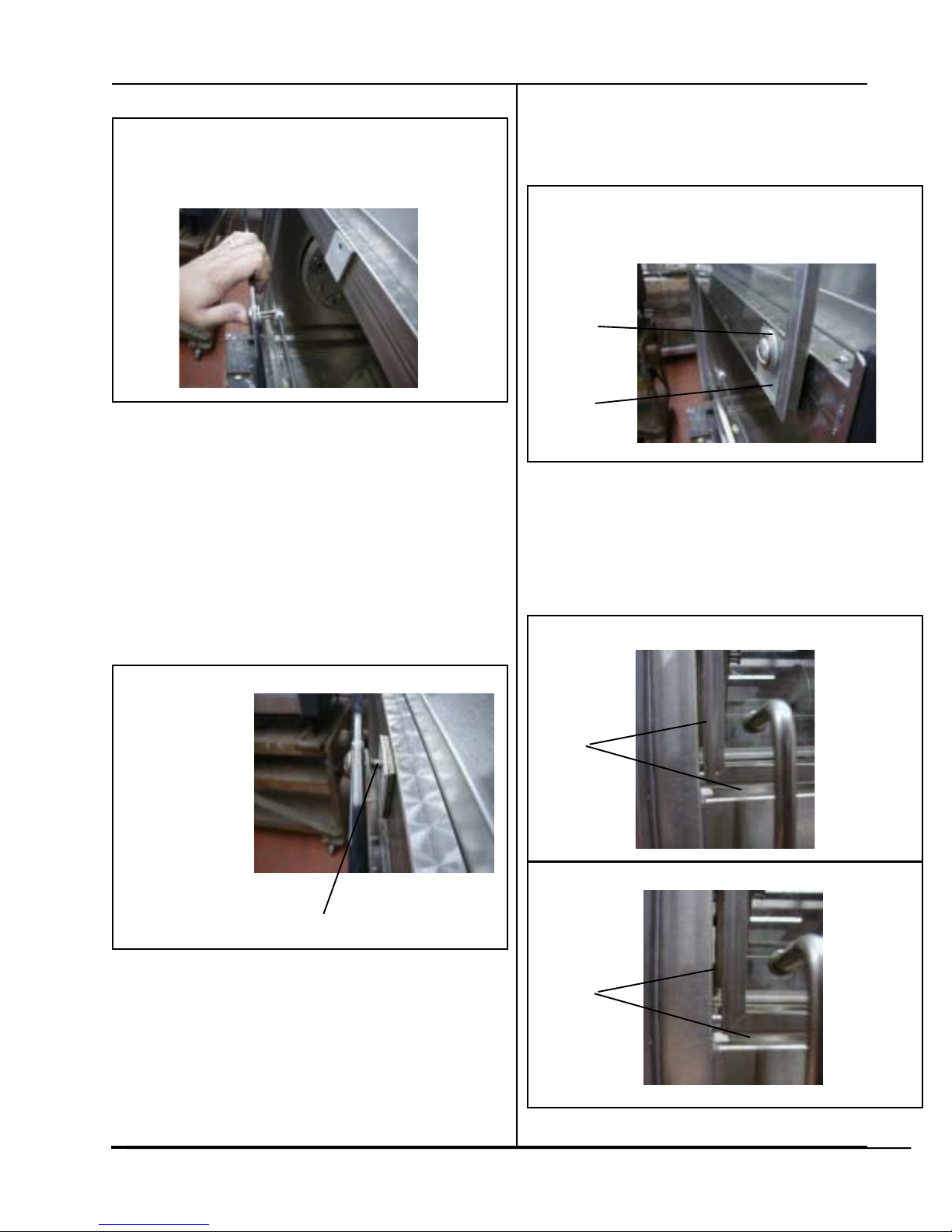

Glass Replacement on the

5.5E & 10.10E Machines

Makesure that thehandle and allassociated hardware

isavailableat thesite ororderthe mountingkit from

Hickory.

Make sure that the glass bar is in the open

position.

ClosedPosition

OpenPosition

Column2Column1

Metalspacer

Squaresiliconwasher

Roundsiliconewasher

Flatwasher

1/4-20x1” special screw

Glass

Newerstyleunitsincorporatethe spacer welded

on the glass bar..

Uppermountinghardware

Makesure that thehandle and allassociated hardware

isavailableatthesiteororder themounting hardware

fromHickory.

Glasshandle, flat washer,lock washer,10/32screw

Glass

Theglassmounts betweenthe glasshandleand theflat

washer.

Installthe glasshandle. Be suretouse Loc-Tite.

NOTE:THE 90 BEND ON THE GLASS

HANDLE IS LOWER THAN THE GLASS. DO

NOT MOUNT THE HANDLE WITH THE 90

DEGREEBENDUP.

Glass

Frame

Glass

Handle

USEHIGHTEMPERATURELOC-TITE

onallscrews for both theglasshandle and the

uppermountingscrews.

Otherwisethe handlewillcomelooseandchip

theglassorfallslightlyandchiparoundthe

mountingscrewholes. Thiswillleadtobreak-

age!

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 14 of 15

DONOT TIGHTEN. Thiswill ensurethat youhave

enoughplayto movetheglassaroundwithout

bumpingtheglass.

Proceedwith theremaining screws(use hiheat Loc-

tite). Makesure that the glassis sandwiched be-

tweensiliconewasher andthe siliconespacer.

Slightlyturneachscrew untilsnug. Itshouldbesnug

butloose enough to move. Adjust the glass sothat

thespacing isevenaround thesides andbottomof

themachine. Youcannow verifytheglassspacing

withthe sideandthebottomofthemachine.

ImproperlySpaced

ProperlySpaced

Column4Column3

Replacingthefront glass

Insertthe screw ontothe glass (usehi heat Loc-tite).

Asahint, startwiththemiddlescrewitwillgiveyou

someleveragewiththe glass.

Slowlyturnthe screw onto the glass bar- DONOT

TIGHTEN. Make sure that you do not seeany

threadsor that the glassrestson the threads.

Make sure that when resting the glass on the

screws,it onlyrestsontheun-threadedportion

of the screw (closest to the head of the screw).

Beforemovingglassmakesure threadsare inserted

ontometal spacer

ThreadsExposed

Note:

Uneven

Spacing

Note:

Even

Spacing

Silicone

Washer

Silicone

Spacer

4900 Westside Avenue, North Bergen, New Jersey 07047

Tel: [201] 223-0050 Fax: [201] 223-0950

Hickory Industries, Inc.

N/5.5E Installation 8/5/97

Page 15 of 15

Iftheglassisnot evenlyspaced, adjusttheglassuntil

itsevenlyspaced.

CAUTION: Ifthe screwsare notsnug enough,when

loweringtheglassdoor,theglassmyhitthe screws

andchiptheglass.

CAUTION:Whentighteningthescrews,iftheglass

shiftsdown, the glassdoor will betoo close tothe

roofof themachine whenthe glassdoor isshut.

Opendoor andtighten uppermountingscrews.

Closethe door andverify that thesideand bottom

spacingisevenallaround.

Makesure all screwsaretight and havebeenreplaced

usinghiheatLoc-Tite.

Returnequipmentback tooperatingcondition.

Caution

Operators should not use a razor blade

or knife to clean the glass.

Glass should not be cleaned with abra-

sives, soft scrub or any pad, i.e. Brillo,

Scotch Brite, scouring pad etc. This

will scratch the glass and render the

glass faulty.

Tempered glass will break if scratched,

shipped or mishandled in any way. It

can break in a day or a year. BUT IT

WILL BREAK.

LeftBlankIntentionally

Column5

This manual suits for next models

1

Table of contents

Popular Convection Oven manuals by other brands

Cosmo

Cosmo COS-30ESWC user manual

Standex

Standex TRI-STAR Cyclone Series Installation and operating instructions

Inoksan

Inoksan INOSMART INO-FBG010 instruction manual

Moffat

Moffat Bakbar E35 Brochure & specs

turbofan

turbofan E35 Series Installation & operation manual

Vulcan-Hart

Vulcan-Hart VC44GC ML-136494 Installation & operation manual

Lang

Lang GCOD-AP Installation and operation instructions

Melissa

Melissa 651-016 Specifications

KitchenAid

KitchenAid ELECTRIC SLIDE-IN 9751596 installation instructions

Cuizimate

Cuizimate RBSOV12L instruction manual

Moorwood Vulcan

Moorwood Vulcan MV 2 Series owner's manual

Jenn-Air

Jenn-Air JGRP536WP installation instructions